Method for producing pure copper high precision semi hollow section bar

A manufacturing method and high-precision technology, applied in the field of manufacturing and metal processing, to achieve the effect of practical method, novel design concept and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

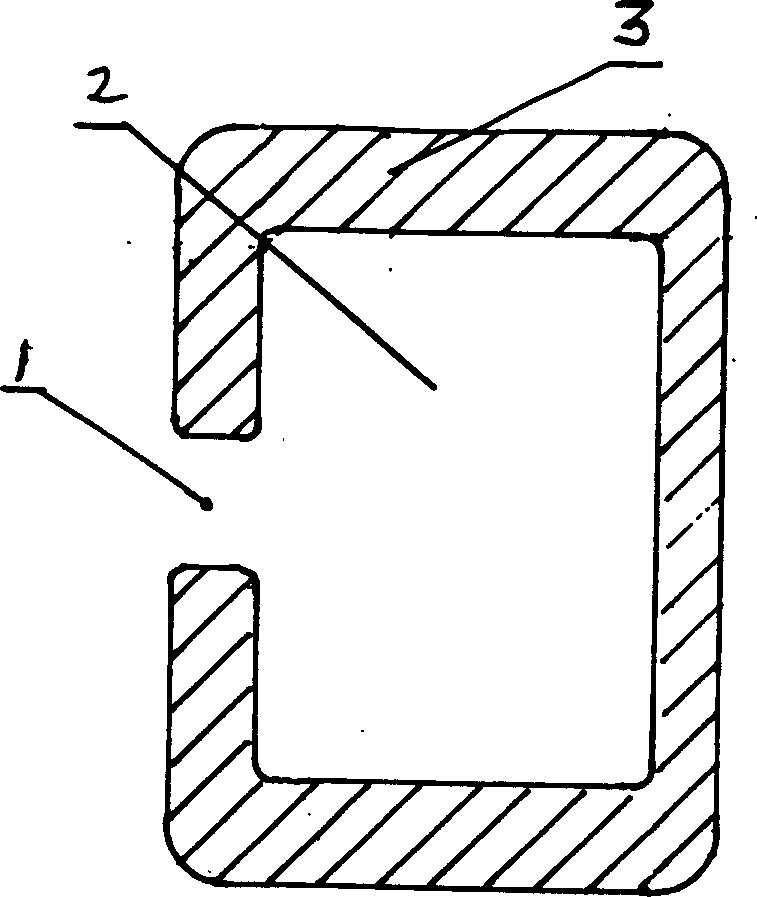

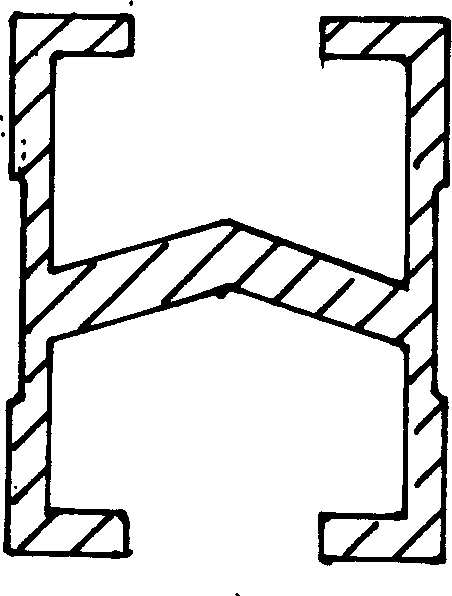

[0054] A method for manufacturing a pure copper high-precision semi-hollow profile, comprising the following steps:

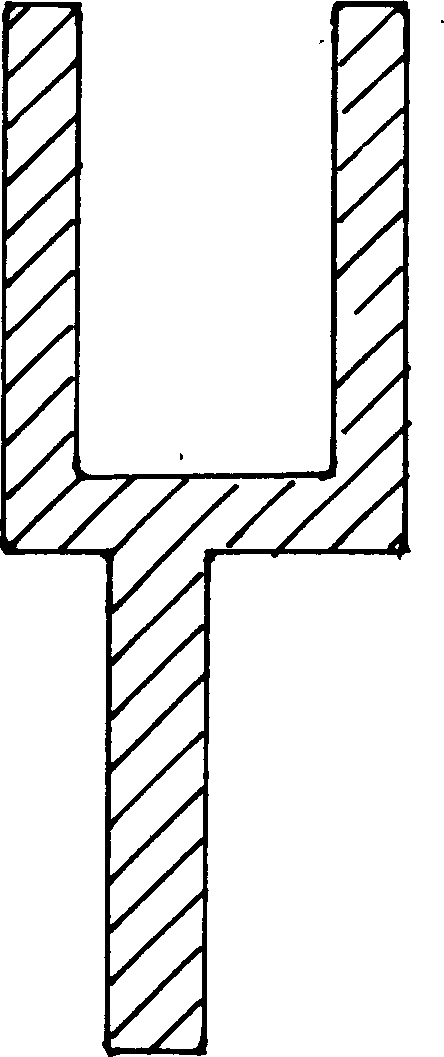

[0055] 1. Hot extrusion process for preparing V-shaped billet with enlarged opening

[0056] Heat the ingot that meets the quality standard of pure copper for electrician use to about 850°C, and use a V-shaped hot extrusion die (32) to Profile extrusion process production. The die cavity of V-type hot extrusion die (32) is V-shaped, and its opening is greater than the opening that C section bar requires. The ratio of the area A enclosed by the mold from the tongue to the tongue base (6) to the area W of the tongue base width section (10) is less than 1.4.

[0057] The V-type hot extrusion die (32) is positioned with the tongue-shaped die holder (33) by the positioning pin hole (5), and is connected as a whole.

[0058] The outlet cone (8) is used to reduce extrusion resistance and protect extruded products from being scratched.

[0059] The sizing belt (9) ...

Embodiment 2

[0069] A kind of manufacturing method of pure copper high-precision semi-hollow profile as in embodiment 1, but use the drawing machine stretching of adjustable die base, and straighten the bigger bending of semi-hollow profile at any time.

Embodiment 3

[0071] A method of manufacturing pure copper high-precision semi-hollow profiles as in Embodiments 1 and 2, but the cold-drawing combination die is made of high-alloy cold-working die steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com