Patents

Literature

602results about "Stopper details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

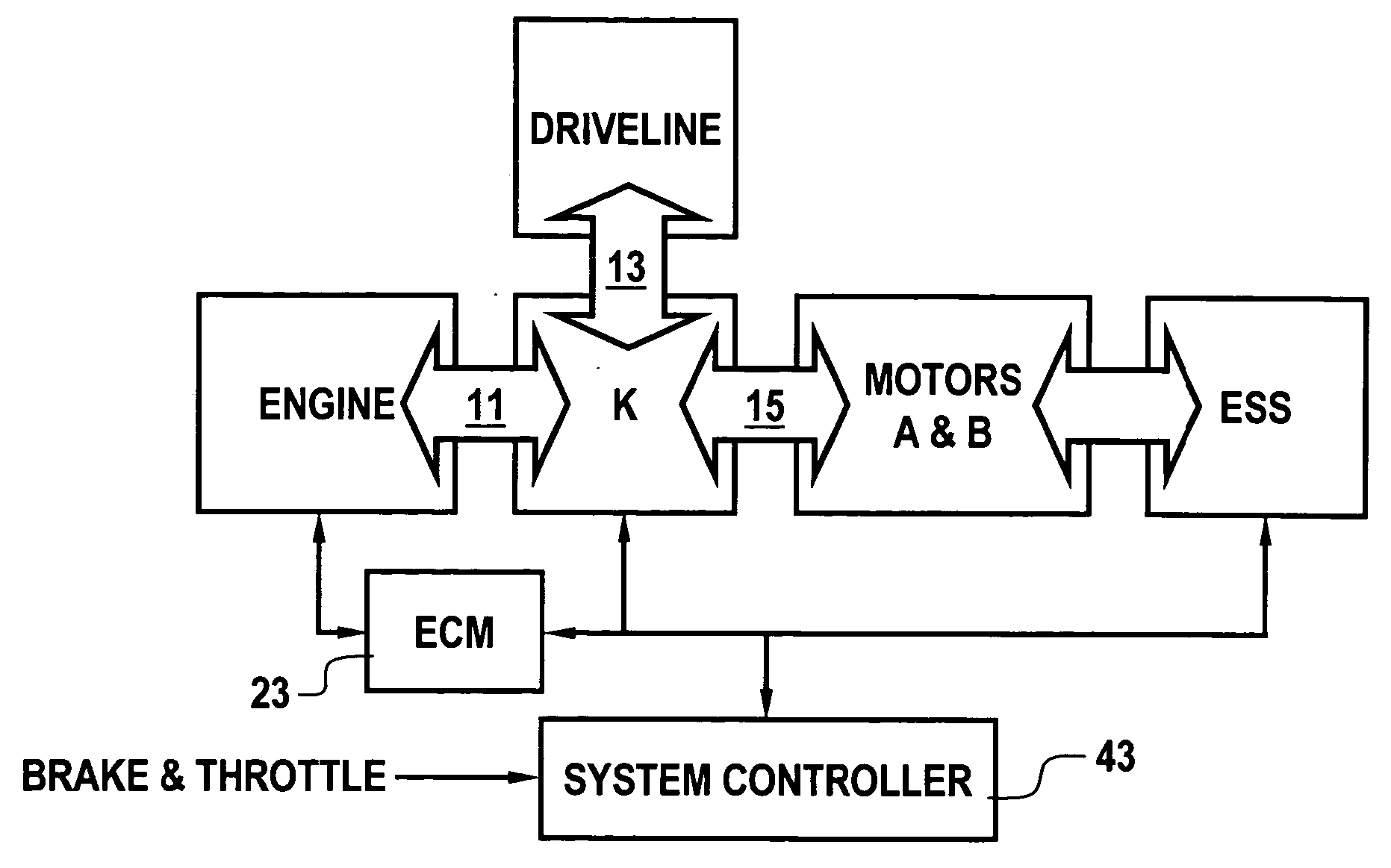

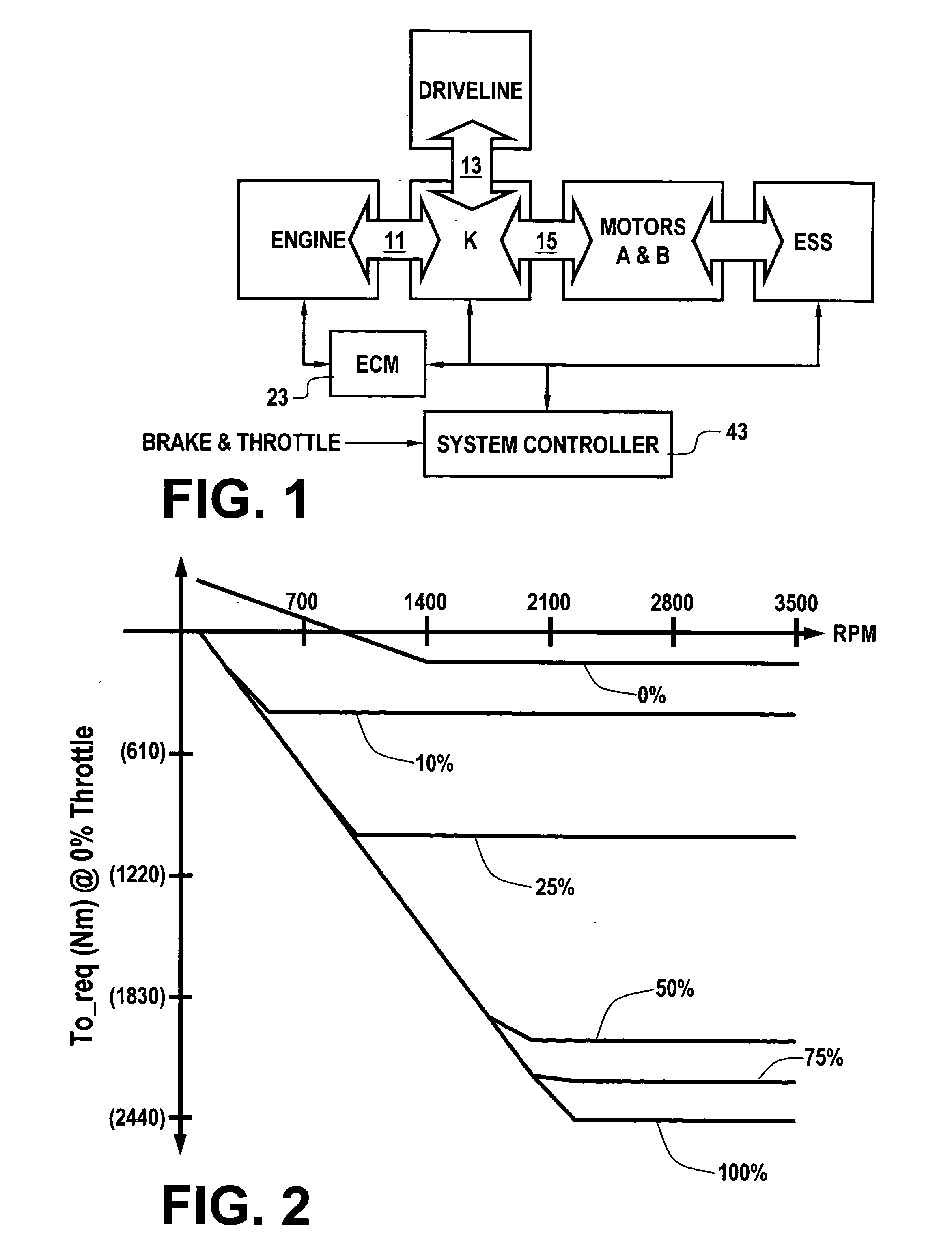

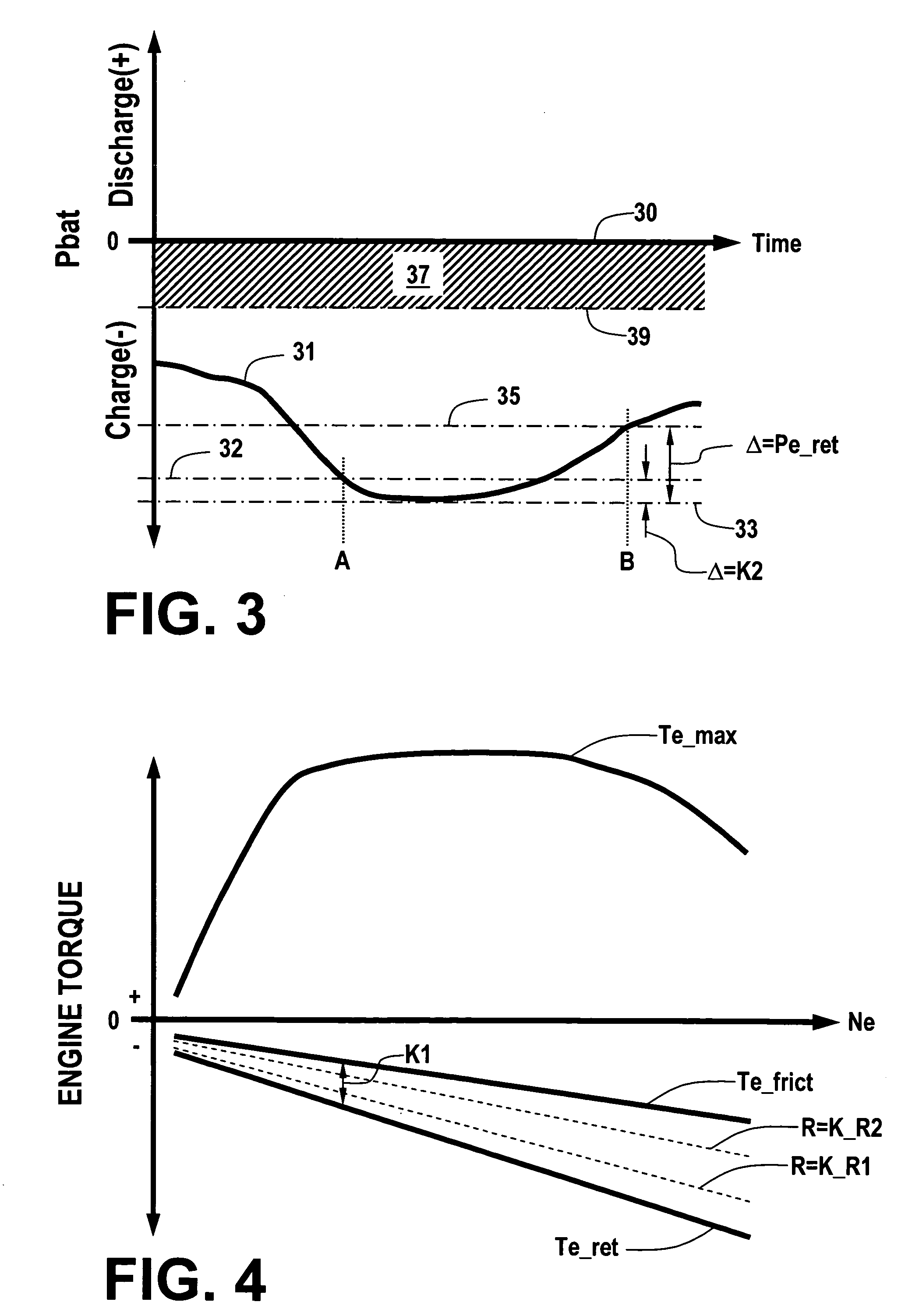

Engine retard operation scheduling and management in a hybrid vehicle

ActiveUS20050255966A1Hybrid vehiclesBraking element arrangementsOperation schedulingElectric machine

A hybrid vehicle includes a powertrain having a retarded diesel engine, an electric machine and energy storage system. The engine and motor are operatively coupled through one or more planetary gearsets and selective coupling paths in accordance with application and release of various torque transfer devices to a drivetrain via an output. Regenerative and retarded engine braking are coordinated to provide priority to energy return to an energy storage system in accordance with predetermined power flow limits.

