Circumferential air inlet structure of shell-and-tube type air preheater

A technology of air preheater and air intake structure, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of distortion and damage of heat exchange tubes, achieve reasonable structure and ensure service life , the effect of proper tube bundle protection measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

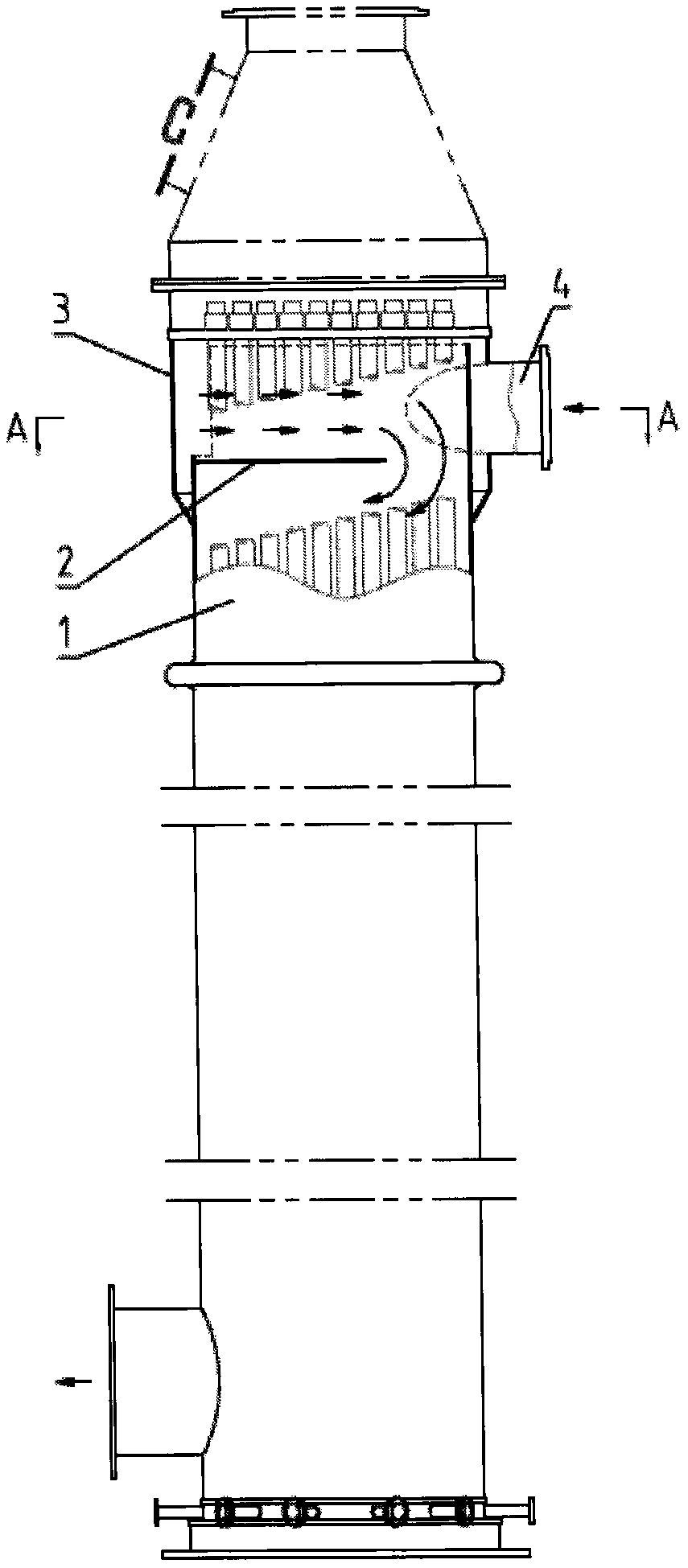

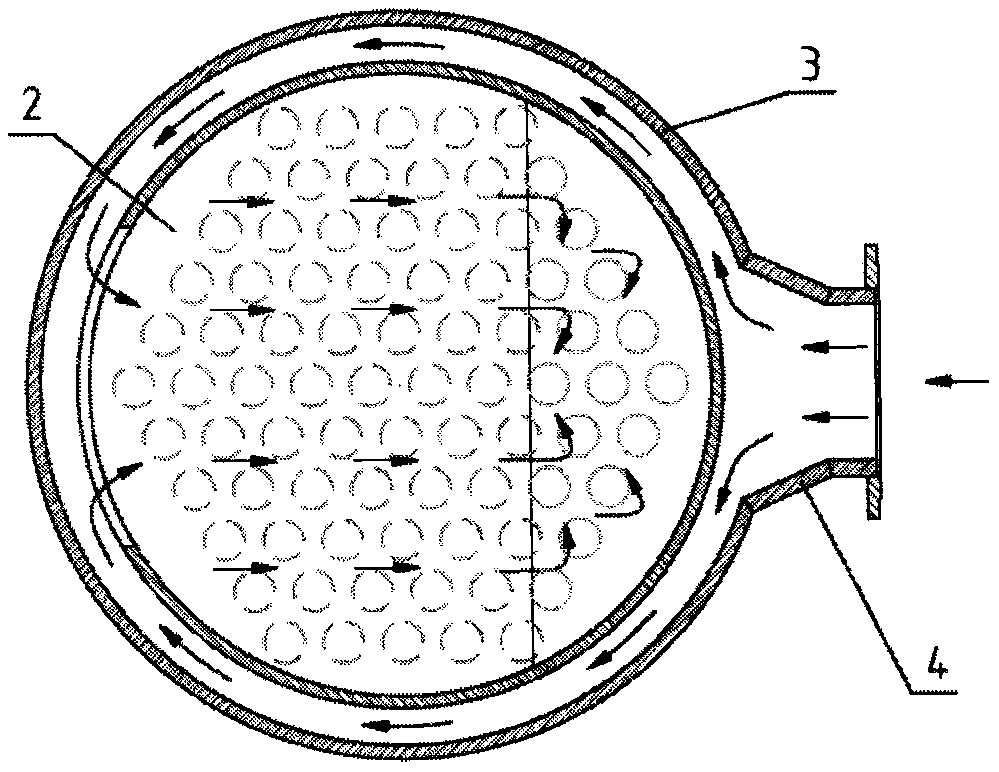

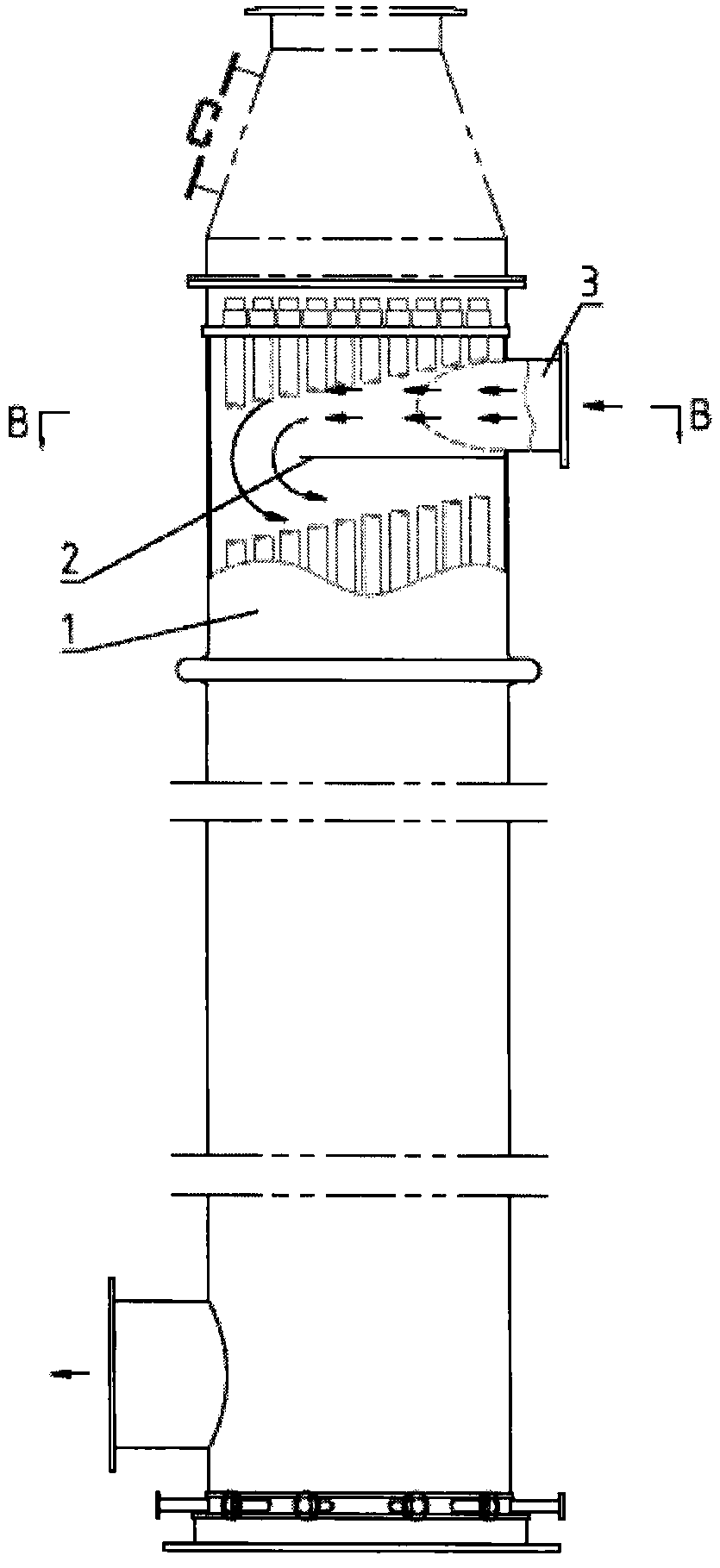

[0028] A shell-and-tube air preheater annular air intake structure comprises: a casing 1 , a baffle 2 , an outer casing 3 , and a cold air inlet 4 . The outer shell 3 and the cold air inlet 4 are assembled and welded, and then a circular hole is opened in the outer shell 3 according to the figure to form the shell-side air inlet structure; the shell 1 and the outer shell 3 are positioned and fixed with a rib plate and then assembled and welded; After exiting the opening position and size of the shell 1, a long opening is opened; the cold air inlet 4 has an opening of 180 degrees with the shell 1, and the baffle plate 2 is adjusted according to the opening direction; the shell 1 and the tube bundle are assembled. Tube sheet assembly welding.

[0029] The annular air inlet structure proposes a new design for the structure of the cold air inlet of the air preheater, which solves the problems of distortion and damage of the tube bundles existing in the air preheater for many years...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com