Method for automatically acquiring volume and strain cloud diagram of cylindrical test piece in loading process

An automatic acquisition and strain cloud map technology, applied in the preparation of test samples, image analysis, image data processing, etc., can solve the problems of low precision, low measurement efficiency, low degree of automation, etc., to achieve high precision and efficiency, logical Clear, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

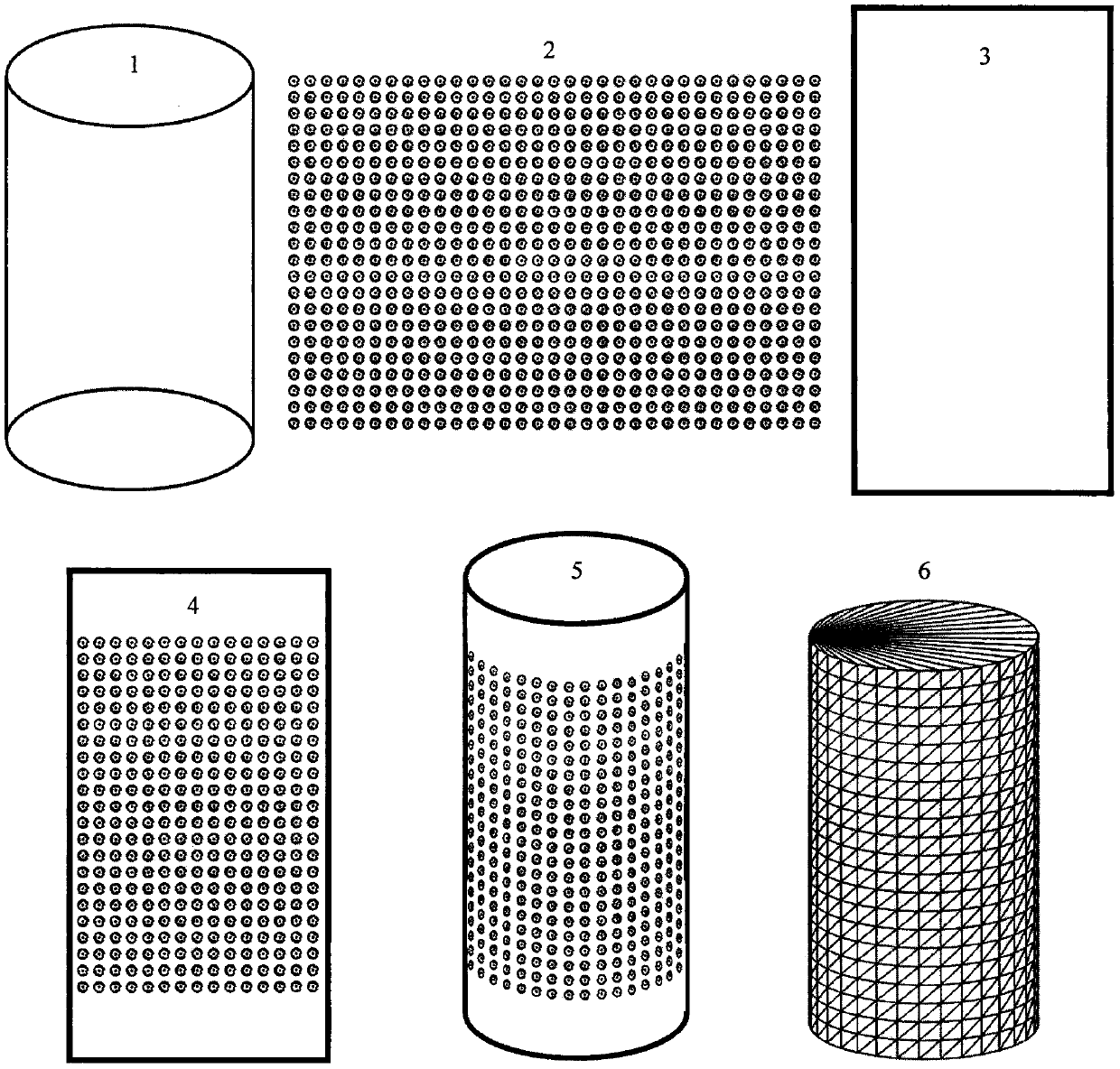

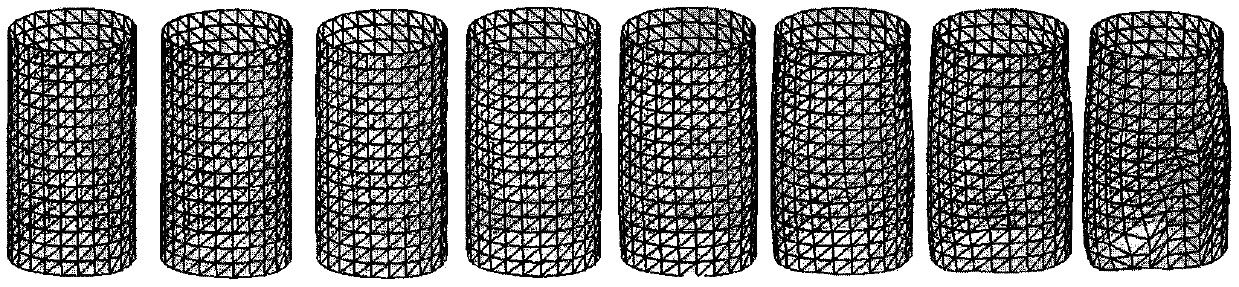

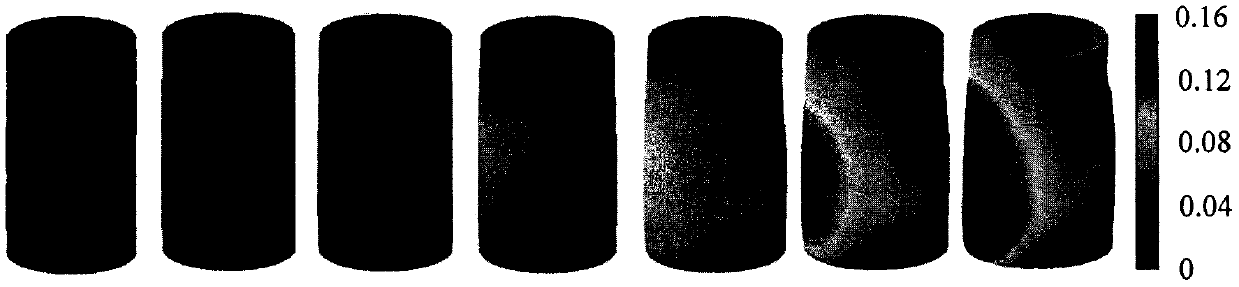

[0045] This embodiment is the acquisition process of the volume and strain nephogram of a cylindrical soil sample during the triaxial test. Specifically include the following steps:

[0046] 1) Prepare a cylinder with a diameter of 71 mm and a height of 142 mm to be tested;

[0047] 2) Design and print 384 identifiable marking points (16 rows and 24 columns) uniformly arranged in the form of a rectangular lattice on the rubber film used to wrap the test piece;

[0048] 3) Place the test piece inside the triaxial pressure chamber, wrap the surface of the test piece with a rubber film and adjust the position of the rubber film so that the marking points on it can just cover the entire test piece;

[0049] 4) By means of photogrammetry, a three-dimensional Cartesian coordinate system is established according to the actual physical size and the initial position of the marked point on the surface of the test piece in this three-dimensional coordinate system is obtained;

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com