Centrifugal model test simulation method and system for barrier dam

A centrifugal model test and simulation system technology, applied in the field of centrifugal model test simulation of barrier dams, can solve problems such as complex material properties, unevenly distributed pore structure, uneven large deformation, etc., and achieve low test cost and wide application range , control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

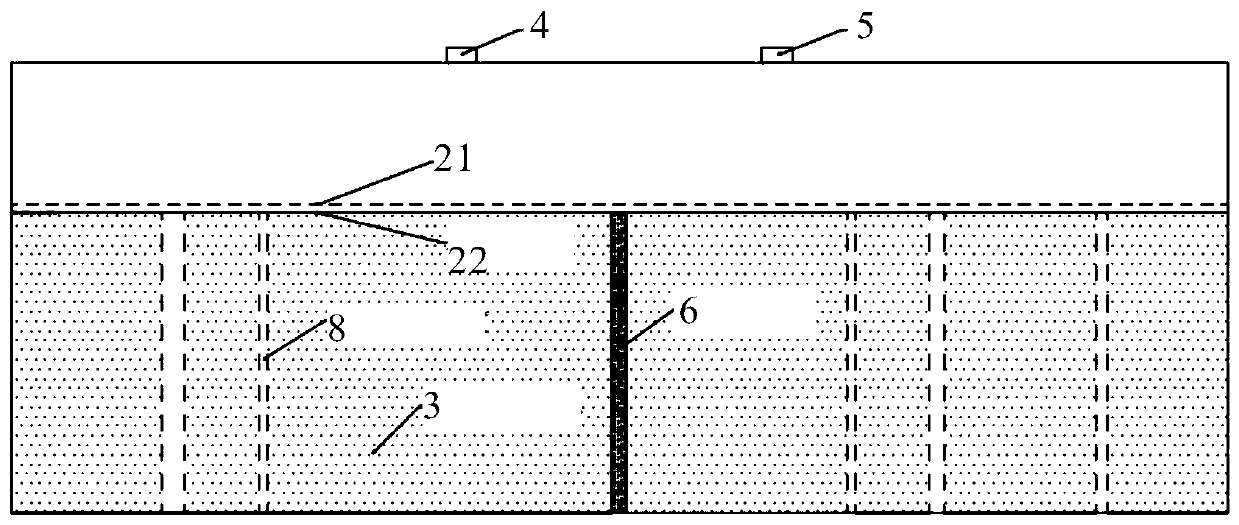

[0026] The idea of the present invention is to construct a simulated dam body with a certain grade of crushed stone and sand-soil mixed material, and randomly arrange potassium nitrate powder in it, and after the centrifugal acceleration is stabilized at the set value, pass water into the model box, Potassium nitrate powder is dissolved to form a non-uniformly distributed pore structure in the damming body, simulating the generation of non-uniform deformation.

