Method for efficiently preparing blind rivet steel

A high-efficiency, steel wire technology, applied in the direction of manufacturing tools, heat treatment equipment, process efficiency improvement, etc., can solve the problems of low production efficiency, high defect rate, and residual soap powder on the surface, etc., to improve the work hardening rate and the surface quality of finished products Qualified, the effect of reducing the problem of diameter out-of-tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

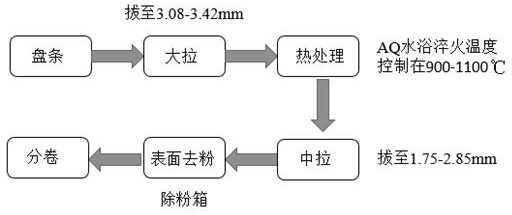

[0022] This specific embodiment adopts following technical scheme: as figure 1 shown, including the following steps:

[0023] S1. Raw material preparation: select low carbon steel wire rod.

[0024] S2. One-time drawing: the low-carbon steel wire rod is drawn to a diameter of 3.08-3.42 mm after large-scale drawing.

[0025] S3. Heat treatment: water bath quenching, traditional heating lead bath quenching, our company uses AQ water bath quenching, no heavy metal ion discharge, more environmentally friendly, by changing the length of the quenchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com