Preparation method for silver-doped iron-based superconductor

An iron-based superconductor, silver-doped technology, applied in the use of superconductor elements, superconducting/high-conducting conductors, cable/conductor manufacturing, etc., can solve the problems of large brittleness, difficult forging, drawing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

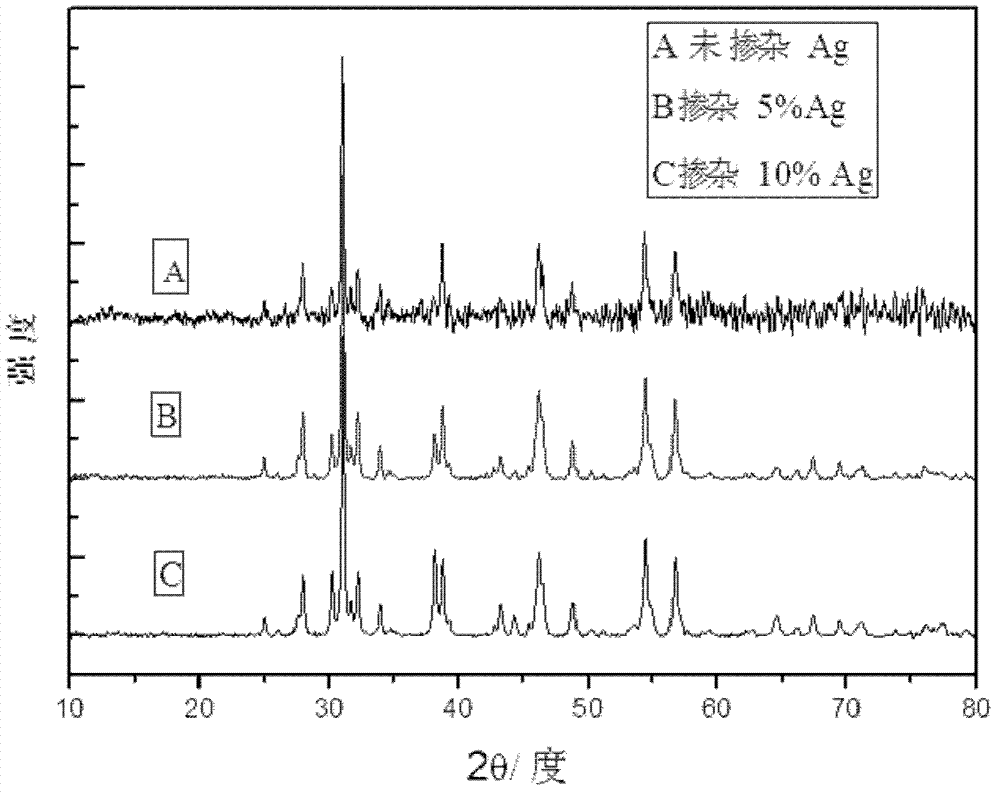

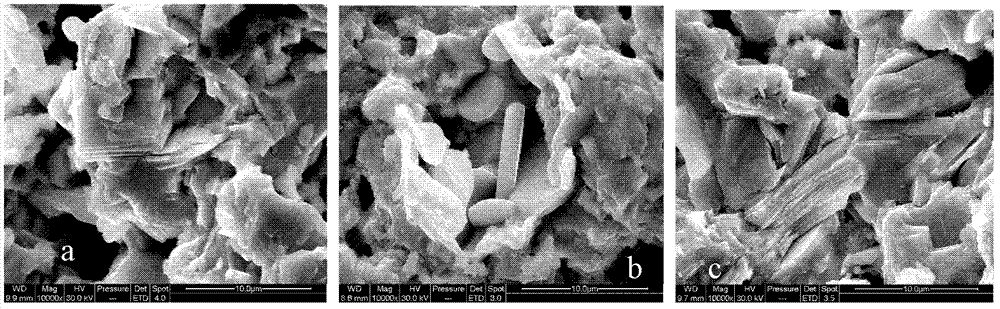

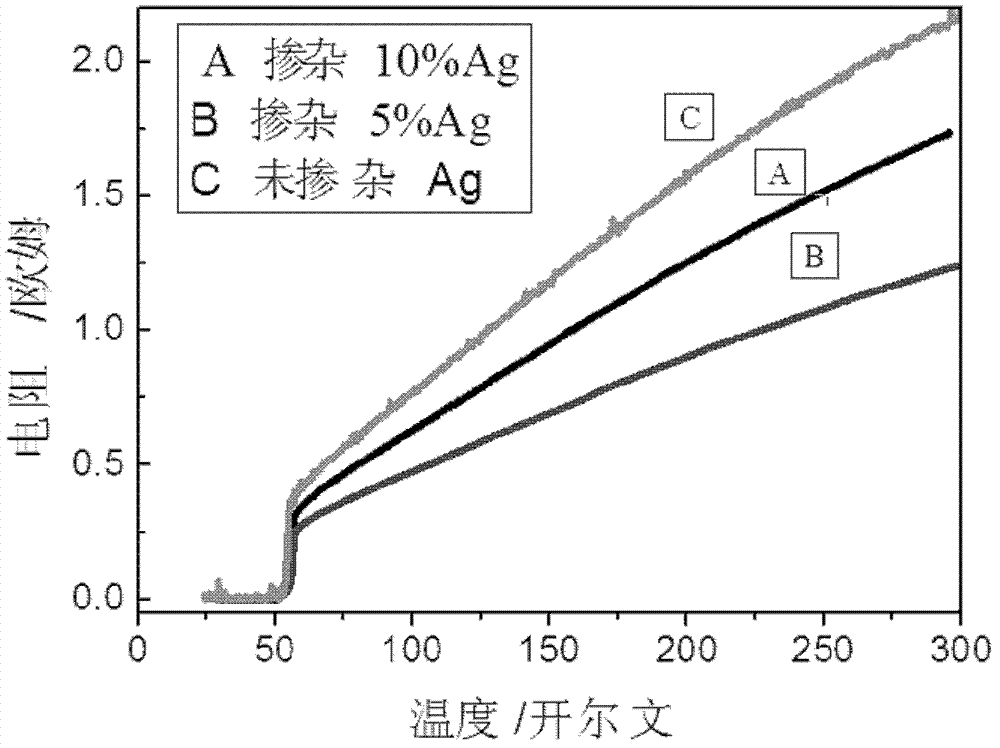

[0019] Example 1: 5% Ag doped SmO 0.7 f 0.3 Preparation of FeAs Superconductor

[0020] Step 1: Preparation of initial powder

[0021] Sm powder and As powder were weighed according to the molar ratio of 1:1.03 and mixed under Ar protection atmosphere. The mixed Sm powder and As powder were packaged in a quartz tube for sintering, and the vacuum degree was 10 -6 Pa, the heat treatment process is as follows: from room temperature to 400°C, the heating rate is 5°C / min; from 400°C to 600°C, the heating rate is 1°C / min; at 600°C for 5 hours; from 600°C to 900°C, the heating rate is 1°C / min; heat preservation at 900°C for 10 hours; finally cool the furnace to room temperature.

[0022] Step 2: 5% Ag-doped SmO 0.7 f 0.3 Preparation of FeAs Superconductor

[0023] In a glove box protected by high-purity argon gas, SmAs powder, Fe powder, Fe 2 o 3 Powder, FeF 3 The powder is mixed according to the ratio of 30:13:7:3.6, and 5% silver is added; then it is fully ground; it is ...

Embodiment 2

[0026] Example 2: 5% Ag doped CeO 0.8 f 0.2 Preparation of FeAs Superconductor

[0027] Step 1: Preparation of initial powder

