Asymmetric self-compensating rolling working roll applicable to short-stroke roll shifting and implementation method thereof

A work roll, self-compensating technology, used in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of uneven wear, edge drop and crown shape that cannot be achieved in short strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

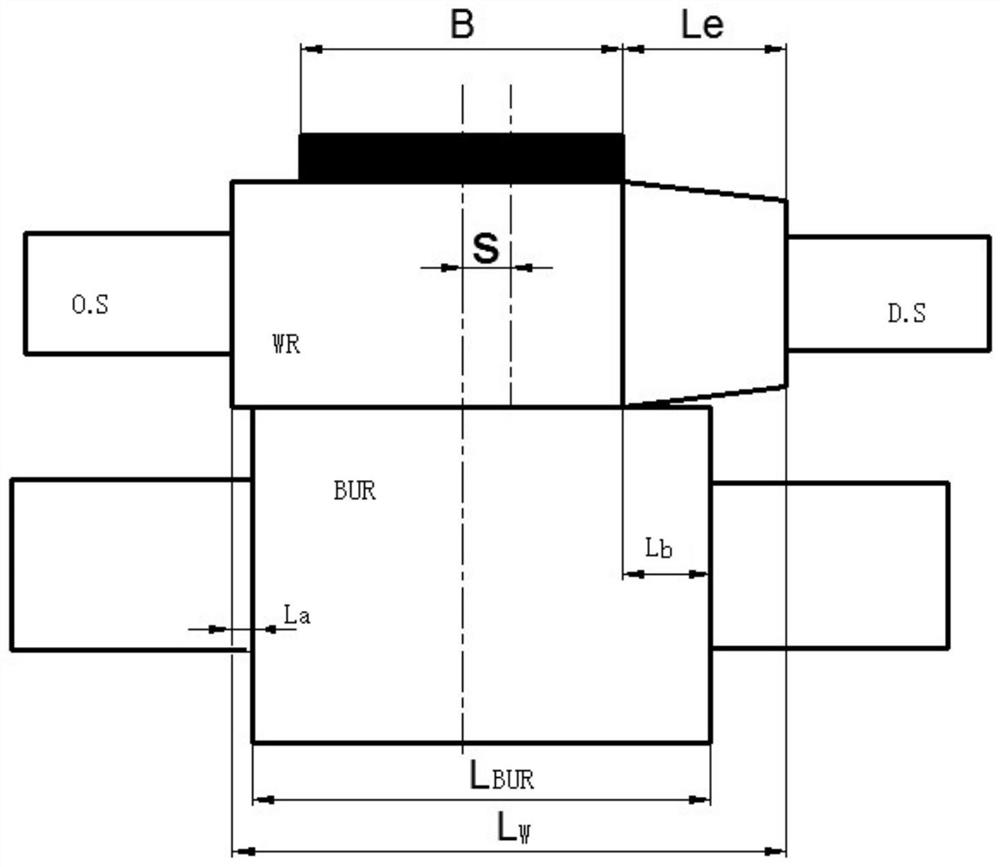

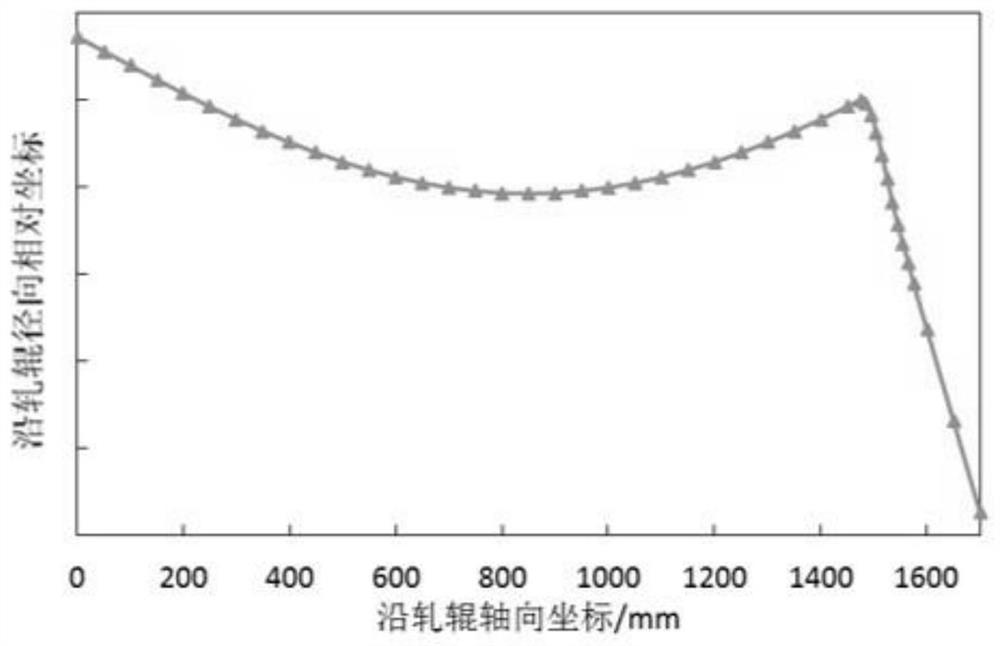

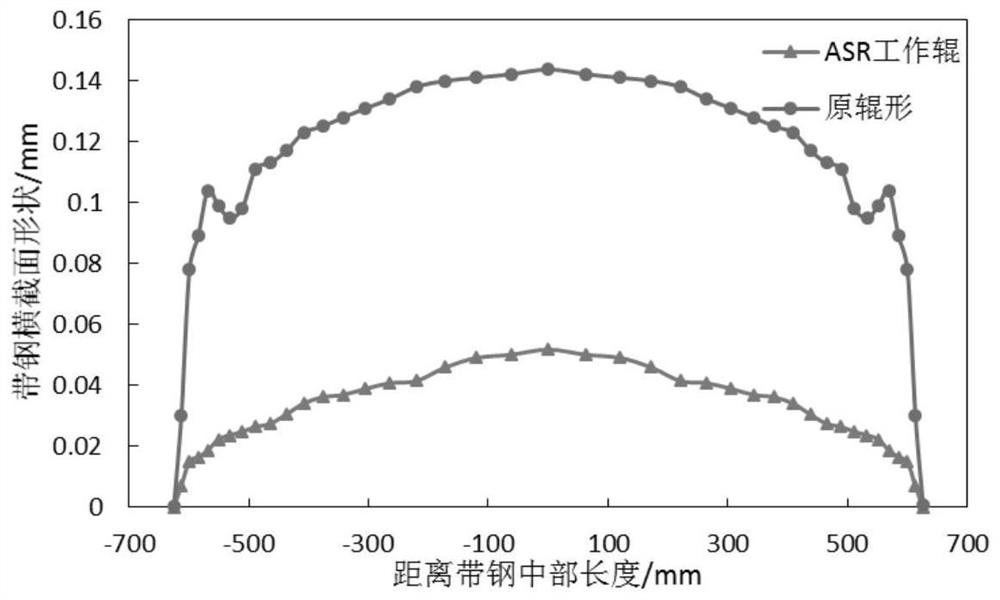

[0054] This embodiment provides an ASR-S (Asymmetry Self-compensating Rolling for Short Stroke System) work roll suitable for uneven wear, edge drop and crown profile control, which is suitable for short stroke shifting. This embodiment uses an asymmetric Self-compensating work rolls, according to the wear pattern of the rolls in the rolling process, through the specially designed roll shape curve of the work rolls, coupled with a specific roll shifting method, one side of the groove box worn by the grooved work rolls is opened to make the wear shape From "U" shape to "L" shape, the rolled piece is always rolled in the relatively flat area of the roll shape, and the asymmetry of the roll shape and roll shifting is used to effectively change the wear of the work roll and improve the roll gap. asymmetry. The roll shape of the work roll is represented by a piecewise function, which includes a crown adjustment section, a wear control section, and a structural process section con...

no. 2 example

[0068] This embodiment provides a method for realizing asymmetric self-compensating rolling work rolls suitable for short-stroke roll shifting. The work rolls include a crown adjustment section, a wear control section, and a structural process section connected in sequence; the method includes:

[0069] S1, determine the strip width range, take the maximum width strip as the reference strip, and record its width as B 0 ;

[0070] S2, determine the roll shifting strategy, the roll shifting strategy includes the roll shifting of hot roll material and the roll shifting of silicon steel;

[0071] If the width of the hot roll material is less than or equal to the width of the silicon steel -200mm, the roll shifting can be carried out according to the periodic normal roll shifting strategy; -100mm~-30mm, after two pieces are rolled, the rolls are shifted once according to the two hot roll materials, each time the rolls are shifted 1mm~5mm, and the rolls are shifted in the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com