Owner:GM GLOBAL TECH OPERATIONS LLC

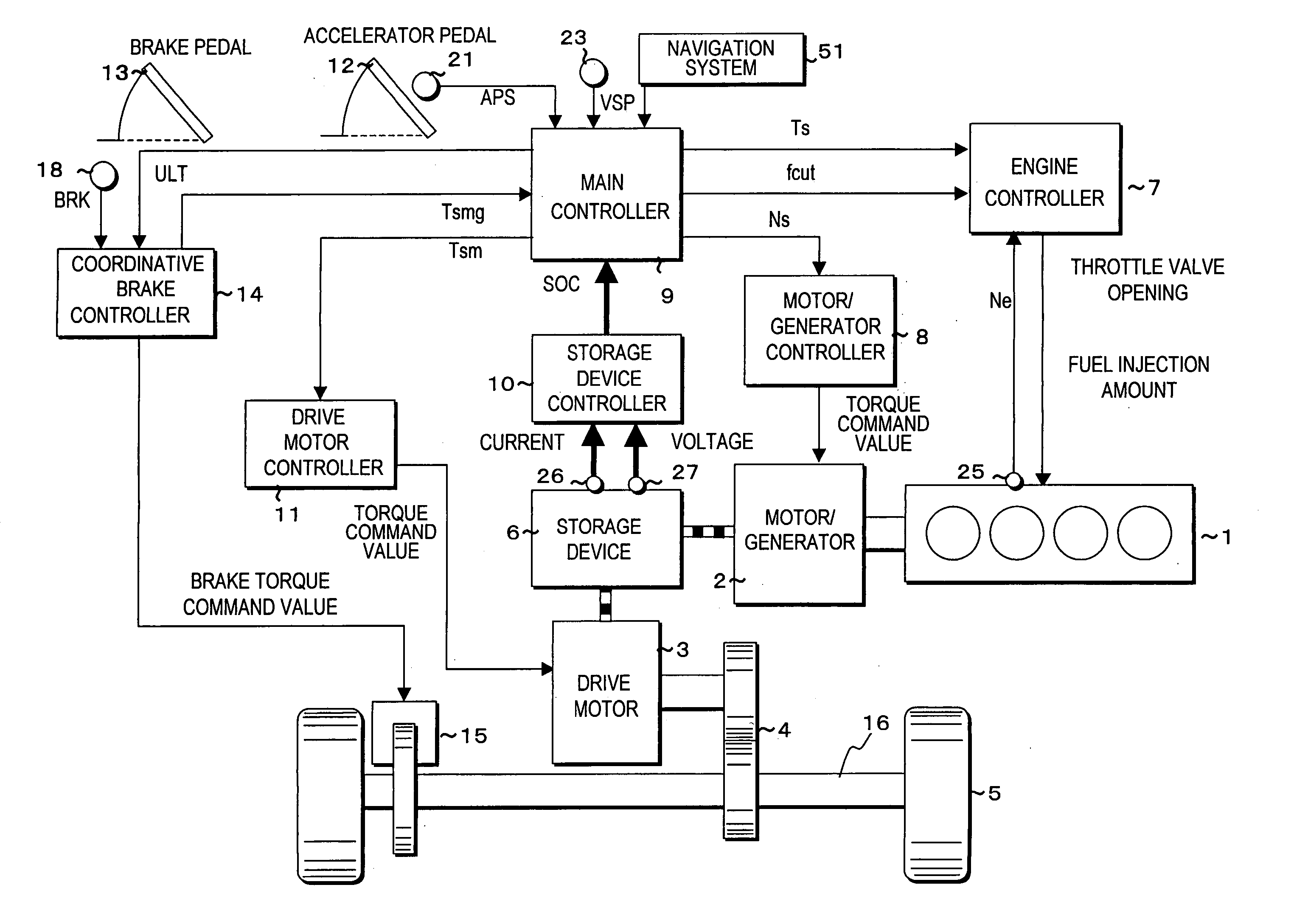

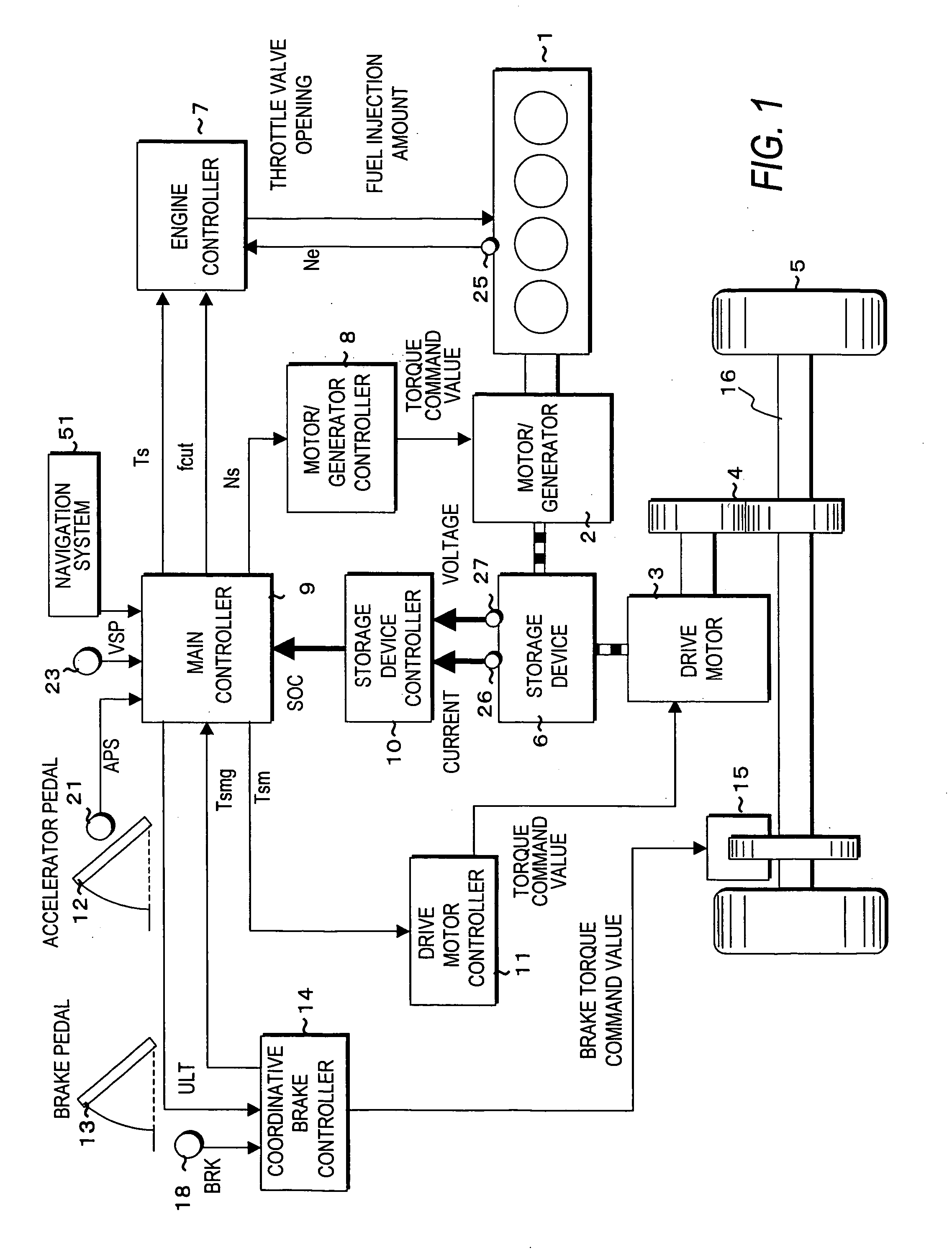

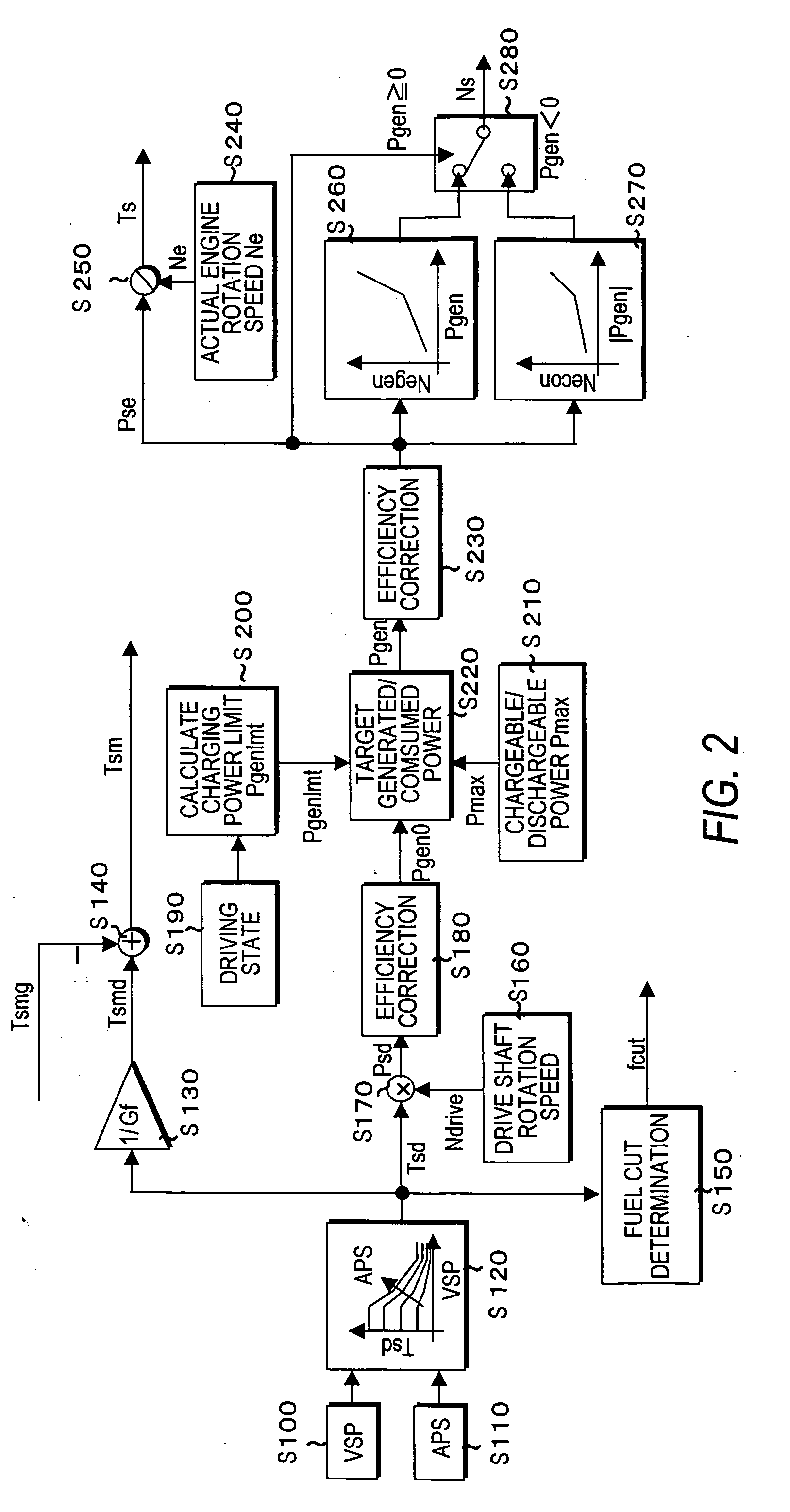

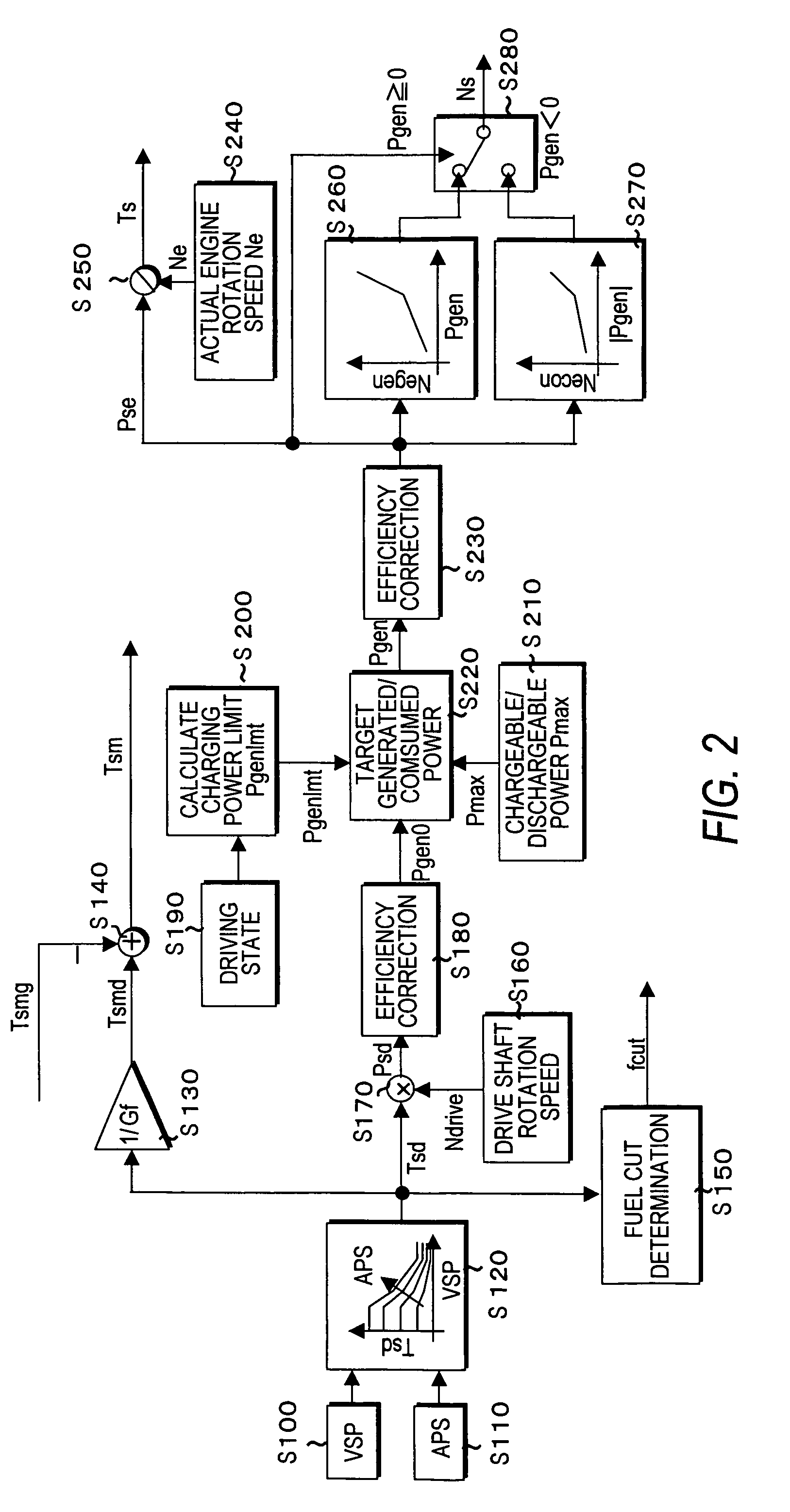

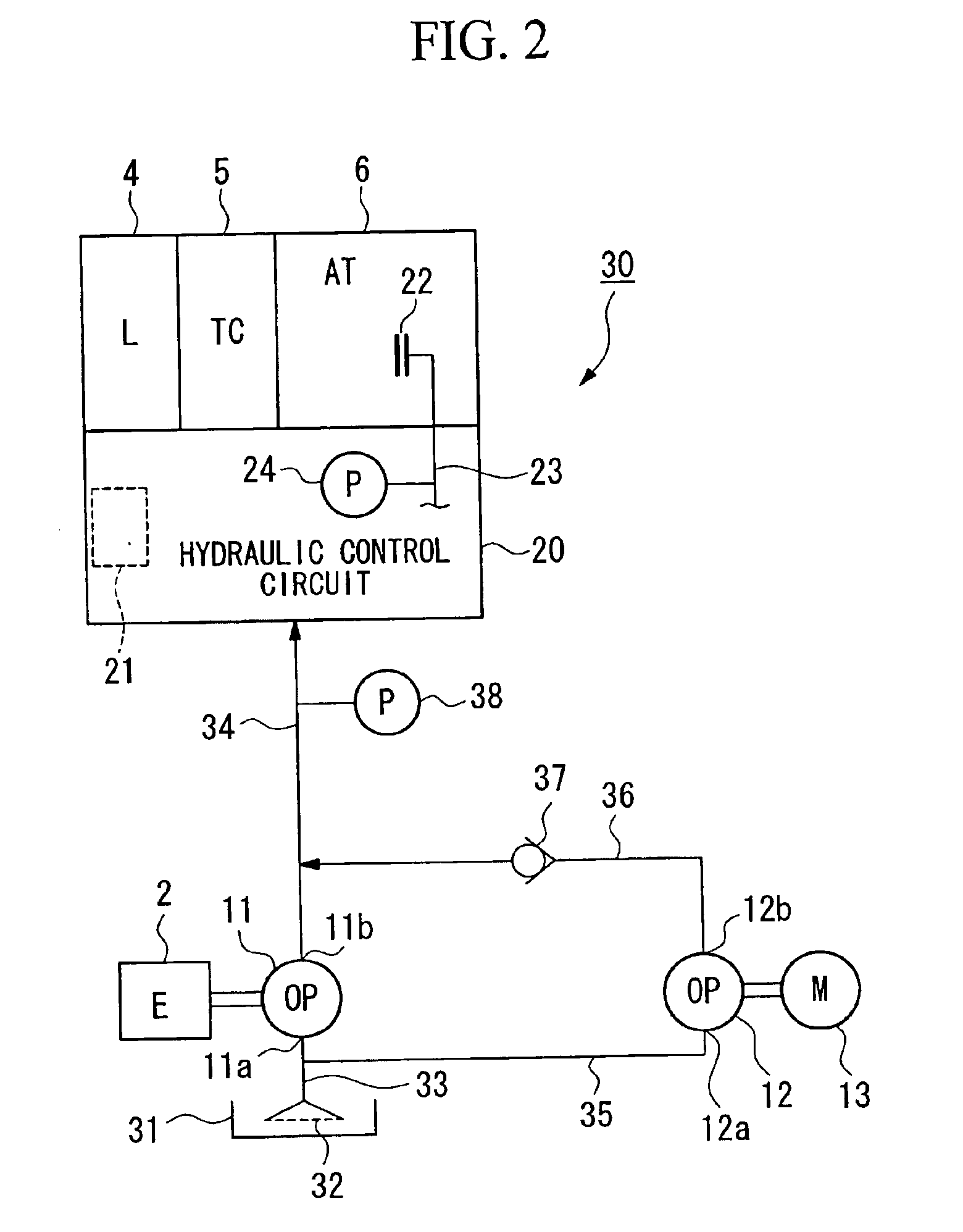

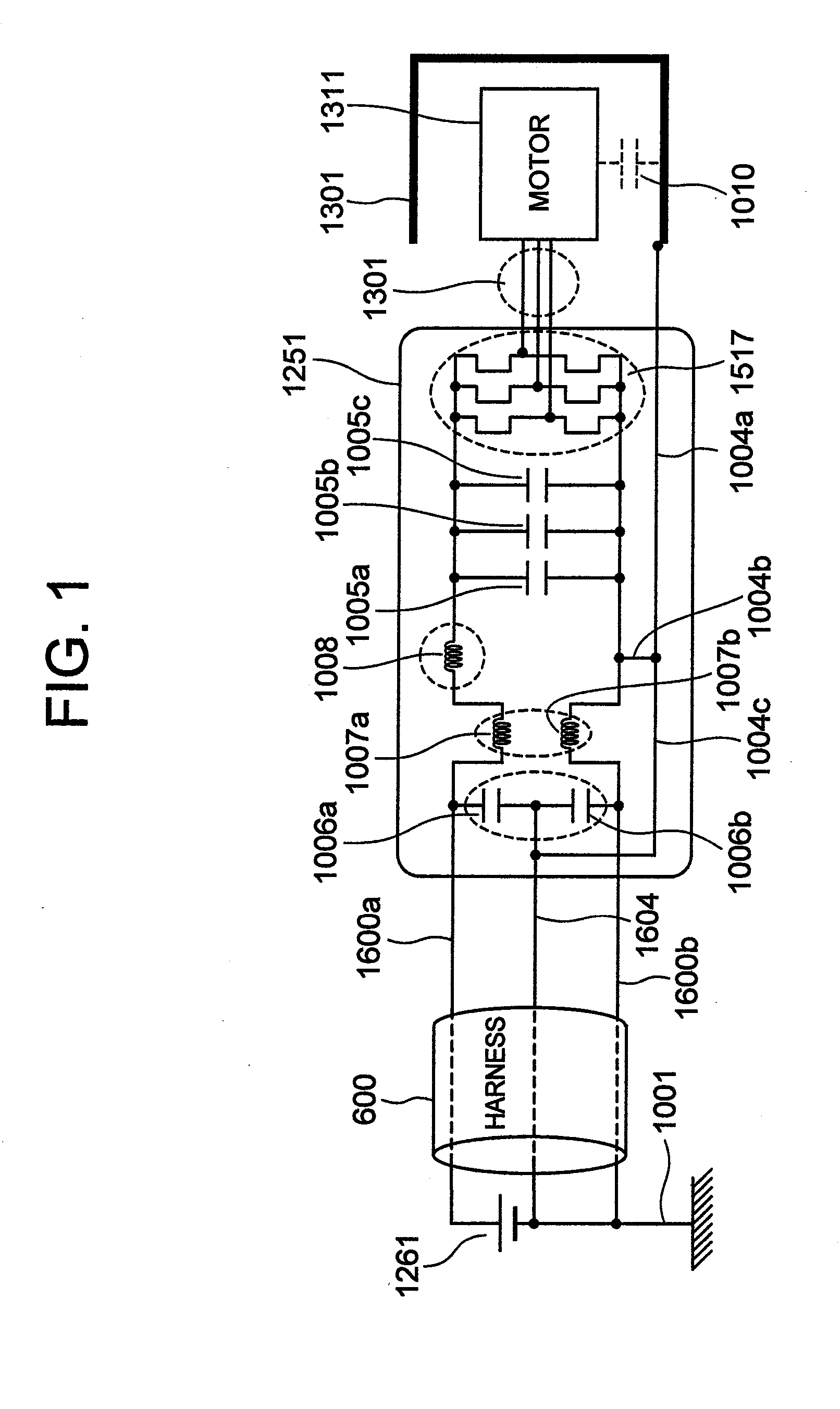

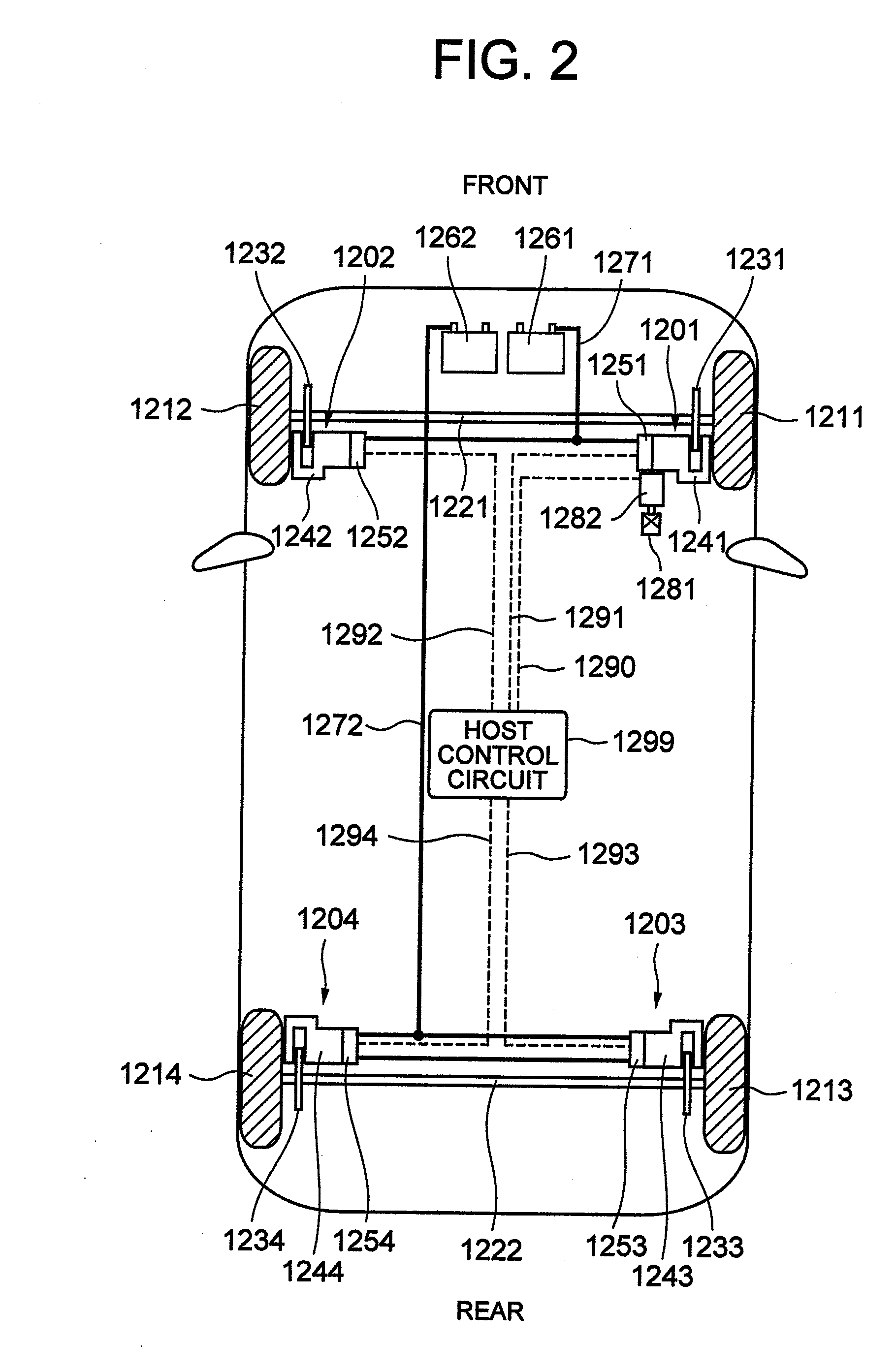

Regeneration control for hybrid vehicle

InactiveUS20050189894A1Prevent speedingDc motor stoppersAsynchronous induction motorsState of chargeDrive motor

Disclosed is a control apparatus for a hybrid vehicle having an engine, a drive motor (3) that regenerates power, and an electric power storage device (6) that gives / receives power to / from the drive motor (3). The control apparatus includes power consumption means (2) for consuming power; a sensor (26, 27) that detects a state of charge of the electric power storage device; means (18, 23, 51) for detecting a driving state of the vehicle; and a controller (9). The controller (9) is programmed to calculate a chargeable energy amount Ecap in the electric power storage device (6) on the basis of a difference between a fully charged state of the electric power storage device and the detected state of charge; set a power |Pgen0| regenerated by the drive motor (3); calculate a chargeable power Pmax in the electric power storage device according to the detected state of charge; calculate a regenerated energy E resulting from regenerative braking from the detected driving state of the vehicle; calculate a charging power limit Pgenlmt according to the calculated regenerated energy E; and control the power consumption means (2) to consume a power equal to a difference between the power |Pgen0| regenerated by the drive motor (3) and the charging power limit |Pgenlmt| when the calculated regenerated energy E is greater than the chargeable energy amount Ecap in the electric power storage device and when the charging power limit |Pgenlmt| is smaller than the chargeable power |Pmax|.

