Method for improving corrosion resistance of low-alloy ultrahigh-strength steel weldment

An ultra-high-strength steel and corrosion-resistant technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of poor corrosion resistance of welded joints, achieve good corrosion resistance and wear resistance, and improve corrosion resistance , The effect of reducing welding residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An embodiment of the present invention provides an improved post-weld heat treatment process for low-alloy ultra-high-strength steel plates. Post-weld heat treatment is performed on a section of weld seam of a base material 1 with a thickness of 10 mm. The base material 1 is Q1100 ultra-high-strength steel. The austenite formation temperature A was measured C1 The temperature is 645°C, and the thickness of the weld 21 is 10mm.

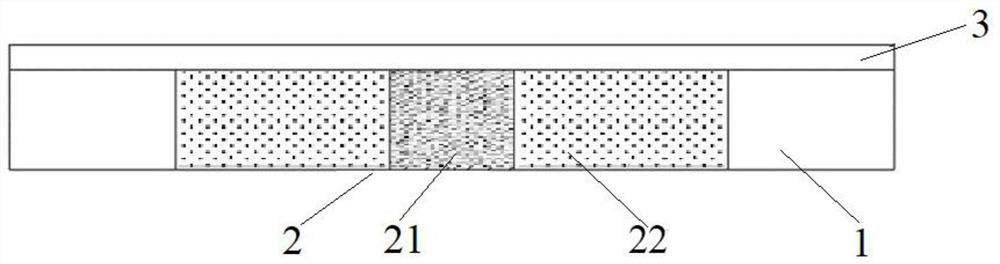

[0036] Such as figure 1 As shown, the post-weld heat treatment in this embodiment adopts local heating, including the following steps:

[0037] (1) Install the heater so that the heater completely covers the weld zone, and the uniform heating zone formed by the heater covers the entire welding joint 2, and the width of the uniform heating zone is 60mm for the weld zone and both sides;

[0038] (2) Install the insulation belt 3, the insulation material is ceramic fiber, the insulation belt 3 covers the weld area and both sides 200mm, and is fix...

Embodiment 2

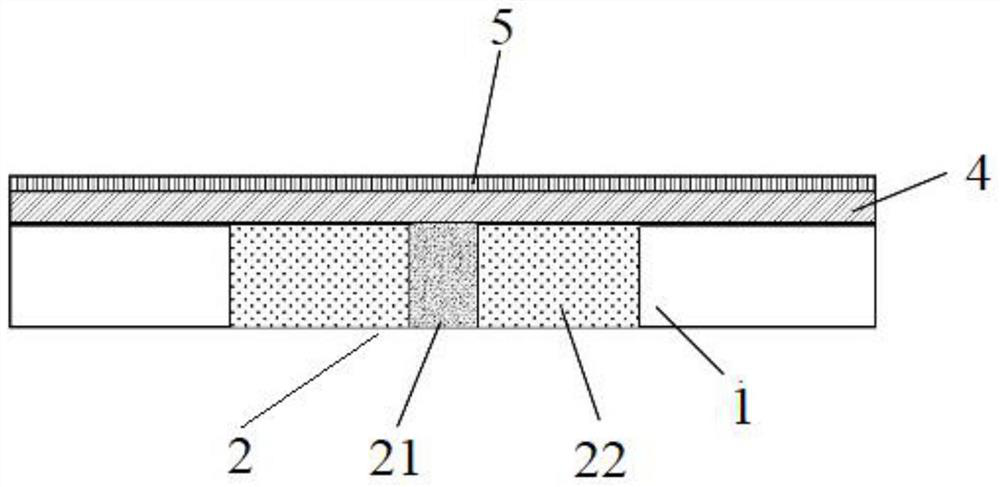

[0049] Embodiments of the present invention provide an improved post-weld surface treatment process for low-alloy ultra-high-strength steel plates, such as figure 2 As shown, the Q1100 steel plate welded joint 2 after post-weld heat treatment in embodiment 1 is subjected to surface treatment, including the following steps:

[0050](1) Derust, remove weld reinforcement and polish the welded joint 2 to make the surface roughness reach Ra1.6, then degrease the surface of the welded joint 2, and place the pretreated weldment in workbench;

[0051] (2) select alumina ceramic powder with a purity greater than 99.7% and a particle size of 60 μm, dry it, and use laser additive manufacturing to form a layer of 2 mm thick alumina ceramic layer 4 in the welding seam and the 60 mm working area on both sides, Then the surface of the alumina ceramic layer 4 is ground and polished;

[0052] (3) Spray a layer of anti-rust paint layer 5 on the surface of the weldment processed by the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com