Method for forecasting high-temperature-alloy creep life

A creep life and prediction method technology, applied in the application field of materials science and engineering technology, can solve the problems of curve inconsistency, large results, low creep life, etc., to reduce costs, reduce harm, and improve prediction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples will further illustrate the present invention, so that those skilled in the art can better understand the advantages and characteristics of the present invention.

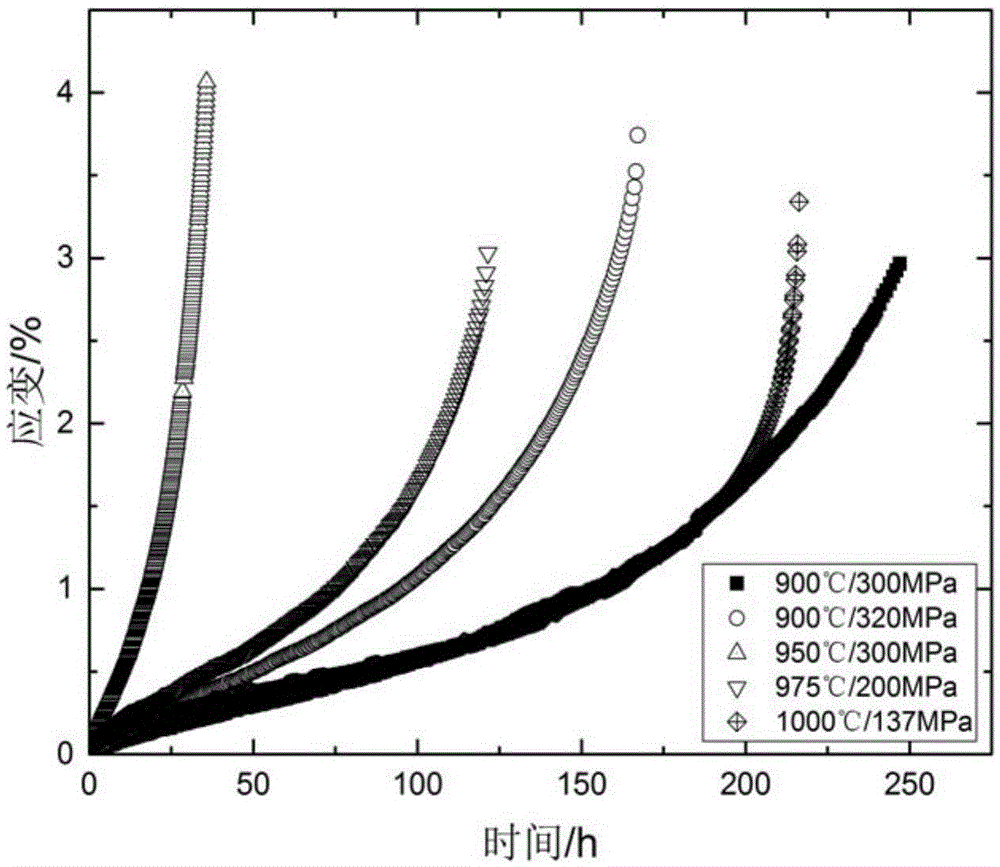

[0023] First, taking the K465 alloy as the research object, using a high-temperature creep testing machine, its creep curves under five different temperature and stress conditions were obtained. The experimental conditions were 1000°C / 137MPa, 975°C / 200MPa, and 950°C / 300MPa , 900°C / 320MPa, 900°C / 300MPa, take a data point every 30 minutes during the experiment, see the experimental results figure 1 .

