Method for processing lump non-crystal alloy blank and its device used thereof

An amorphous alloy, processing method technology, applied in metal processing equipment, metal extrusion control equipment, metal extrusion and other directions, to achieve the effect of improving material structure, good stress state, and reducing bamboo breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

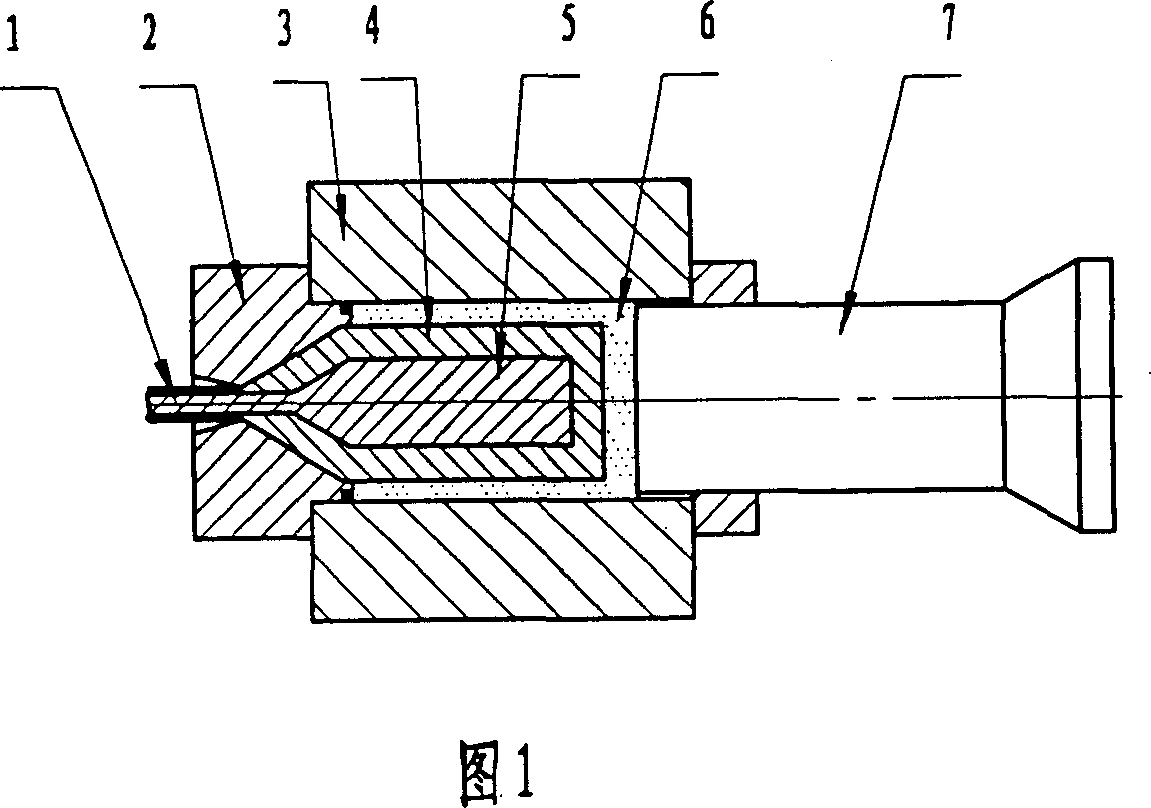

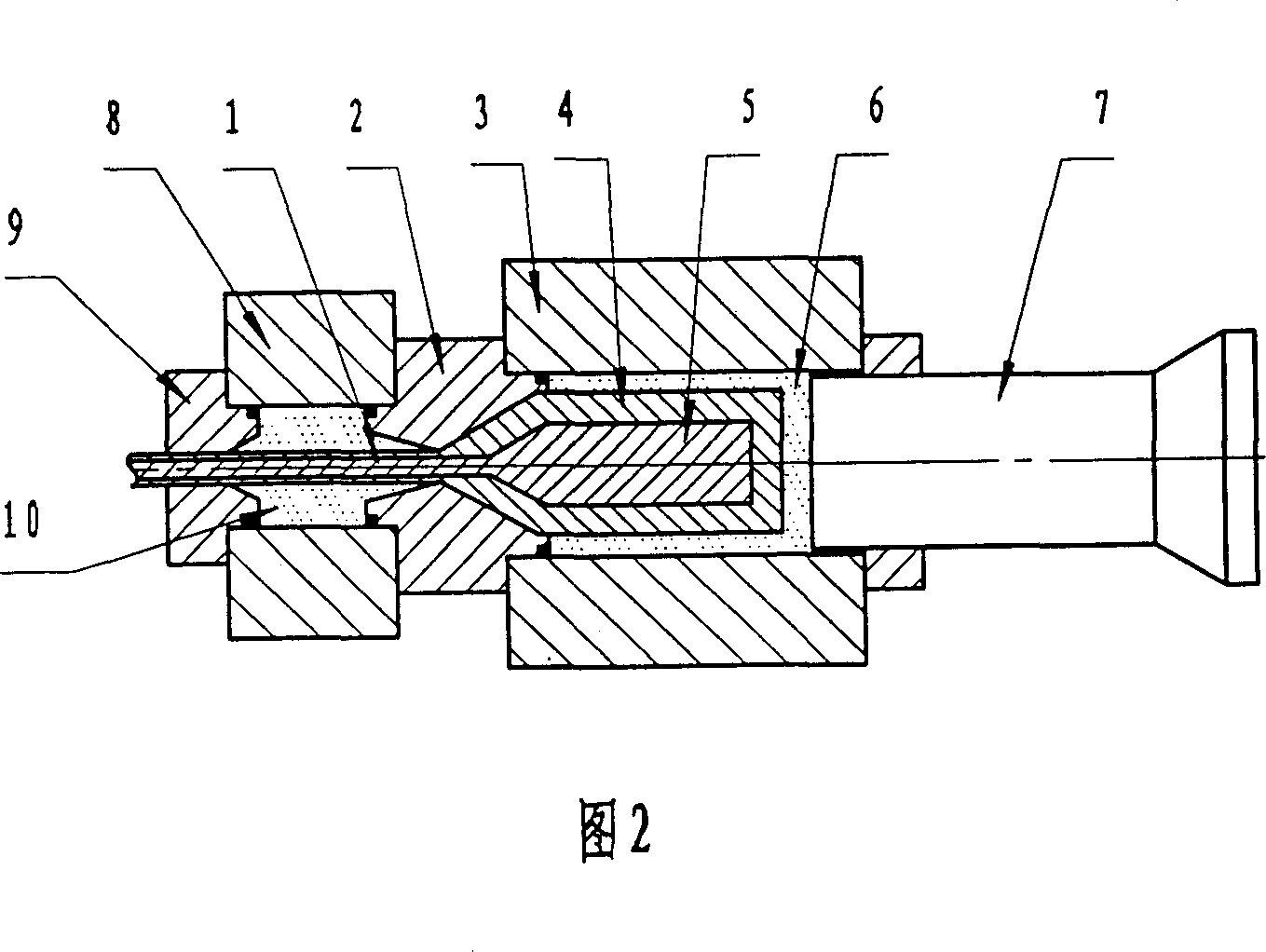

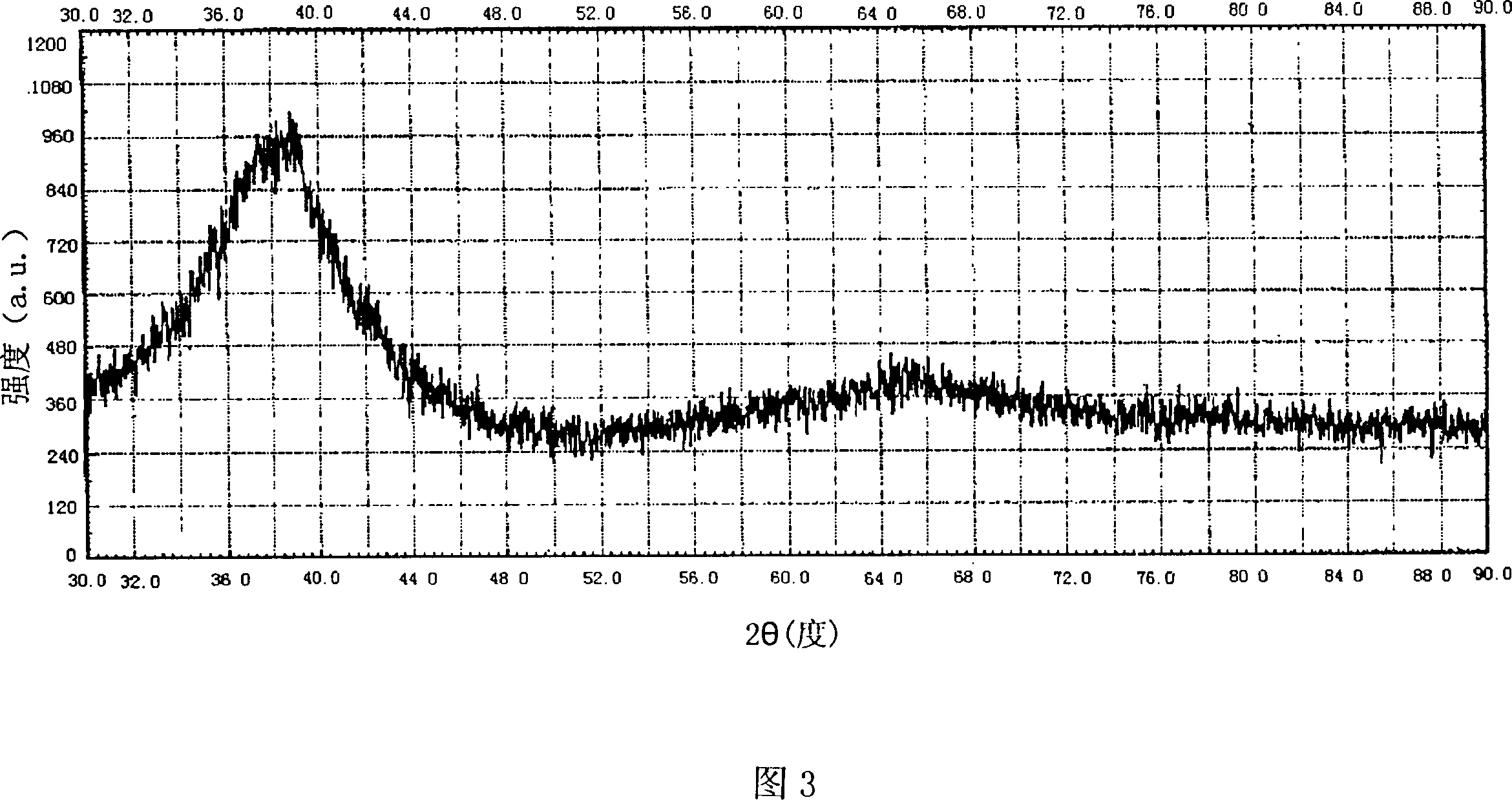

[0025] Put the Zr55Al10Cu30Ni5 alloy billet 5 with a diameter of 16mm into the A3 steel ladle 4 with an outer diameter of 25mm in a tight fit, and then put them together in a precise temperature-controlled resistance heating furnace for heating. After ℃, heat and soak for 2 minutes; choose graphite + MoS 2 As a lubricant, it is evenly