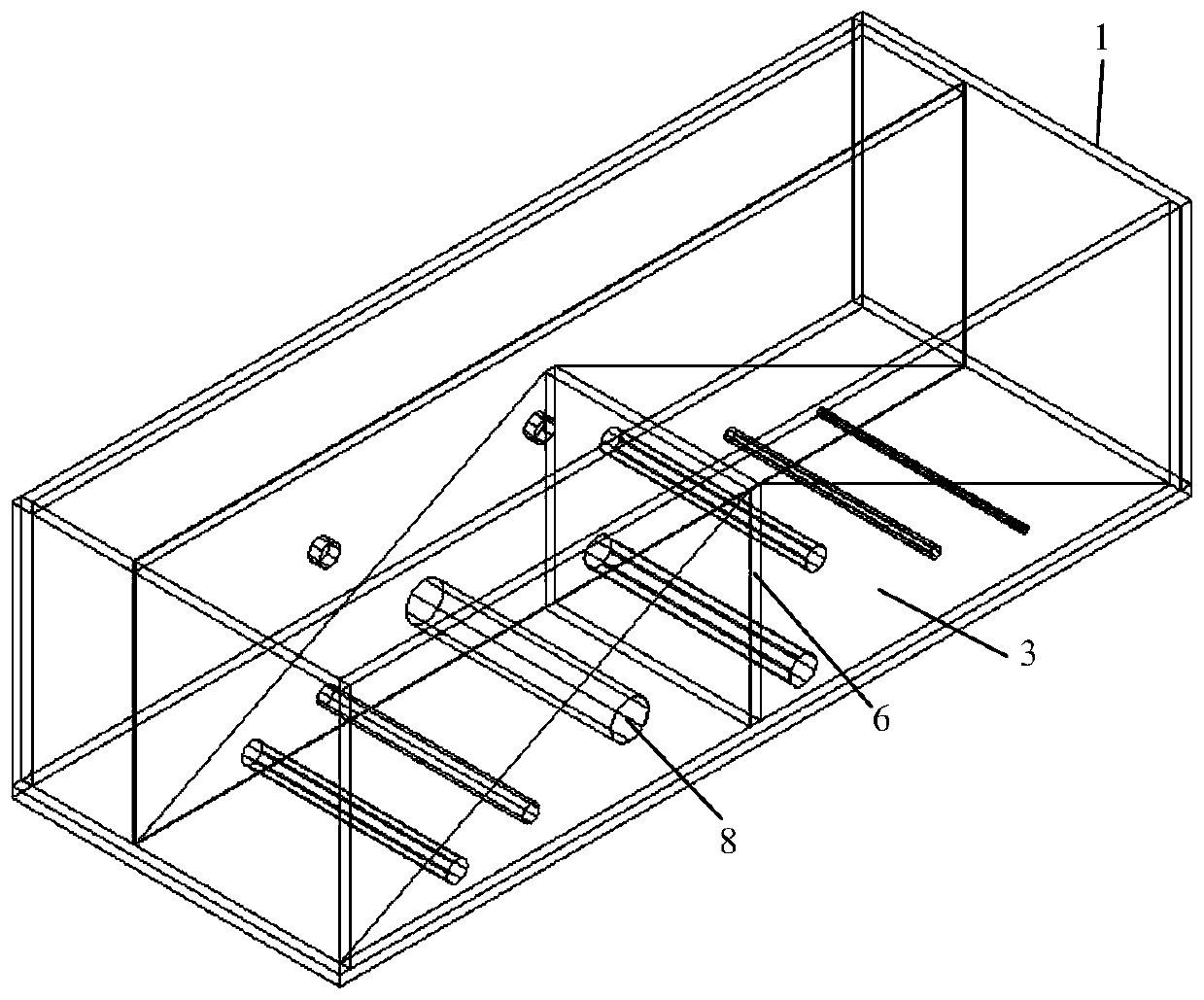

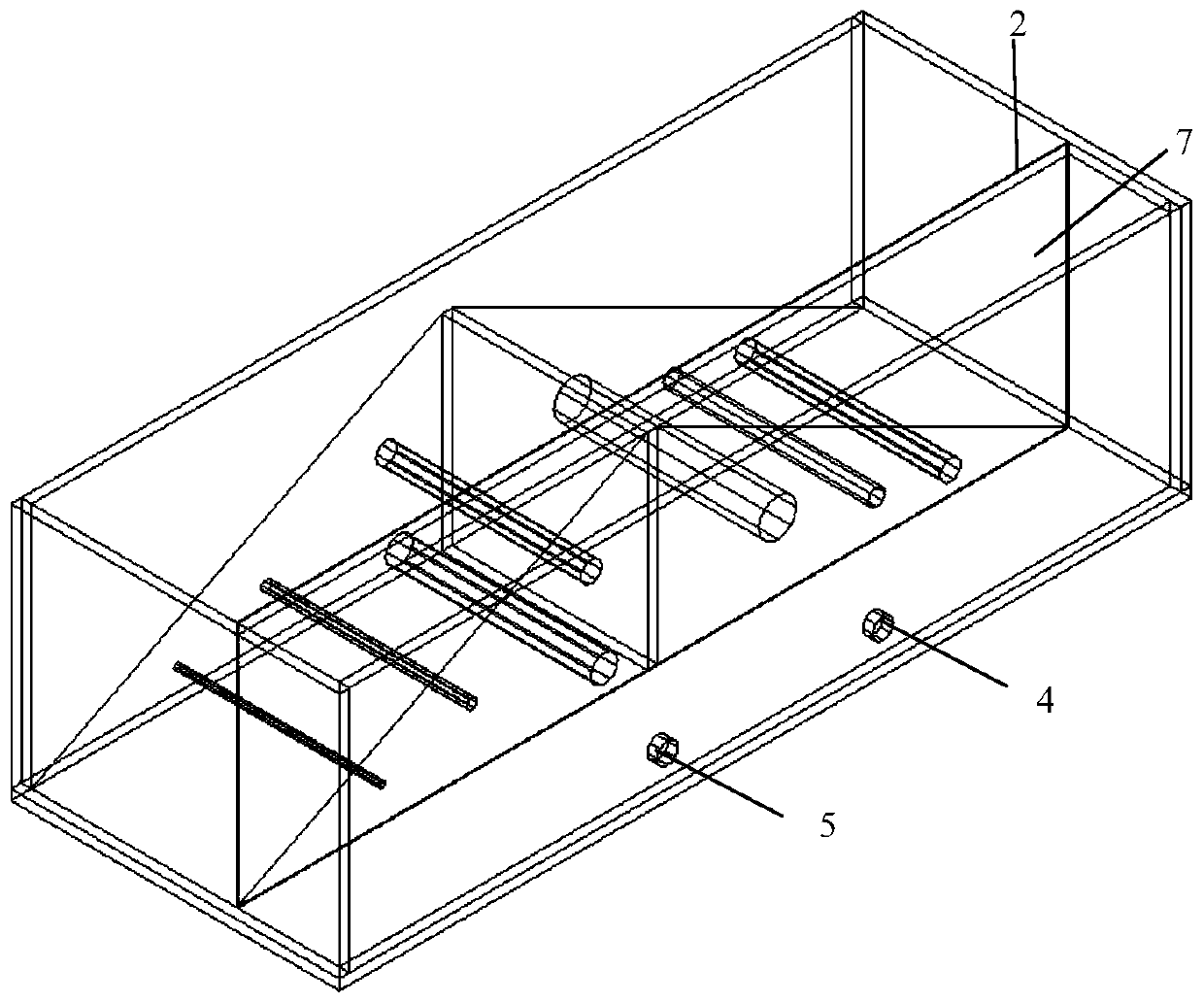

[0027] refer to figure 1 , figure 2 , image 3 and Figure 4 , the simulation system of the present invention comprises a model box 1, a vertical permeable partition 2 is arranged in the model box 1 and the box is divided into two chambers, the side wall of one of the chambers has a water outlet, and in the chamber The indoor layout has a simulated damming body 3 mainly composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com