Owner:NISSAN MOTOR CO LTD

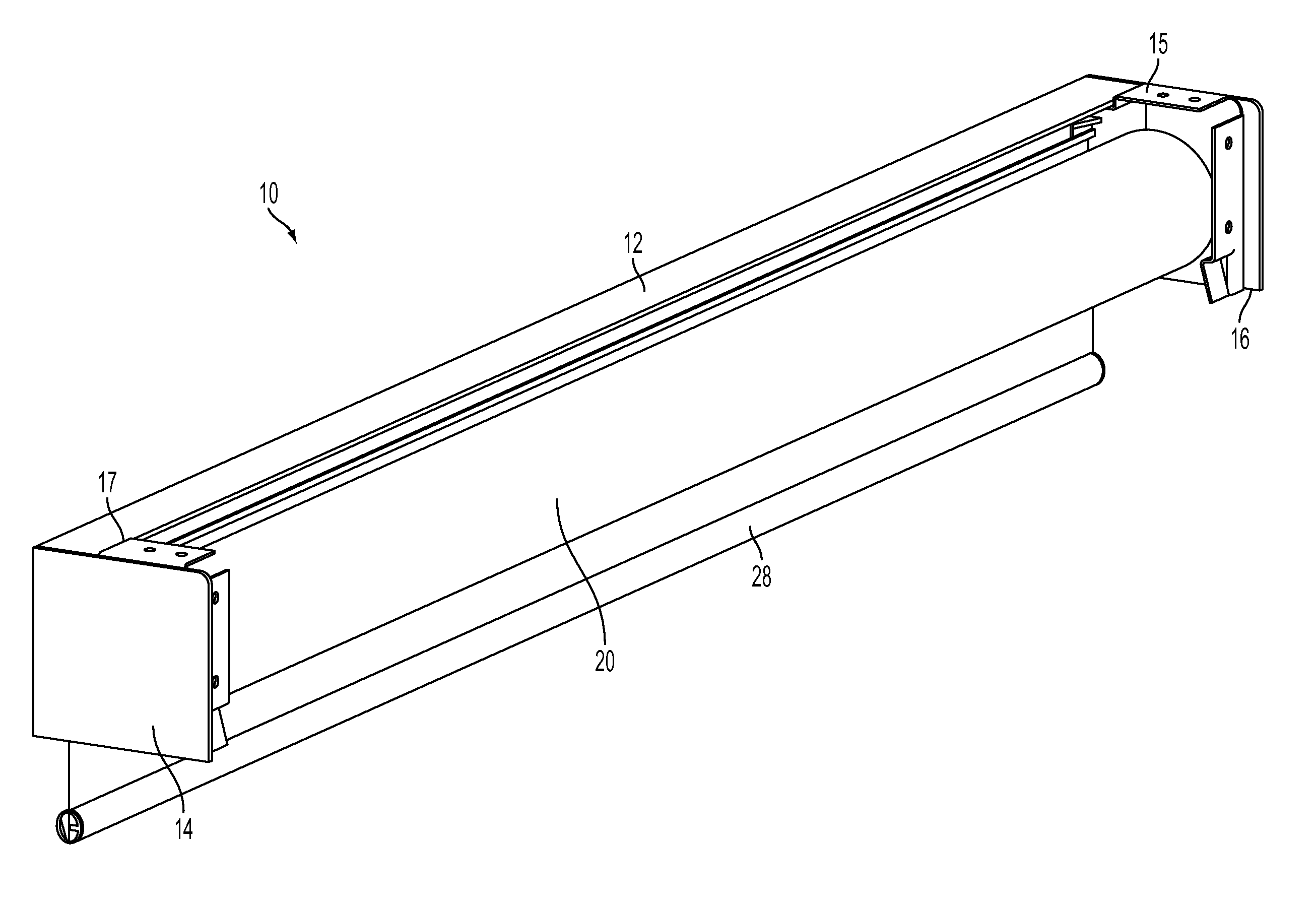

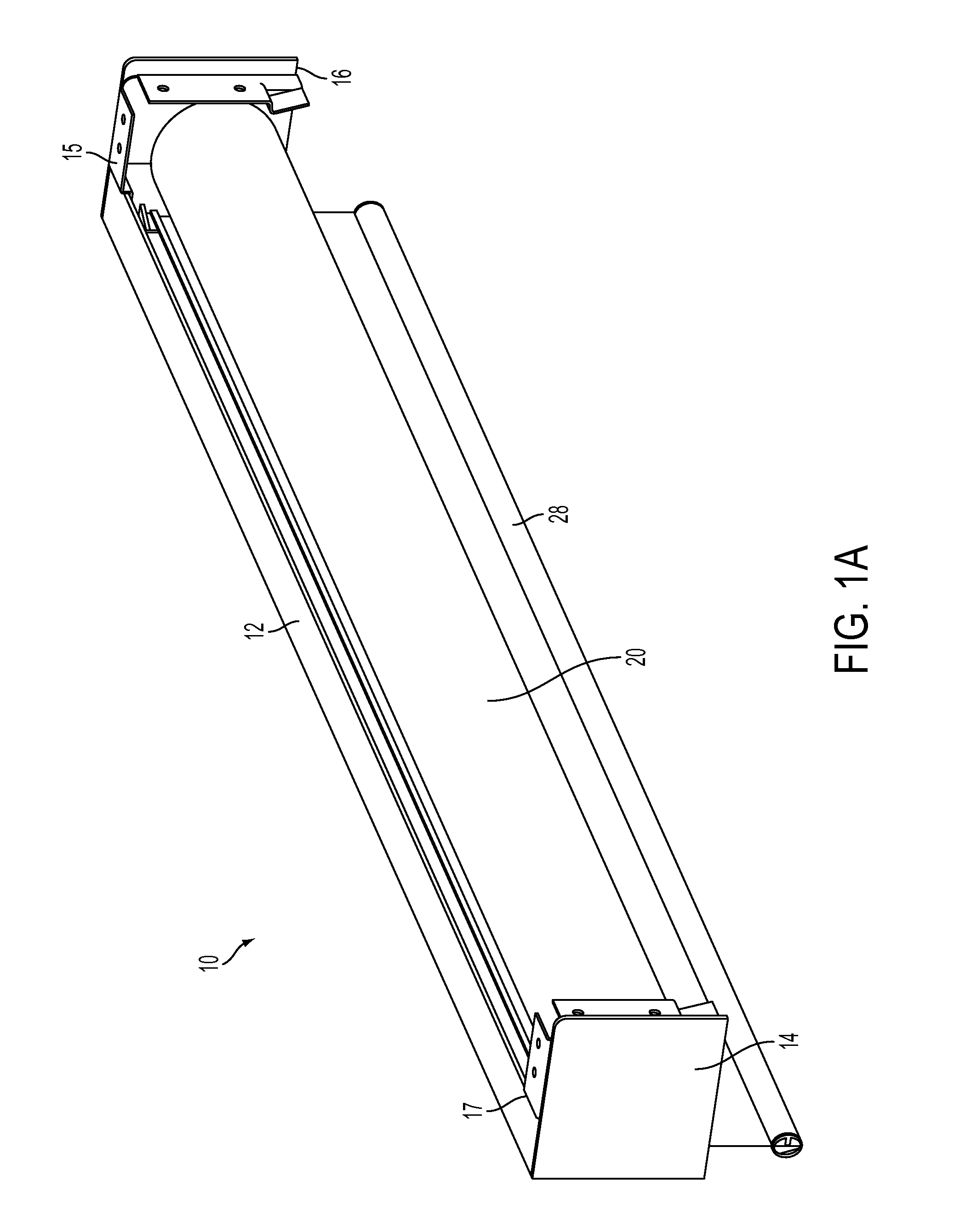

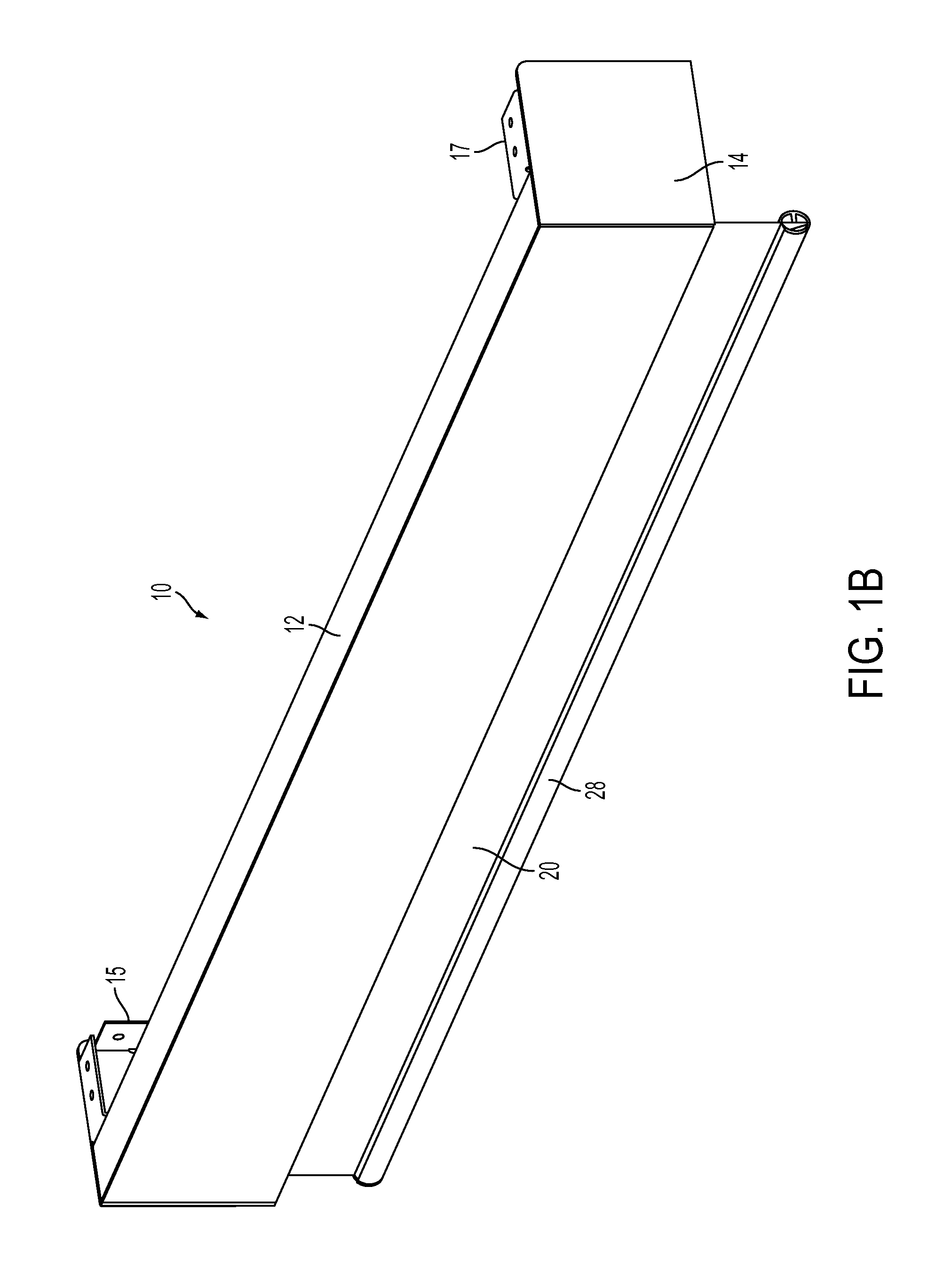

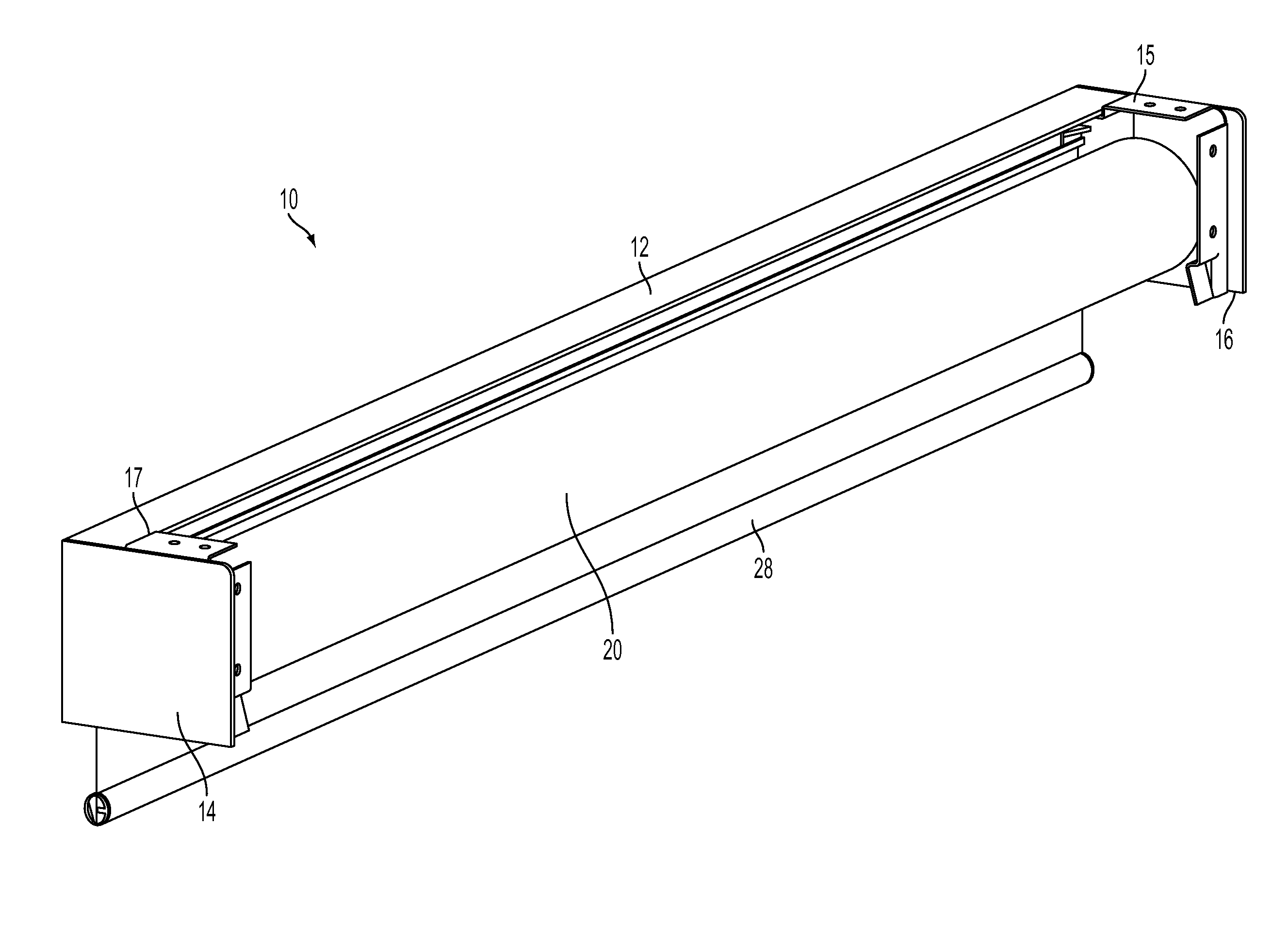

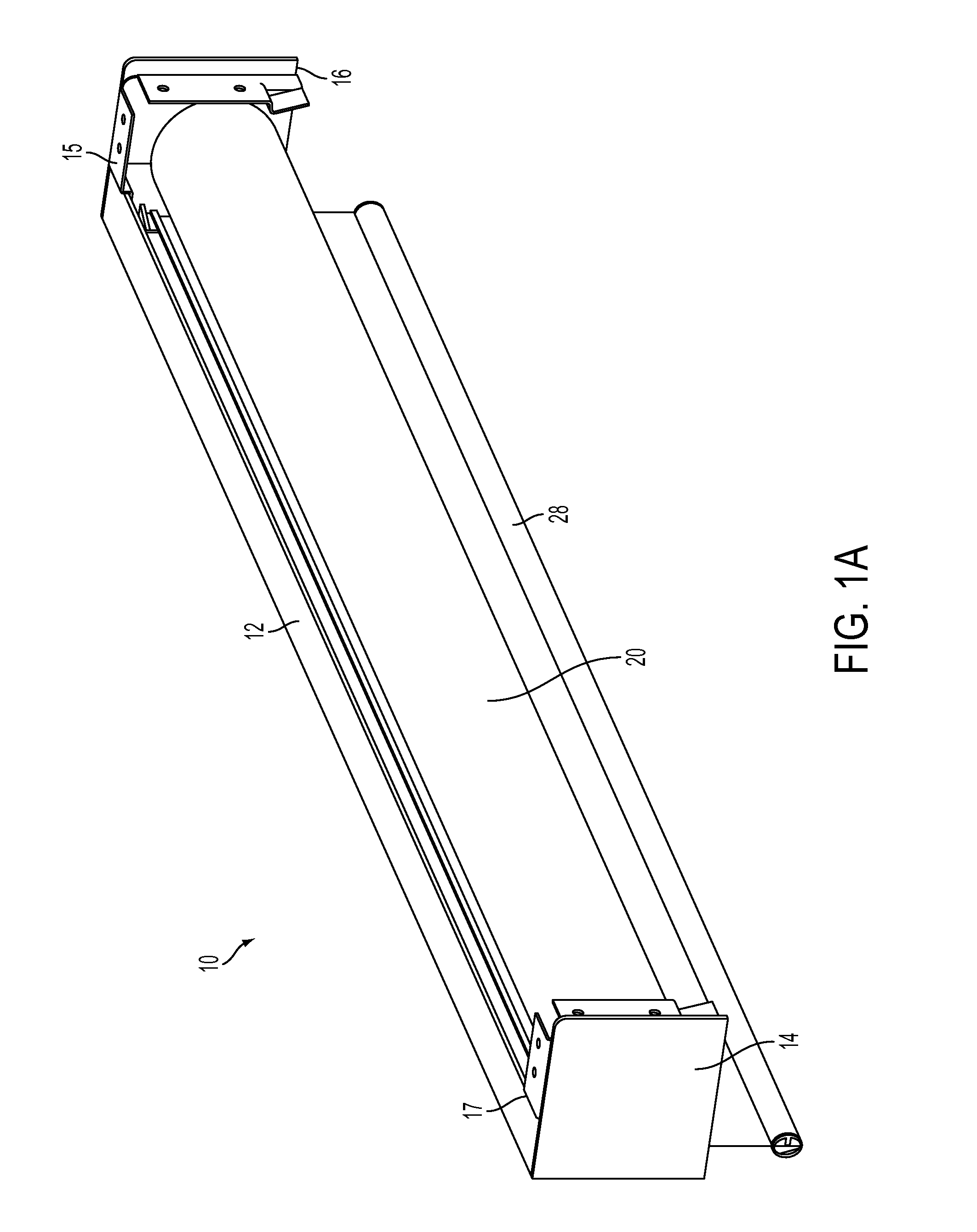

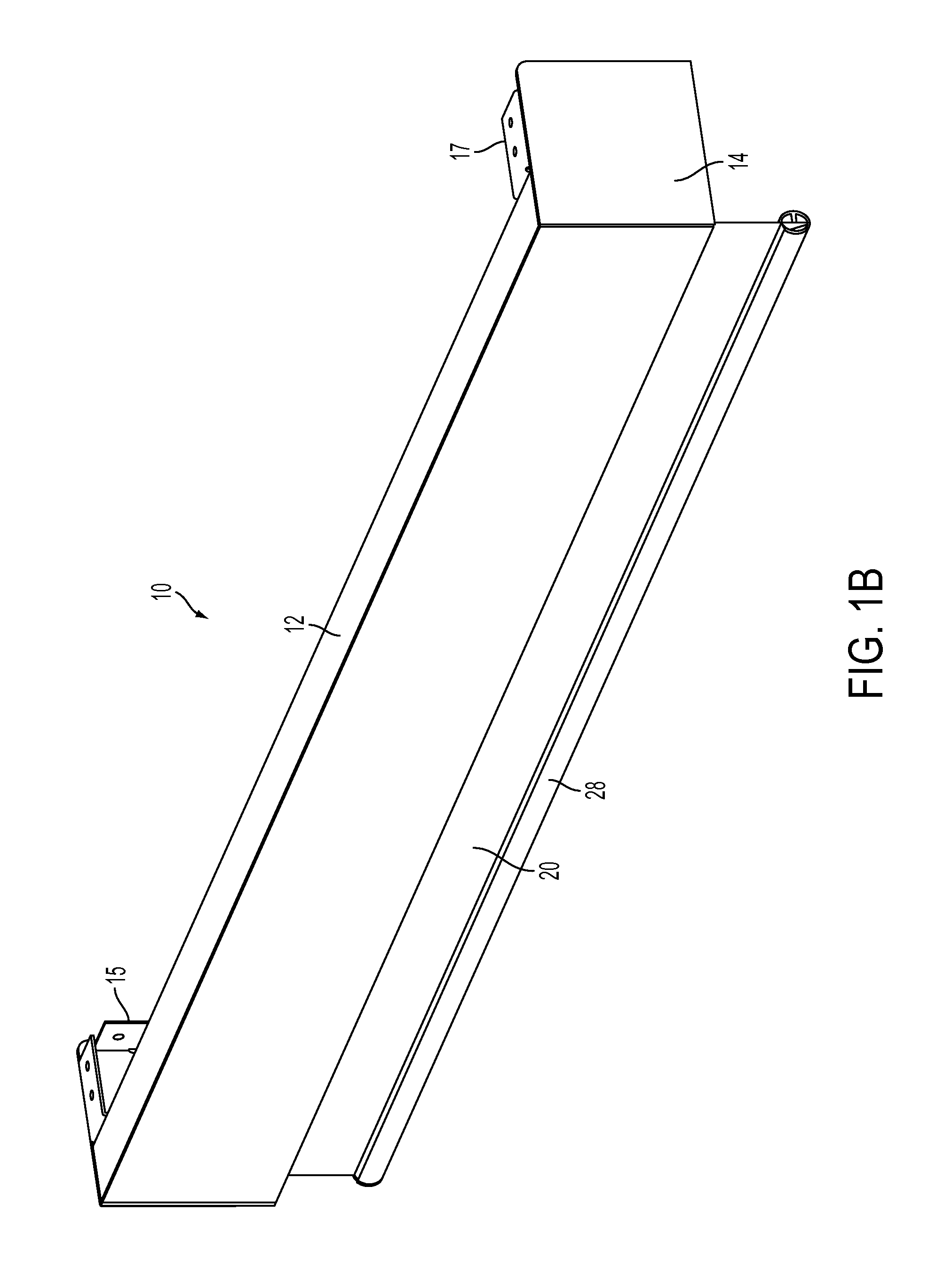

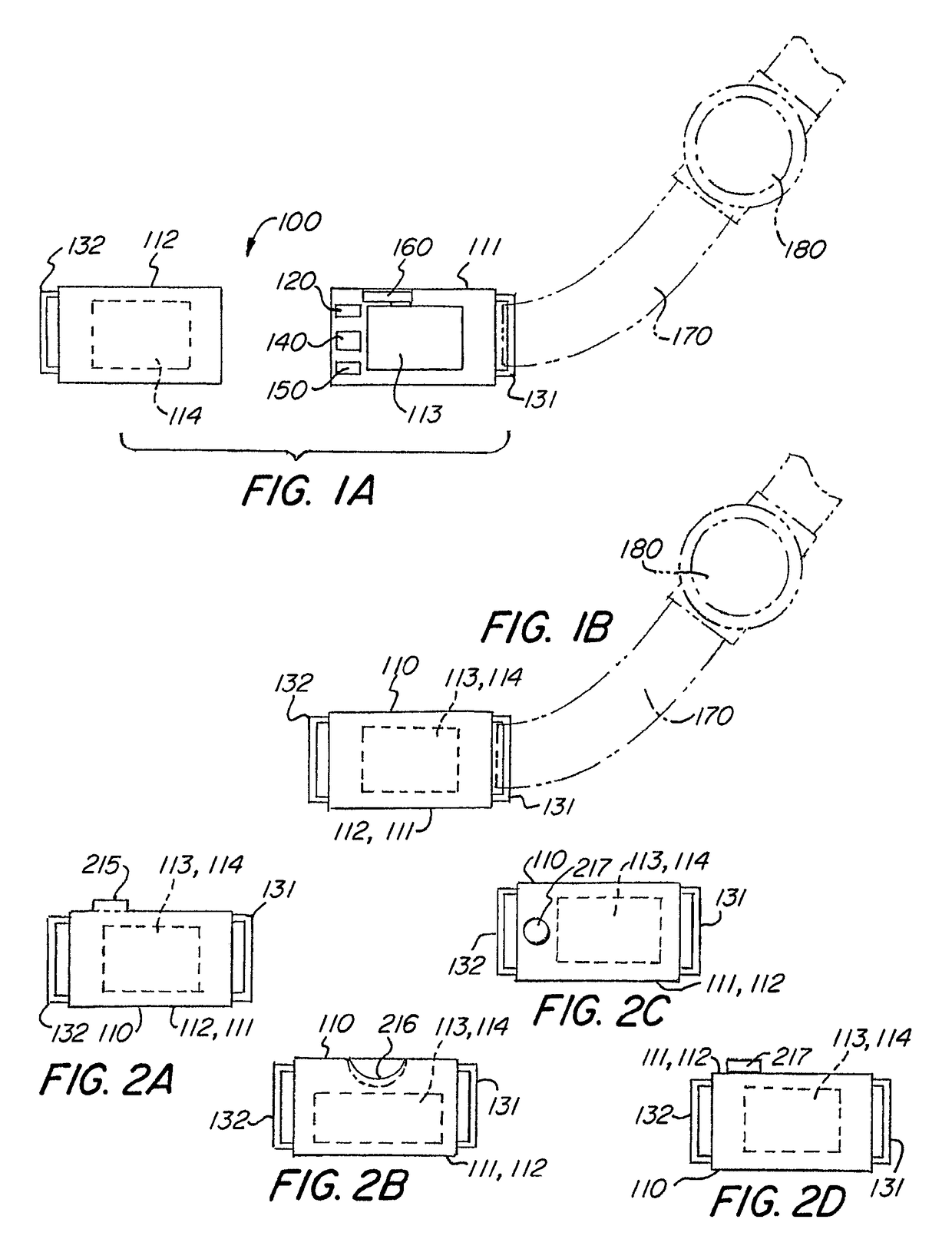

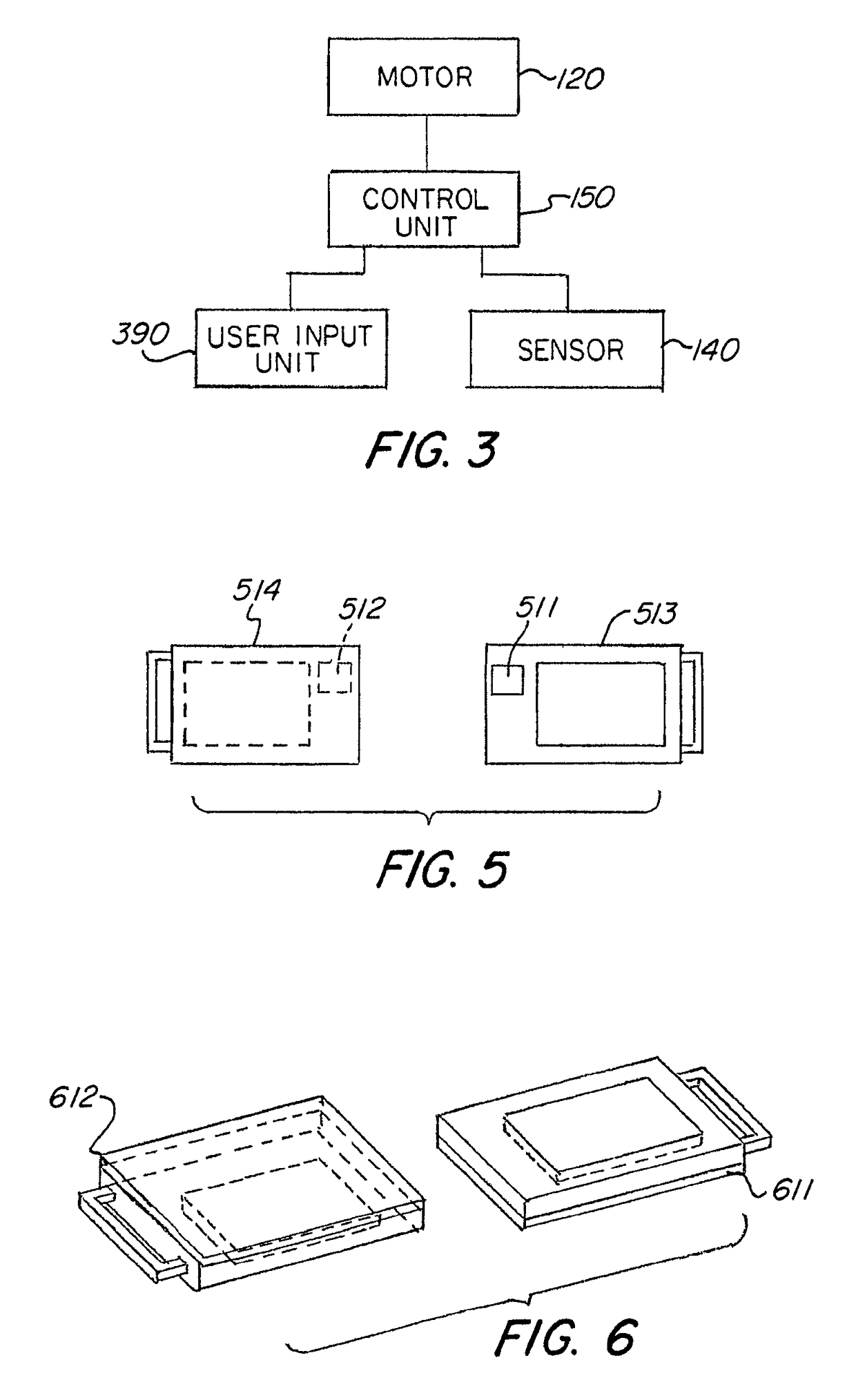

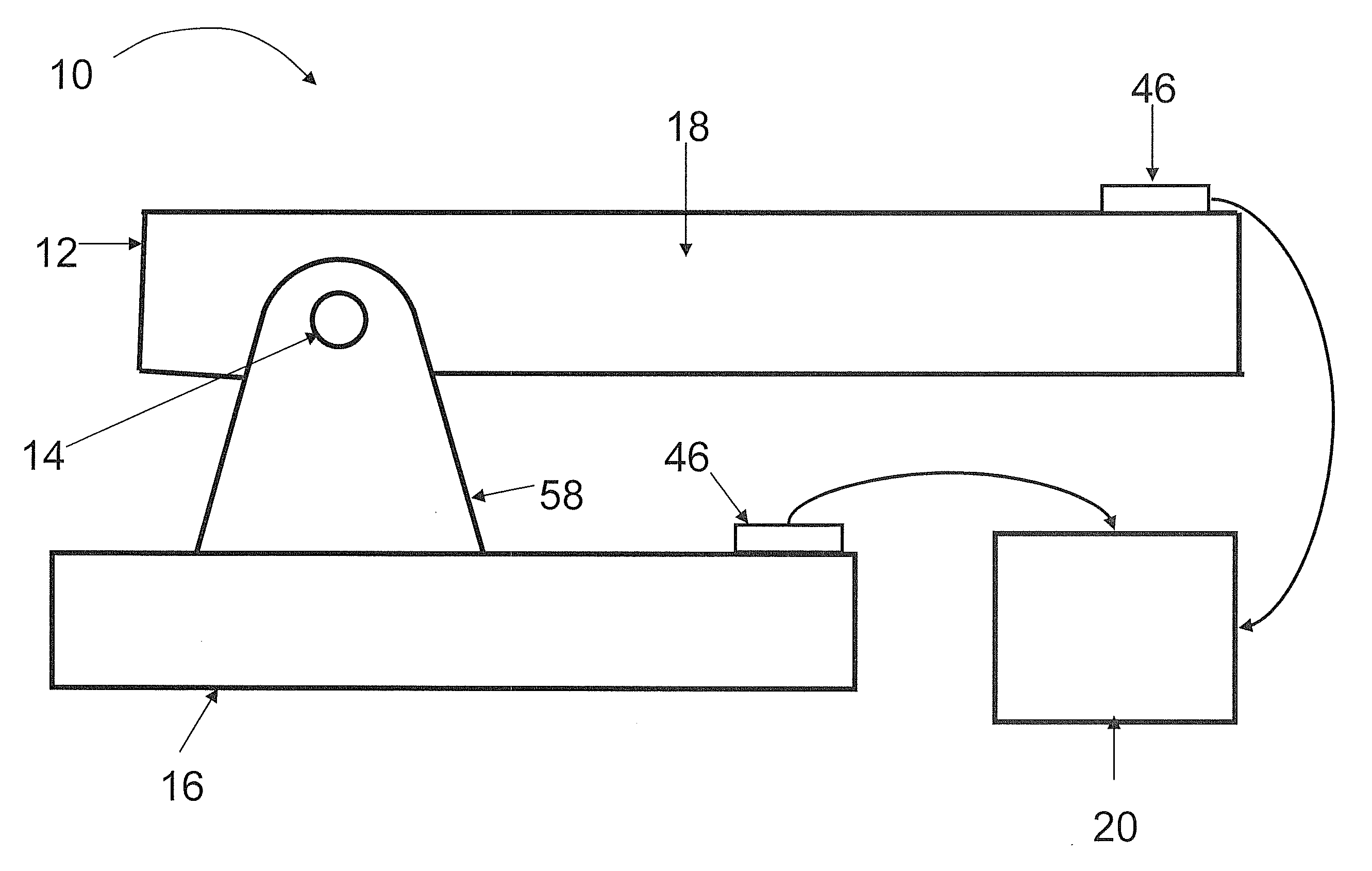

Method for operating a motorized roller shade

InactiveUS8368328B2Easy to useScreensNon-electrical signal transmission systemsMicrocontrollerRemote control

The present invention advantageously provides methods for manually and / or remotely controlling a motorized roller shade that includes a shade attached to a shade tube, a DC gear motor disposed within the shade tube and a microcontroller. One method includes detecting a manual movement of the shade using a sensor, determining a displacement associated with the manual movement, and, if the displacement is less than a maximum displacement, moving the shade to a different position by energizing the DC gear motor to rotate the shade tube. Another method includes receiving a command from a remote control, and moving the shade to a position associated with the command by energizing the DC gear motor to rotate the shade tube.

Owner:THE WATT STOPPER

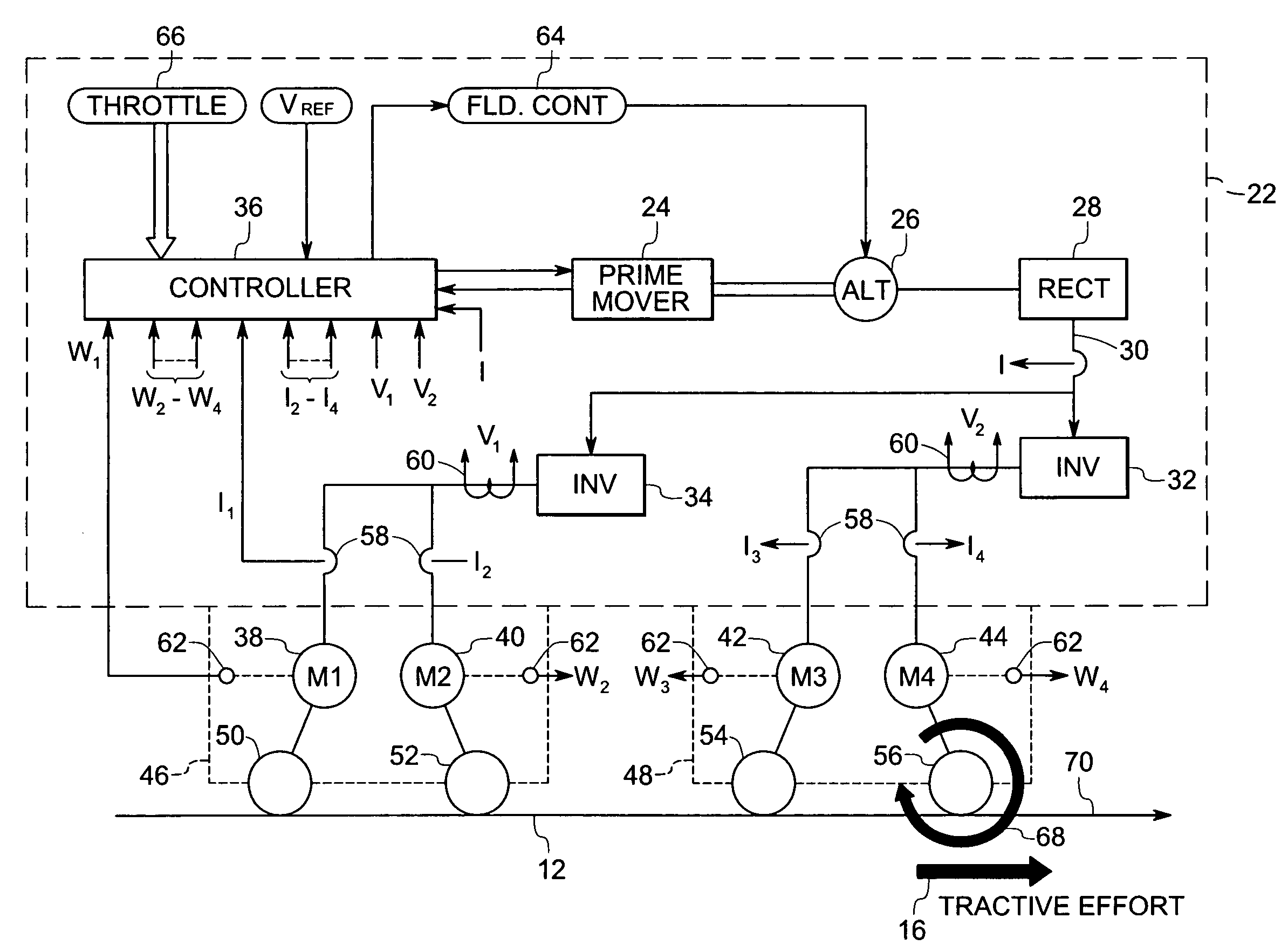

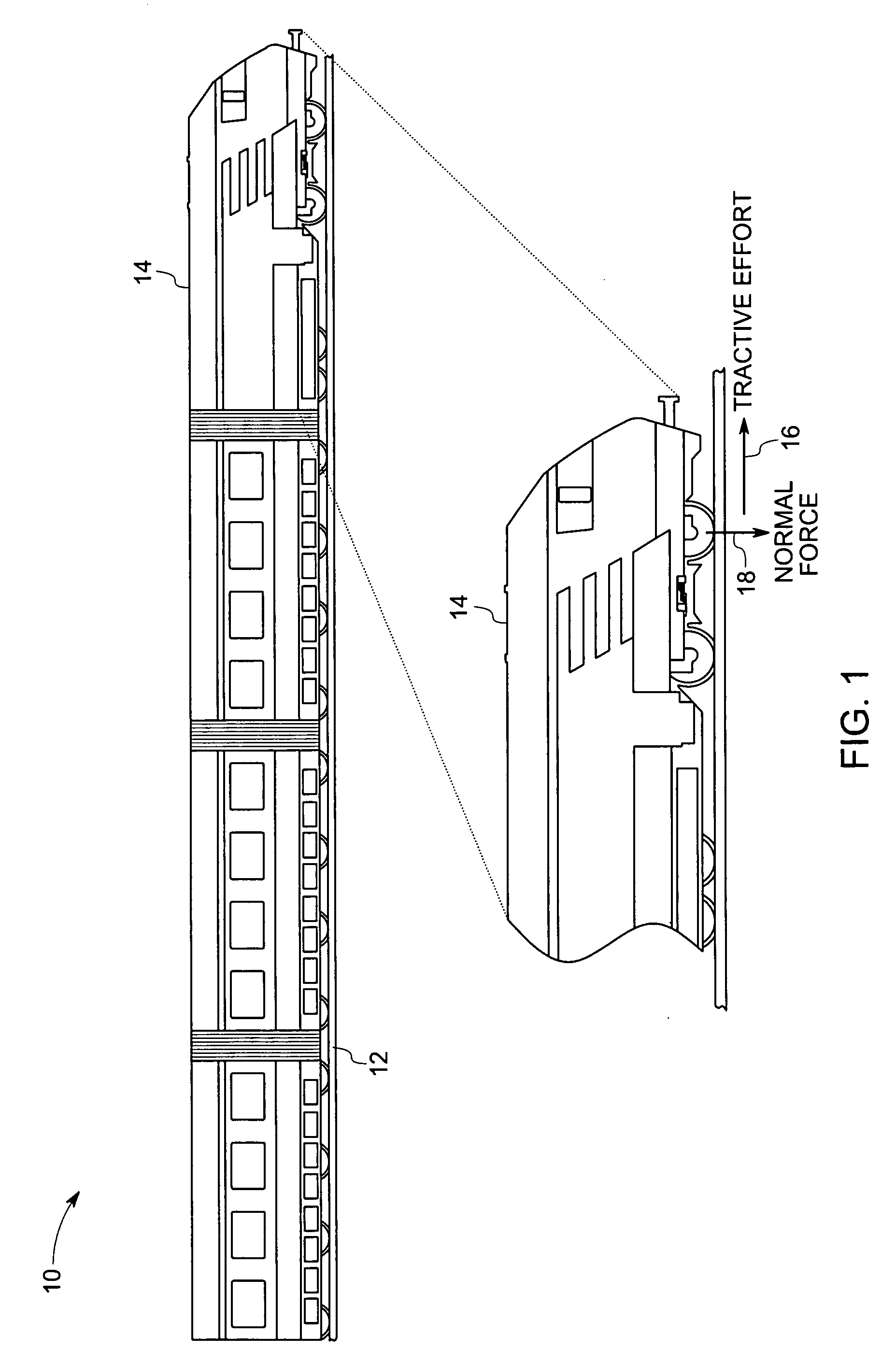

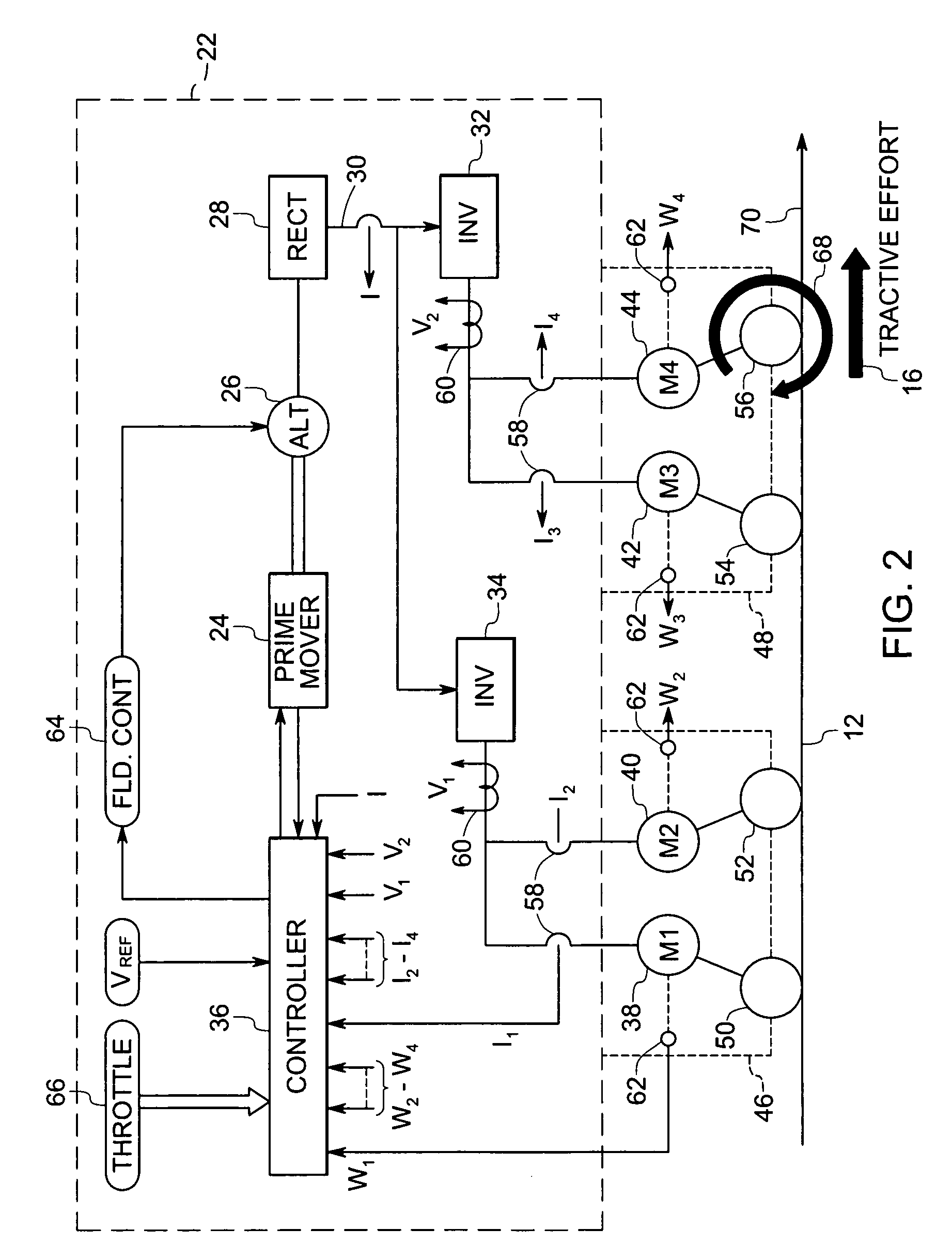

System and method for locomotive adhesion control

ActiveUS20070001629A1Single-phase induction motor startersDC motor speed/torque controlTraction control systemControl circuit

A traction control system for controlling an electric traction motor drivingly coupled to a wheel of a tractive vehicle. The traction control system includes means for determining speed of the wheel, means for determining tractive effort of the wheel and a control circuitry for controlling drive signals to the motor based upon the wheel speed and tractive effort.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

Method for Operating a Motorized Roller Shade

InactiveUS20110203754A1Easy to useElectric signal transmission systemsDC motor speed/torque controlMicrocontrollerRemote control

The present invention advantageously provides methods for manually and / or remotely controlling a motorized roller shade that includes a shade attached to a shade tube, a DC gear motor disposed within the shade tube and a microcontroller. One method includes detecting a manual movement of the shade using a sensor, determining a displacement associated with the manual movement, and, if the displacement is less than a maximum displacement, moving the shade to a different position by energizing the DC gear motor to rotate the shade tube. Another method includes receiving a command from a remote control, and moving the shade to a position associated with the command by energizing the DC gear motor to rotate the shade tube.