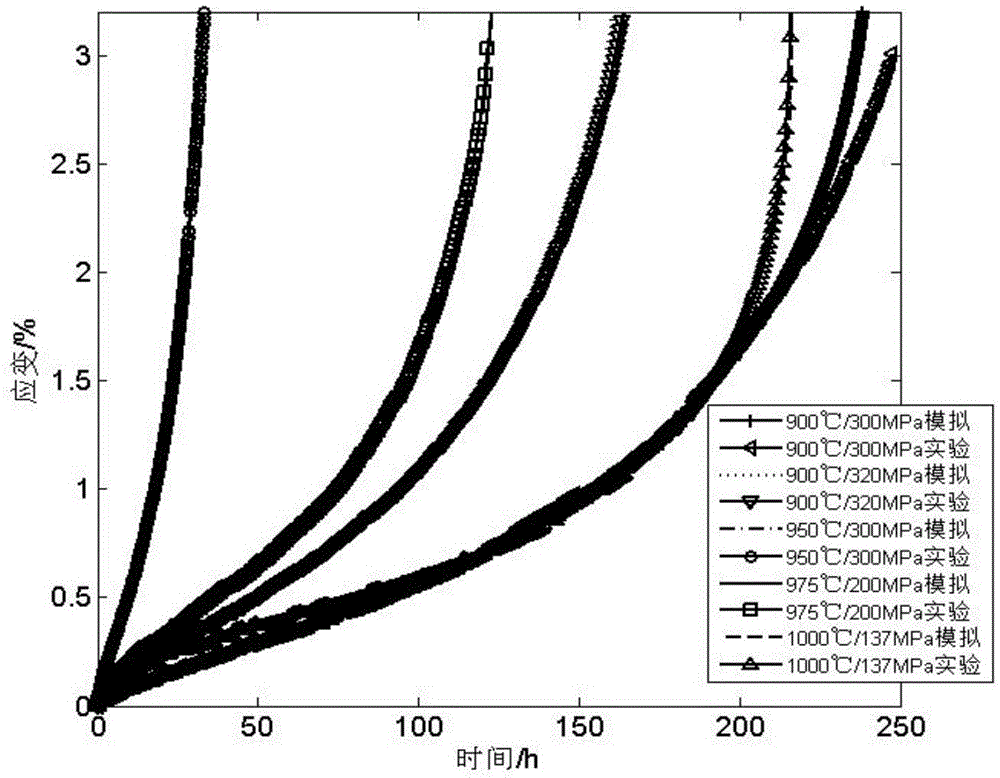

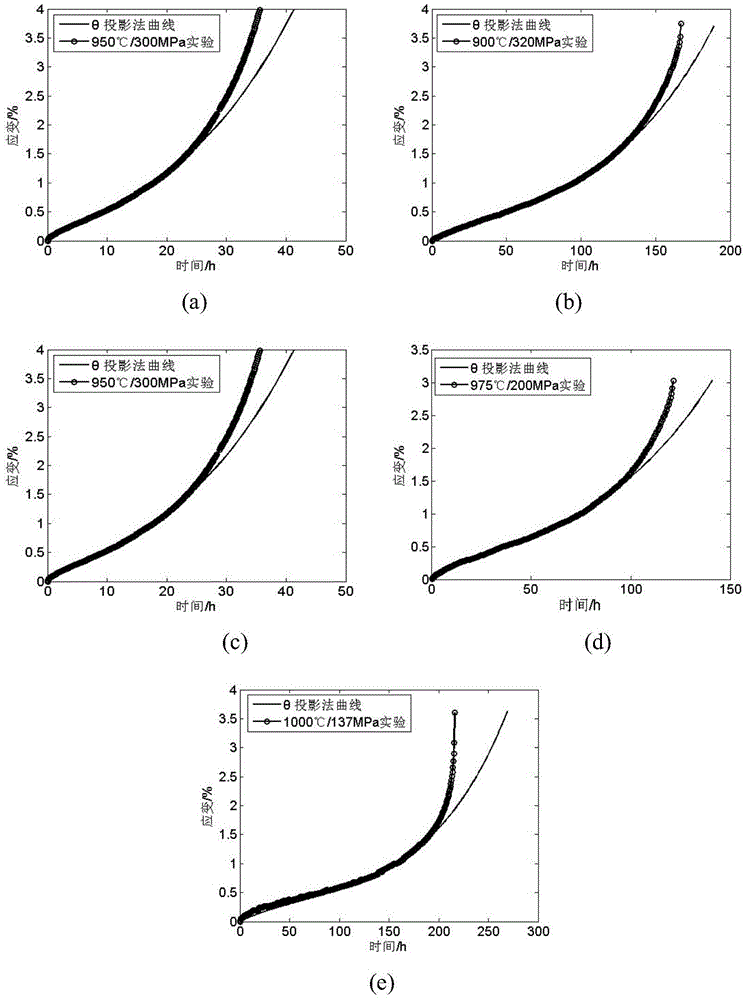

[0024] Secondly, using the formula ε=θ respectively 1 *(1-exp(θ 2 *(1+θ 5* ε)*t))+θ 3 *(exp(θ 4 *(1+θ 5* ε)*t)-1) and the classic θ projection method equation are used to fit the creep data of the creep curve ε1 , θ 2 , θ 3 , θ 4 , θ 5 (See Table 1), get the revised θ projection method equation. The specific fitting method is to use the nonlinear fitting tool of Originlab softwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com