applied to the surface of the extrusion die 2, castor oil is selected as the extrusion medium 6, it is added to the die cavity of the hydrostatic extruder, and then the heating system of the die cavity is started, and the die cavity Heat it together with the extrusion medium 6 to the set extrusion temperature of 390°C, keep it warm for 5 minutes; take the heated sheath 4 and amorphous billet 5 out of the resistance furnace, and quickly put them into the extrusion In the die cavity of the machine, at an appropriate extrusion rate (strain rate is equivalent to 1×10 -1 the s -1 ) for extrusion processing with an extrusion ratio of 2; the extruded ...

Embodiment 2

[0027] Put the Zr41Ti14Ni10Cu12.5Be22.5 alloy billet 5 with a diameter of 9mm into a pure iron sheath 4 with an outer diameter of 20mm in a tight fit, and then put them together in a precise temperature-controlled resistance heating furnace for heating, and the furnace temperature control is accurate to ±5 ℃, heat it to 390℃ and keep it warm for 2 minutes; choose graphite MoS 2 As a lubricant, it is evenly applied to the surface of the extrusion die 2, castor oil is selected as the extrusion medium 6, it is added to the die cavity of the hydrostatic extruder, and then the heating system of the die cavity is started, and the die cavity Heat it together with the extrusion medium 6 to the set extrusion temperature of 390°C, keep it warm for 5 minutes; take the heated sheath 4 and amorphous billet 5 out of the resistance furnace, and quickly put them into the extrusion In the die cavity of the machine, at an appropriate extrusion rate (strain rate is equivalent to 1×10 -1 the s ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com