Owner:THE WATT STOPPER

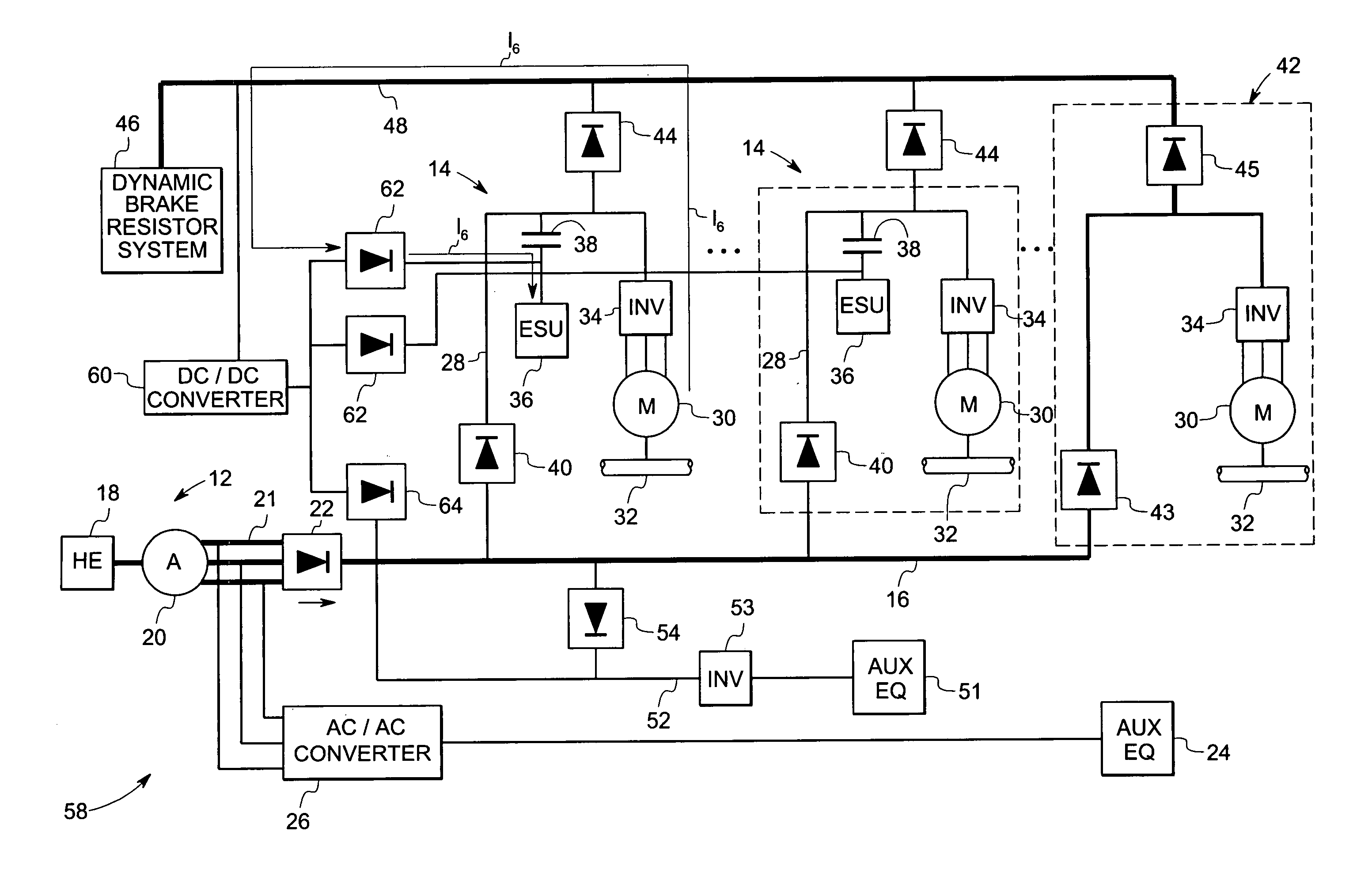

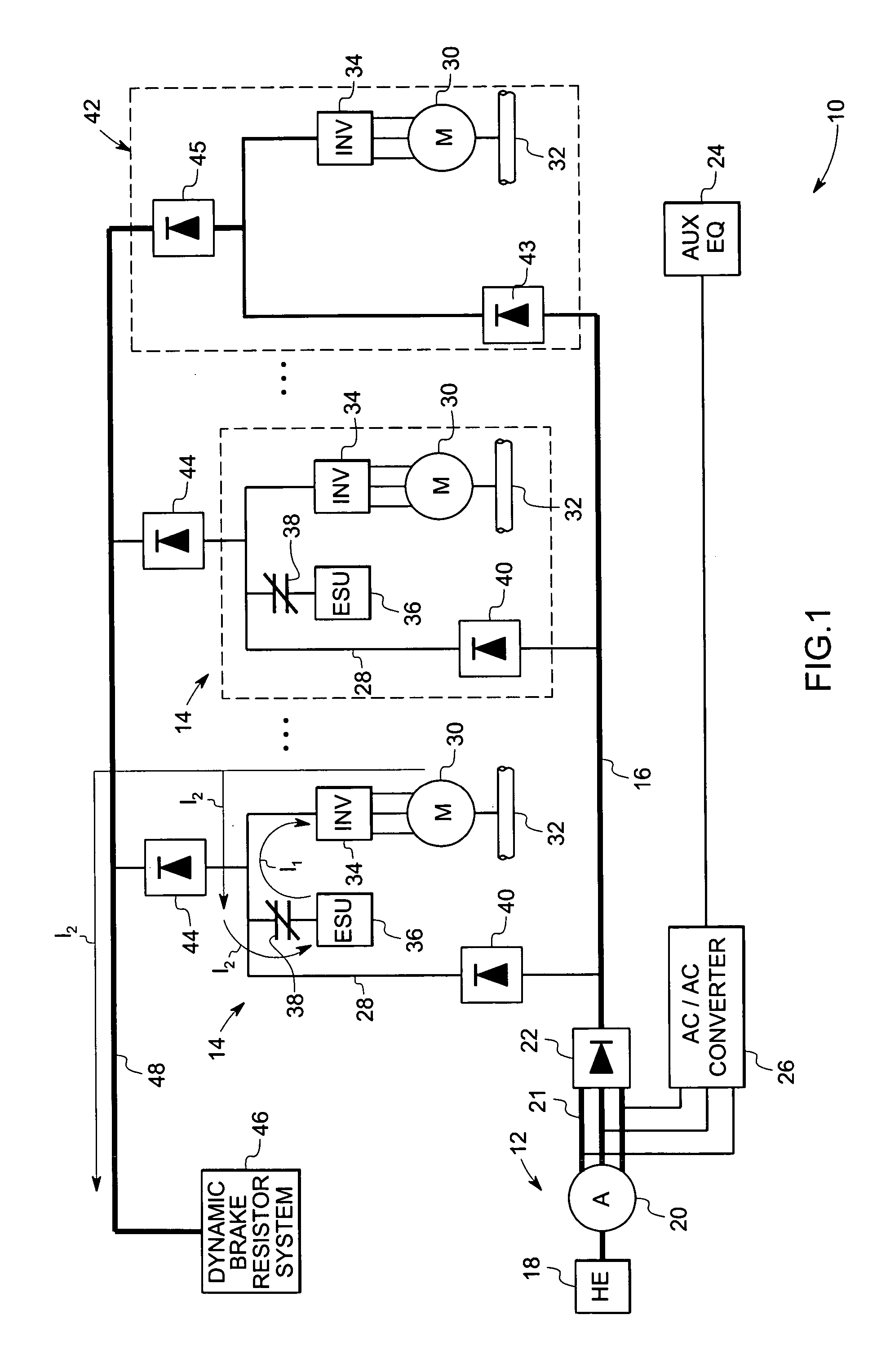

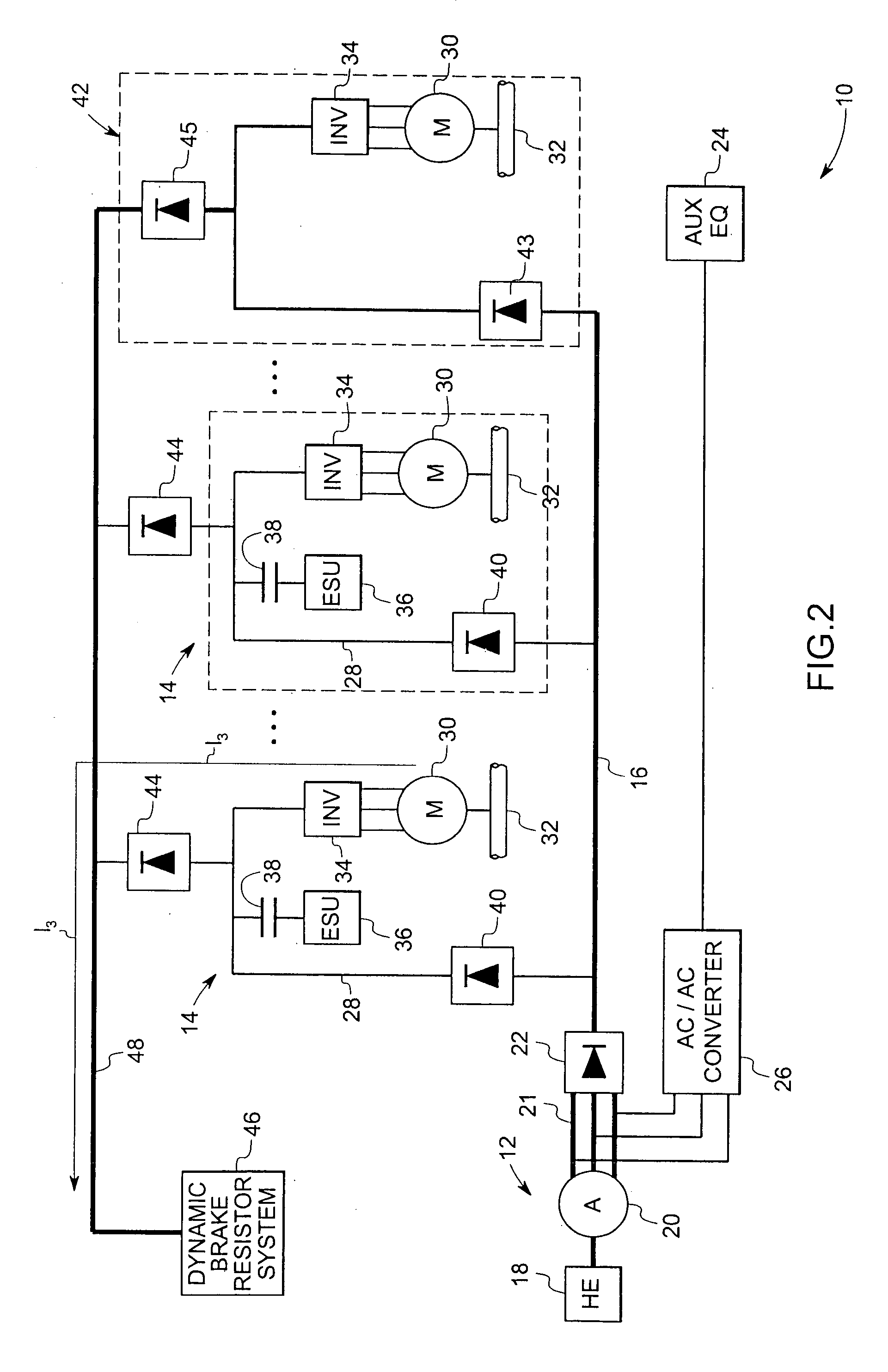

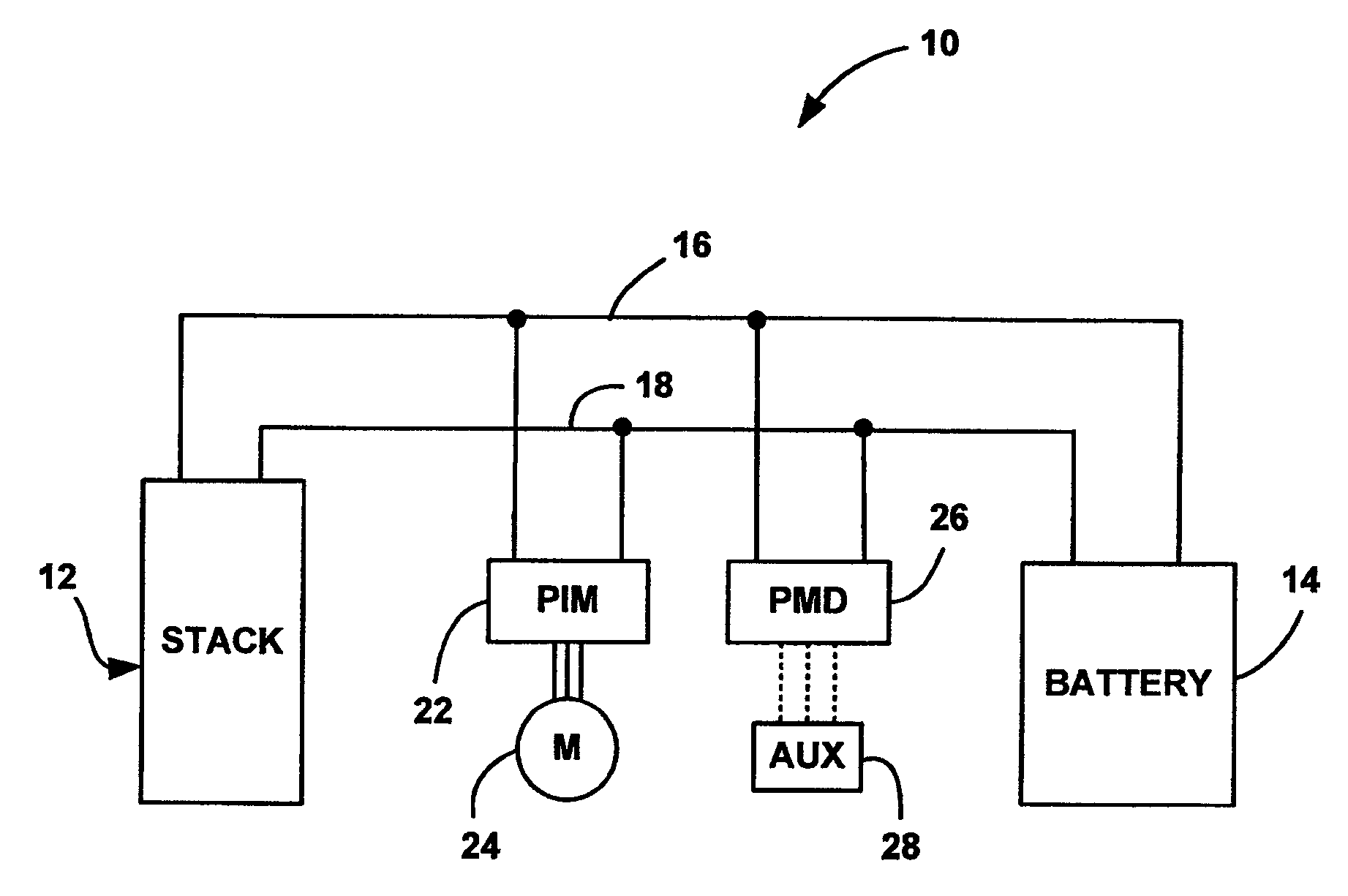

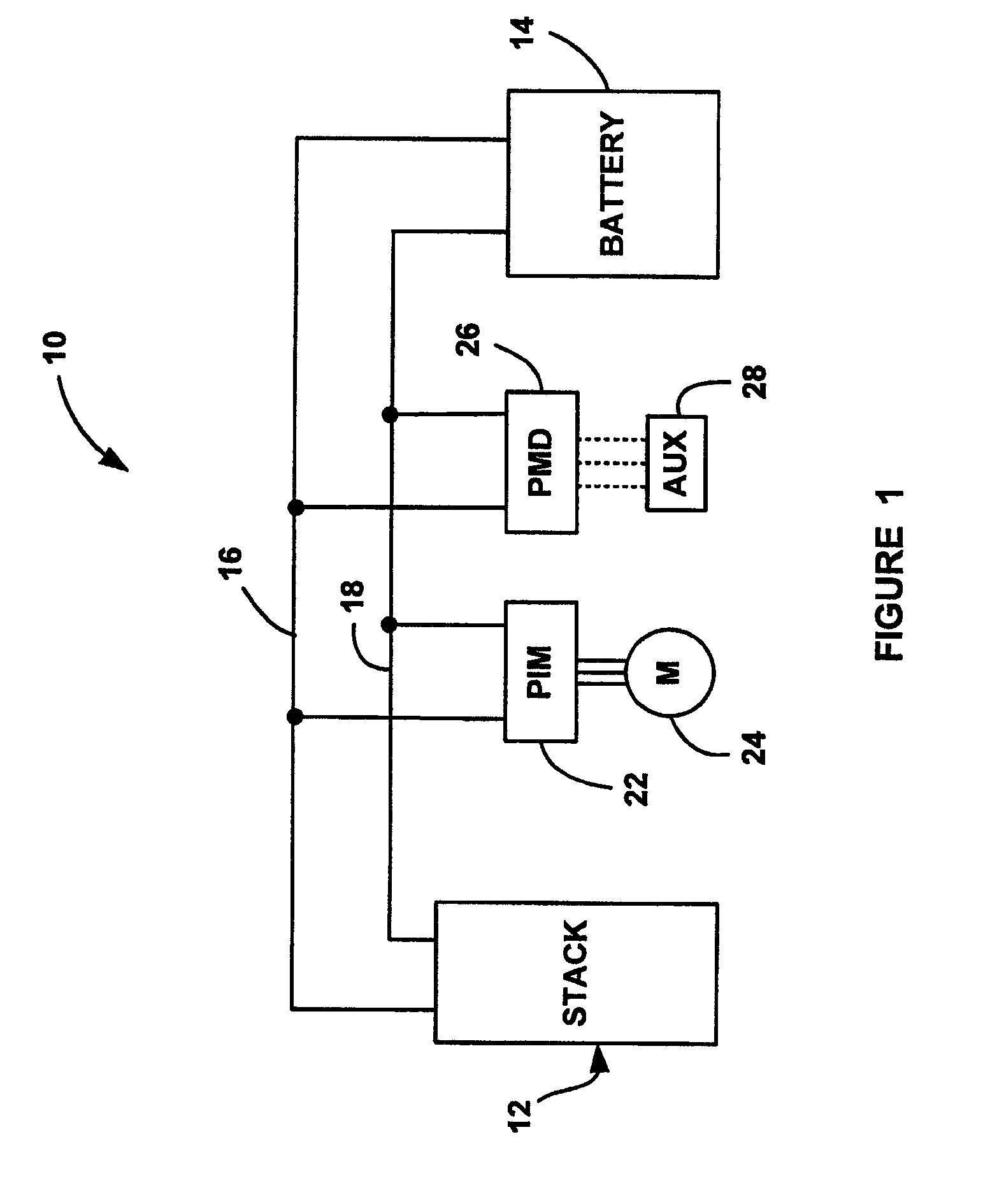

Energy storage system and method for hybrid propulsion

A hybrid propulsion system. The system comprises one or more hybrid propulsion traction drives having an electric motor operable to produce mechanical power for propulsion. A hybrid propulsion traction drive is operable to receive power from an on-board power generation system. The electric motor is operable to receive power from an energy storage unit and operable to supply power to the energy storage unit. The energy storage unit may be coupled to the electric motor via a switch.

Owner:GENERAL ELECTRIC CO

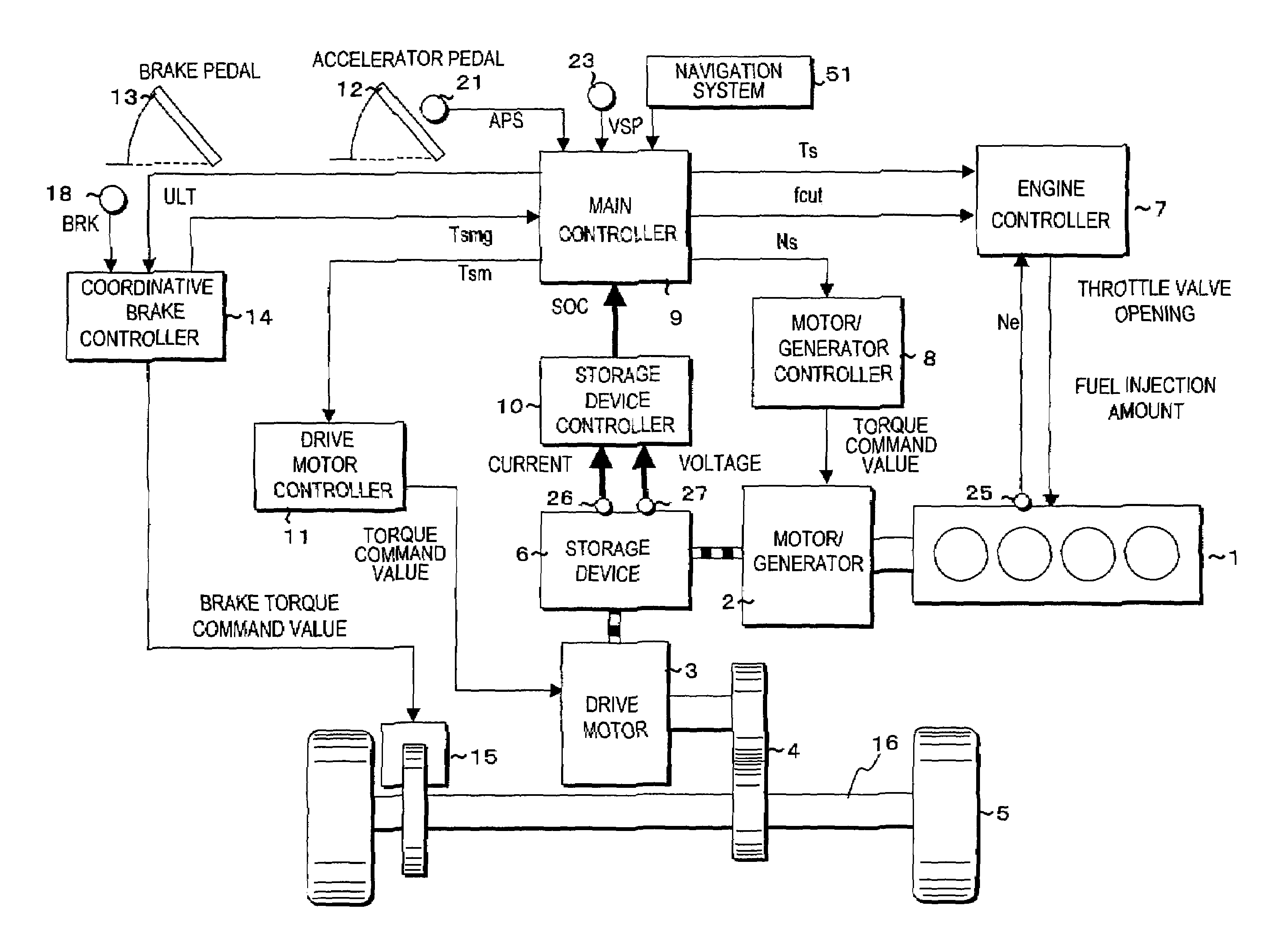

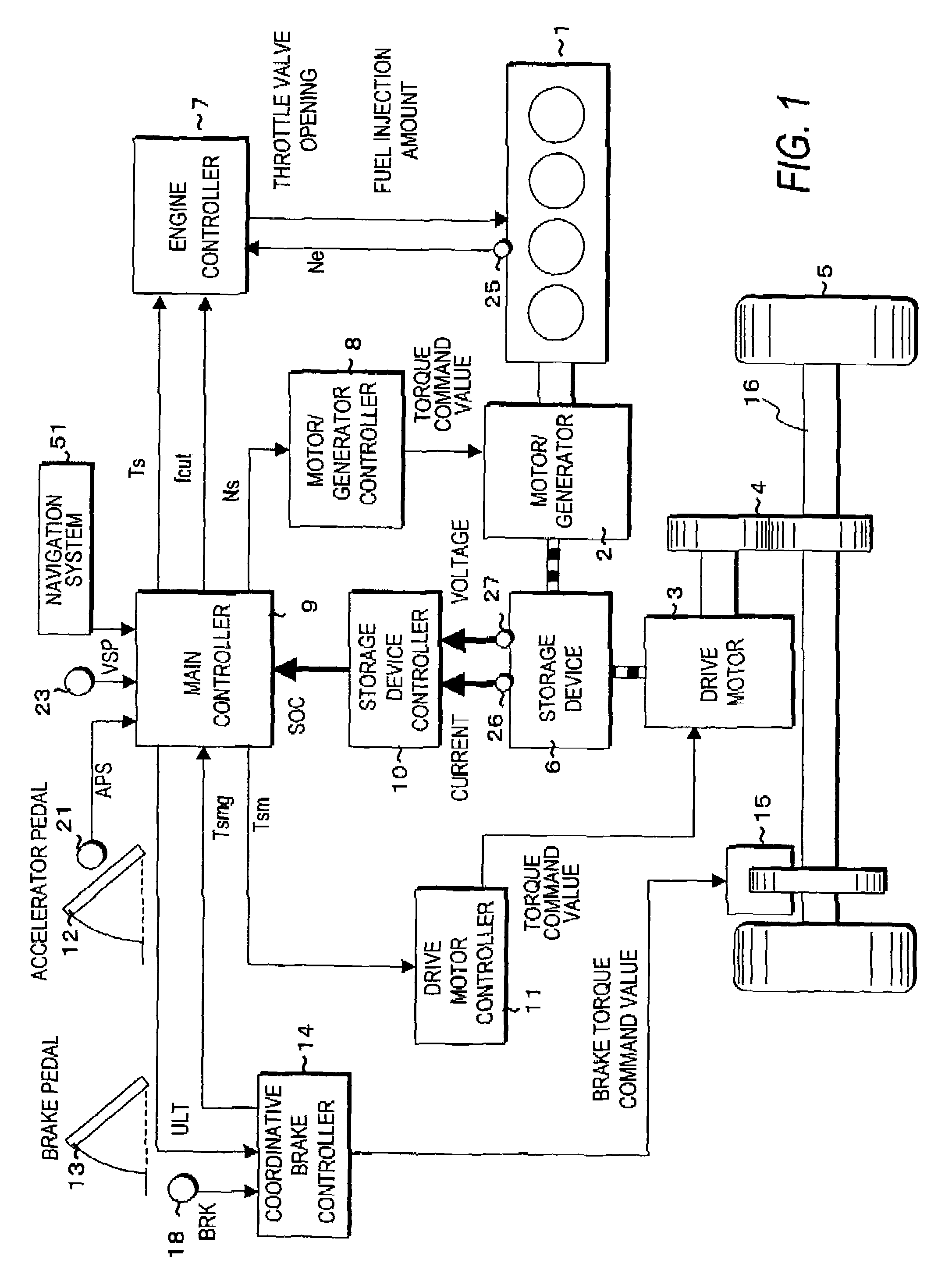

Regeneration control for hybrid vehicle

InactiveUS7034482B2Prevent speedingDc motor stoppersAsynchronous induction motorsState of chargeDrive motor

Disclosed is a control apparatus for a hybrid vehicle having an engine, a drive motor (3) that regenerates power, and an electric power storage device (6) that gives / receives power to / from the drive motor (3). The control apparatus includes power consumption means (2) for consuming power; a sensor (26, 27) that detects a state of charge of the electric power storage device; means (18, 23, 51) for detecting a driving state of the vehicle; and a controller (9). The controller (9) is programmed to calculate a chargeable energy amount Ecap in the electric power storage device (6) on the basis of a difference between a fully charged state of the electric power storage device and the detected state of charge; set a power |Pgen0| regenerated by the drive motor (3); calculate a chargeable power Pmax in the electric power storage device according to the detected state of charge; calculate a regenerated energy E resulting from regenerative braking from the detected driving state of the vehicle; calculate a charging power limit Pgenlmt according to the calculated regenerated energy E; and control the power consumption means (2) to consume a power equal to a difference between the power |Pgen0| regenerated by the drive motor (3) and the charging power limit |Pgenlmt| when the calculated regenerated energy E is greater than the chargeable energy amount Ecap in the electric power storage device and when the charging power limit |Pgenlmt| is smaller than the chargeable power |Pmax|.

Owner:NISSAN MOTOR CO LTD

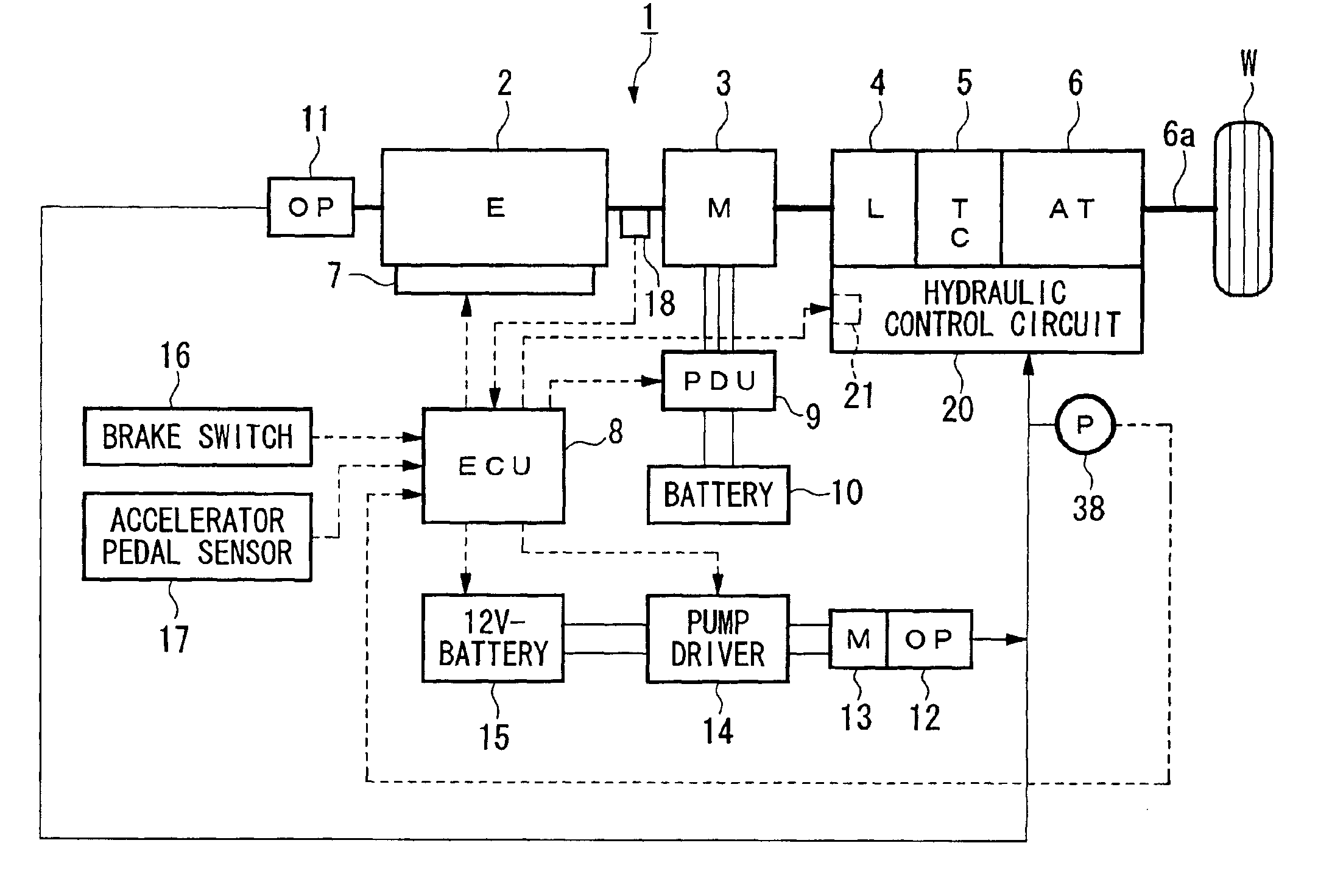

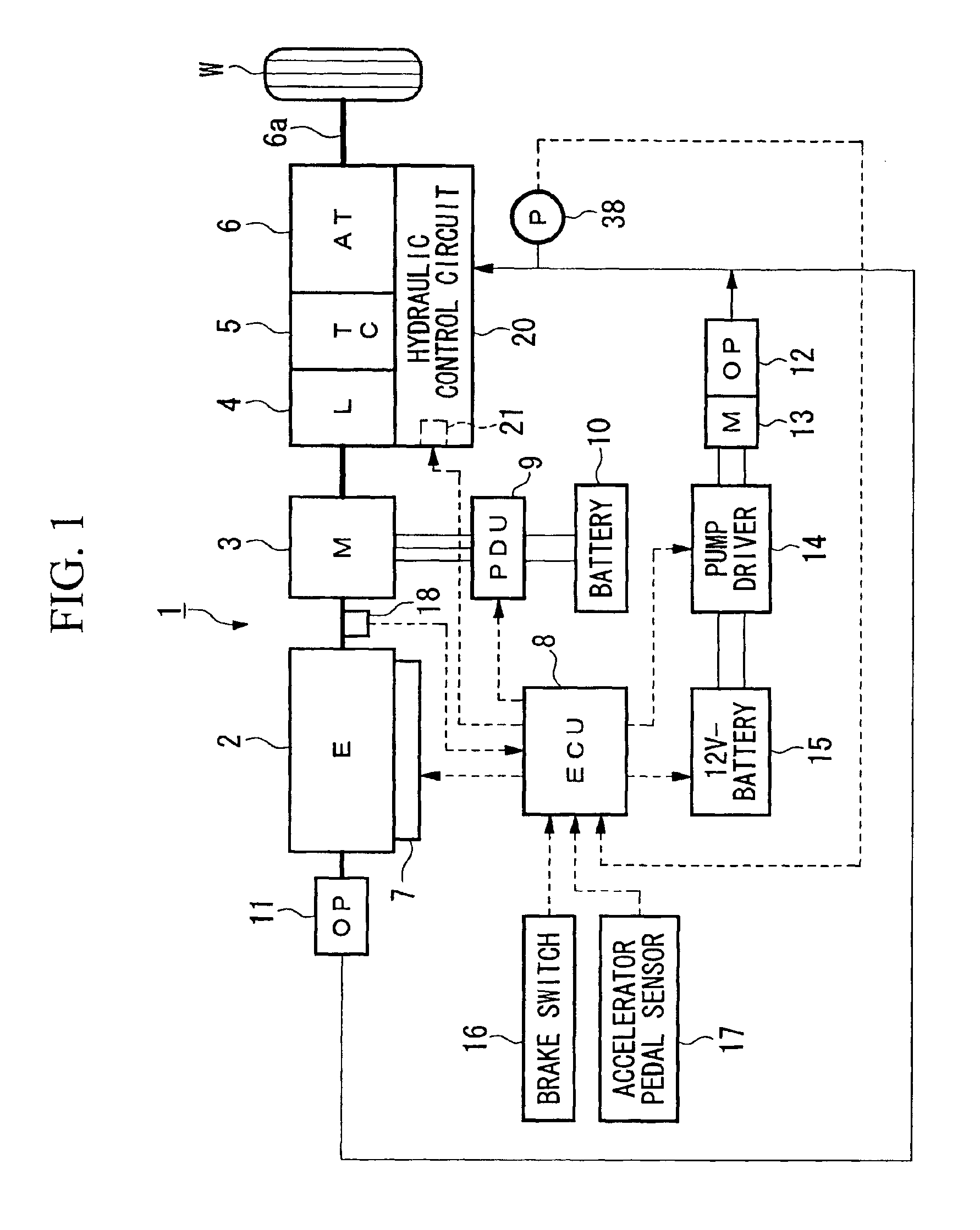

Hydraulic control apparatus for hybrid vehicle

InactiveUS7041030B2Smooth transmissionClutchesInternal combustion piston enginesMotor driveTorque transmission

A hydraulic control apparatus for a hybrid vehicle, which enables a smooth torque transmission when an engine of the vehicle is started from an idling stop state. The hydraulic control apparatus includes an engine and a motor as power sources, a transmission having a torque converter, a clutch for a starting gear, an engine automatic stop and start device which is associated with the engine, a motor-driven oil pump for supplying oil pressure to the transmission, a brake pedal sensor, an accelerator pedal sensor, an engine revolution rate sensor. The oil pressure applied to the clutch is controlled to a level corresponding to a creeping torque when the engine is automatically stopped. When the brake pedal is released, the engine is automatically started, the accelerator pedal is not depressed, and the engine revolution rate is less than an idling revolution rate, the oil pressure applied to the clutch is maintained to the level corresponding to the creeping torque.

