Method and system for zero release treatment of limestone-gypsum desulfurization wastewater

A desulfurization wastewater and treatment system technology, applied in the field of flue gas purification, can solve problems such as high operating costs, complicated treatment methods, and great ecological environmental hazards, and achieve the effects of convenient zero-emission treatment, saving manpower, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

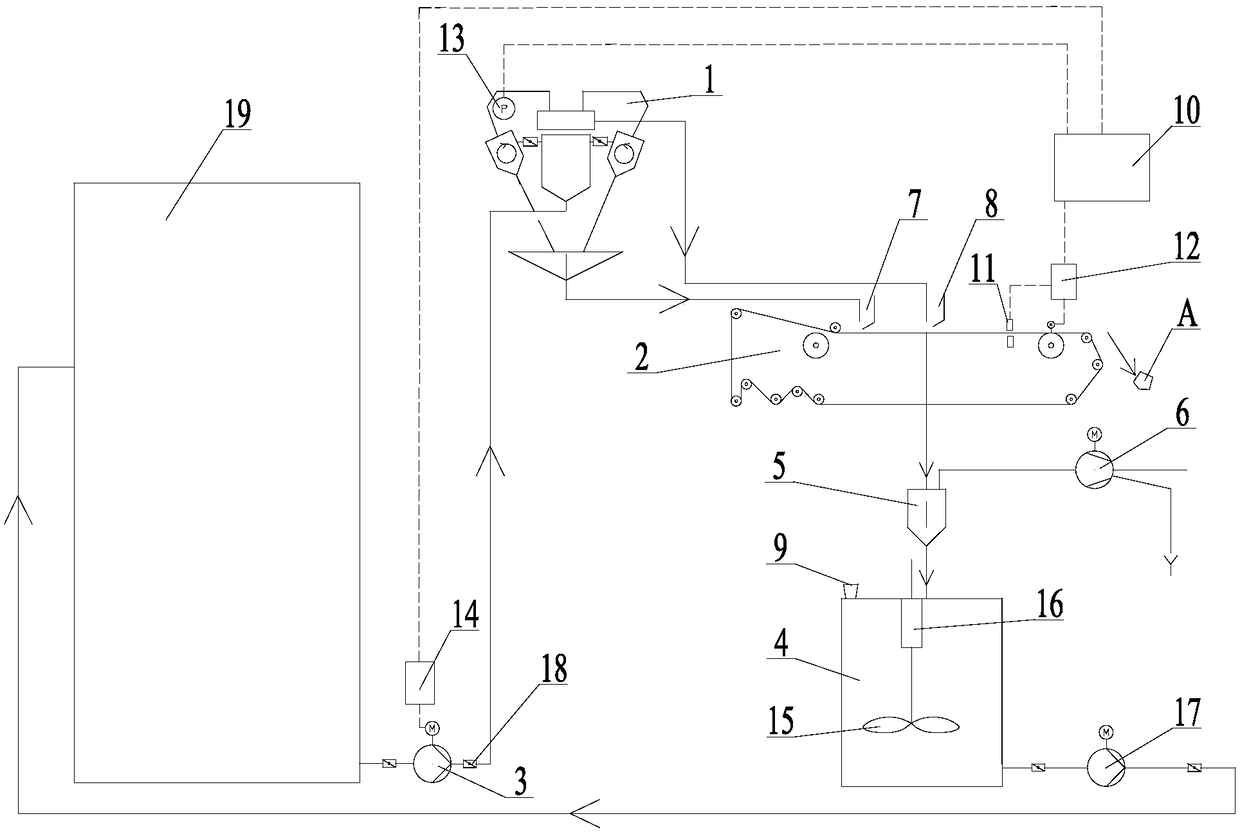

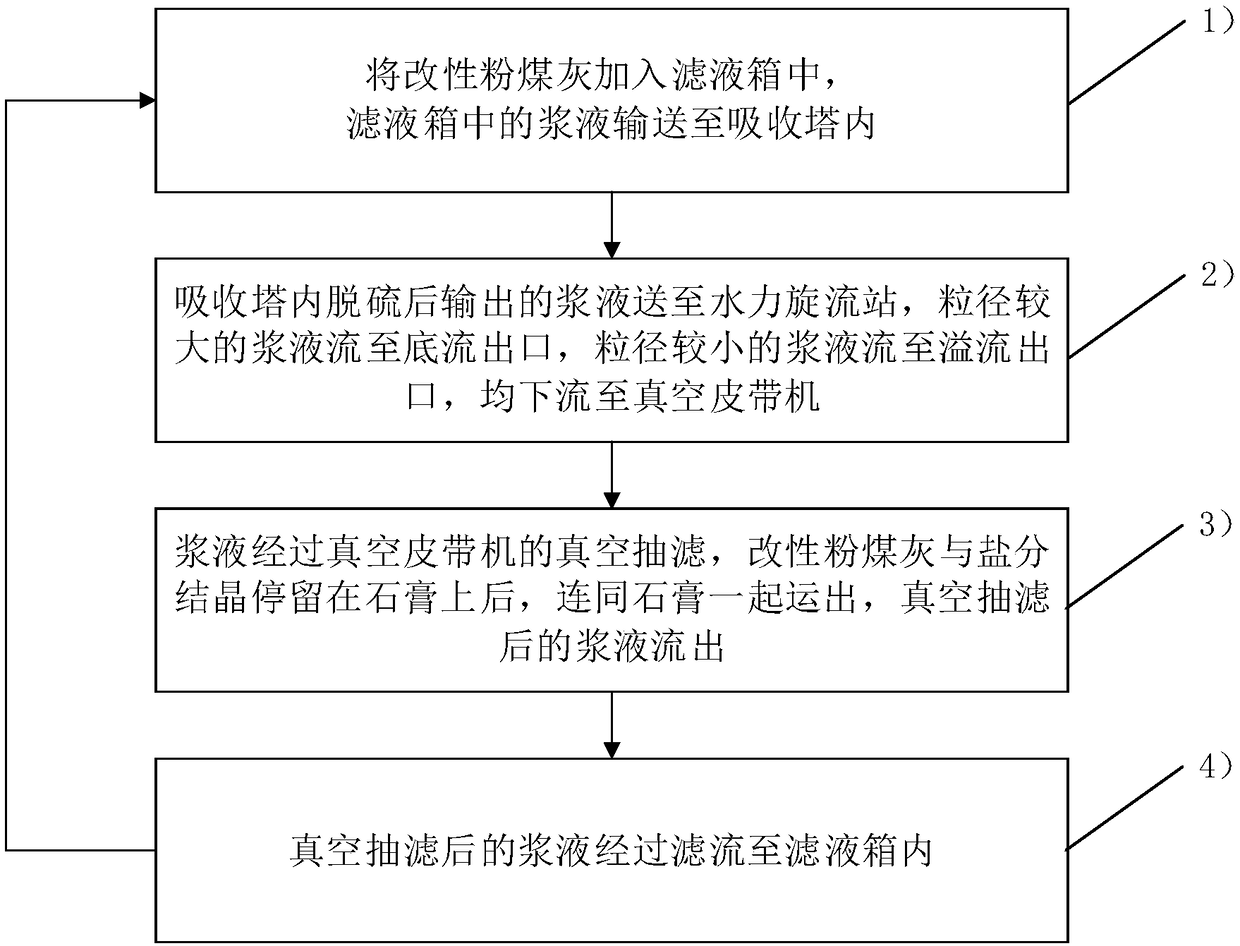

[0032] Such as figure 1 As shown, a limestone gypsum process desulfurization waste water zero discharge treatment system includes a hydrocyclone station 1, a vacuum belt conveyor 2, a first slurry pump 3, a filtrate tank 4, a filtrate tank 5, a vacuum pump 6, an underflow uniform distributor 7 and an overflow A flow uniform distributor 8, the filter box is provided with a modified fly ash feed port 9, the modified fly ash feed port 9 adopts a feed port for adding a modified fly ash with a particle size of 5-20 microns, The top of the feeding port is also provided with a dust suction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com