Composite aluminum plate for 5G signal transmitting tower

A technology for transmission towers and aluminum panels, which is applied to building materials, building components, buildings, etc., can solve problems such as lack of heat insulation, crack prevention, deformation prevention, and deformation and damage of aluminum panels, so as to improve acid and alkali corrosion resistance and improve use The effect of life and improvement of deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

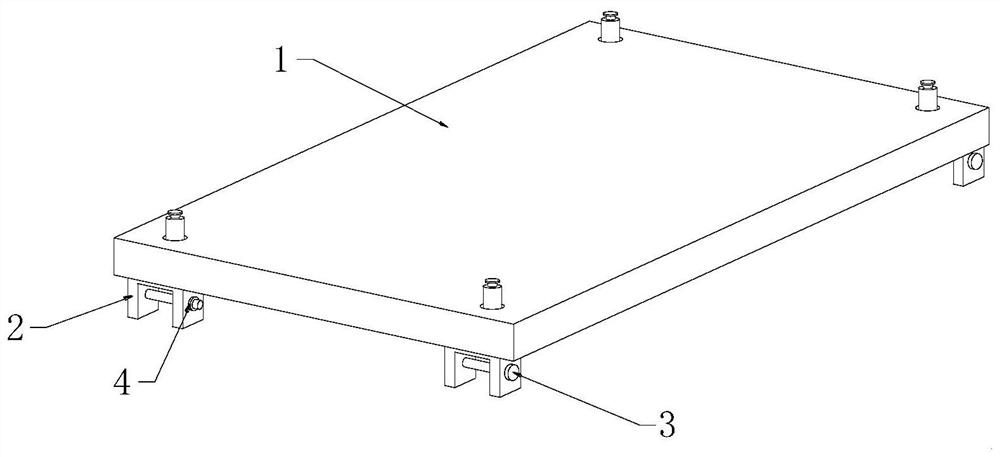

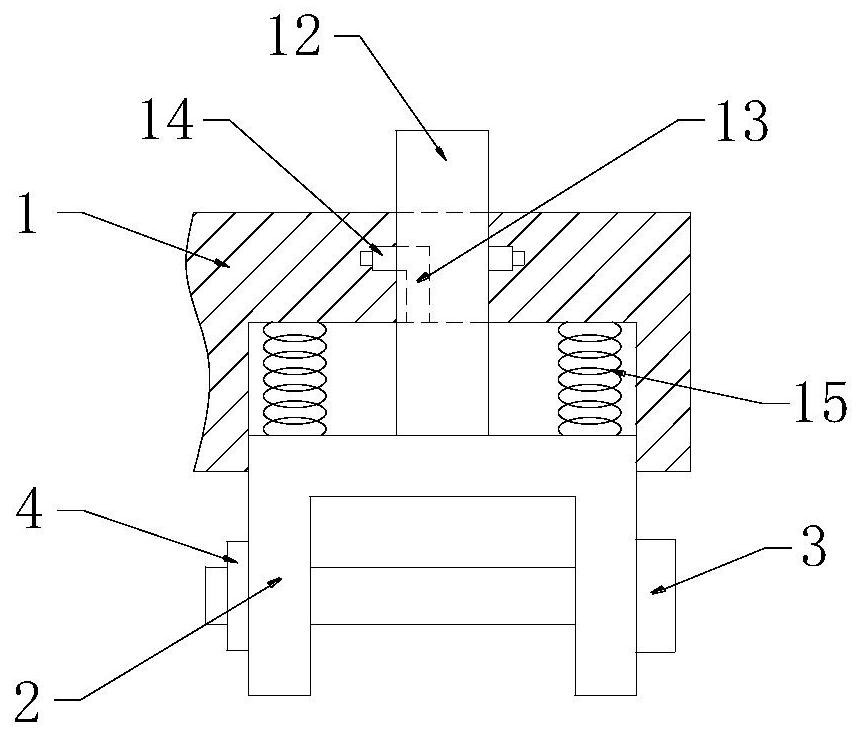

[0027] see Figure 1-4 As shown, a composite aluminum plate for a 5G signal transmission tower includes an aluminum plate main body 1, a U-shaped block 2, mounting bolts 3, and nuts 4; Block 2, one end of the U-shaped block 2 is equipped with a mounting bolt 3, one end of the mounting bolt 3 passes through the U-shaped block 2, and a nut 4 is installed on the annular side of the mounting bolt 3, and one end of the nut 4 is connected to the U-shaped The other end of block 2 fits together;

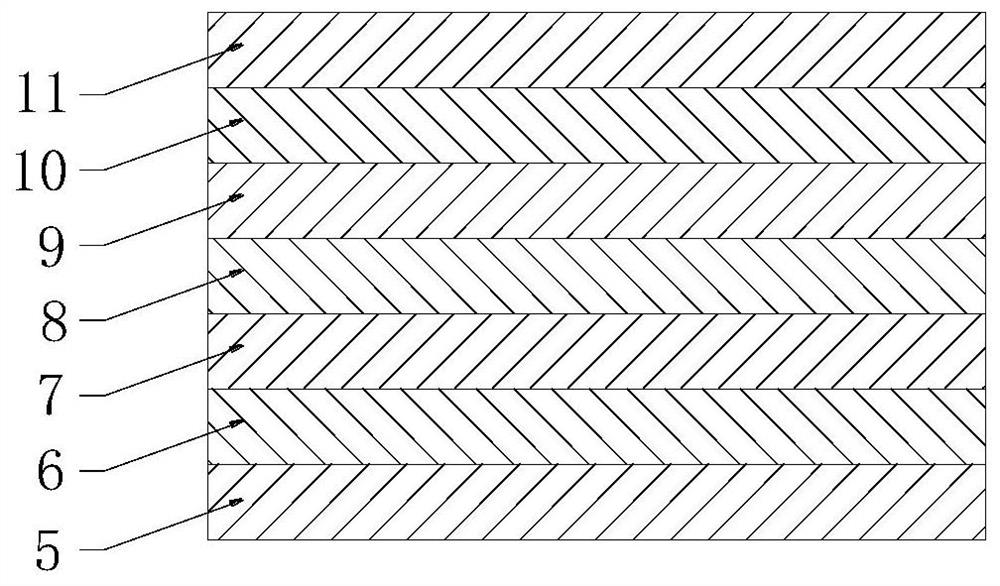

[0028] The aluminum plate main body 1 includes a lower aluminum plate layer 5, a thermal insulation core layer 6, a fireproof core layer 7, an anti-crack layer 8, an anti-deformation layer 9, an upper aluminum plate layer 10 and an anti-corrosion protection layer 11. The top of the lower aluminum plate layer 5 is Equipped with a heat insulating core layer 6, the top of the heat insulating core layer 6 is equipped with a fireproof core layer 7, the top of the fireproof core layer 7 is provid...

Embodiment 2

[0037] see Figure 5 As shown in Comparative Example 1, as another embodiment of the present invention, a cylindrical groove is opened in the middle of the top of the U-shaped block 2, and a miniature bearing is installed on the annular side of the round rod 12, and the outer side of the miniature bearing is fixedly installed Inside the cylindrical groove, a torsion spring 21 is installed on the annular side of the round rod 12, and the outer side of the torsion spring 21 is fixedly installed inside the cylindrical groove, and a magnetic block 22 is fixedly installed on the annular side of the round rod 12, and the cylindrical The inside of the slot is fixedly equipped with two magnetic pieces 23, and the first magnetic piece 22 and the second magnetic piece 23 are on the same level; during work, the round rod 12 is rotated, and the round rod 12 rotates to squeeze the torsion spring 21, and the rotating pin rotates to make the magnetic Block one 22 moves and sticks to the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com