Owner:HONDA MOTOR CO LTD +1

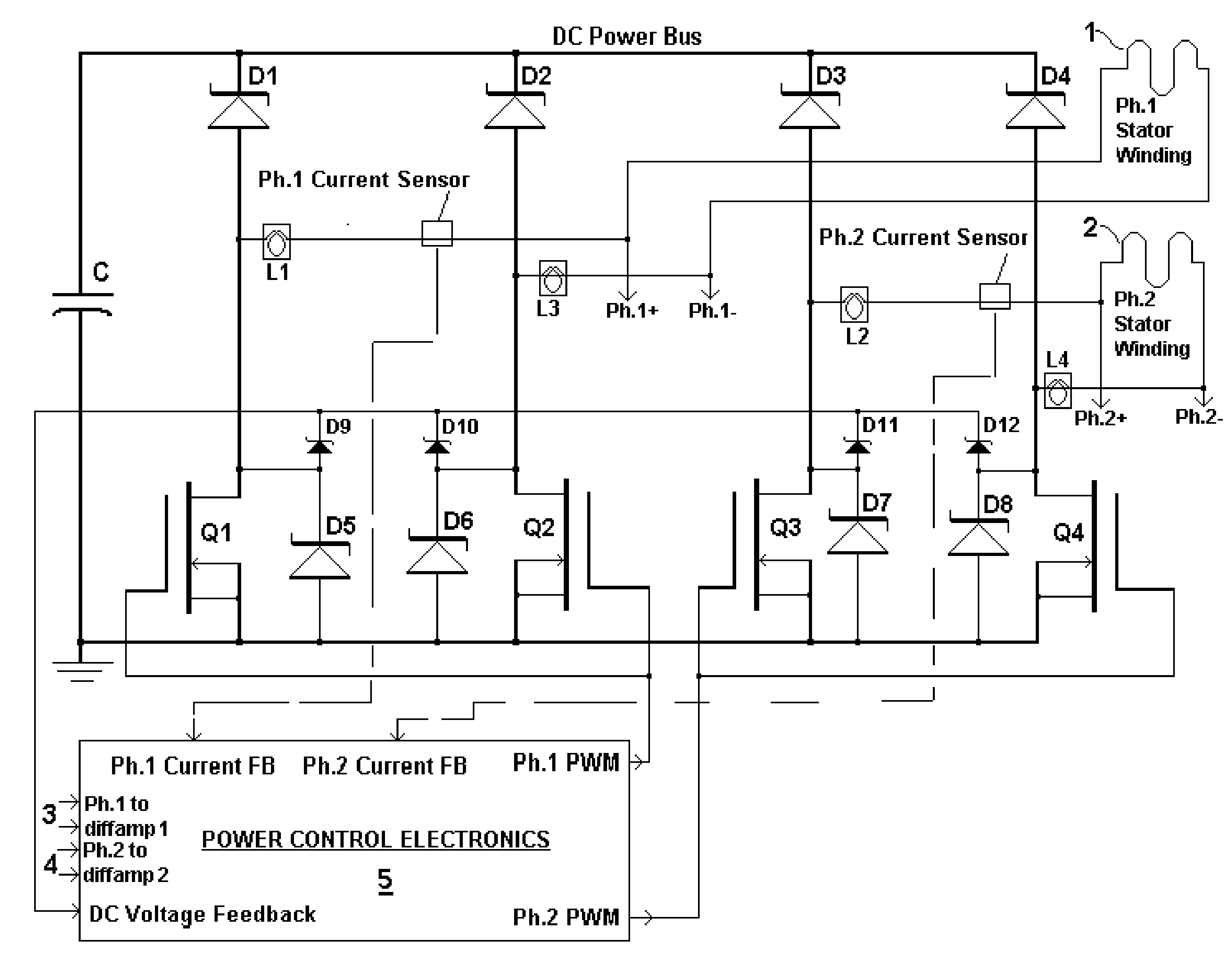

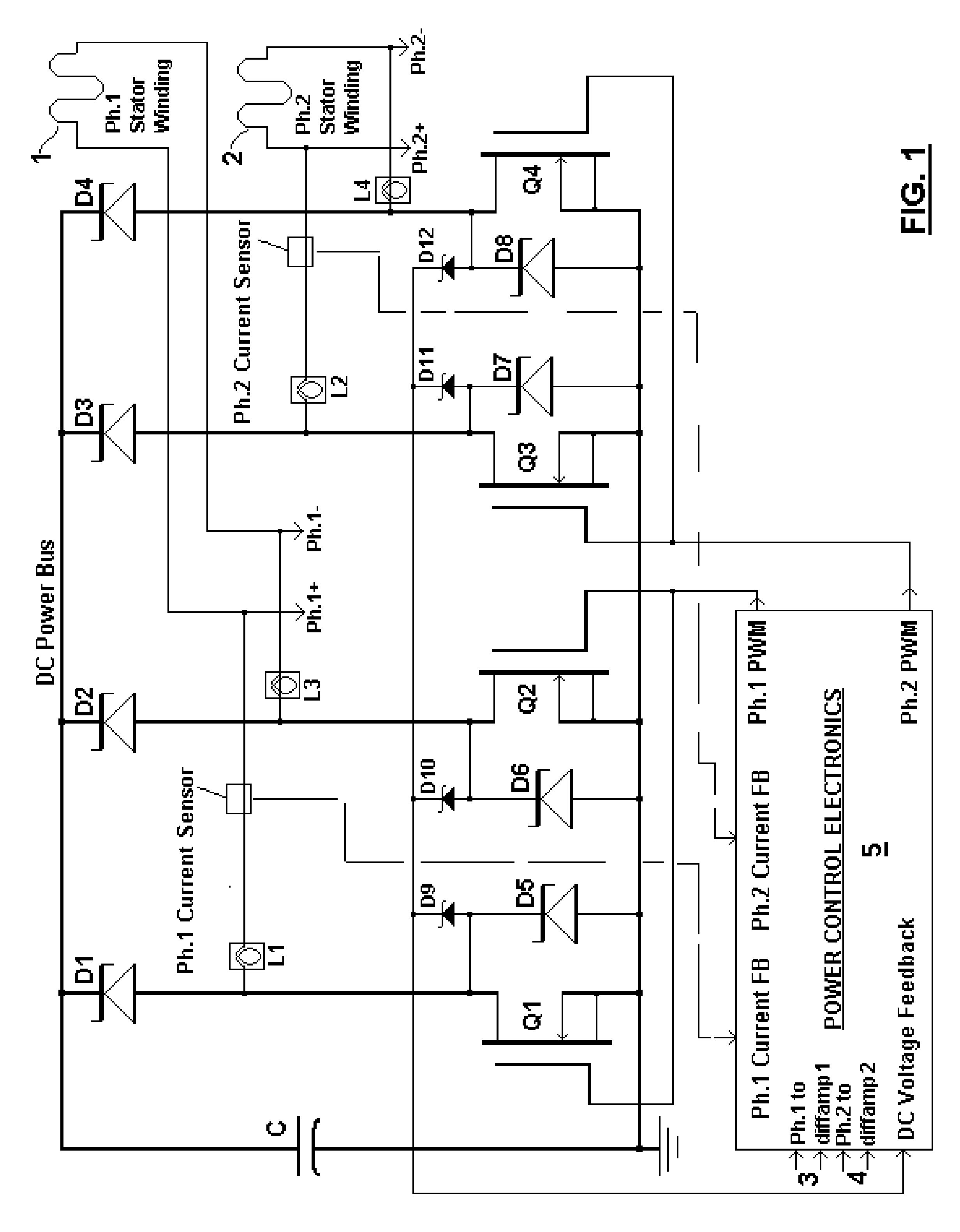

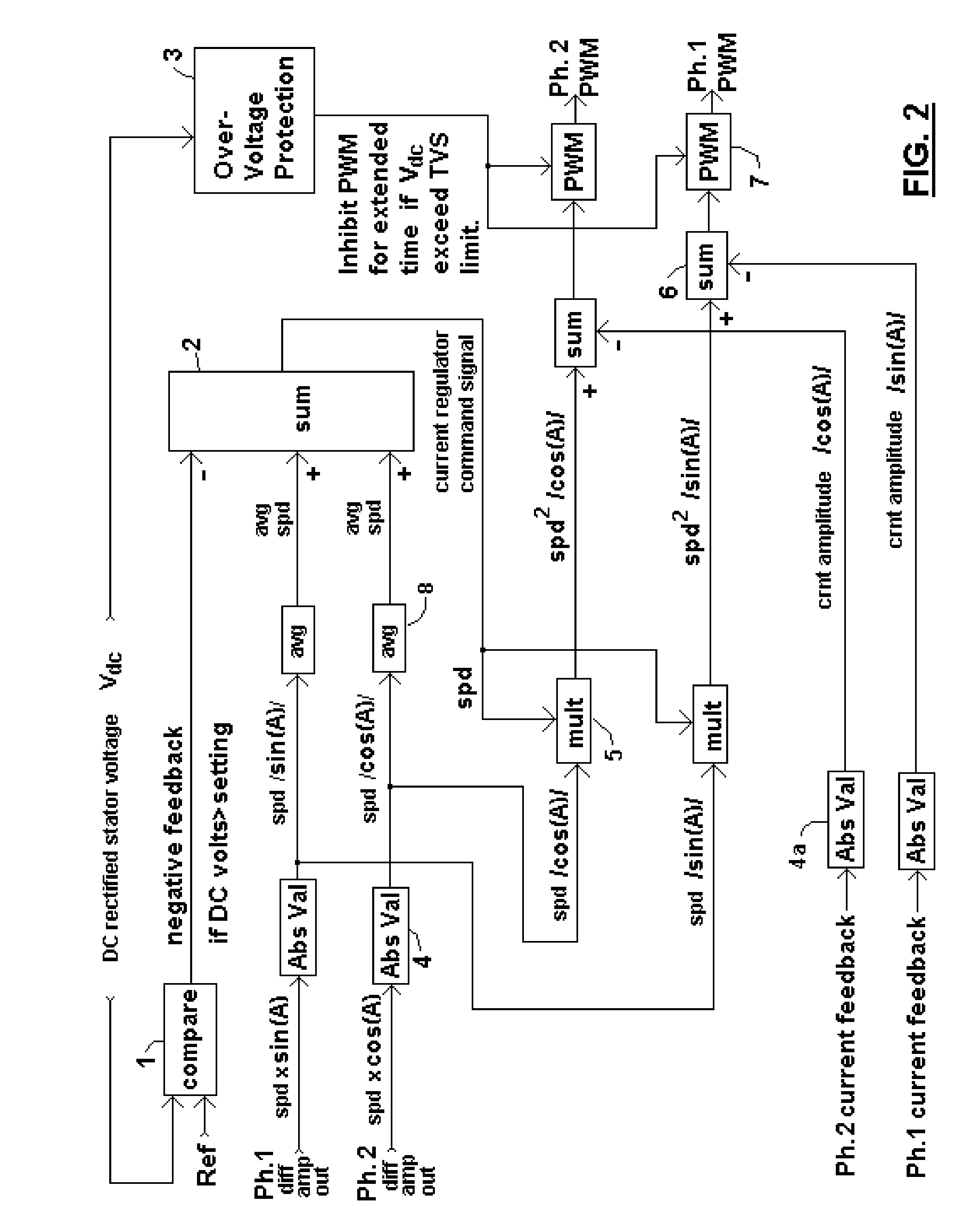

Broad-speed-range generator variations

InactiveUS20120256422A1High energy yieldImprove global economyWindingsMagnetic circuitPower qualityDc current

A brushless generator with permanent-magnet multi-pole rotor disks and stator winding disks in their axial magnetic field includes integral electronics to efficiently generate regulated DC current and voltage from mechanical input power over a broad speed range. All power for the electronics is provided by rectifier diodes from its stator windings. Differential amplifiers provide stator voltage feedback signals. Its power rating is scalable, depending on the number of its disks. Having no iron cores and no gears, it incurs no cogging torque, and no gear friction. Integral power control electronics includes high-frequency pulse-width-modulated boost regulation, which provides regulated current at requisite voltage over its broad speed range. A main wind-powered embodiment to produce DC power for a constant voltage DC load over a broad speed range includes signal processing so output power varies according to the third power of speed. Combined boost-regulation, zero cogging torque, and no gearing, enable a wide speed range, for better power quality and higher wind energy yields.

Owner:FRADELLA RICHARD B

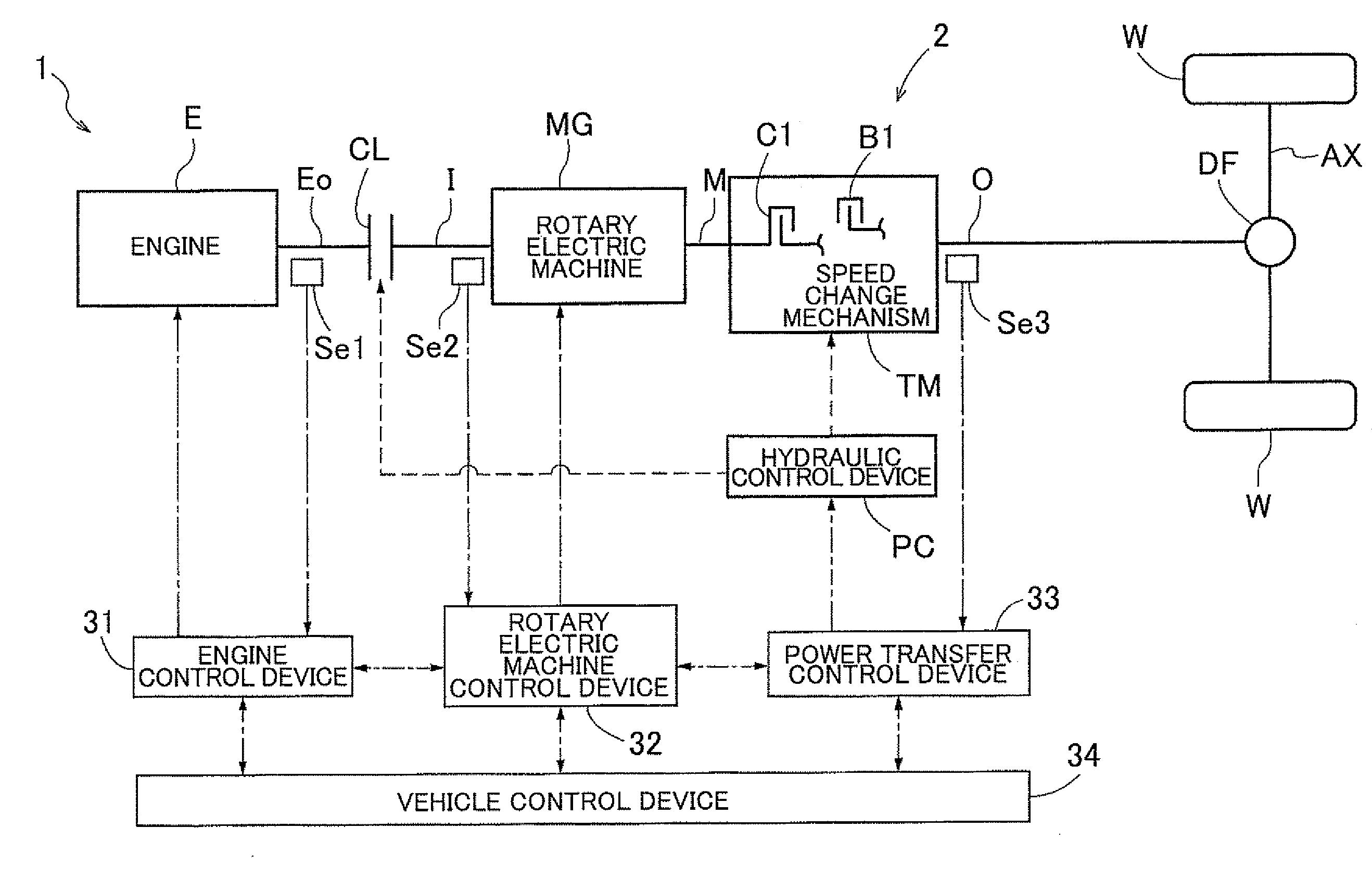

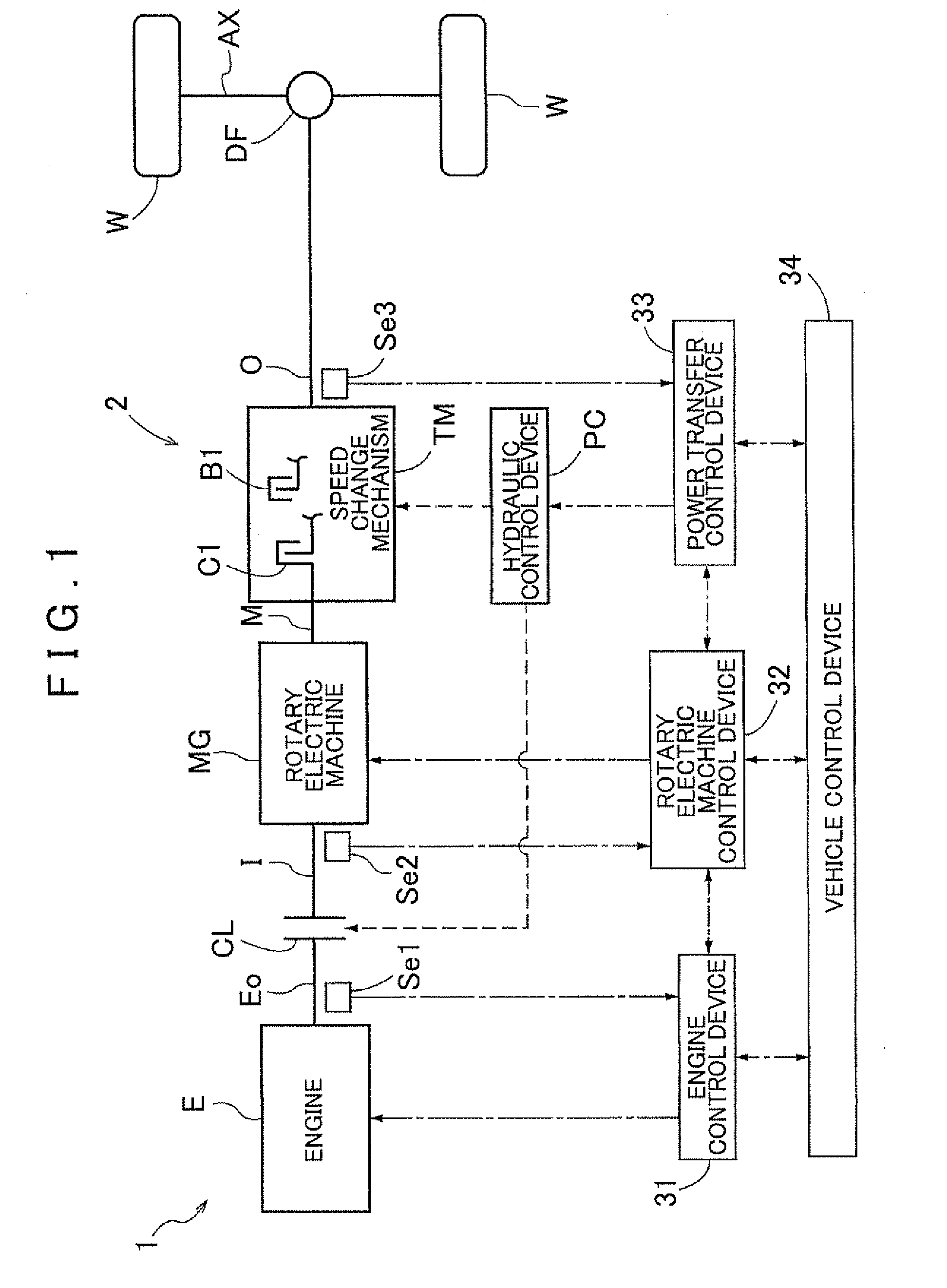

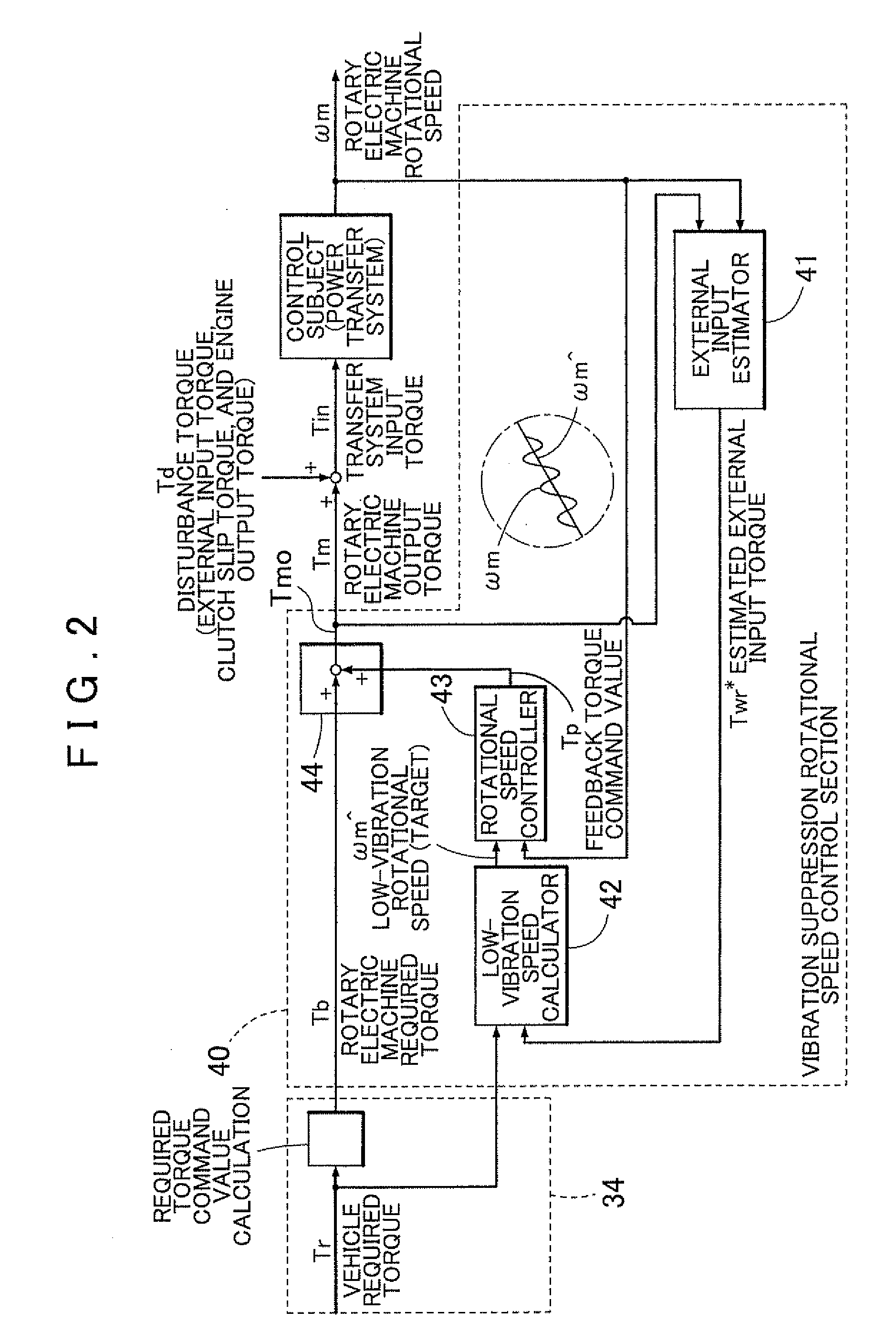

Control device

ActiveUS20120081051A1Suppress torsional vibrationVehicle testingTorque ripple controlElectric machineTransfer system

A control device configured with an external input estimator that reduces a vibration component of a rotational speed of the power transfer system at a rotational speed of the rotary electric machine and estimates transfer system input torque on the basis of the rotational speed of the rotary electric machine, and that estimates external input torque by subtracting at least output torque of the rotary electric machine from the transfer system input torque. A low-vibration speed calculator calculates a low-vibration rotational speed on the basis of the external input torque and vehicle required torque. A rotational speed controller calculates feedback command torque that matches the rotational speed of the rotary electric machine with the low-vibration rotational speed. A torque command value calculator calculates an output torque command value on the basis of the vehicle required torque and the feedback command torque.

