High-performance iron-based superconducting strip and preparation process thereof

A technology of iron-based superconductivity and preparation process, which can be used in the manufacture of superconducting devices, superconducting/high-conducting conductors, cables/conductors, etc. Fully controllable size and deformation, improved current-carrying properties, high texture and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

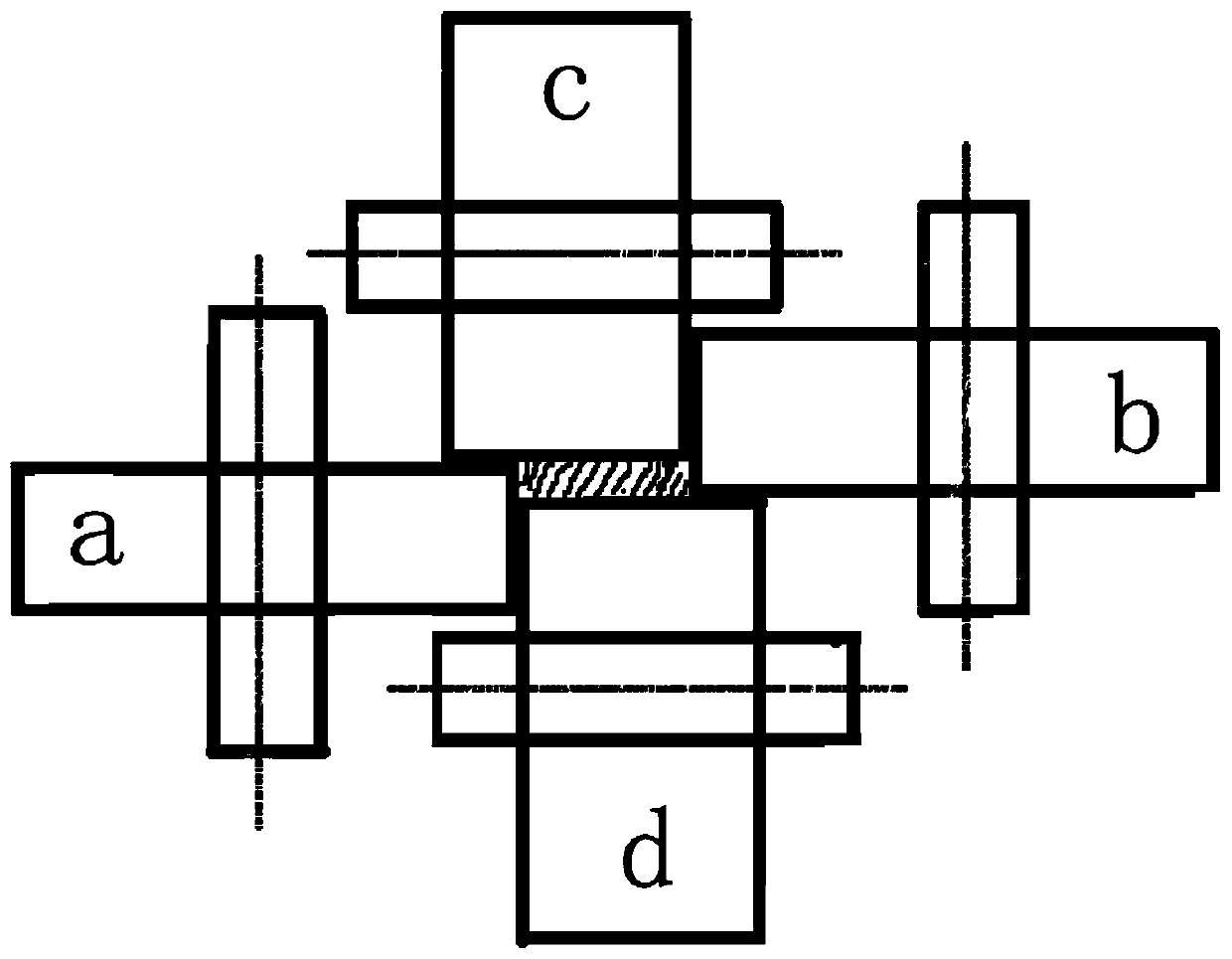

Image

Examples

Embodiment 1

[0030] Single core Ba 0.6 K 0.4 Fe 2 As 2 The preparation of superconducting wire tape, the steps are as follows:

[0031] (1) Under the atmosphere of argon gas, metal barium shavings (mass purity is 99.50%), potassium block (mass purity is 99.95%), iron powder (mass purity is 99.99%) and arsenic particles (mass purity is 99.95%) ), after accurately weighing according to the molar ratio Ba:K:Fe:As=0.6:0.4:2:2, put it into a ball mill jar and ball mill it for 10 hours to make the powder mix evenly. Put the ball-milled powder into the Nb tube, seal both ends with copper plugs, and then heat-treat at 900°C for 50 hours to obtain the precursor powder for preparing superconducting wire strips.

[0032] (2) Fill the prepared precursor powder into a silver tube with a length of 10 cm. The inner diameter of the silver tube is 5 cm and the outer diameter is 8 cm. Seal the two ends with Nb plugs to obtain a tube complex, and squeeze the tube complex A single-core wire with a diamet...

Embodiment 2

[0044] 7 core Ba 0.6 K 0.4 Fe 2 As 2 The preparation of superconducting wire tape, the steps are as follows:

[0045] (1) Under the atmosphere of argon gas, metal barium shavings (mass purity is 99.50%), potassium block (mass purity is 99.95%), iron powder (mass purity is 99.99%) and arsenic particles (mass purity is 99.95%) ), according to the molar ratio Ba:K:Fe:As=0.6:0.4:2:2 after accurate weighing, put into the ball mill jar and ball mill for 10h, put the ball milled powder into the Nb tube, and seal it with a copper plug Heat treatment is carried out after both ends, the temperature of the heat treatment is 950° C., and the temperature is kept for 35 hours, and finally the precursor powder for preparing the superconducting wire tape is obtained.

[0046] (2) Fill the prepared precursor powder into a silver tube with a length of 30 cm. The inner diameter of the silver tube is 4 cm and the outer diameter is 5 cm. Seal the two ends with Nb plugs to obtain a tube complex...

Embodiment 3

[0061] 37 core Ba 0.6 K 0.4 Fe 2 As 2 The preparation of superconducting wire tape, the steps are as follows:

[0062] (1) Under the atmosphere of argon gas, metal barium shavings (mass purity is 99.50%), potassium block (mass purity is 99.95%), iron powder (mass purity is 99.99%) and arsenic particles (mass purity is 99.95%) ), according to the molar ratio Ba:K:Fe:As=0.6:0.5:2:2 after accurate weighing, put into the ball mill jar and ball mill for 10h, put the ball milled powder into the Nb tube, and seal it with a copper plug Heat treatment is carried out after both ends, the temperature of the heat treatment is 900° C., and the temperature is kept for 35 hours, and finally the precursor powder for preparing the superconducting wire tape is obtained.

[0063] (2) Fill the prepared precursor powder into a silver tube with a length of 80 cm. The inner diameter of the silver tube is 6 cm, and the outer diameter is 8 cm. Seal the two ends with Nb plugs to obtain a tube compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com