Manufacturing method for rolled products for nuclear grade in-pile U-shaped embedded part locating pins

A manufacturing method and a technology for inserts, which are applied in the field of heat-resistant alloy manufacturing, can solve the problems of difficult to guarantee final forging temperature, uneven grain size growth, surface coarse grains and mixed crystals, etc. The effect of uniform particle size and structure, uniform and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below with examples, and these examples are only to the description of the best implementation mode of the present invention, do not have any limitation to the scope of the present invention.

[0036] A total of 3 furnace examples have been adopted to illustrate the present invention more specifically.

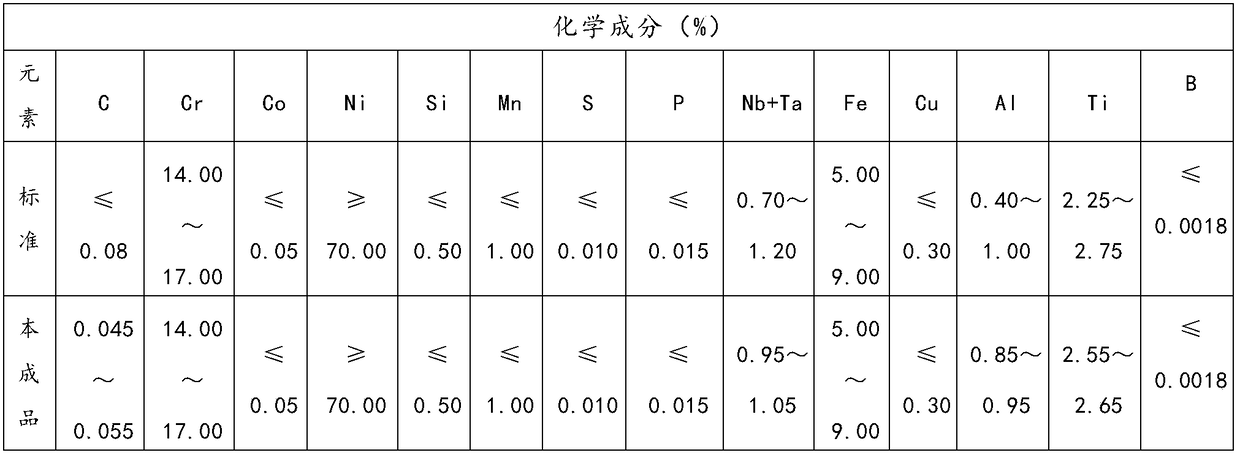

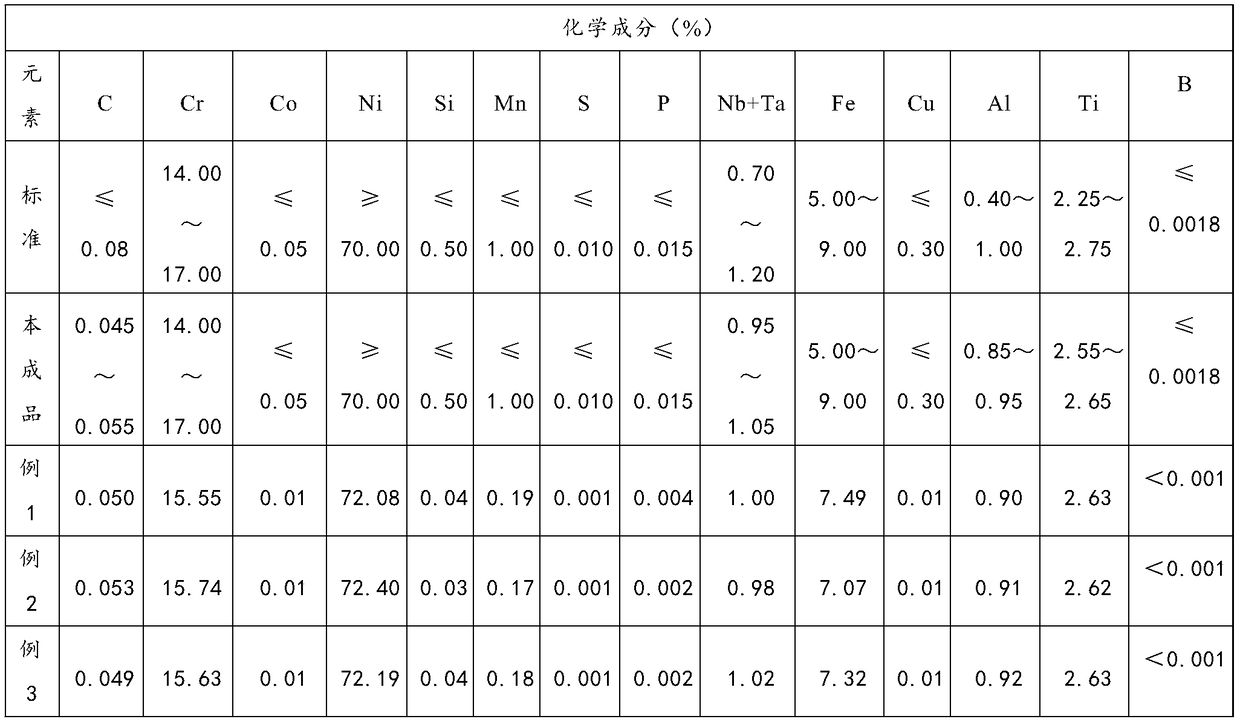

[0037] 1.3 furnace UNS N07750 alloy embodiment chemical composition mass percentage see table 3 below

[0038] Table 3 Chemical composition of 3 heats of UNS N07750 alloy examples

[0039]

[0040] 2. the production technology of embodiment is as follows:

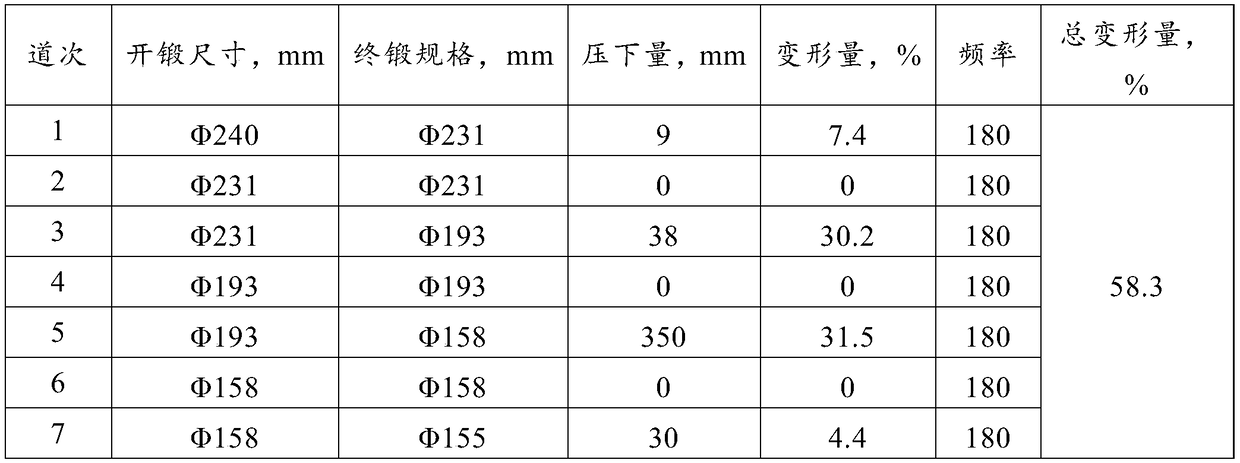

[0041] Using VIM+ESR smelting, the steel ingot is loaded at a furnace temperature of about 600°C, and the steel ingot is heated at a temperature of 1160°C. After heat preservation, the 3150t fast forging machine is opened to a Φ240mm billet, and the final forging temperature of the billet is controlled above 900°C. The amount is 50mm to 70mm, and the surface of the bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com