Owner:AISIN AW CO LTD

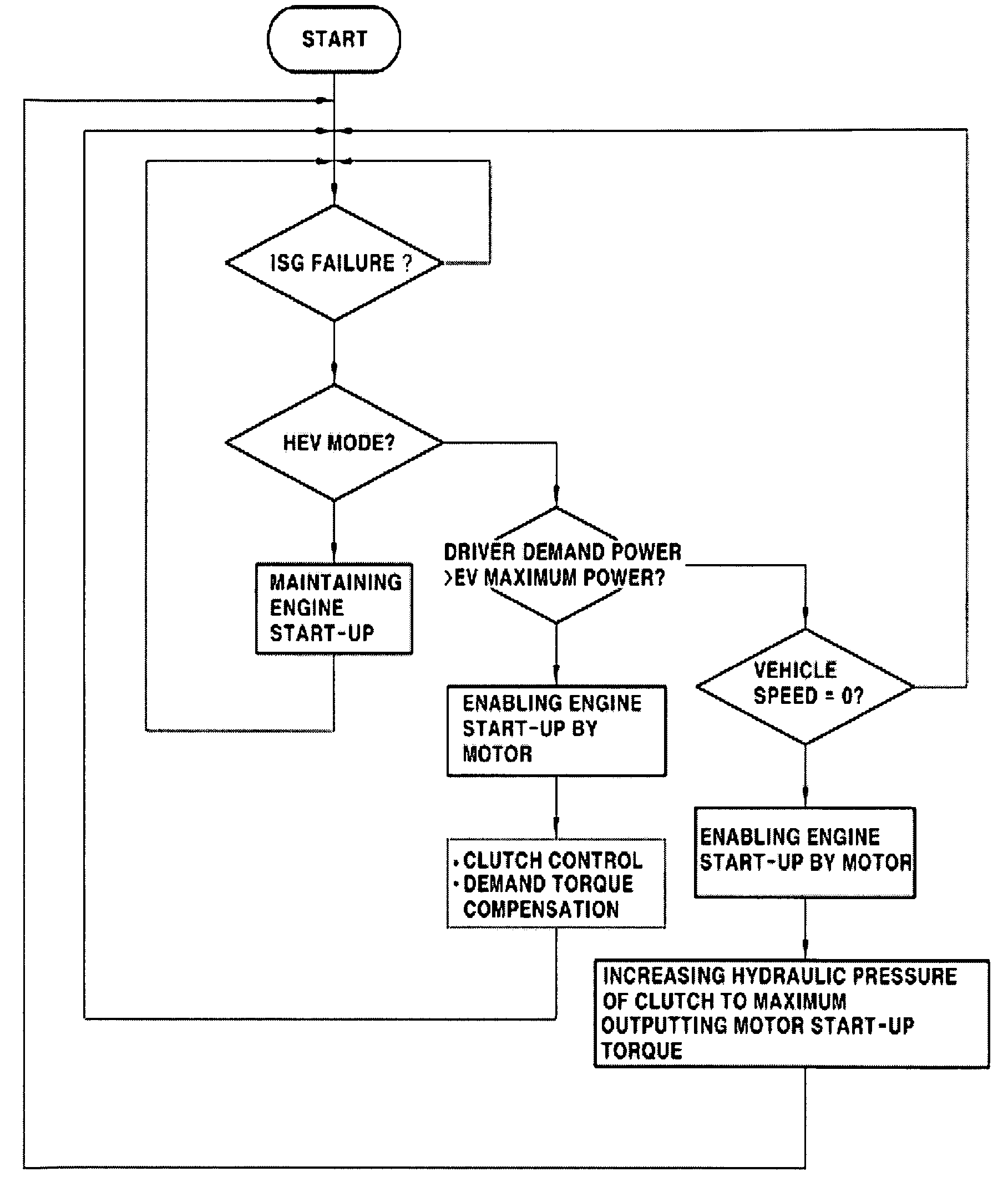

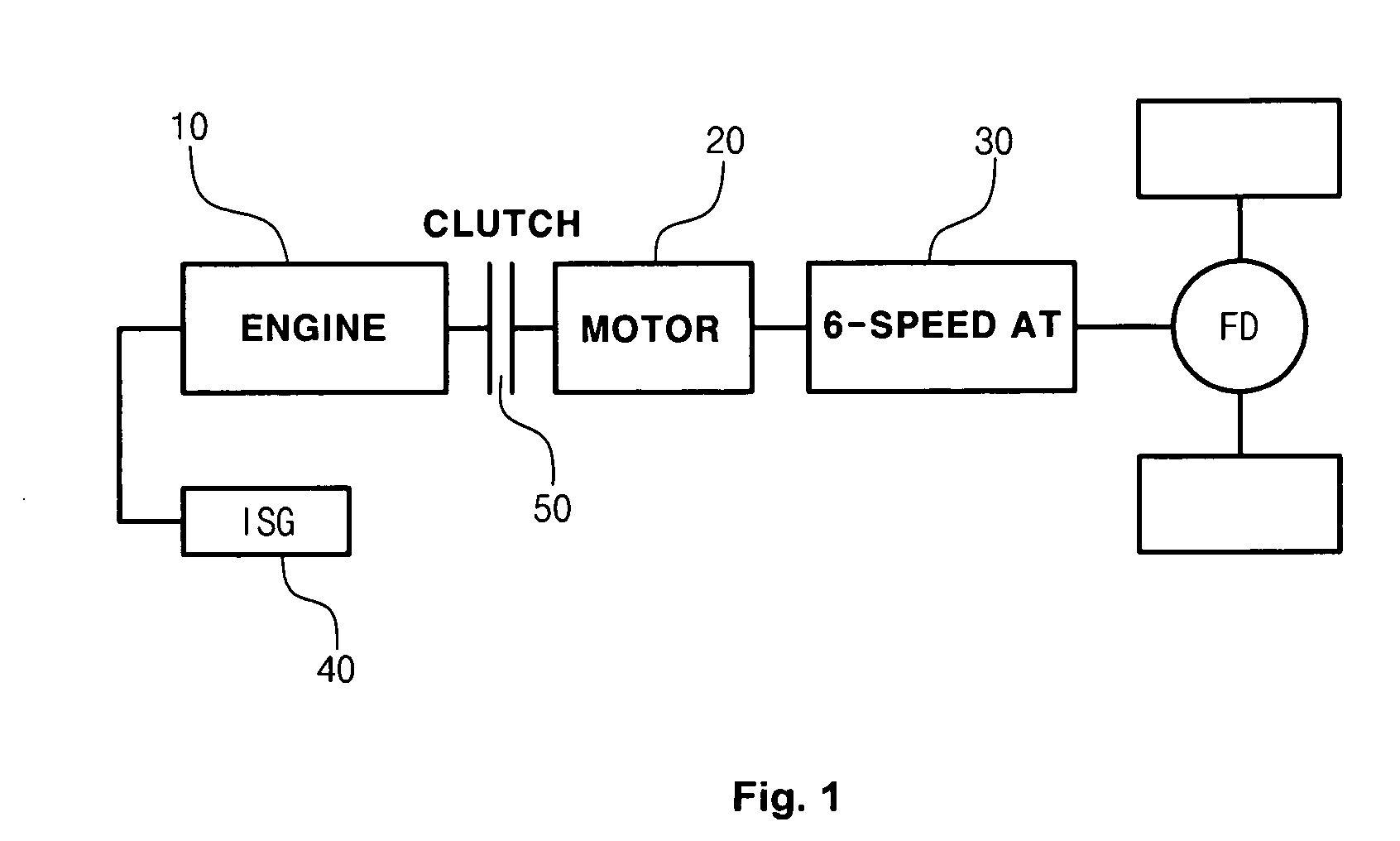

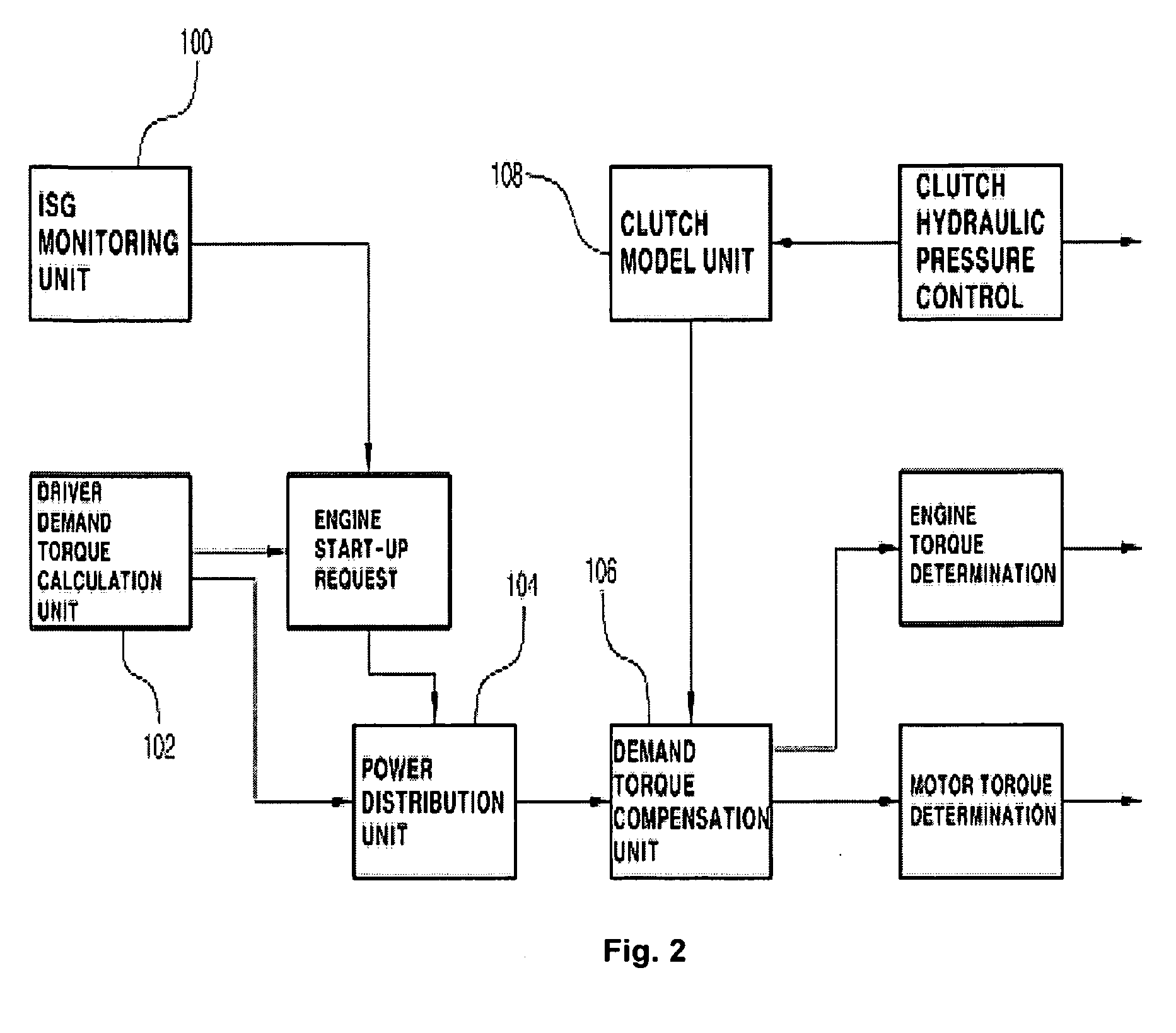

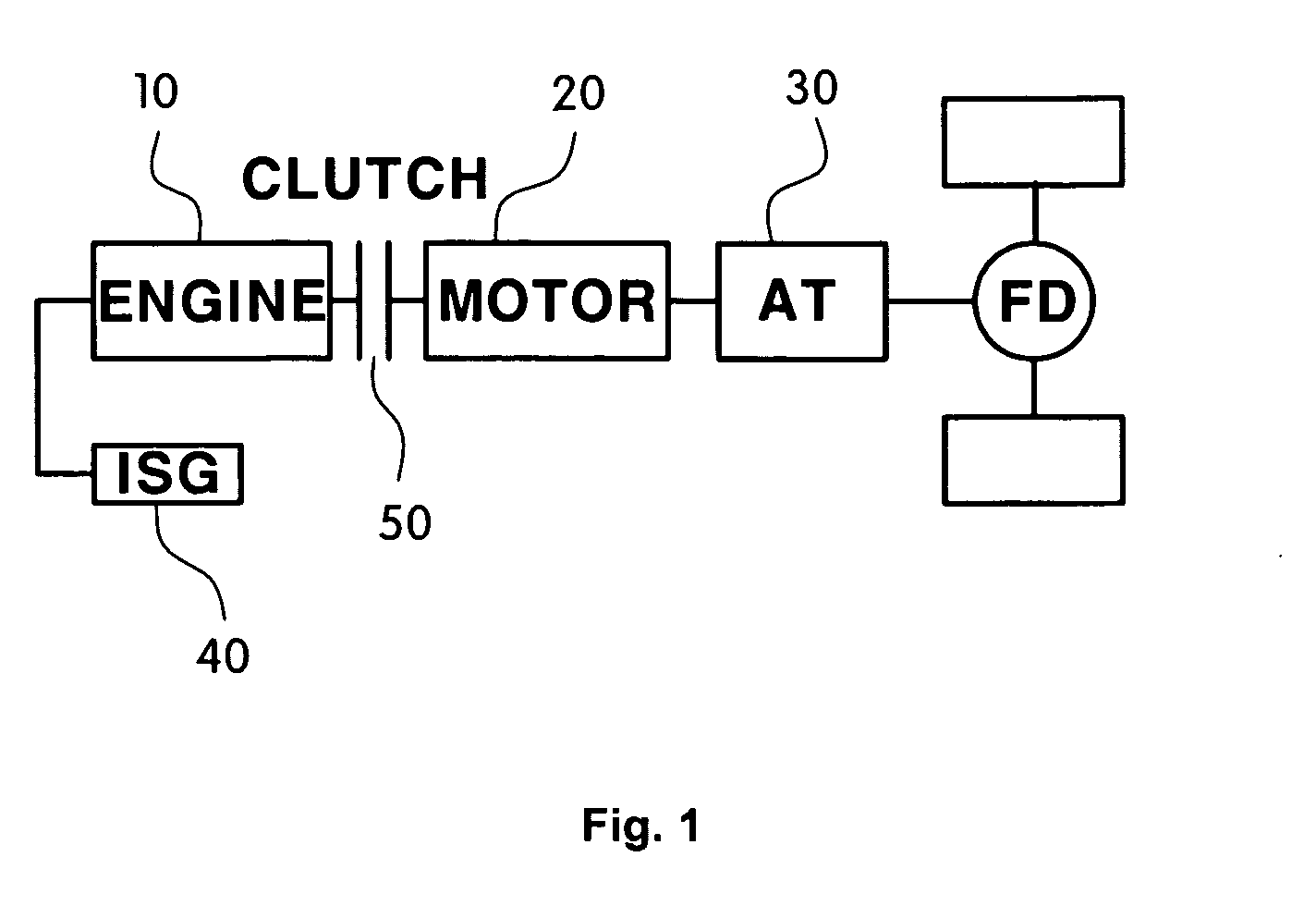

Torque control method for hybrid electric vehicle

ActiveUS20090234524A1Reduce hydraulic pressureInternal combustion piston enginesDigital data processing detailsStarter generatorDriver/operator

The present invention provides a torque control method for an HEV, the method comprising: detecting an operation failure of an integrated starter-generator (ISG); calculating a driver demand torque based on a current accelerator position sensor (APS); controlling the hydraulic pressure and operation of a clutch so as to increase an engine speed to convert the driving mode of the vehicle from electric vehicle (EV) mode to hybrid electric vehicle (HEV) mode in the event that an operation failure of the ISG is detected and the driver demand torque is out of a predetermined range; and compensating the driver demand torque to a desired level based on a transfer torque from the clutch to a motor. The method can improve driving performance and power performance of HEV, in the event of ISG failure, by performing a hydraulic control for a clutch and calculating a driver request torque and a transfer torque from the clutch to a motor to compensate the drive request torque to a desired level.

Owner:HYUNDAI MOTOR CO LTD +1

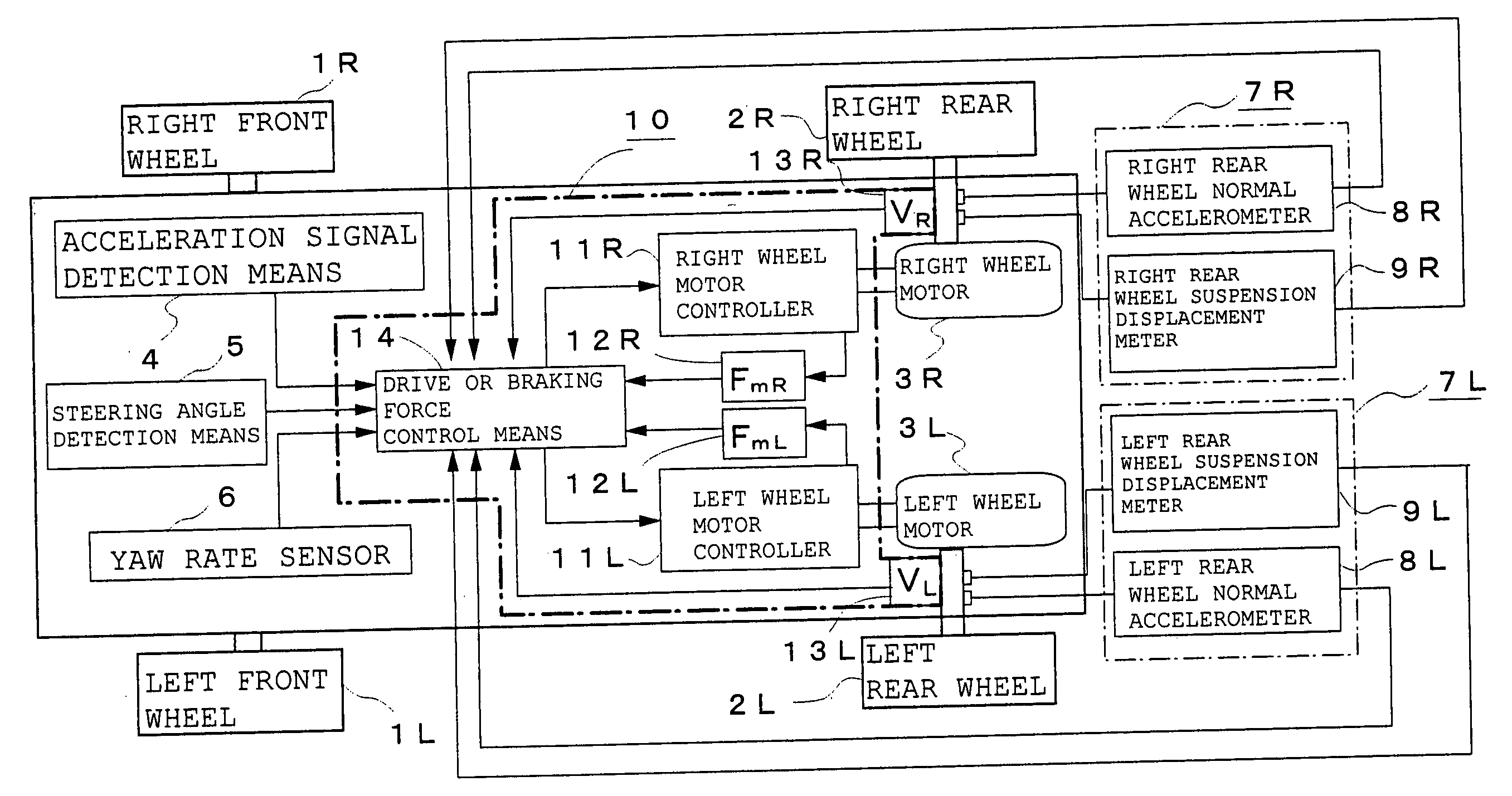

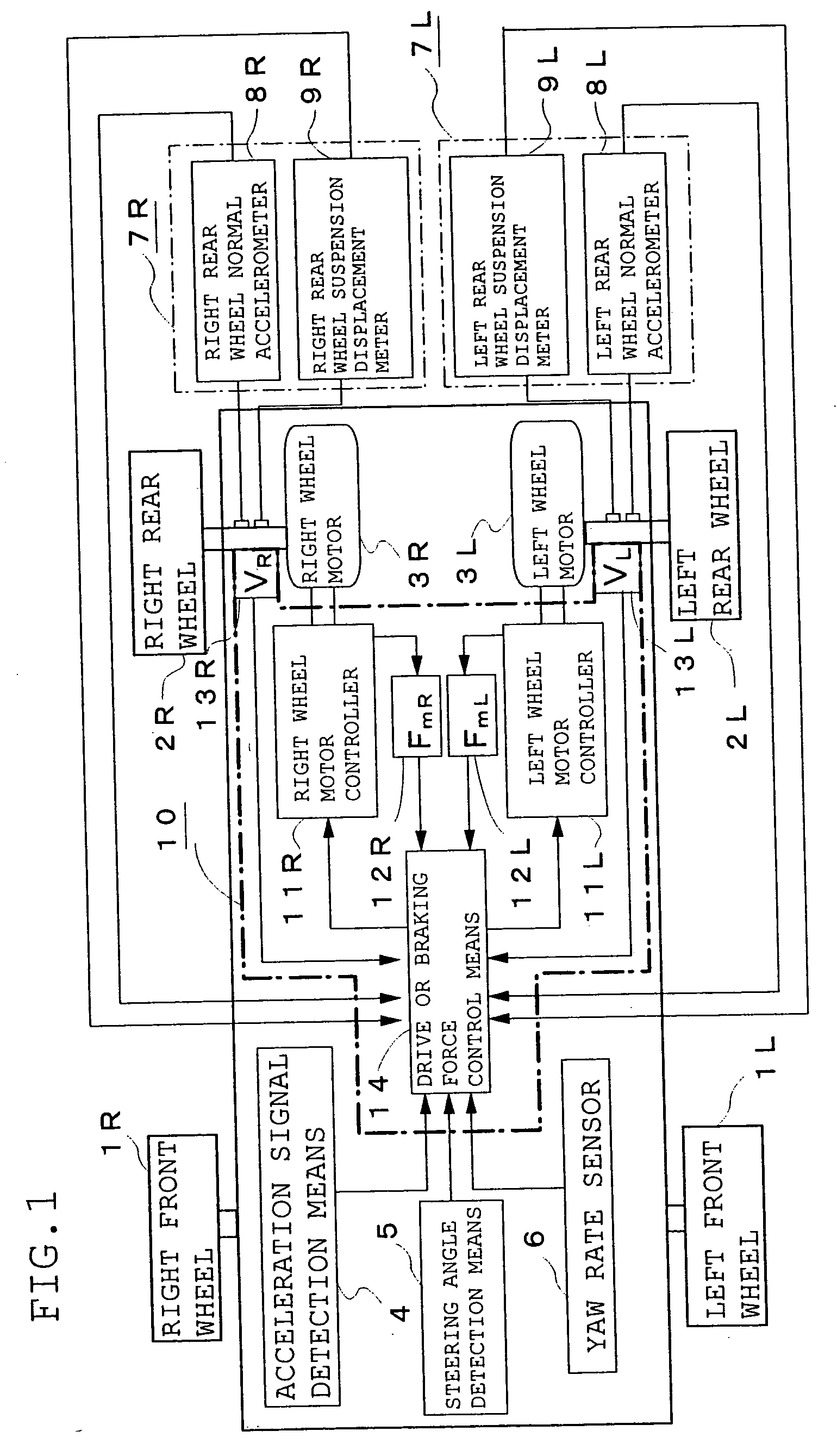

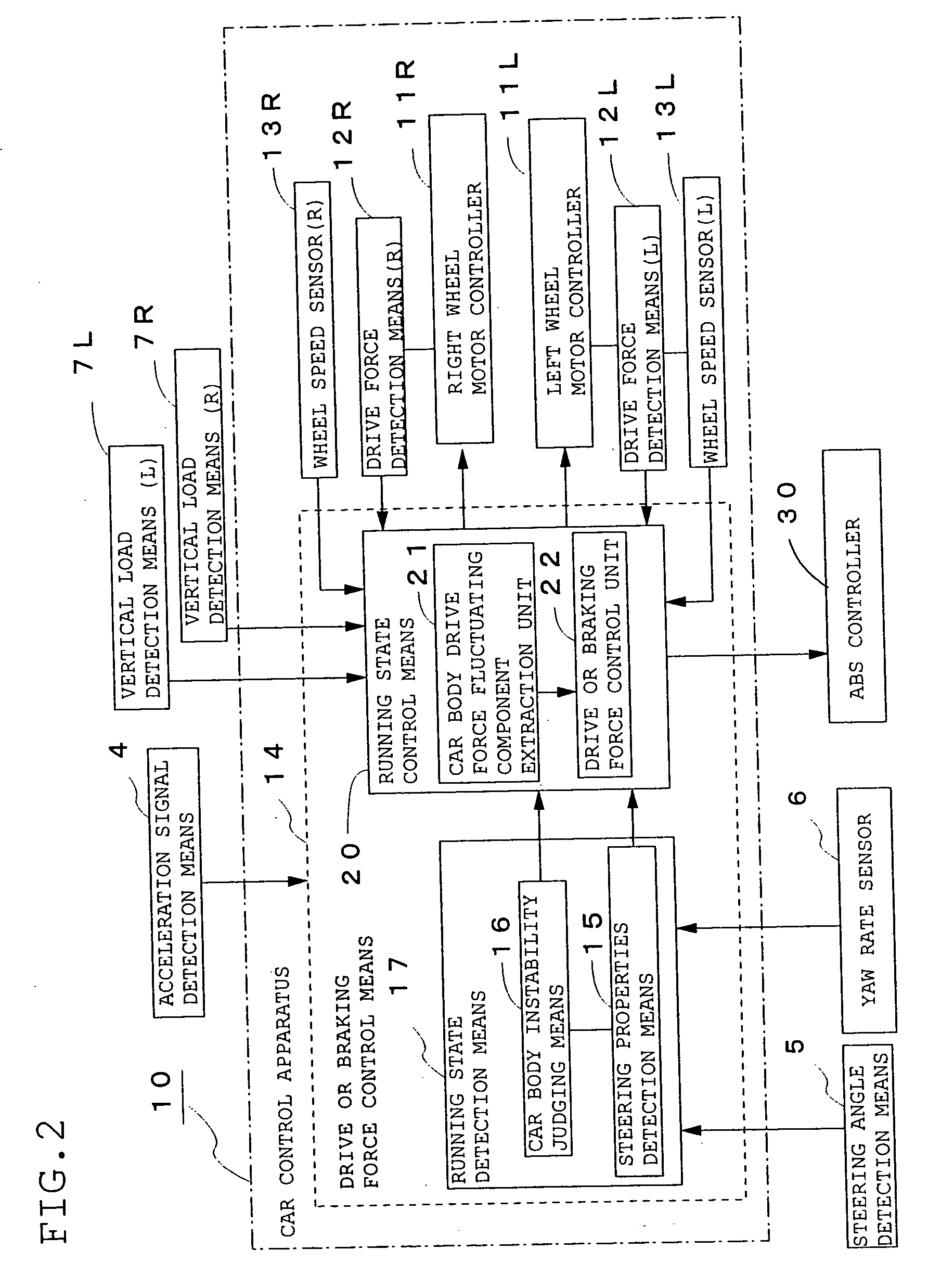

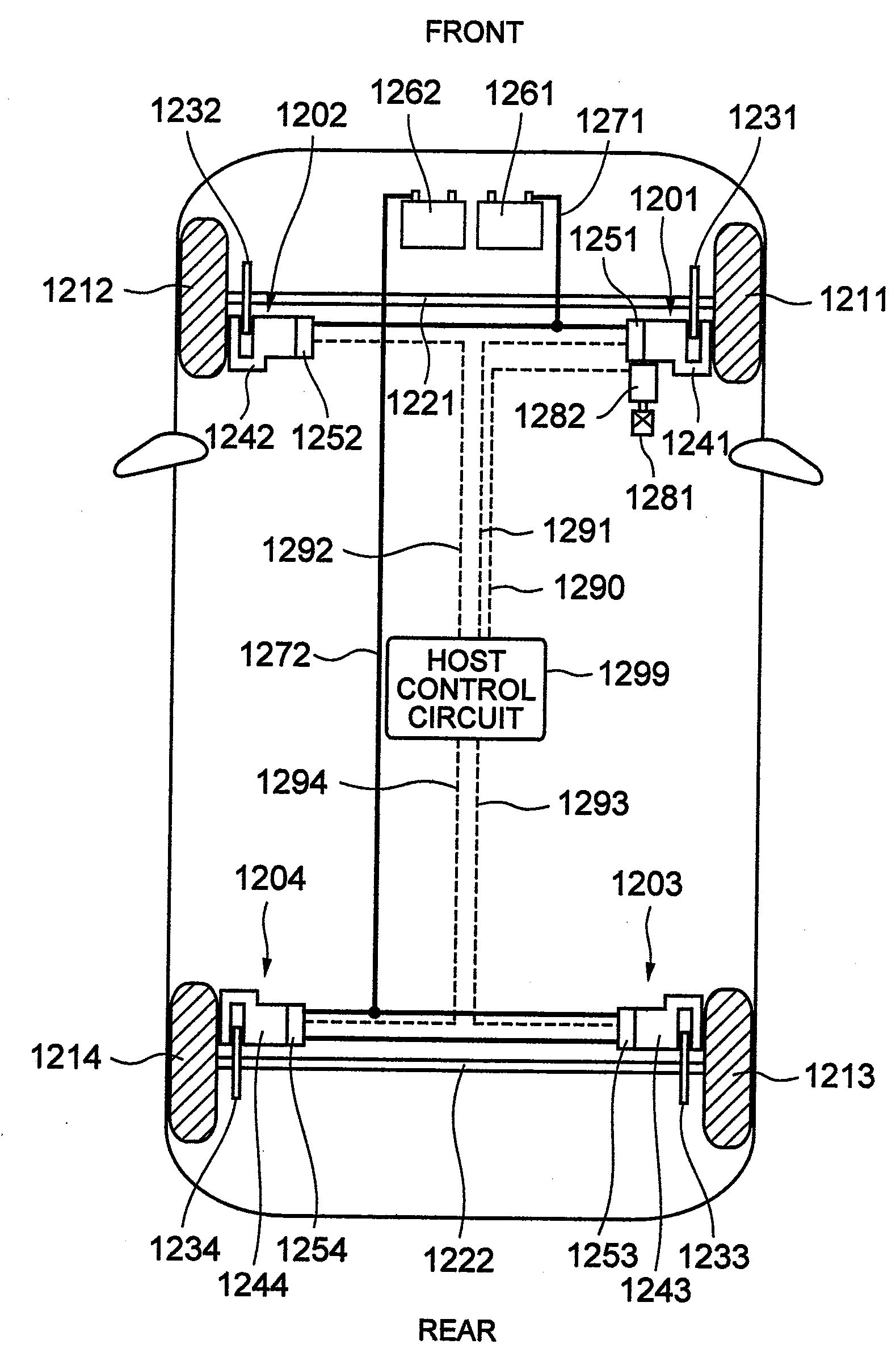

Method and device for controlling device

InactiveUS20050274560A1Eliminate vibrationReduce change levelDC motor speed/torque controlDc motor stoppersDrive wheelRoad surface

A car control apparatus comprising a wheel sensor 13, wheel torque calculating means 23 for calculating wheel torque from the wheel speed, drive force detecting means 12 for detecting drive force generated by an electric motor 3, car body drive force calculating means 24 for calculating car body drive force from the above drive force and wheel torque, car body drive force fluctuating component extracting means 25 for extracting multiple frequency band fluctuating components of the car body drive force, and drive or braking force control unit 22 for controlling the running state of a car, wherein drive or braking force to be applied to each wheel is obtained from main drive force, slip ratio control drive force and tire disturbance compensation drive force calculated based on the extracted fluctuating components of the car body drive force and supplied to a motor controller 11 to drive or brake the drive wheel 2 and apply micro-vibration to the tire in order to suppress micro-vibration generated between the tire and the road surface, thereby making it possible to improve the road holding properties of the tire and the driving stability of the car by compensating for disturbance applied to the tire.

