Ultralow-yield-ratio cold-rolled dual-phase steel and manufacturing method thereof

A dual-phase steel, ultra-low-yield technology, applied in the field of steel materials, can solve the problems of affecting the formability, the high price of Mo element, and the impact on the final performance, to improve the formability and resilience performance, and good comprehensive mechanical properties. , to avoid the effect of wrinkling the surface of the parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

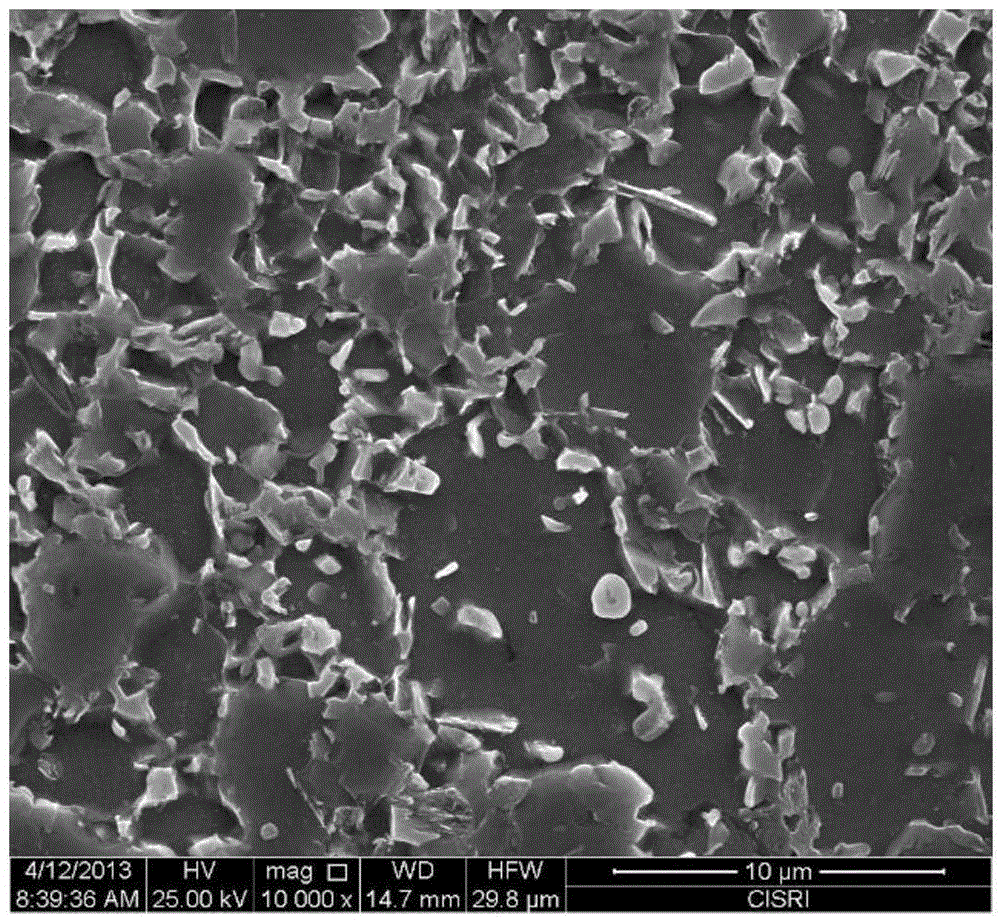

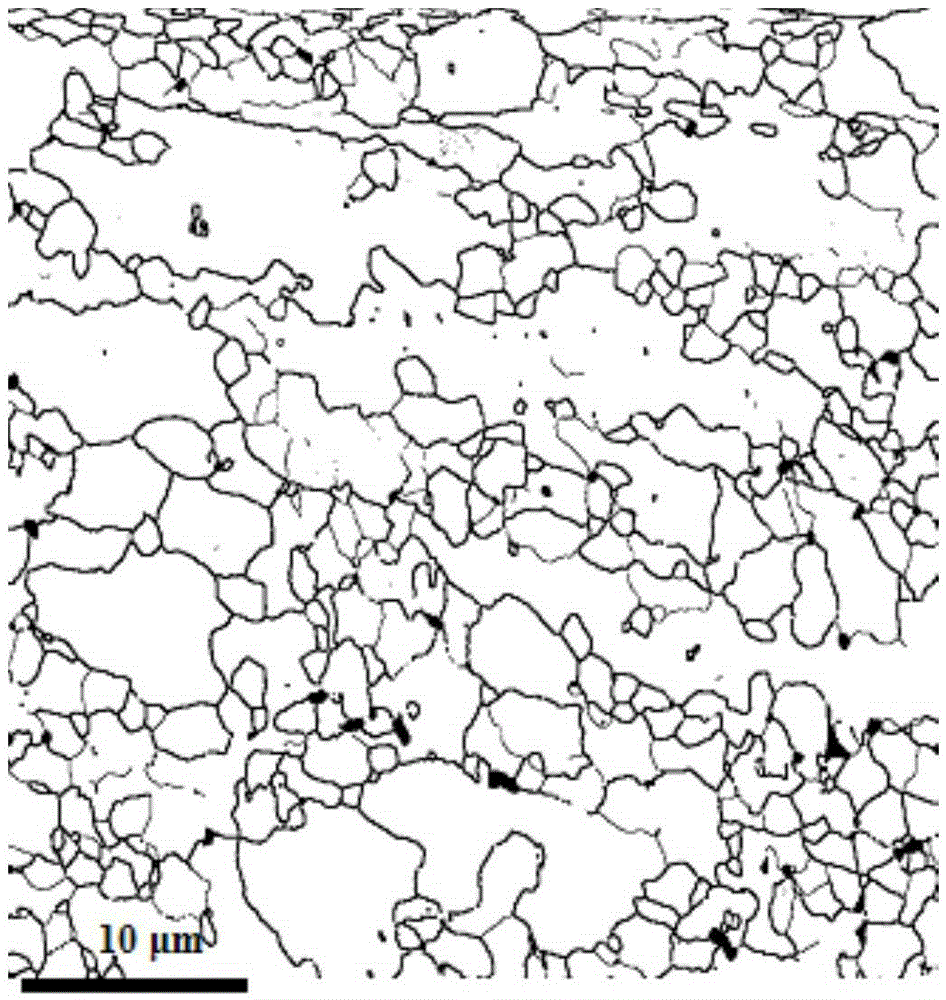

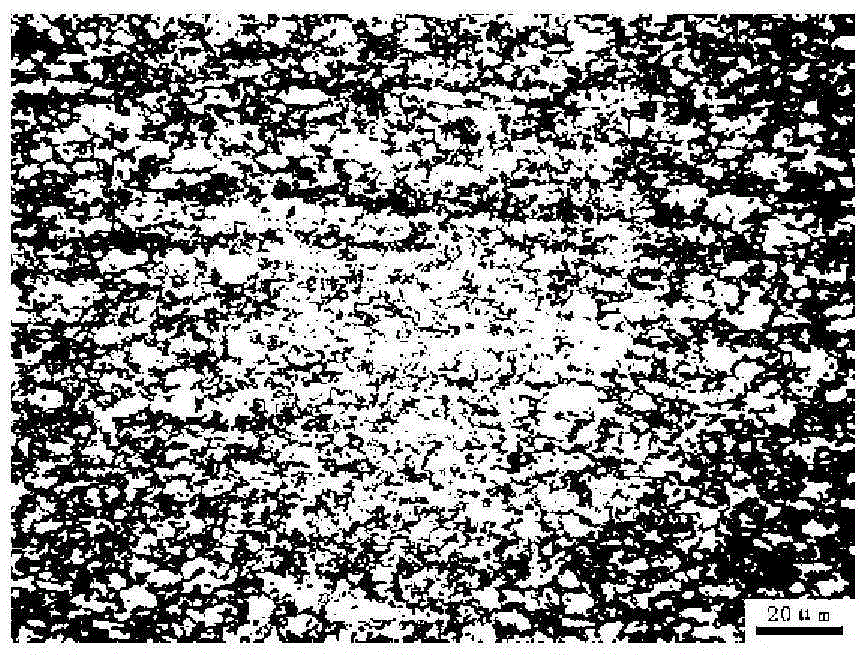

[0031] The trial-manufactured DP780 cold-rolled dual-phase steel has introduced a small amount of retained austenite into the microstructure with ferrite matrix and martensite islands as the basic characteristics, thus ensuring that the strength level reaches the level of similar steel companies. , elongation A 50 Stable increase to more than 20% (A 80 ≥18%), ultra-low yield ratio 0.44~0.45. Its manufacturing process is as follows:

[0032] 1) Smelting and continuous casting into slabs, components and weight percentages of slabs: C: 0.16%, Mn: 1.81%, Si: 0.47%, Al: 0.058%, P: 0.0069%, S: 0.0038%, Nb0 .04%, the balance is Fe and unavoidable impurities;

