Method for preparing FeSeTe film by pulse laser deposition coating technology

A pulsed laser deposition, iron-selenium technology, applied in the field of high-temperature superconducting thin films, can solve the problems of easy introduction of impurities and unfavorable film growth, and achieve the effect of overcoming the introduction of impurities, easy composition, and good crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

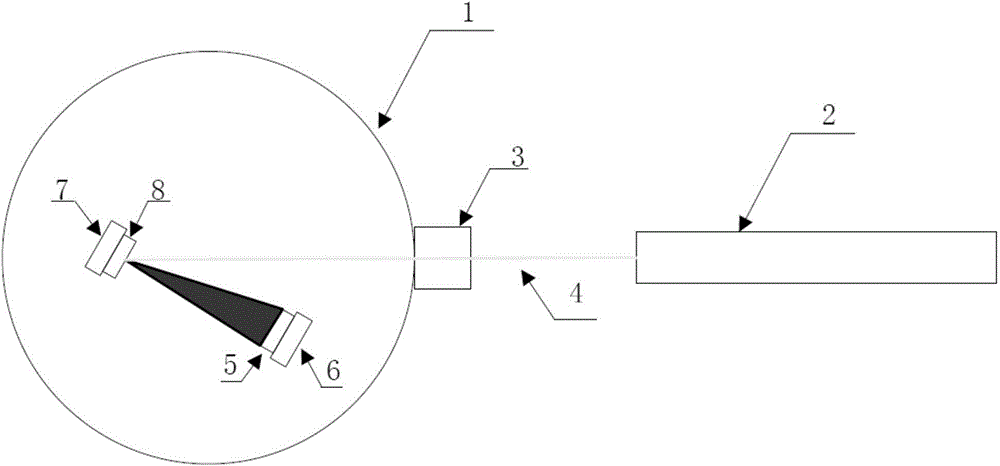

Image

Examples

Embodiment 1

[0021] 1. FeSe 0.5 Te 0.5 Target preparation:

[0022] a) Fe, Se, Te powders are mixed and ground evenly in a molar ratio of 1:0.5:0.5;

[0023] b) The ground powder is sintered in a vacuum quartz tube at 700°C for 24 hours, and quenched at 400°C;

[0024] c) The sintered iron selenium tellurium is ground into powder again, and then pressed into a target with a diameter of 1 inch and a thickness of 2 mm;

[0025] d) The suppressed FeSe 0.5 Te 0.5 Sinter at 700°C for 24 hours in a vacuum quartz tube, and quench at 400°C.

[0026] 2. Pulsed laser deposition on SrTiO 3 FeSe grown on the substrate 0.5 Te 0.5 The thin film method is as follows:

[0027] a) SrTiO 3 Substrate and FeSe 0.5 Te 0.5 The target is put into the growth chamber, and the vacuum is evacuated to 10 -8 mbar, heat the substrate to 310°C through the heating wire in the substrate holder, wait until the temperature stabilizes, and the air pressure reaches 10 -7 about mbar;

[0028] b) Adjust laser par...

Embodiment 2

[0033] 1. FeSe 0.7 Te 0.3 Target preparation:

[0034] a) Fe, Se, Te powders are mixed and ground evenly in a molar ratio of 1:0.7:0.3;

[0035] b) The ground powder is sintered in a vacuum quartz tube at 700°C for 24 hours, and quenched at 400°C;

[0036] c) The sintered iron selenium tellurium is ground into powder again, and then pressed into a target with a diameter of 1 inch and a thickness of 2 mm;

[0037] d) The pressed material is sintered in a vacuum quartz tube at 700°C for 24 hours, and quenched at 400°C.

[0038] 2. Pulsed laser deposition on LaAlO 3 FeSe grown on the substrate 0.7 Te 0.3 The thin film method is as follows:

[0039] a) LaAlO 3 Substrate and FeSe 0.7 Te 0.3 The target is put into the growth chamber, and the vacuum is evacuated to 10 -8 mbar, heat the substrate to 310°C through the heating wire in the substrate holder, wait until the temperature stabilizes, and the air pressure reaches 10 -7 about mbar;

[0040] b) Adjust laser paramete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com