Owner:BRIDGESTONE CORP

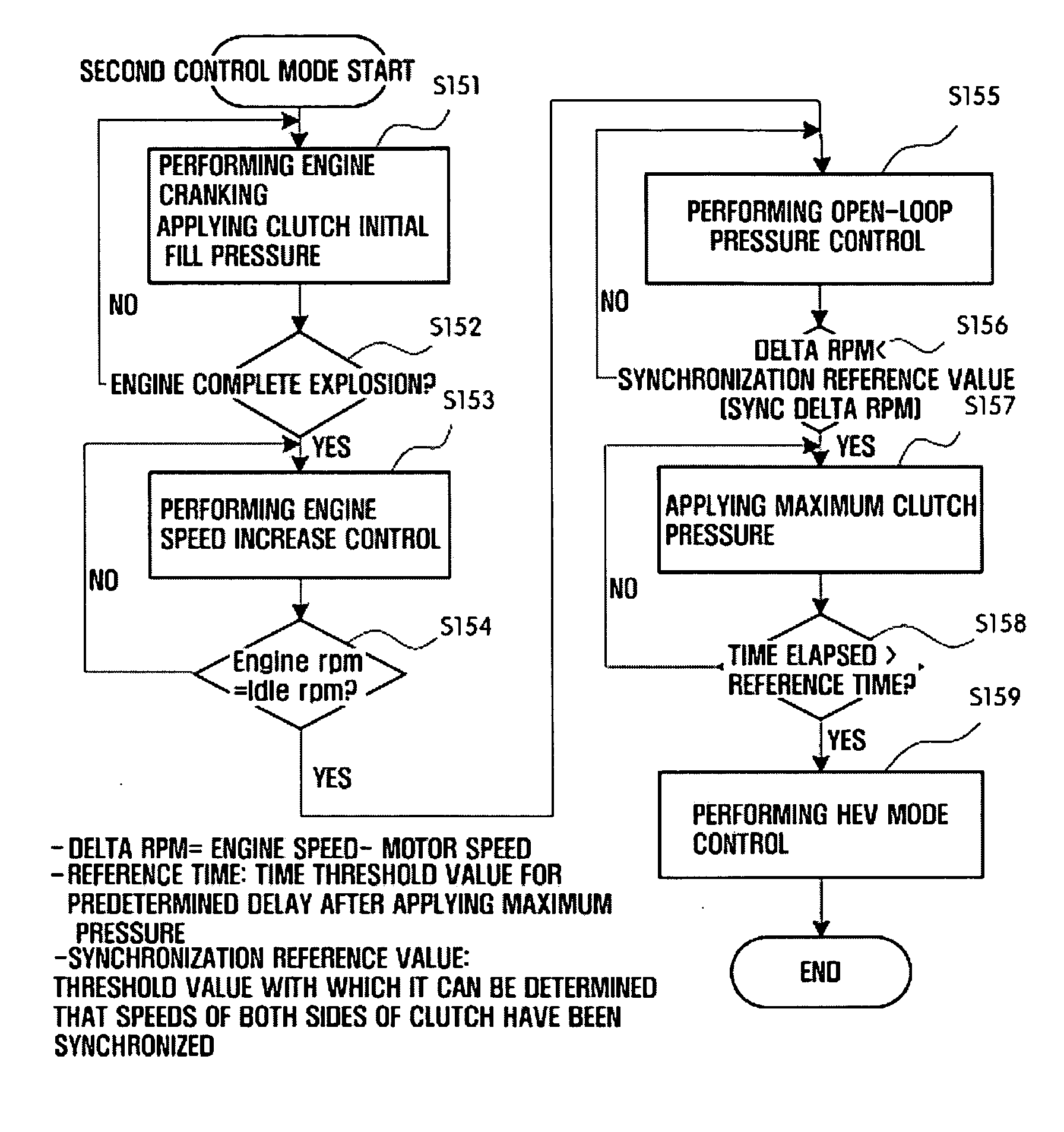

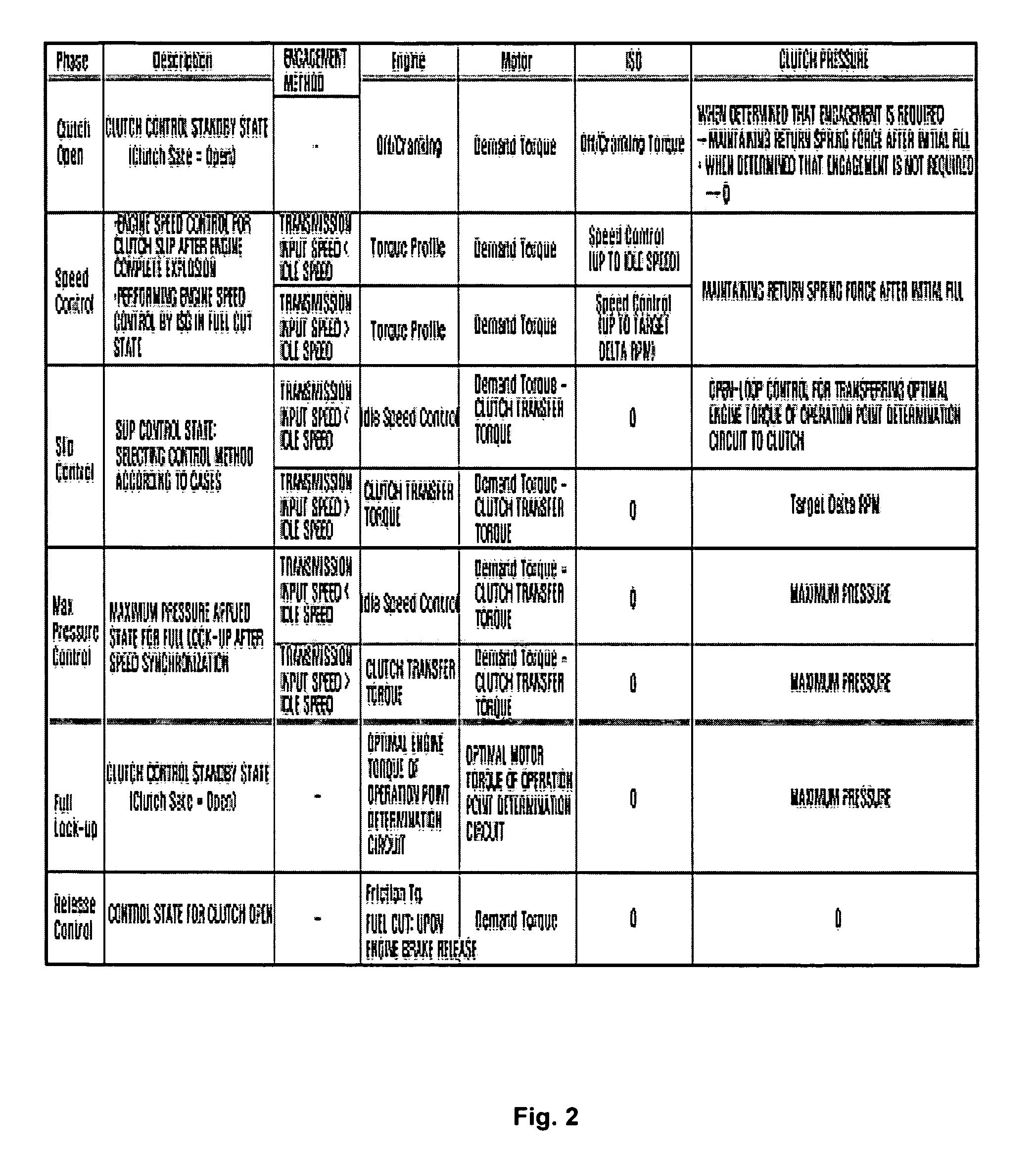

Mode change control method of hybrid vehicle

The present invention provides a mode change control method of a hybrid vehicle, which can improve driving performance and power performance and provide a more stable vehicle behavior control during a mode change from an EV mode to a HEV mode. For this purpose, a transmission input speed is compared with an engine idle speed. If the transmission input speed is lower than the engine idle speed, the pressure of a clutch is open-loop controlled so that an optimal engine torque of operation point determination circuit can be transferred to the clutch. On the other hand, if the transmission input speed is equal to or higher than the engine idle speed, the clutch pressure is feedback-controlled so that a delta RPM follows a target delta RPM profile.

Owner:HYUNDAI MOTOR CO LTD +1

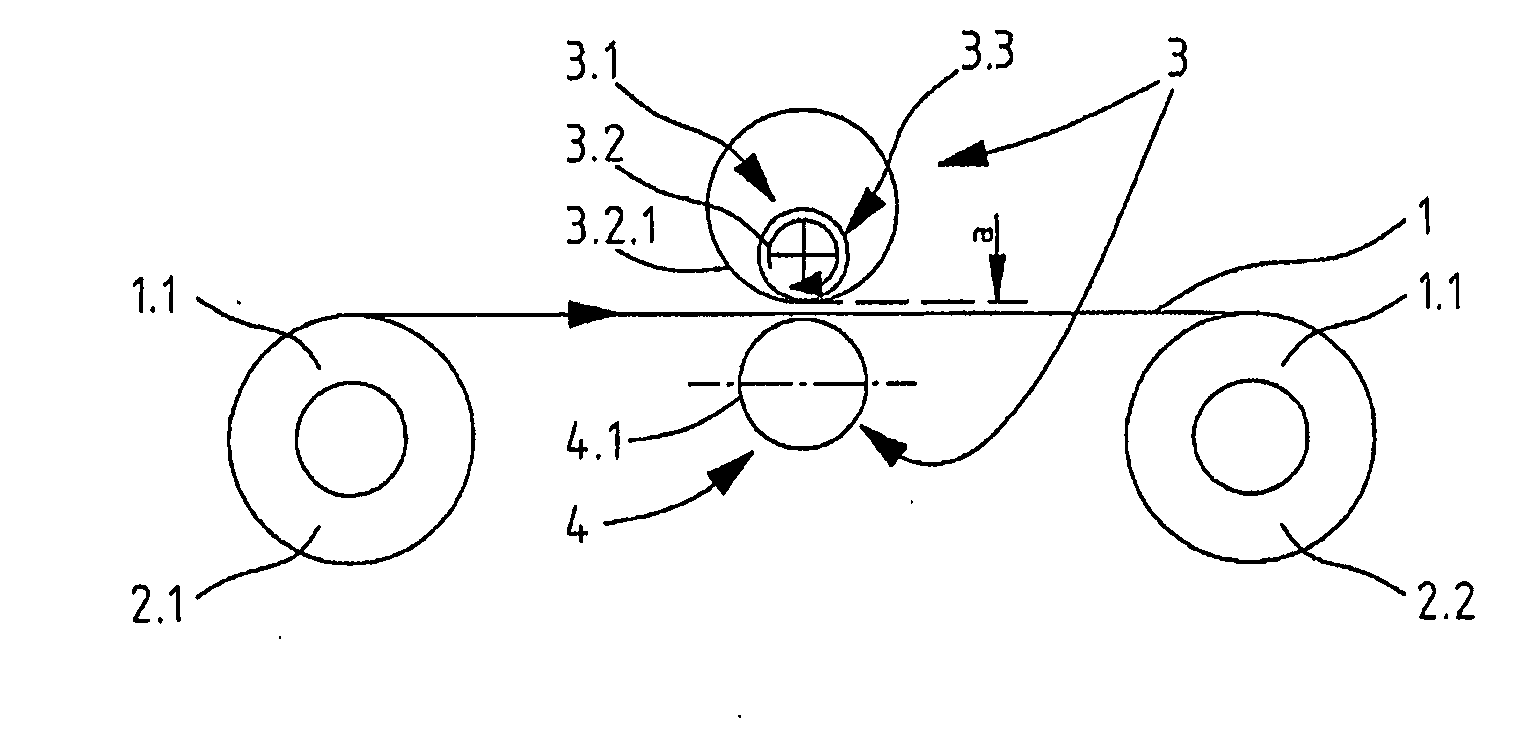

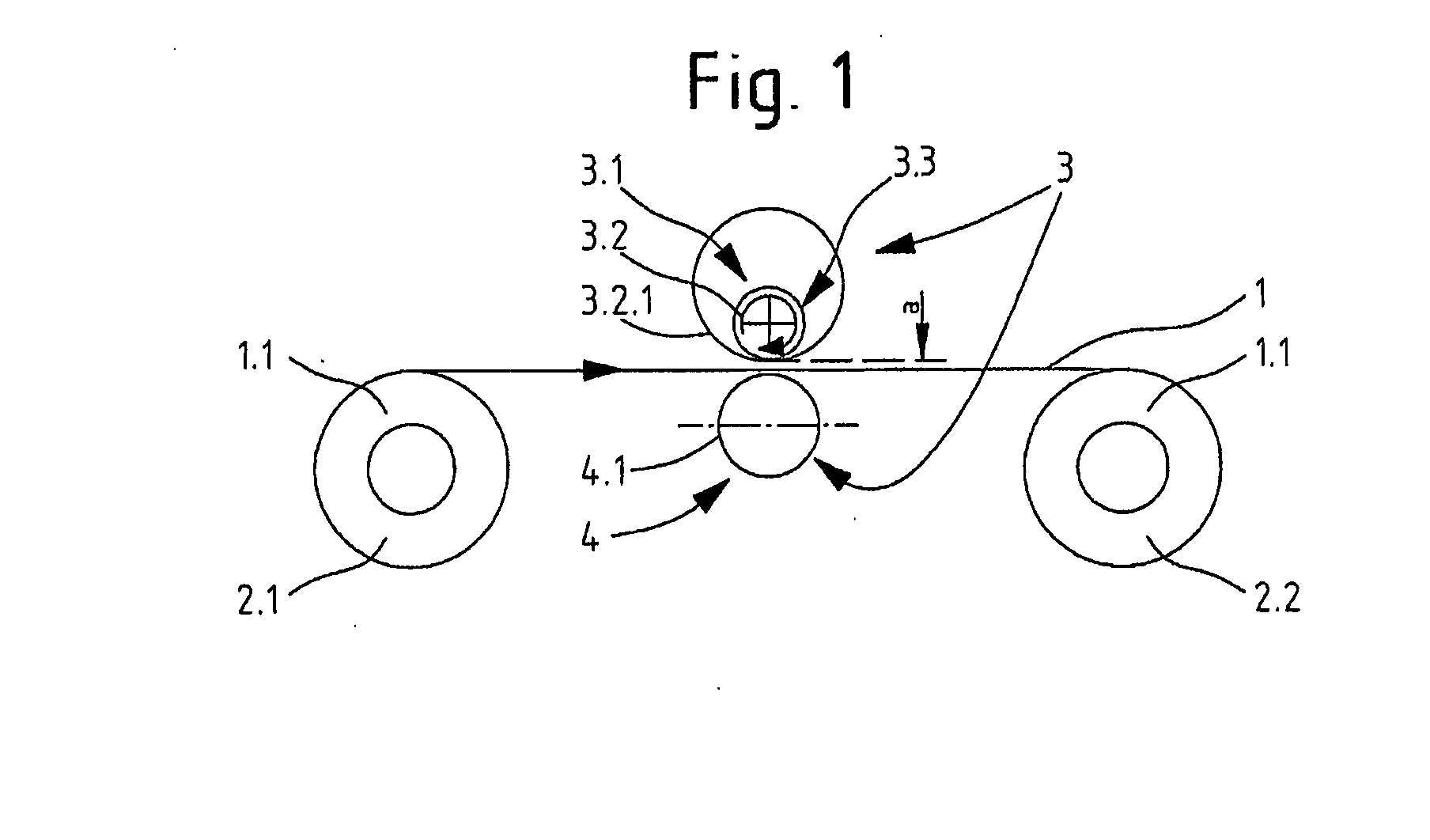

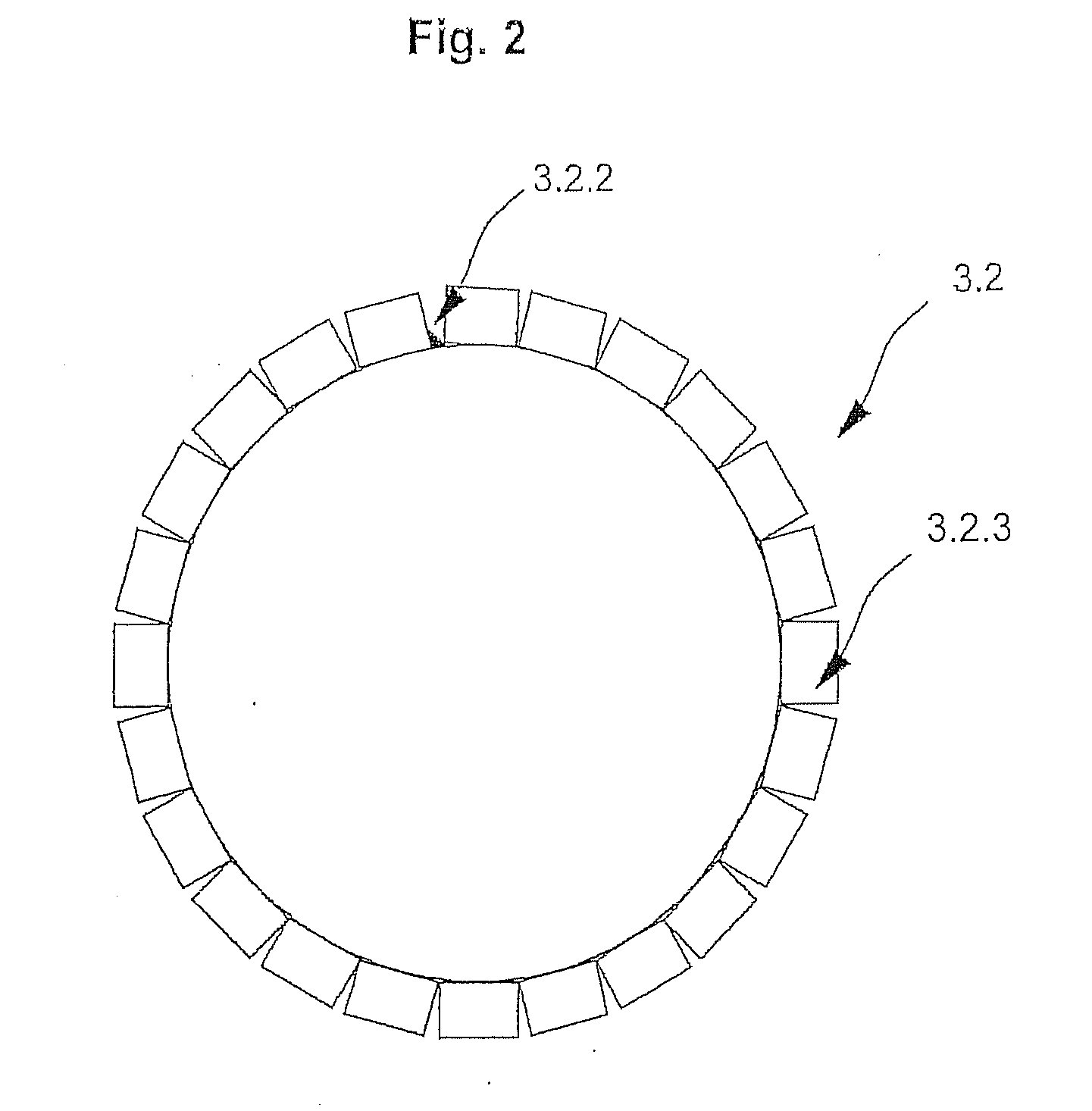

Method For Braking A Running Metal Strip And Unit For Carrying Out The Method

InactiveUS20090026303A1Simple designAC motor controlDigital data processing detailsEngineeringEddy current brake

The method and unit for braking a metal strip (1), running off a wind-out coiler (2.1) in the form of a coil (1.1) and running onto a wind-on coiler (2.2) again, are to guarantee that a surface of the metal strip remains undamaged and a full effective braking force is exerted on the metal strip (1) by means of an eddy current brake (3.1) with a rotating magnet system (3.2). The above is achieved, whereby the braking force is exerted on the metal strip (1) by means of an induced counter-torque against a support bearing (4) to one side in a non-contact manner, whereby the support bearing (4) may be embodied as a counter roller (4.1).

Owner:STEINERT ELEKTROMAGNETBAU

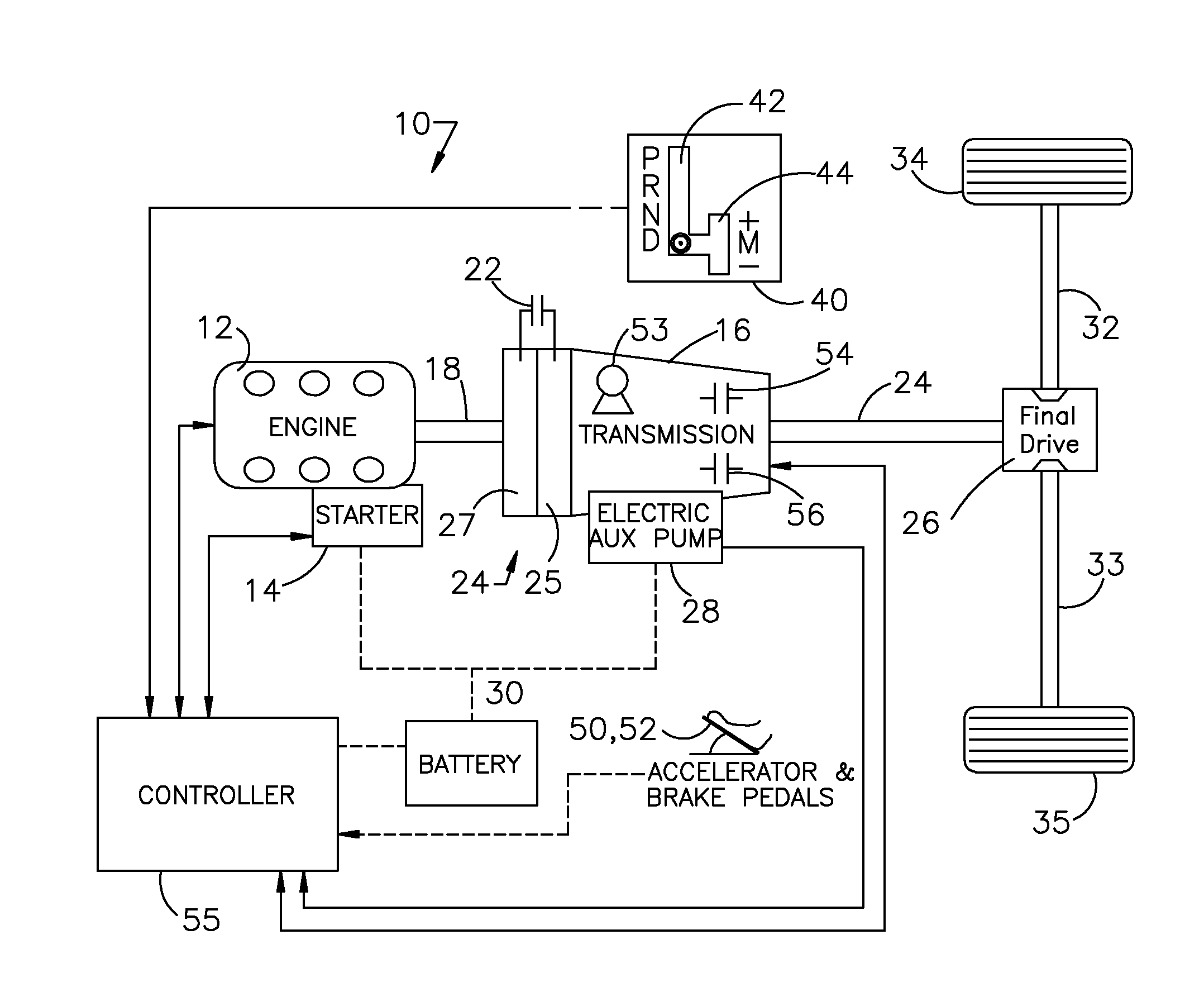

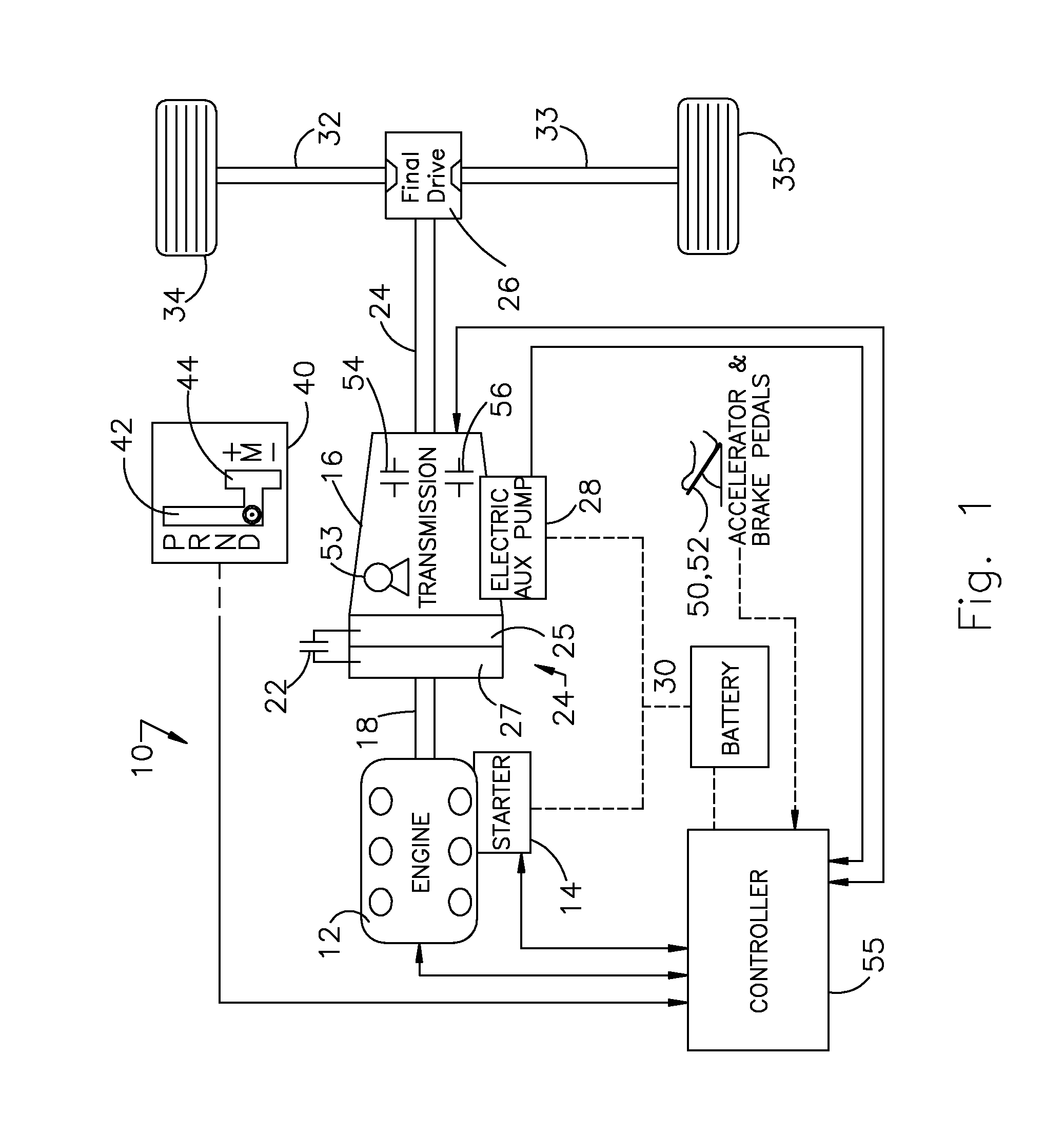

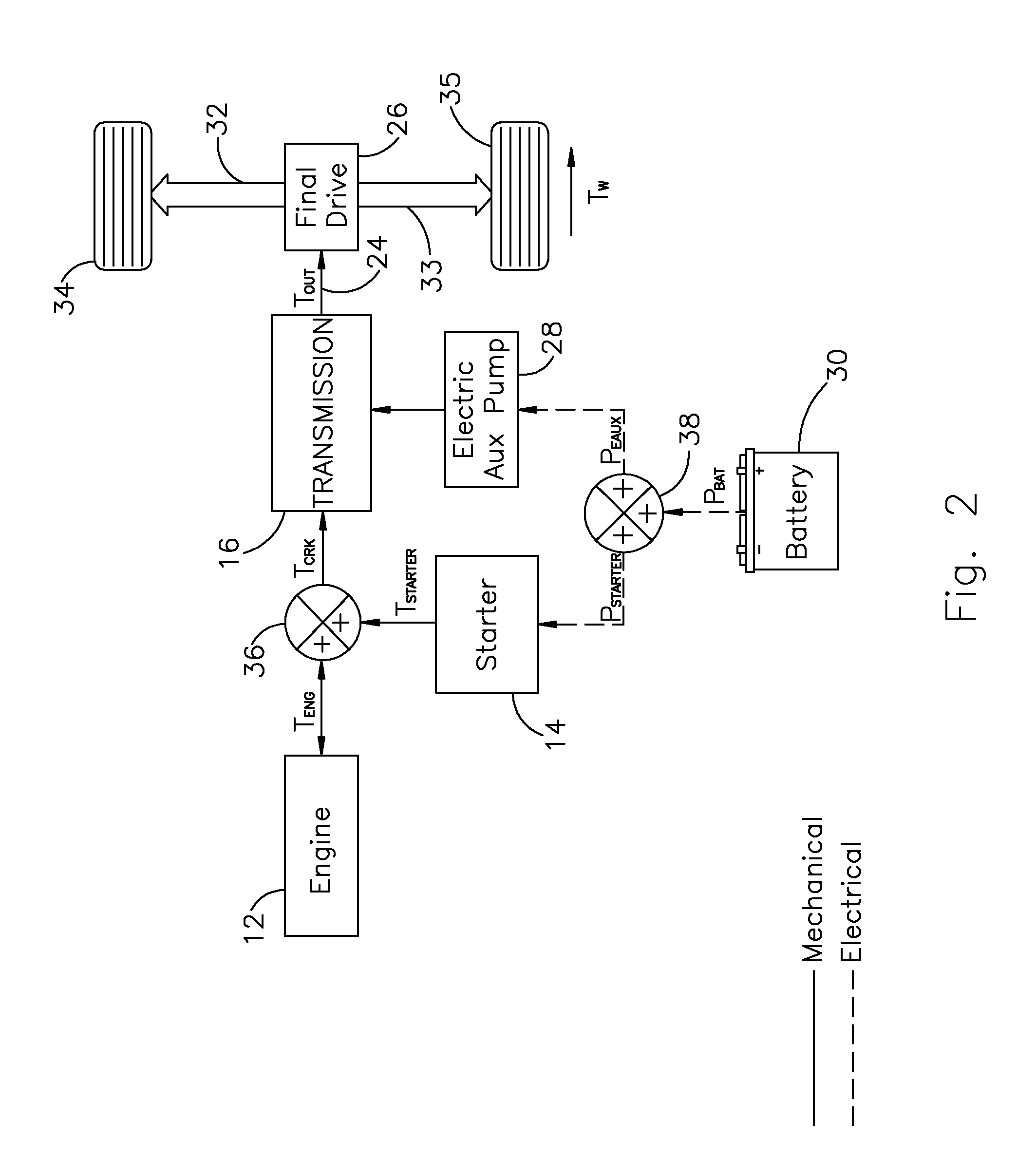

Control of an Engine Restart in a Hybrid Electric Vehicle

ActiveUS20110070999A1Improve controlAvoid uneven performanceHybrid vehiclesElectric motor controlElectric vehiclePowertrain

A method for restarting an engine in a hybrid electric powertrain includes using an auxiliary pump while the engine is shutdown to maintain stroke pressure in an oncoming transmission friction control element whose engagement is required to launch the vehicle following the restart, initiating an automatic engine restart, increasing a torque capacity of the control element while the engine is restarting, and using pressure produced by a transmission pump in the transmission to lock the control element after the engine restarts.