[0028] Ce powder and As powder were weighed according to the molar ratio of 1:1 and mixed under Ar protection atmosphere. The mixed Ce powder and As powder are packaged in a high-vacuum quartz tube for sintering, and the vacuum degree of the quartz tube is 10 -4 Pa, the heat treatment process is as follows: room temperature-400°C, heating rate is 5°C / min; 400°C-600°C, heating rate is 5°C / min; 600°C for 10 hours; 600°C-900°C heating rate is 5°C / min; heat preservation at 900°C for 20 hours; finally cool the furnace to room temperature.

[0029] Step 2: 5% Ag doped CeO 0.8 f 0.2 Preparation of FeAs Superconductor

[0030] In a glove box protected by high-purity argon gas, CeAs powder, Fe powder, Fe 2 o 3 Powder, FeF 3 The powder is mixed according to the ratio of 30:12:8:2.4, and 5% silver powder is added, and then fully ground; it is pressed ...

Embodiment 3

[0031] Example 3: 10% Ag doped NdO0.7 f 0.3 Preparation of FeAs Superconductor

[0032] Step 1: Preparation of initial powder

[0033] Weigh the Nd powder and As powder according to the molar ratio of 1:1.1 and mix them under Ar protective atmosphere; package the mixed Nd powder and As powder in a high-vacuum quartz tube for heat treatment, and the vacuum degree of the quartz tube is 10 -5 Pa. The heat treatment process is as follows: from room temperature to 400°C, the heating rate is 5°C / min; from 400°C to 600°C, the heating rate is 3°C / min; at 600°C for 5 hours; from 600°C to 900°C, the heating rate is 3°C / min ; 900 ° C for 20 hours; Finally, the furnace was cooled to room temperature.

[0034] Step 2: 10% Ag-doped NdO 0.7 f 0.3 Preparation of FeAs Superconductor

[0035] In a glove box protected by high-purity argon gas, NdAs powder, Fe powder, Fe 2 o 3 Powder, FeF 3 The powder is mixed according to the ratio of 30:13:7:3.9, and 10% silver powder is added, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com