Method and structure for arranging horizontal structural joints on concrete face of rockfill dam

A technology of concrete panels and horizontal structural joints, applied in dams, barrages, water conservancy projects, etc., can solve problems such as panel deformation and damage, prevent cracking and extrusion damage, improve reliability, and solve deformation damage and leakage problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

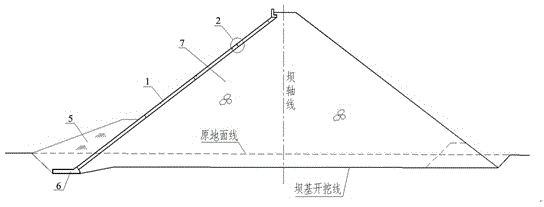

[0017] The present invention is implemented like this: see first figure 1 , the dam type is that a concrete face plate 1 is provided on the upstream face of the dam body 7 of the rockfill structure. When the concrete face plate 1 is poured, the face plate is divided into several pieces from bottom to top. Part of the concrete face plate 1 and plinth 6 is covered by bedding 5 . A horizontal arc-shaped seam 2 is set at the block of the adjacent concrete panel 1. The horizontal arc-shaped seam 2 is an arc-shaped structure. Near both sides, the joint faces separate adjacent concrete panels 1 .

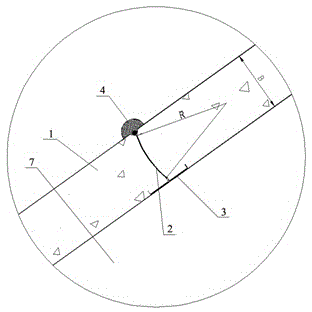

[0018] look figure 2 , the bottom surface and the top surface of the horizontal arc-shaped seam 2 are respectively provided with a copper water stop 3 and a plastic water stop 4. The bottom surface refers to the contact surface between the concrete panel 1 and the dam body 1, and the top surface refers to the concrete surface. The exposed side of panel 1. The arrangement of the plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com