Heat treatment process for improving corrosion resistance of aluminium alloy

A technology of corrosion resistance and aluminum alloy, which is applied in the field of aluminum alloy, can solve the problems of restricting the development and application of aluminum alloy and poor corrosion resistance, and achieve the goal of improving intergranular corrosion resistance, corrosion resistance, and intragranular structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

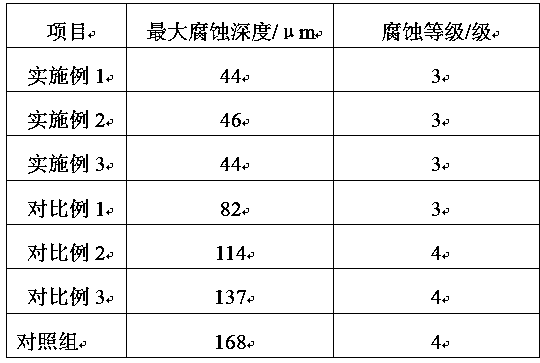

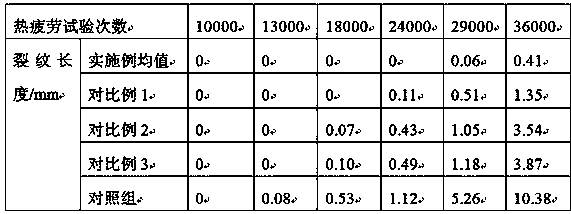

Examples

Embodiment 1

[0020] A heat treatment process for improving the corrosion resistance of aluminum alloys, comprising the following steps:

[0021] (1) Soak the aluminum alloy workpiece in acetone for 40 minutes, then take it out, wash it, and dry it to constant weight;

[0022] (2) Heat the aluminum alloy workpiece after the above treatment to 320°C, keep it warm for 6 hours, then adjust the temperature to 280°C with the assistance of the first pulse strong magnetic field, put the aluminum alloy workpiece into the salt bath, and keep it for 22min , and then take out the aluminum alloy workpiece;

[0023] (3) Heat the aluminum alloy workpiece after the above treatment to 420°C, keep it warm for 4 hours, and then lower the temperature to 120°C under the second pulsed strong magnetic field, and keep it for 10 hours;

[0024] (4) Heat the aluminum alloy workpiece after the above treatment to 200°C in the first ultrasonic field, keep it for 35 minutes, remove the first ultrasonic field, adjust t...

Embodiment 2

[0032] A heat treatment process for improving the corrosion resistance of aluminum alloys, comprising the following steps:

[0033] (1) Soak the aluminum alloy workpiece in acetone for 40 minutes, then take it out, wash it, and dry it to constant weight;

[0034] (2) Heat the aluminum alloy workpiece after the above treatment to 330°C, keep it warm for 6-8 hours, then adjust the temperature to 285°C with the assistance of the first pulse strong magnetic field, put the aluminum alloy workpiece into the salt bath, Keep it for 25min, then take out the aluminum alloy workpiece;

[0035] (3) Heat the aluminum alloy workpiece after the above treatment to 425°C, keep it warm for 4-6 hours, and then lower the temperature to 122°C under the second pulsed strong magnetic field, and keep it for 11 hours;

[0036] (4) Heat the aluminum alloy workpiece after the above treatment to 200°C in the first ultrasonic field, keep it for 40 minutes, remove the first ultrasonic field, adjust the te...

Embodiment 3

[0044] A heat treatment process for improving the corrosion resistance of aluminum alloys, comprising the following steps:

[0045] (1) Soak the aluminum alloy workpiece in acetone for 40 minutes, then take it out, wash it, and dry it to constant weight;

[0046] (2) Heat the aluminum alloy workpiece after the above treatment to 326°C, keep it warm for 7 hours, then adjust the temperature to 282°C with the assistance of the first pulse strong magnetic field, put the aluminum alloy workpiece into the salt bath, and keep it for 23min , and then take out the aluminum alloy workpiece;

[0047] (3) Heat the aluminum alloy workpiece after the above treatment to 422°C, keep it warm for 5 hours, and then lower the temperature to 121°C under the second pulsed strong magnetic field, and keep it for 10-11 hours;

[0048] (4) Heat the aluminum alloy workpiece after the above treatment to 200°C in the first ultrasonic field, keep it for 38 minutes, remove the first ultrasonic field, adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com