Heterostructure-based multi-type reinforced austenitic stainless steel and manufacturing method

A technology of austenitic stainless steel and martensitic stainless steel, which is applied in the field of high-strength plastic alloy production, can solve the problems of poor mechanical properties of stainless steel, low elongation of materials and low chemical stability, etc., and achieves easy mass production, yielding The effect of strength improvement and good economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0032] Table 1 is the composition of the steel of the embodiment of the present invention. Table 2 shows the mechanical properties obtained by two different heat treatment processes in the embodiment of the present invention.

[0033] Table 1

[0034] C Si mn Cr Ni Mo Cu 0.048 0.27 0.65 15.13 8.09 2 1.22

[0035] Table 2

[0036]

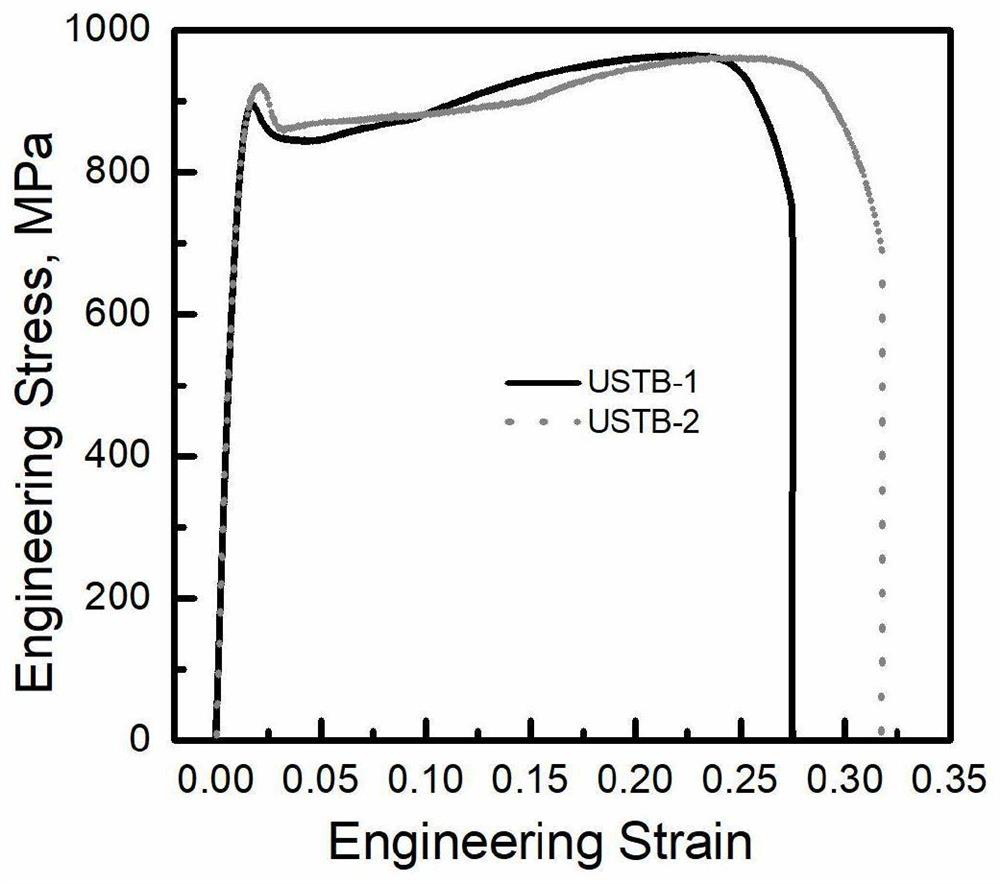

[0037] According to the chemical composition designed in Table 1, ingots were obtained through vacuum melting. USTB-1 and USTB-2 are obtained through the following two heat treatment processes respectively.

[0038] USTB-1: hot forging (1200°C) → solution treatment (1050°C / 1h) → cold rolling (45% reduction) → annealing (580°C / 1h)

[0039] USTB-2: hot forging (1200°C)→hot rolling (1050°C)→cold rolling (45% reduction)→annealing (580°C / 1h)

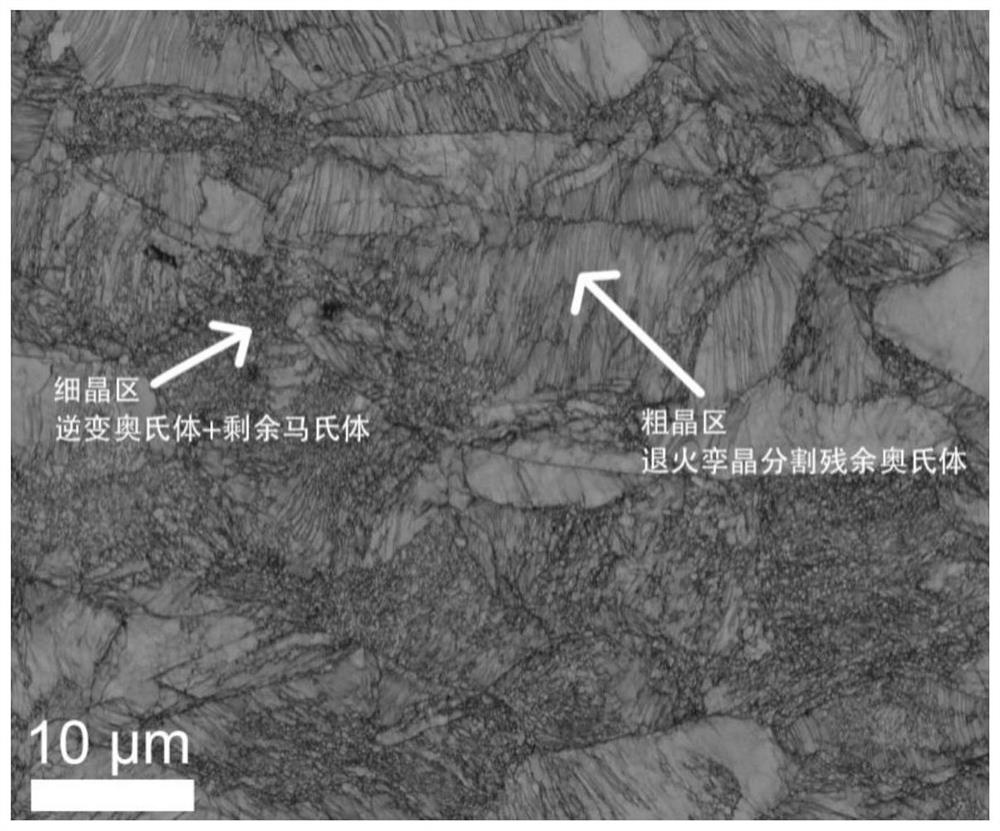

[0040] according to figure 1 According to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com