A method for refining β grains of tc18 titanium alloy by step strain rate forging process

A strain rate, TC18 technology, applied in the field of forging, can solve problems such as multi-pass and large deformation, and achieve the effects of increasing strain rate, promoting nucleation, and strengthening pinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

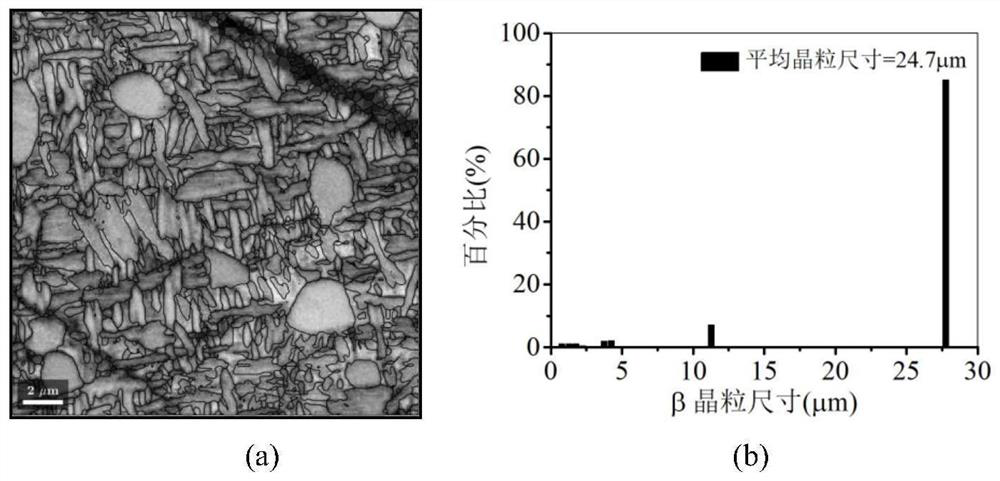

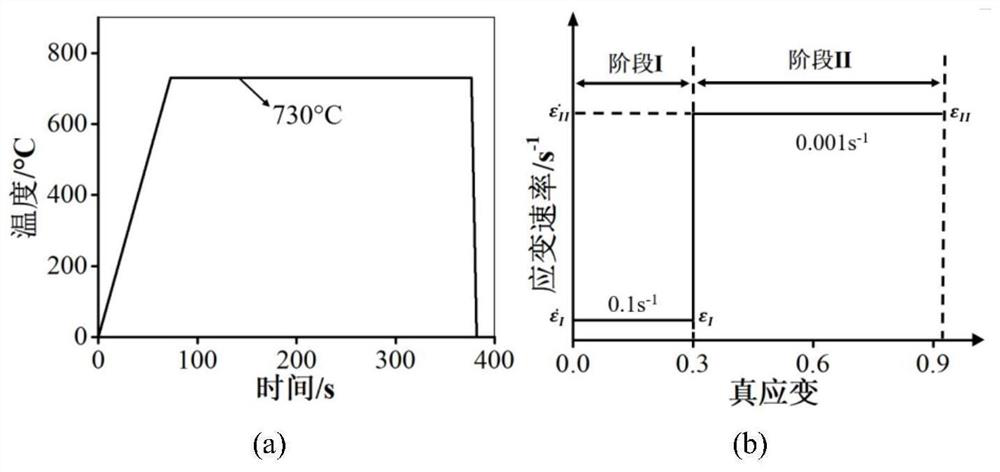

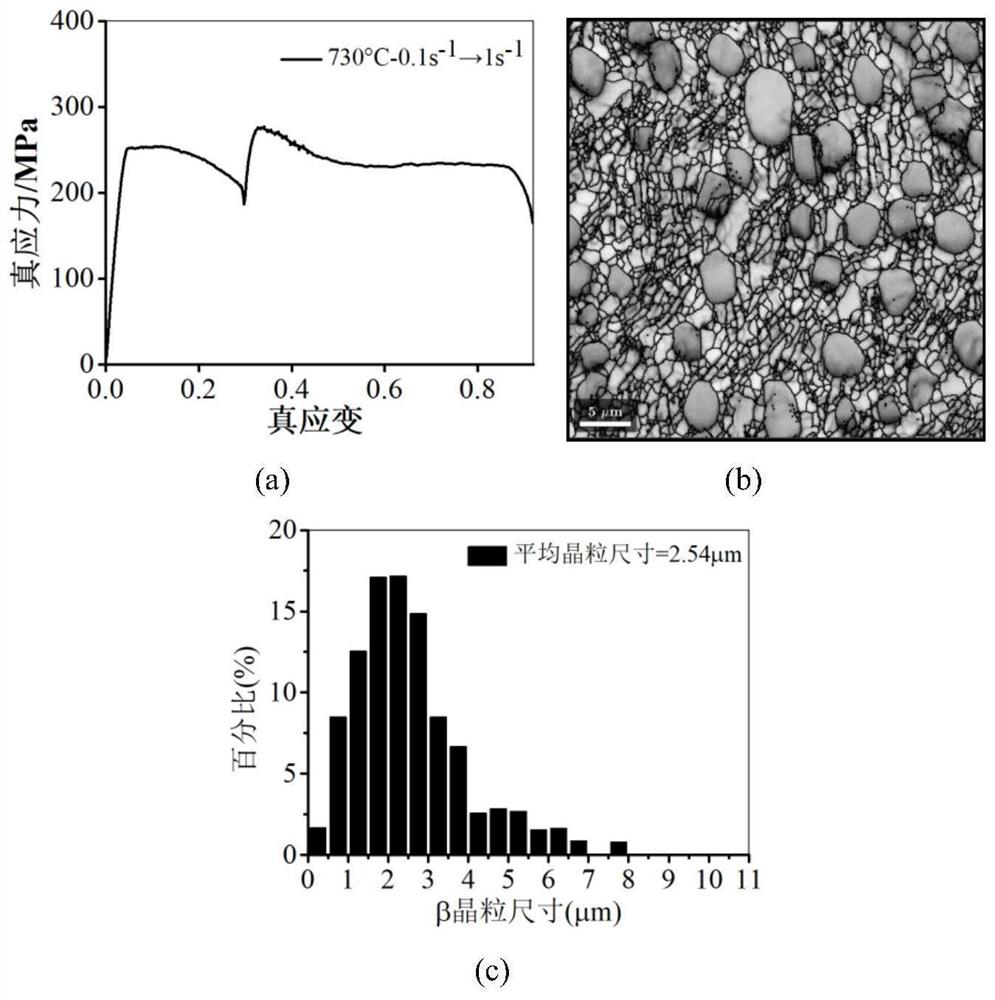

[0020] Step 1: The TC18 titanium alloy forging billet whose initial structure is a dual-state structure is heated to the forging temperature of the α+β dual-phase region, and after the temperature of the forging billet is kept uniform, step strain rate forging is performed. The forging temperature is 730 ° C. The strain rate consists of two stages: the first stage has a strain rate of 0.1s -1 , the strain rate of the second stage is 1s -1 , the deformation of the first stage is 20% of the height of the blank (true strain 0.3), the deformation of the second stage is 40% of the height of the blank (true strain 0.62), and the total deformation of the two stages is 60% (true strain 0.92) , the strain rate changes immediately after the first stage of deformation, without interval holding time;

[0021] In step 1, the forging process flow of TC18 titanium alloy forging blank is as follows: figure 2 As shown in (a): the forging billet is first heated to 730 °C at a heating rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com