Special slow release fertilizer for grapes and preparation method thereof

A slow-release fertilizer and grape technology, which is applied to the field of slow-release fertilizers for grapes and its preparation, can solve the problems of incomplete fertilizer nutrients, inability to grow and develop normally, increase labor costs and work intensity, etc., and improve physical and chemical properties and biological properties. Activity, increase and renewal of soil organic matter, and the effect of promoting microbial reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

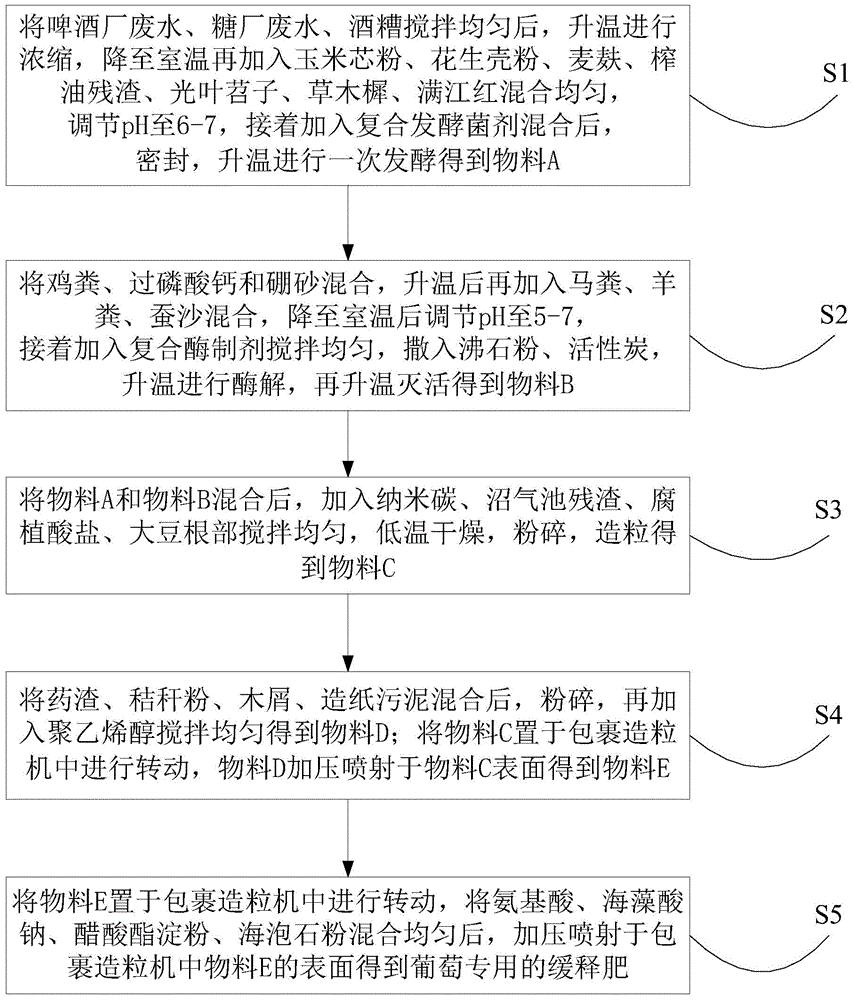

[0025] refer to figure 1 , the preparation method of a kind of grape-specific slow-release fertilizer that the present invention proposes, comprises the steps:

[0026] S1. Stir brewery wastewater, sugar factory wastewater, and distiller's grains evenly, heat up to concentrate, and then add corn cob powder, peanut shell powder, wheat bran, oil extraction residue, sweet clover, sweet clover, and Manjianghong to mix evenly. Adjust the pH to 6-7, then add the compound fermentation agent and mix, seal, heat up and ferment to obtain material A;

[0027] S2. Mix chicken manure, superphosphate and borax, add horse manure, sheep manure and silkworm excrement after heating up, adjust pH to 5-7 after cooling down to room temperature, then add compound enzyme preparation and stir evenly, sprinkle zeolite powder , activated carbon, heat up to carry out enzymolysis, and then heat up to inactivate to obtain material B;

[0028] S3. After mixing material A and material B, add nano-carbon, ...

Embodiment 1

[0033] A special slow-release fertilizer for grapes proposed by the present invention, its raw materials include by weight: 100 parts of brewery wastewater, 80 parts of sugar factory wastewater, 20 parts of distiller's grains, 90 parts of corn cob powder, 50 parts of peanut shell powder, wheat bran 40 parts, 60 parts of oil pressing residue, 60 parts of sweet potato, 70 parts of sweet clover, 80 parts of Manjianghong, 5 parts of zeolite powder, 12 parts of activated carbon, 30 parts of horse manure, 40 parts of sheep manure, 35 parts of chicken manure, 30 parts of silkworm excrement 1.2 parts of calcium superphosphate, 0.1 part of borax, 3 parts of compound enzyme preparation, 12 parts of compound fermentation bacteria agent, 5 parts of nano-carbon, 40 parts of digester residue, 20 parts of humate, 35 parts of soybean root, 20 parts of medicinal residue 25 parts of straw powder, 20 parts of wood chips, 3 parts of polyvinyl alcohol, 5 parts of paper sludge, 18 parts of amino aci...

Embodiment 2

[0042] A slow-release fertilizer for grapes proposed by the present invention, its raw materials include by weight: 120 parts of brewery wastewater, 50 parts of sugar factory wastewater, 30 parts of distiller's grains, 80 parts of corncob powder, 60 parts of peanut shell powder, wheat bran 30 parts, 90 parts of oil pressing residue, 50 parts of sweet potato, 80 parts of sweet clover, 60 parts of Manjianghong, 8 parts of zeolite powder, 10 parts of activated carbon, 50 parts of horse manure, 20 parts of sheep manure, 45 parts of chicken manure, 20 parts of silkworm excrement 2 parts of calcium superphosphate, 0.08 parts of borax, 5 parts of compound enzyme preparation, 8 parts of compound fermentation bacteria agent, 10 parts of nano-carbon, 30 parts of digester residue, 30 parts of humate, 15 parts of soybean root, 25 parts of medicinal residue 16 parts of straw powder, 26 parts of wood chips, 1 part of polyvinyl alcohol, 8 parts of paper sludge, 12 parts of amino acids, 20 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com