Operating method for olefin conversion device

A conversion device and olefin technology, applied in the direction of chemical instruments and methods, organic chemistry, chemical recovery, etc., can solve the problems of inability to carry out scorch, long time, and cost, and achieve shortened start-up time, fast heating speed, and avoid multiple times The effect of transfer agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

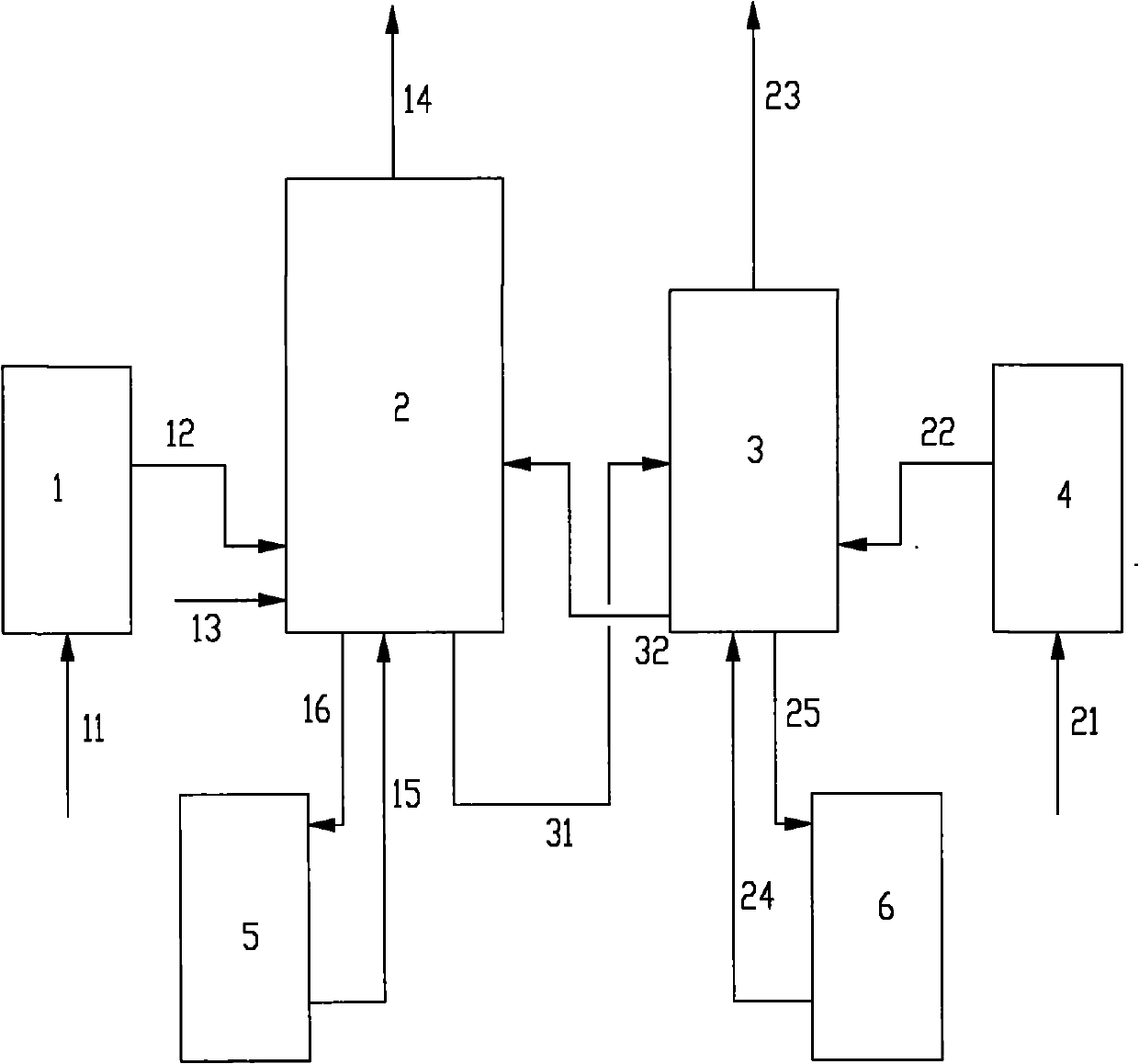

[0043] During start-up, the steam 11 is heated to 400-500°C by the start-up steam superheater 11, and then becomes superheated steam 12, which is injected into the reactor 2. The reactor 2 catalyst 15 and the superheated steam 12 are fully mixed in the reactor 2, the reactor 2 catalyst is heated, and it is heated up. In order to control the heating rate, the amount of superheated steam is proportional to the dosing speed, and with the Dosing and temperature rise in Reactor 2 need to be adjusted accordingly. At the same time, for the regenerator 3 system, after the air 21 is heated to 700-750°C by the auxiliary combustion chamber 4, it becomes high-temperature air 22 and is injected into the regenerator 3. At the same time, the regenerator catalyst at normal temperature is added from the catalyst tank 6 of the regenerator 3 24. The normal-temperature regenerator catalyst 24 and the high-temperature air 22 are fully mixed in the regenerator 3 to heat the regenerator catalyst and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com