[0033] 2) Hot rolling is performed on the slab after conventional heating, the cumulative rolling reduction is 86%, the thickness of the hot-rolled finished product is 5.0mm, and the final rolling temperature is controlled at 850-880°C;

[0034] 3) Carry out coiling, control coiling temperature at 670 ℃;

[0035] 4) Carry ou...

Embodiment 2

[0044] 1) Smelting and continuous casting into slabs, components and weight percentages of slabs: C: 0.13%, Mn: 1.7%, Si: 0.43%, Al: 0.04%, P: 0.0068%, S: 0.0079%, N : 0.0043%, Nb0.028%, the balance is Fe and unavoidable impurities;

[0045] 2) Hot rolling is performed on the slab after conventional heating, the cumulative rolling reduction is 90%, the thickness of the hot-rolled finished product is 4.5mm, and the final rolling temperature is controlled at 850-880°C;

[0046] 3) Carry out coiling, control coiling temperature at 670 ℃;

[0047] 4) Carry out conventional pickling;

[0048] 5) Carry out cold rolling, control the cumulative reduction rate of cold rolling to 66.7%, and roll into a steel plate with a thickness of 1.5mm;

[0049] 6) Carry out continuous annealing, control the annealing temperature at 800-840°C, and annealing time 90-120 seconds;

[0050] 7) Cooling to 700-740°C at a slow cooling rate of 3-5°C / s;

[0051] 8) Perform rapid cooling, the cooling spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com