Corrosion-resistant and anti-fatigue pipeline steel for underwater oil and gas production and transportation and production method thereof

A production method and anti-fatigue technology, which is applied in the field of steel pipes and pipeline steel plates for the production and transportation of H-rich and S-rich oil and gas media, can solve the problems of high strength and low yield ratio, and improve fatigue resistance, corrosion resistance, Effect of Reducing Corrosion Sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

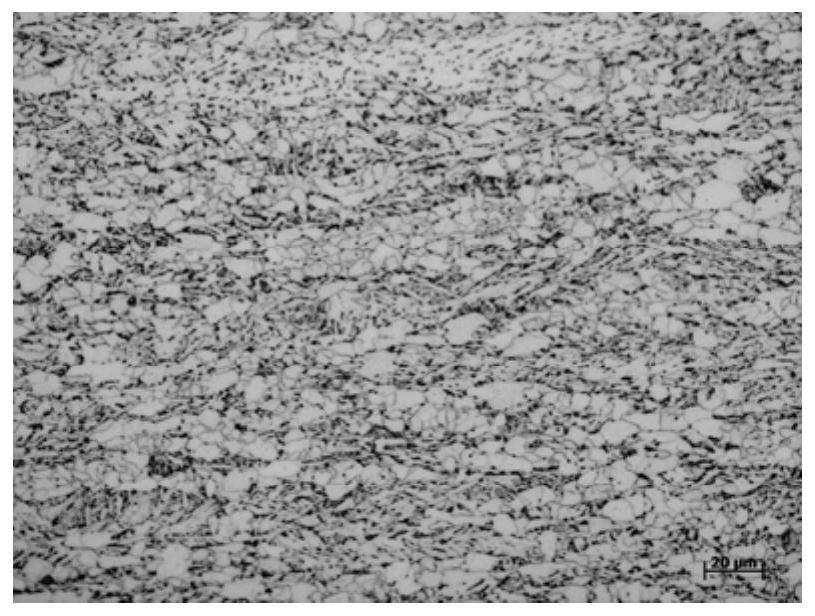

Image

Examples

Embodiment Construction

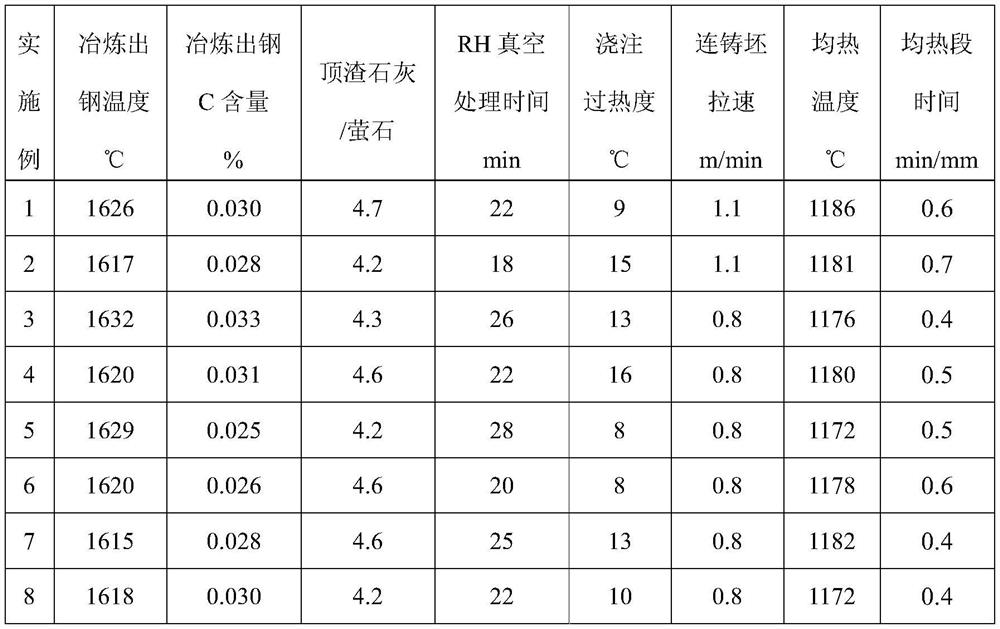

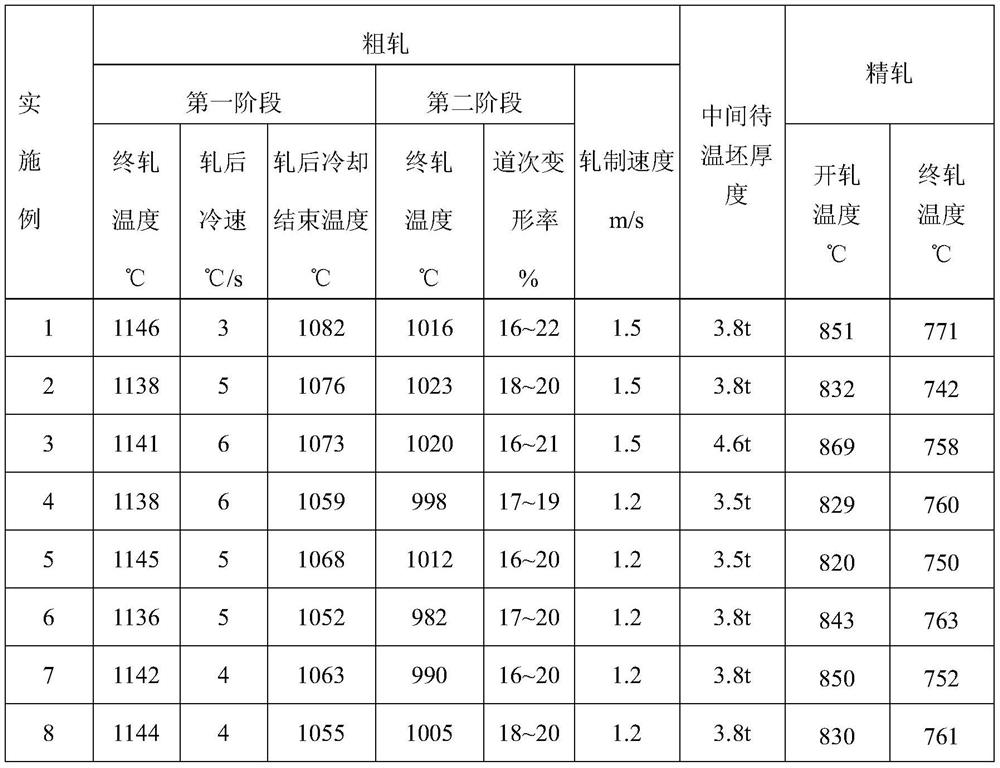

[0048] Below by embodiment the present invention will be further described.

[0049] In the embodiment of the present invention, smelting, continuous casting, heating, rolling, and cooling are carried out according to the component ratio of the technical solution.

[0050] Smelting: including converter smelting and out-of-furnace refining; when the converter is tapping, the tapping temperature is ≤1635°C, C≤0.035%, the slag is blocked and the steel is tapped, and lime and fluorite are added in the ratio of 4 / 1 to 5 / 1 to make the roof. Slag; during the refining process, the RH vacuum treatment time is ≥15min, and Ca treatment is carried out;

[0051] Continuous casting: the pouring superheat of continuous casting slab is ≤20℃, and the casting speed of continuous casting slab is 0.8~1.2m / min.

[0052] Heating: The continuous casting slab adopts multi-stage heating of preheating section, heating section I, heating section II, and soaking section. The temperature of the soaking s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com