Hot rolling process of crossed steel

A special-shaped steel and cross-shaped technology, applied in the direction of metal rolling, can solve problems such as easy torsion and bending, unstable operation of rolled pieces, rolling defects, etc., achieving significant economic and social benefits, high cost, and low cost. Morph uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

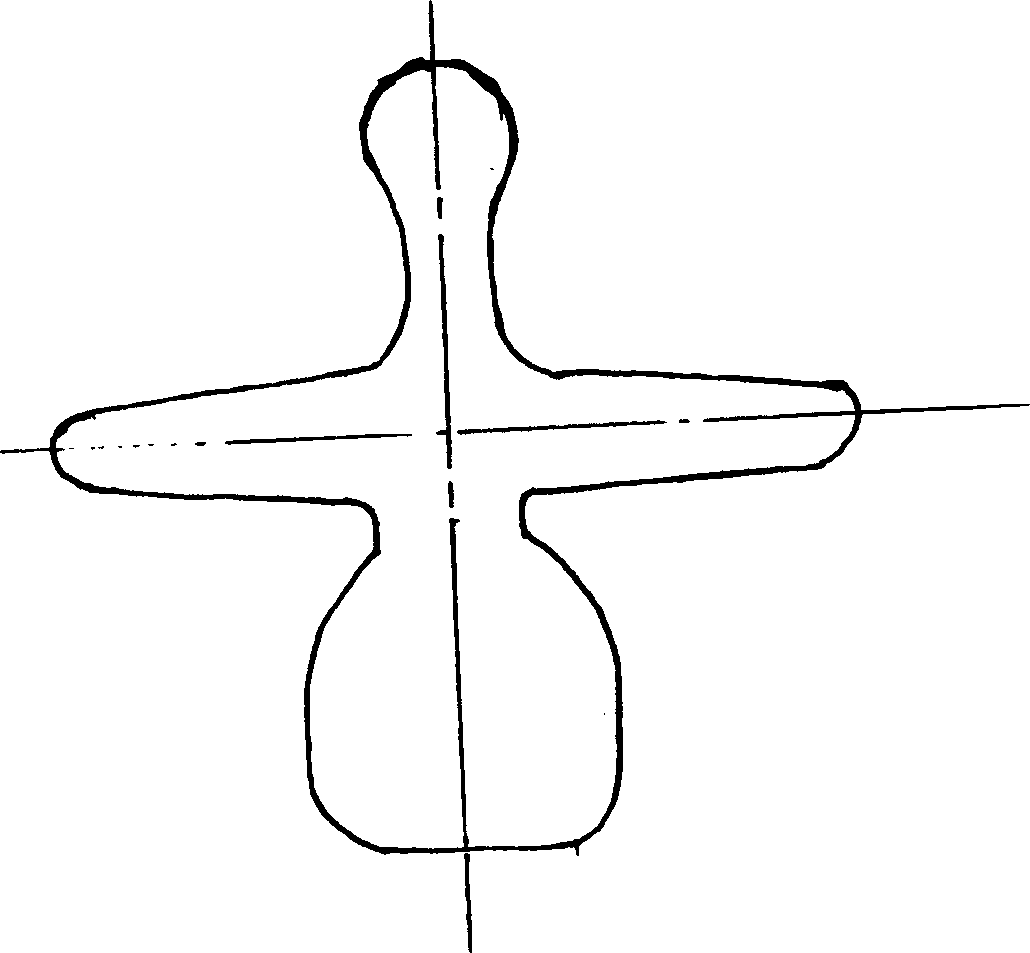

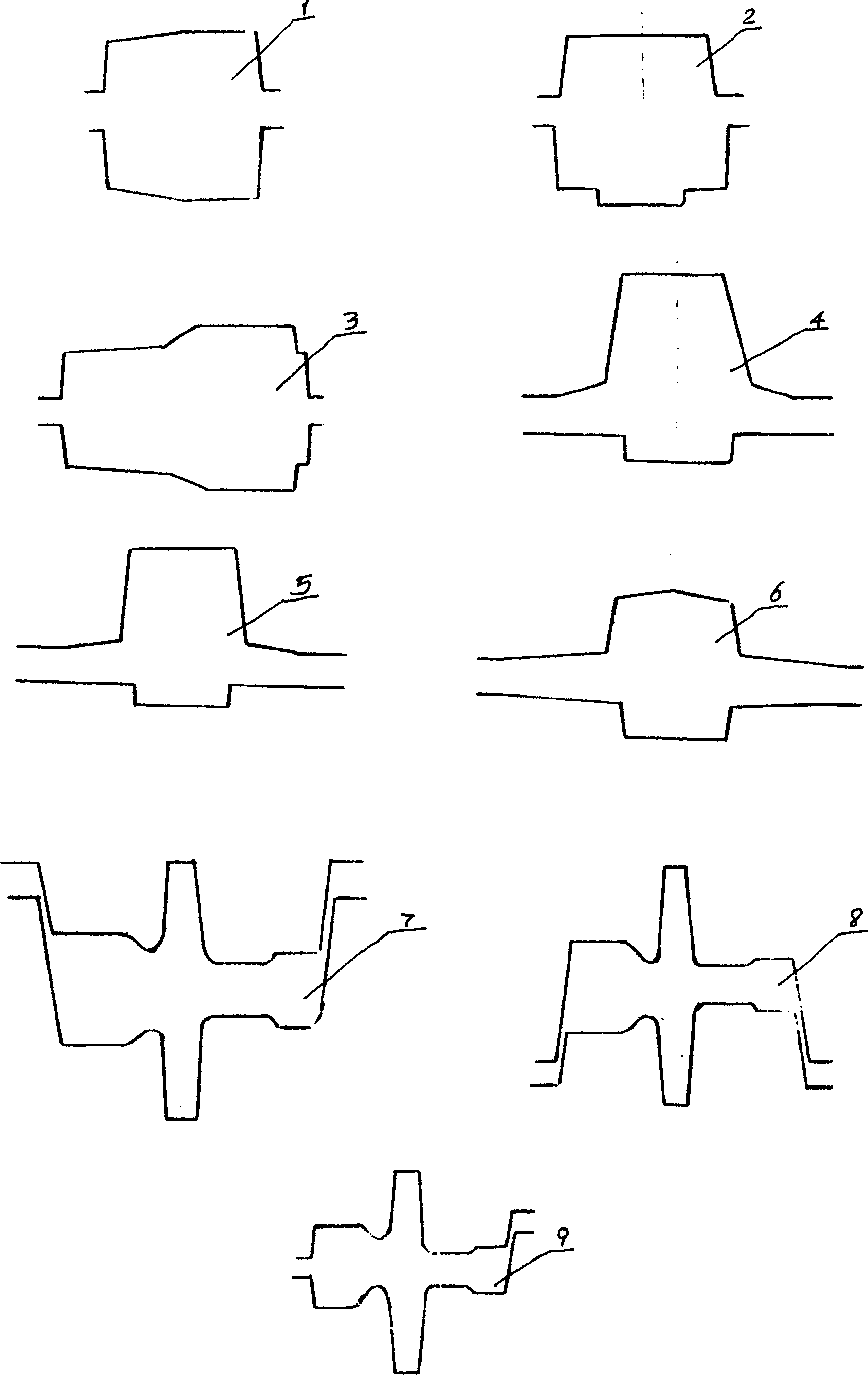

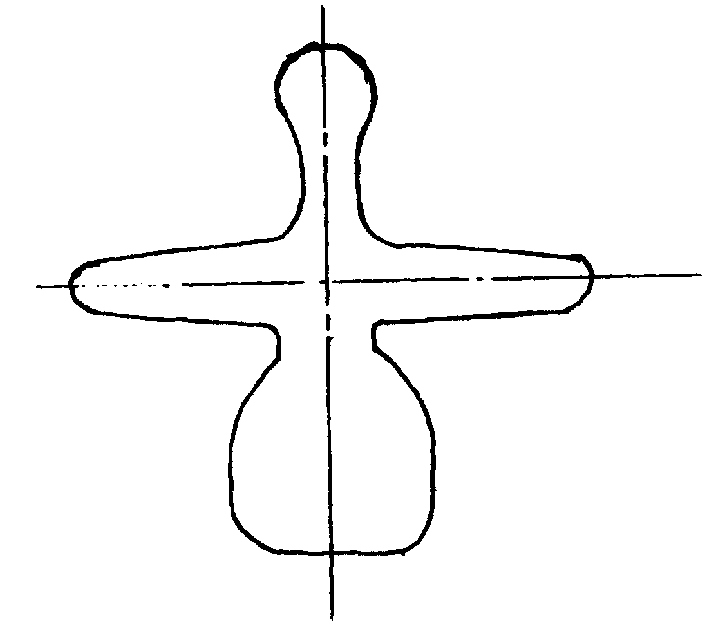

[0012] According to the cross-sectional shape characteristics of the special-shaped steel, a new type of pass system is designed, which organically combines the two stages of rough rolling and finishing rolling. The pass system is composed of ordinary trapezoidal holes, bottom slot cap holes, convex trapezoidal holes and double wedge rail holes. Ordinary trapezoidal holes, convex trapezoidal holes and bottom groove hat-shaped holes are used in the rough rolling stage, and double-wedge rail-shaped holes are used in the finishing rolling stage. Ordinary trapezoidal holes and convex trapezoidal holes are used to solve the uneven deformation in rolling under high temperature conditions, and obtain metal blanks suitable for biting into bottom slot hat-shaped holes through their special shapes. The hat-shaped hole of the bottom groove is pressed laterally and vertically, and the metal billet required for the leg and tail is obtained by means of the rolled piece turning steel, vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com