Liquid fermentation culture medium for shiitake mushrooms and method for producing shiitake mushrooms through the same

A technology of liquid fermentation and culture medium, applied in botany equipment and methods, fertilizer mixture, gardening, etc., can solve the problems of low efficiency, high cost, and long mycelium culture period of shiitake mushrooms, and achieve easy source, low price, and production short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

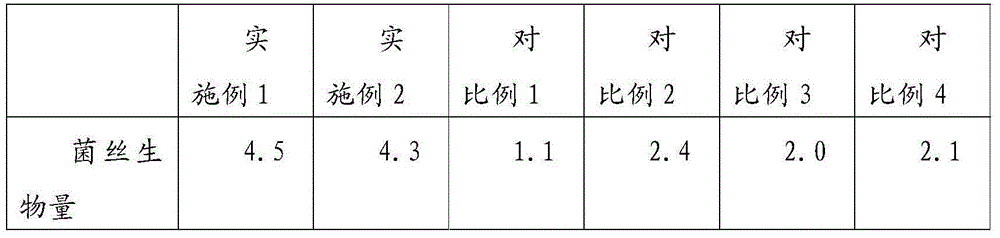

Embodiment 1

[0041] According to the formula of bran, weigh it according to a 500L standard fermentation tank: 10000g of bran, 5000g of soybean meal, 3000g of glucose, 500g of potassium dihydrogen phosphate, 250g of magnesium sulfate, 100g of CMC-Na (cellulase inducer), and put them into a 200L stainless steel frying pan. In a cooking pot, add 100L of water and stir to dissolve, boil for 20 minutes and then filter, add water to the filtrate to 500L, and add 350g of fresh soybean oil, set aside. The fermenter was emptied for 2 hours under the conditions of steam pressure 0.13-0.15Mpa and temperature 121°C; the above-mentioned prepared liquid fermenter culture medium was filled into tanks, and it was sterilized under the conditions of steam pressure 0.13-0.15Mpa and temperature 121°C for 40 minutes. After the internal temperature of the liquid in the fermenter is cooled to below 28° C., inoculate under sterile conditions with an inoculum size of 2% (v / v). Fermentation culture temperature is ...

Embodiment 2

[0043] According to the formula of bran, weigh it according to a 500L standard fermentation tank: 10000g of bran, 5000g of soybean meal, 3000g of glucose, 500g of potassium dihydrogen phosphate, 250g of magnesium sulfate, 100g of CMC-Na (cellulase inducer), and put them into a 200L stainless steel frying pan. In a cooking pot, add 100L of water and stir to dissolve, boil for 20 minutes and then filter, add water to the filtrate to 500L, and add 350g of fresh soybean oil, set aside. The fermenter was emptied for 2 hours under the conditions of steam pressure 0.13-0.15Mpa and temperature 121°C; the above-mentioned prepared liquid fermenter culture medium was filled into tanks, and it was sterilized under the conditions of steam pressure 0.13-0.15Mpa and temperature 121°C for 40 minutes. After the internal temperature of the liquid in the fermenter is cooled to below 28°C, inoculate under aseptic conditions, and inject 1000 mL of liquid parent seed of shiitake mushrooms into a bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com