Automotive trim panel injection moulding technology based on BP (Back Propagation) neural network

An injection molding process, BP neural network technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as large warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below, and the description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0017] A kind of automotive interior panel injection molding process based on BP neural network, comprises the following steps:

[0018] A. Establish a plastic mold flow CAE analysis model;

[0019] B. Use moliflow2015 software to simulate the injection molding process parameters of plastic parts, and determine the settable process parameters that need to be considered to solve the problem of excessive product warpage by applying CAE analysis and optimization;

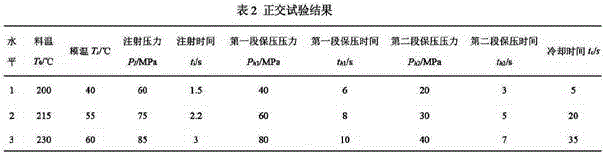

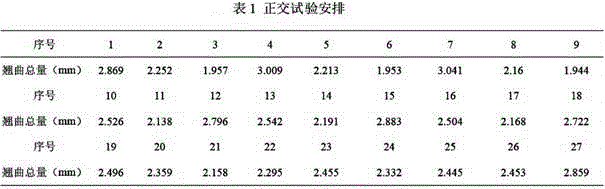

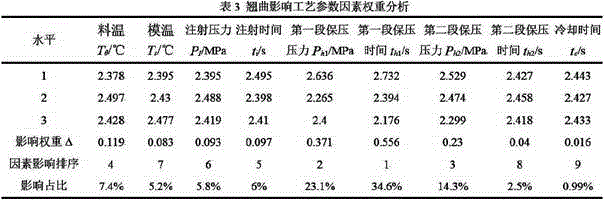

[0020] C. Use Mintab to carry out the Tugachi method plane orthogonal test design on the above-mentioned process parameters, and use CAE software for warpage analysis to obtain the warpage deformation results at each factor level, use Mintab to analyze the influence weight of factors, and initially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com