Owner:FORD GLOBAL TECH LLC

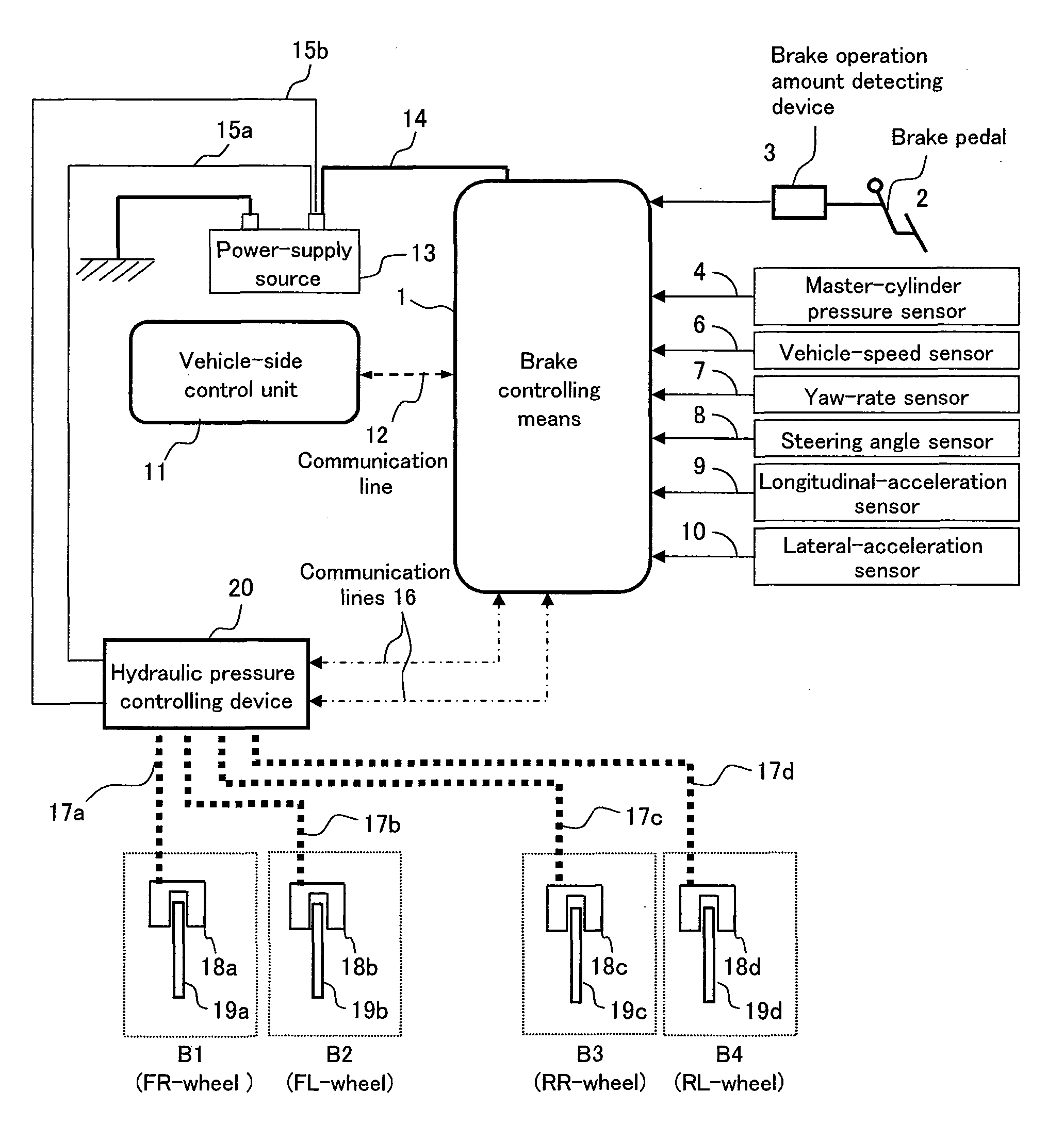

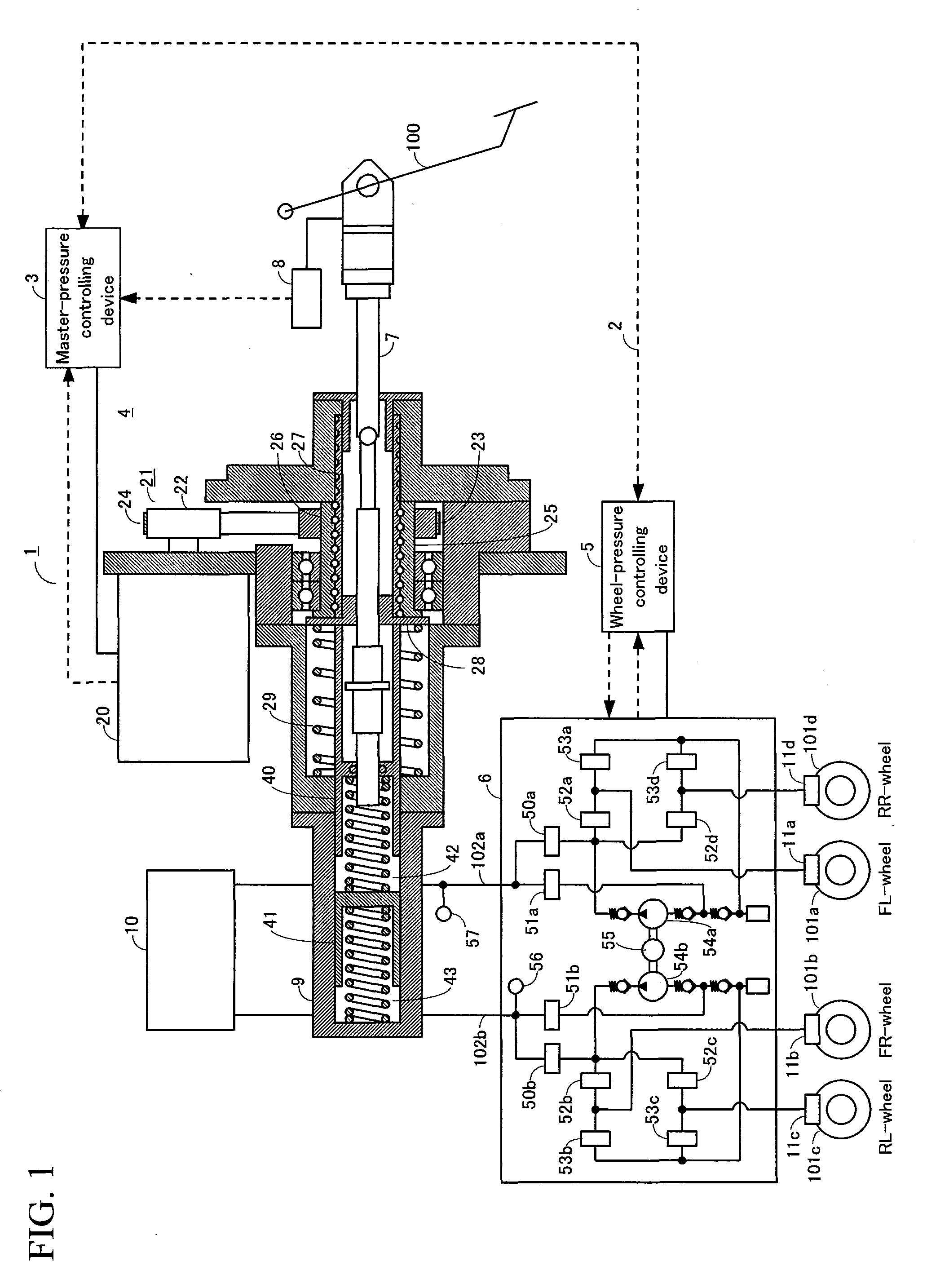

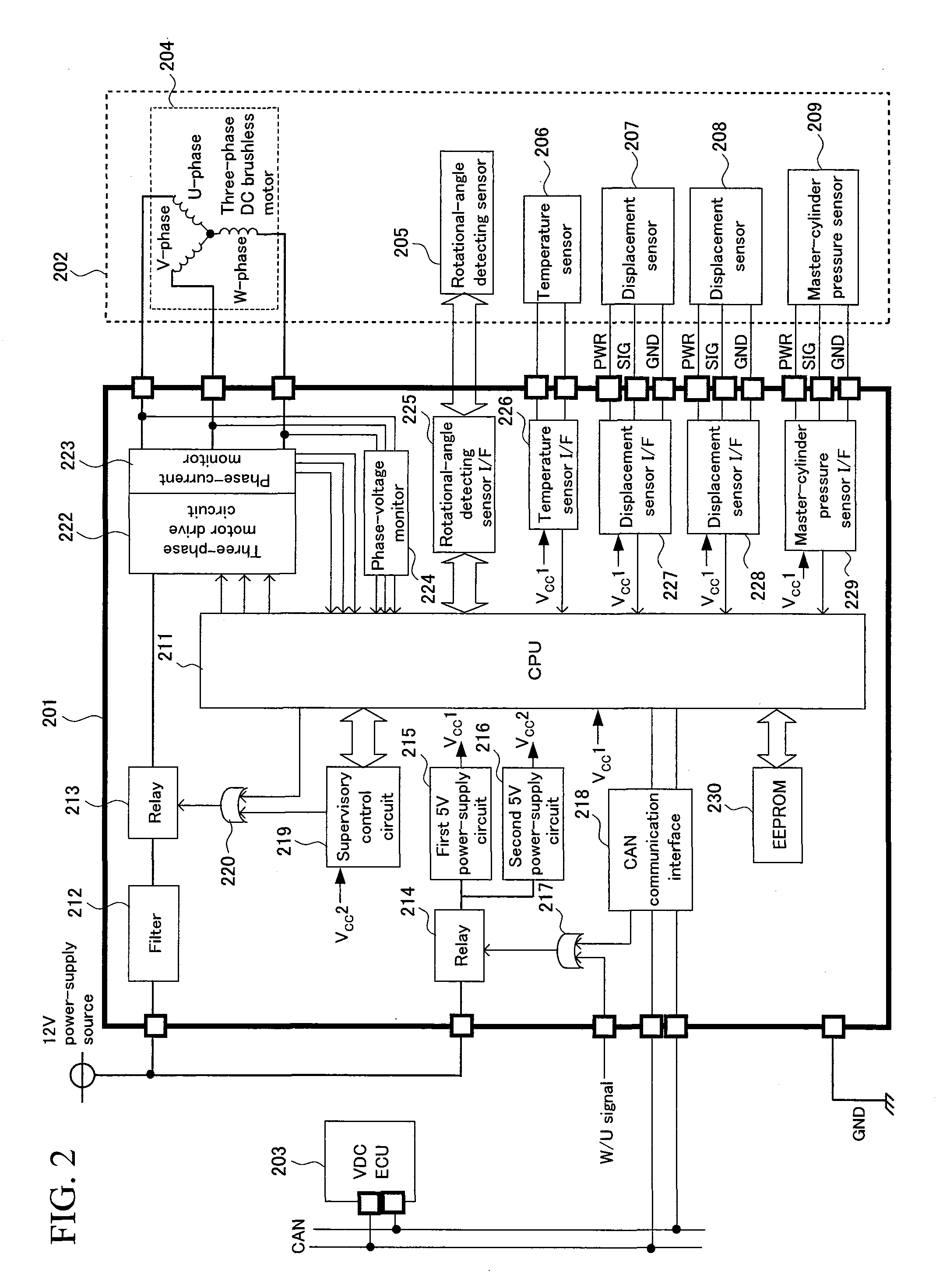

Brake Control System

ActiveUS20100062897A1Reduction in wasteful electric-power consumptionLow heat generationBraking element arrangementsDynamo-electric converter controlDriver/operatorControl system

Provided is a brake control apparatus for a vehicle which detects an amount of brake-pedal operation by means of an electric signal, and then calculates a braking force demanded by a driver from the electric signal, and thereby generates the demanded braking force. A control mode for a braking force is switched from a normal control mode to a stationary-vehicle control mode, if a determination that the vehicle is in a stationary state is followed by another determination that an electric signal corresponding to an actual braking force exceeds a command value for a stationary-vehicle braking force while the vehicle is in the stationary state. The control mode for a braking force is switched from the stationary-vehicle control mode to the normal control mode, if it is determined that the demanded braking force becomes smaller than the command value for the stationary-vehicle braking force. In addition, in the stationary-vehicle control mode, a braking force generated by a means for braking is equal to the command value for the stationary-vehicle braking force, whereas, in the normal control mode, the braking force generated by the means for braking is equal to the braking force demanded by the driver.

Owner:HITACHI ASTEMO LTD

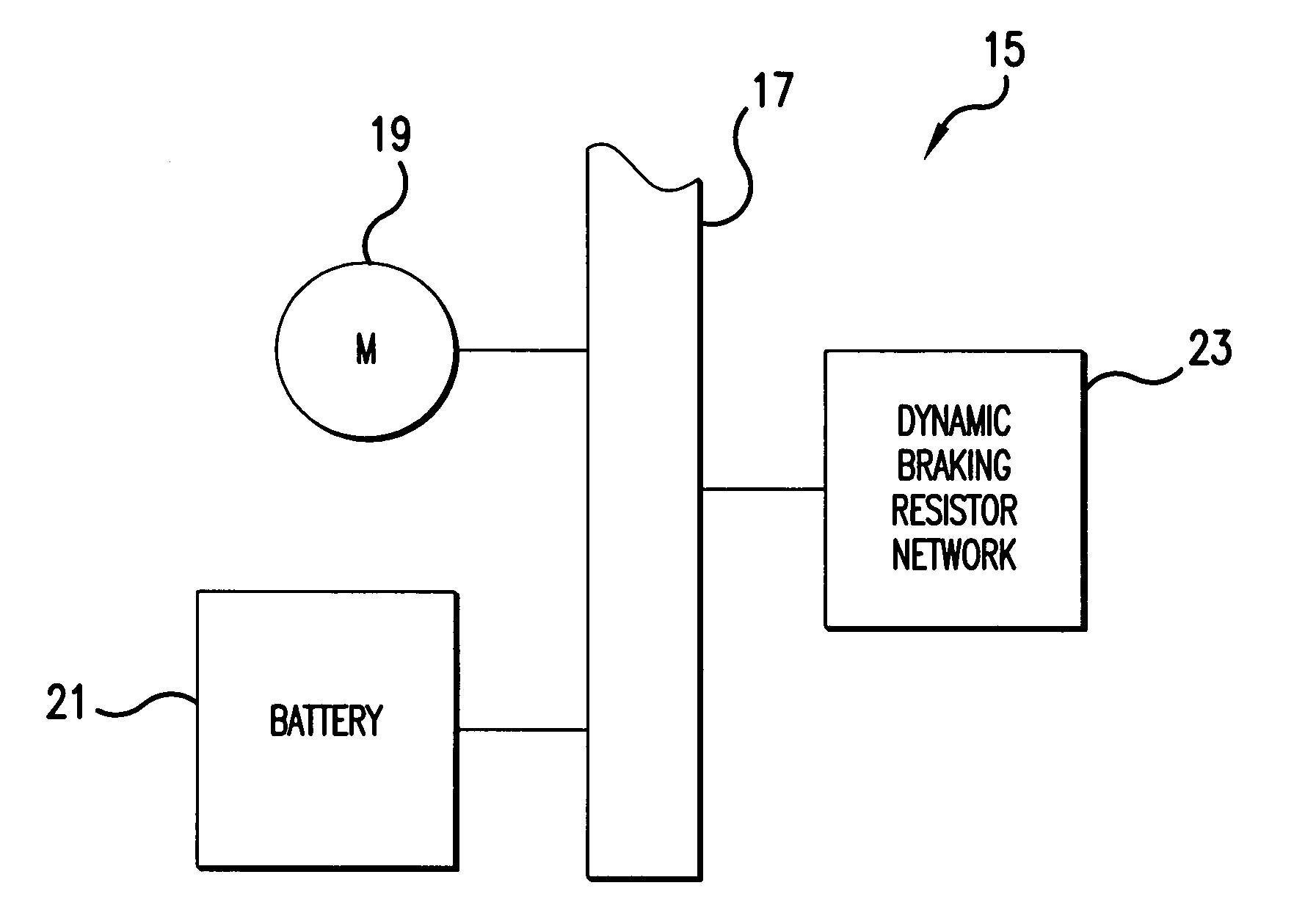

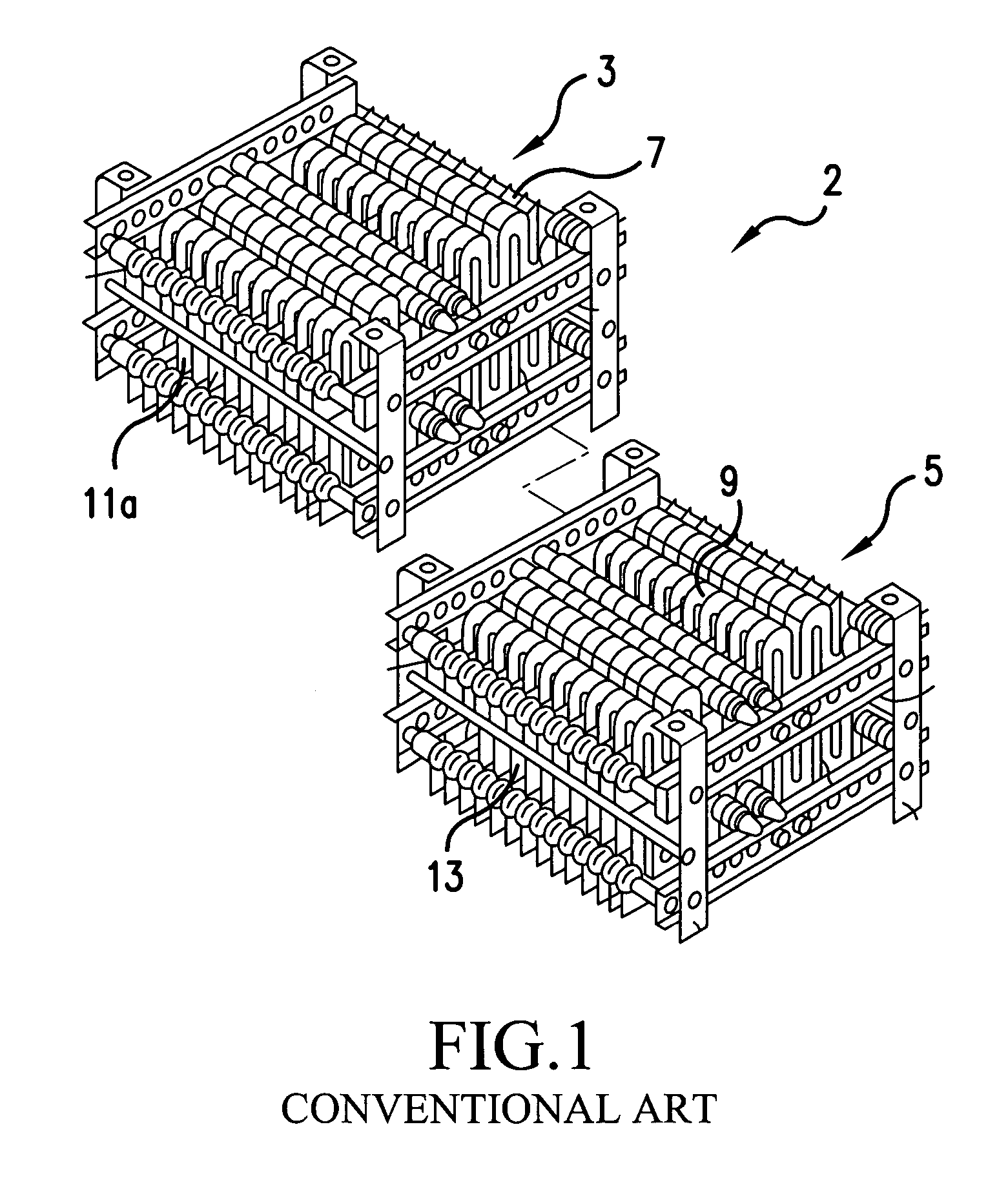

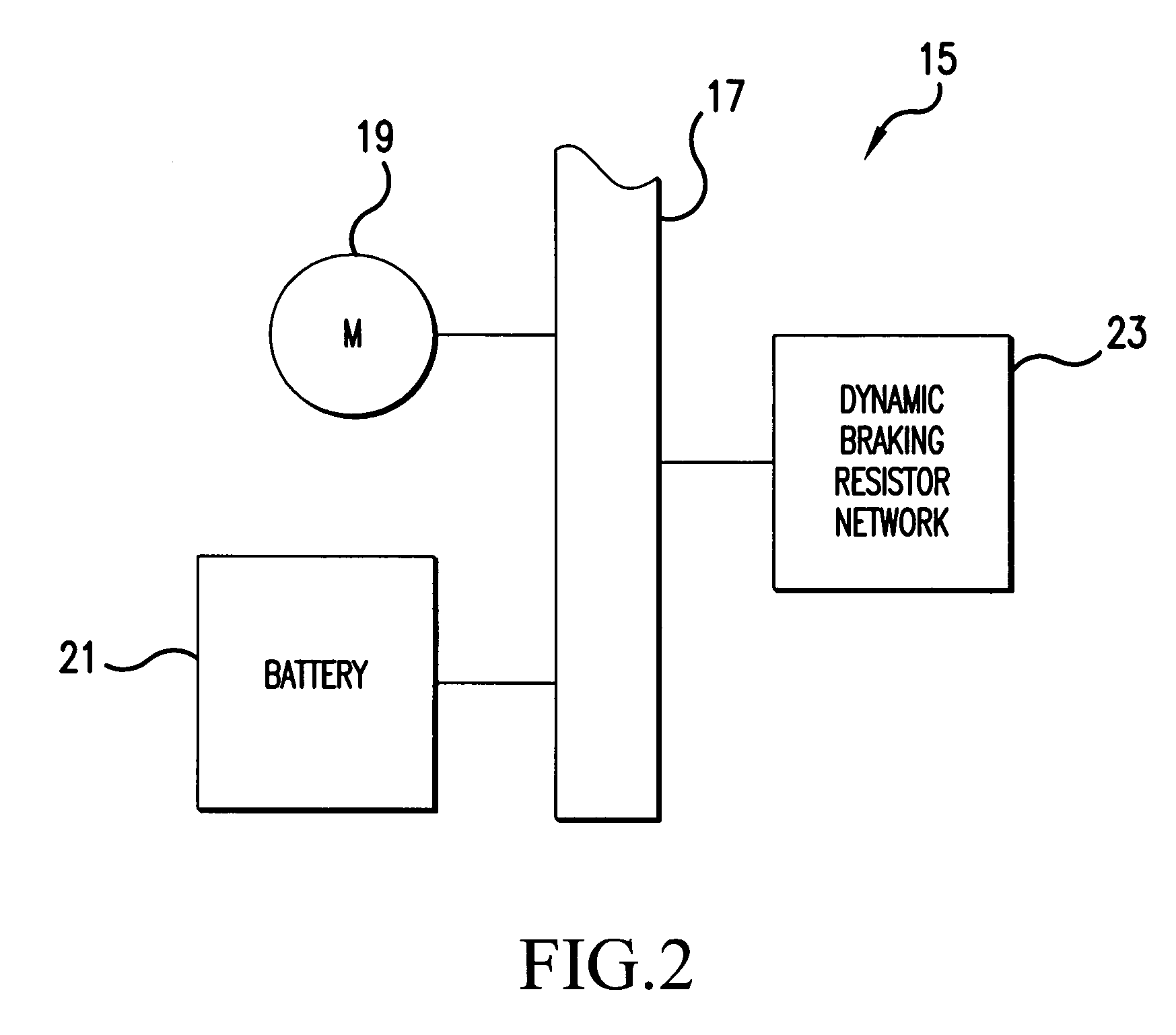

Multi-stage dynamic braking resistor network

A multi-stage dynamic braking resistor network (23) is provided that includes a plurality of dynamic brake resistors (1a–d) for dissipating, as heat, regenerative energy inputted onto a system bus (17) by a motor or actuator (19), and a plurality of switches (31a–d) for connecting the dynamic brake resistors (1a–d) to and from the system bus (17), respectively. The multi-stage dynamic braking resistor network (23) further includes a control circuit (25) for controlling the switches (31a–d) such that the dynamic brake resistors (1a–d) are connected to and from the system bus (17) on the basis of a predetermined voltage threshold of the system bus and on the basis of a predetermined rotation pattern.

Owner:HONEYWELL INT INC

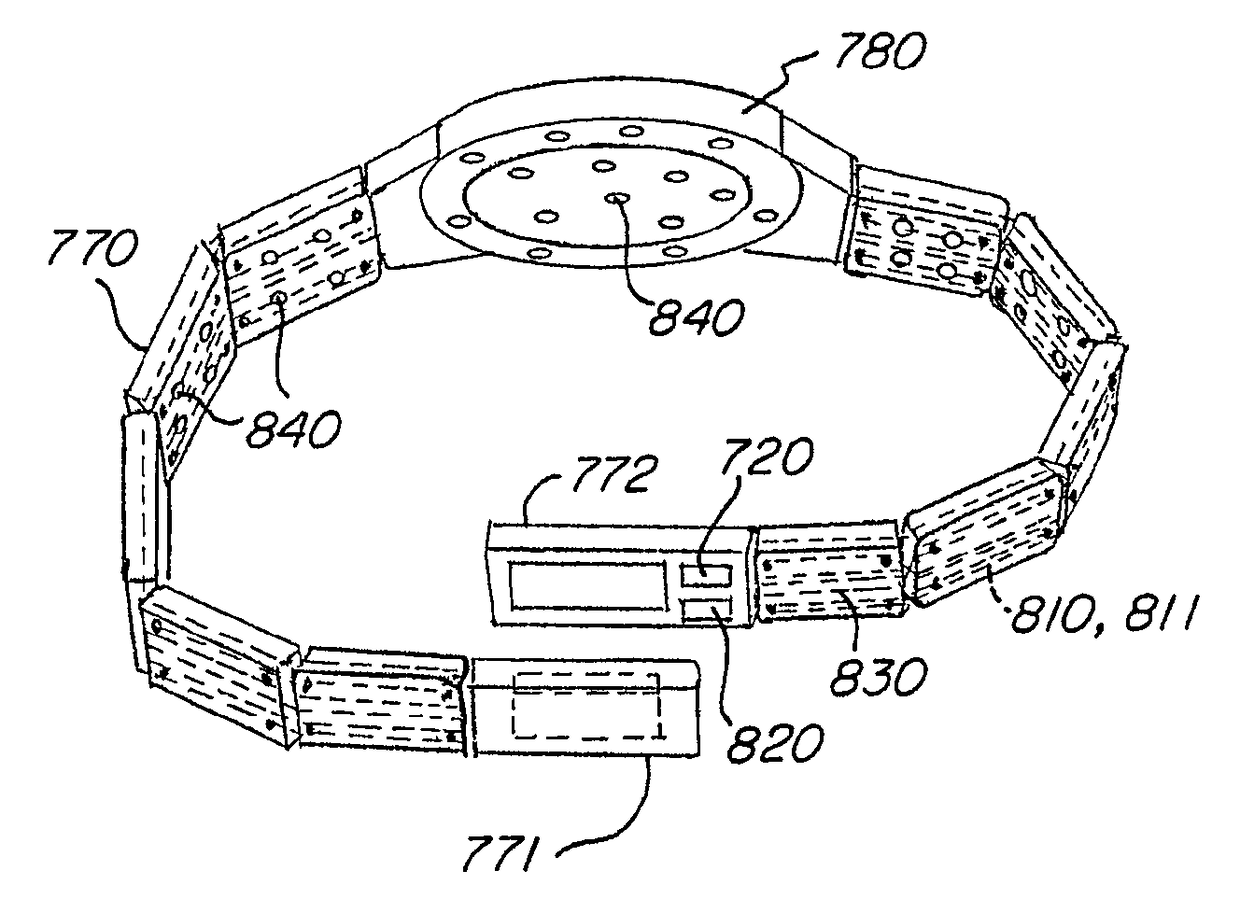

Self-fitting, self-adjusting, automatically adjusting and/or automatically fitting magnetic clasp

ActiveUS9609921B1Simple one handSimple hand free operationShielding materialsMachine supportsEngineeringBiological activation

Provided is an automatically adjustable clasp having two separable magnet pieces which may magnetically adhere to each other to form a closed clasp. The clasp also includes a motor, an anchor mechanism for attaching the clasp to a band, sensors, and a control unit. The sensors acquire and send information related to the clasp or the band to the control unit, which may activate the motor. The activation of the motor changes the position of the anchor mechanism with respect to the rest of the clasp, thereby loosening or tightening of the band attached to the anchor mechanism. Also provided is a wearable band with the automatically adjustable clasp. The wearable band may include a shape memory material such that the band may self-assemble around a body part when a stimulus is applied to the shape memory material. The self-assembly process may enable the automatic clasp of the magnet pieces.

Owner:FEINSTEIN PATENTS

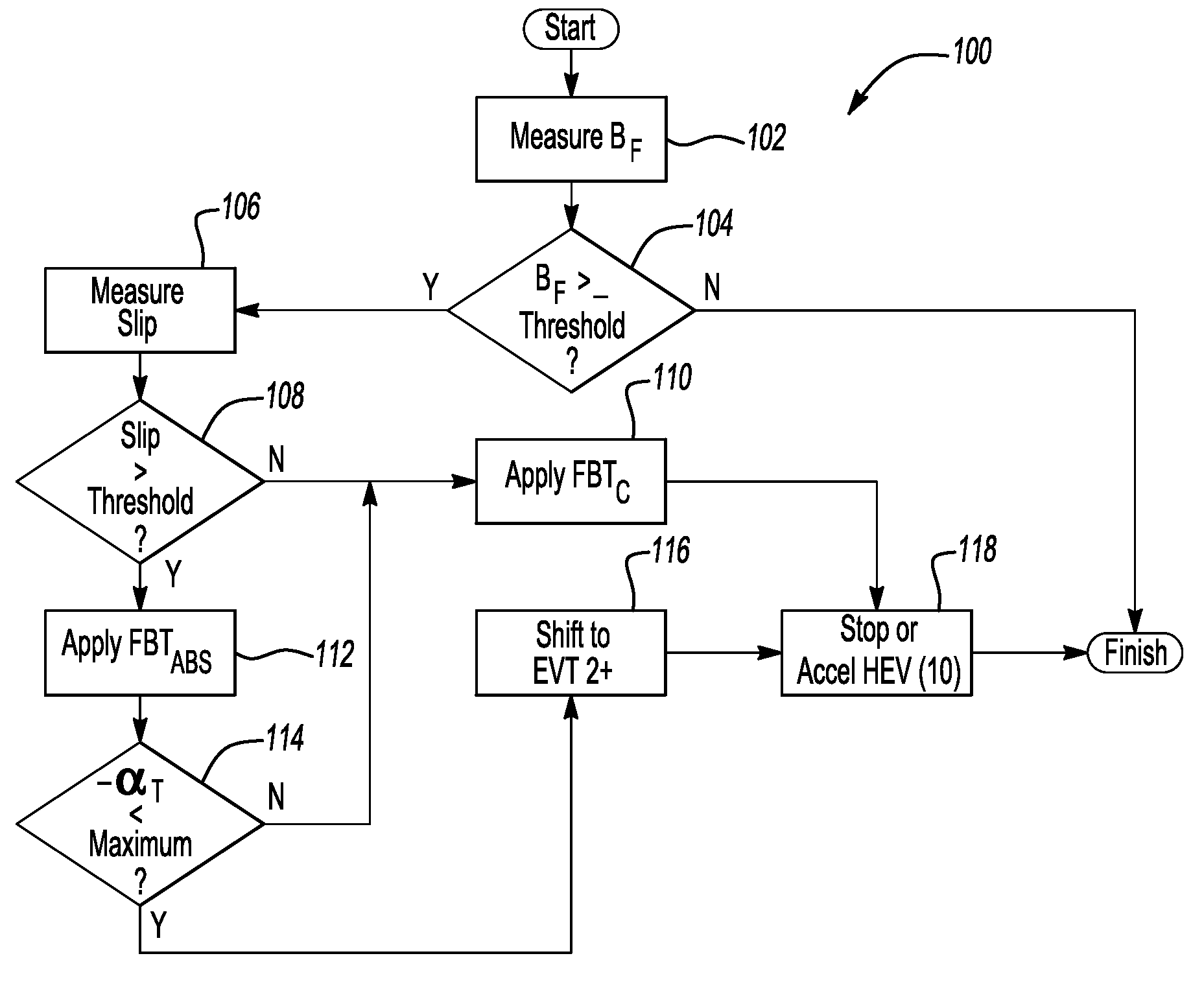

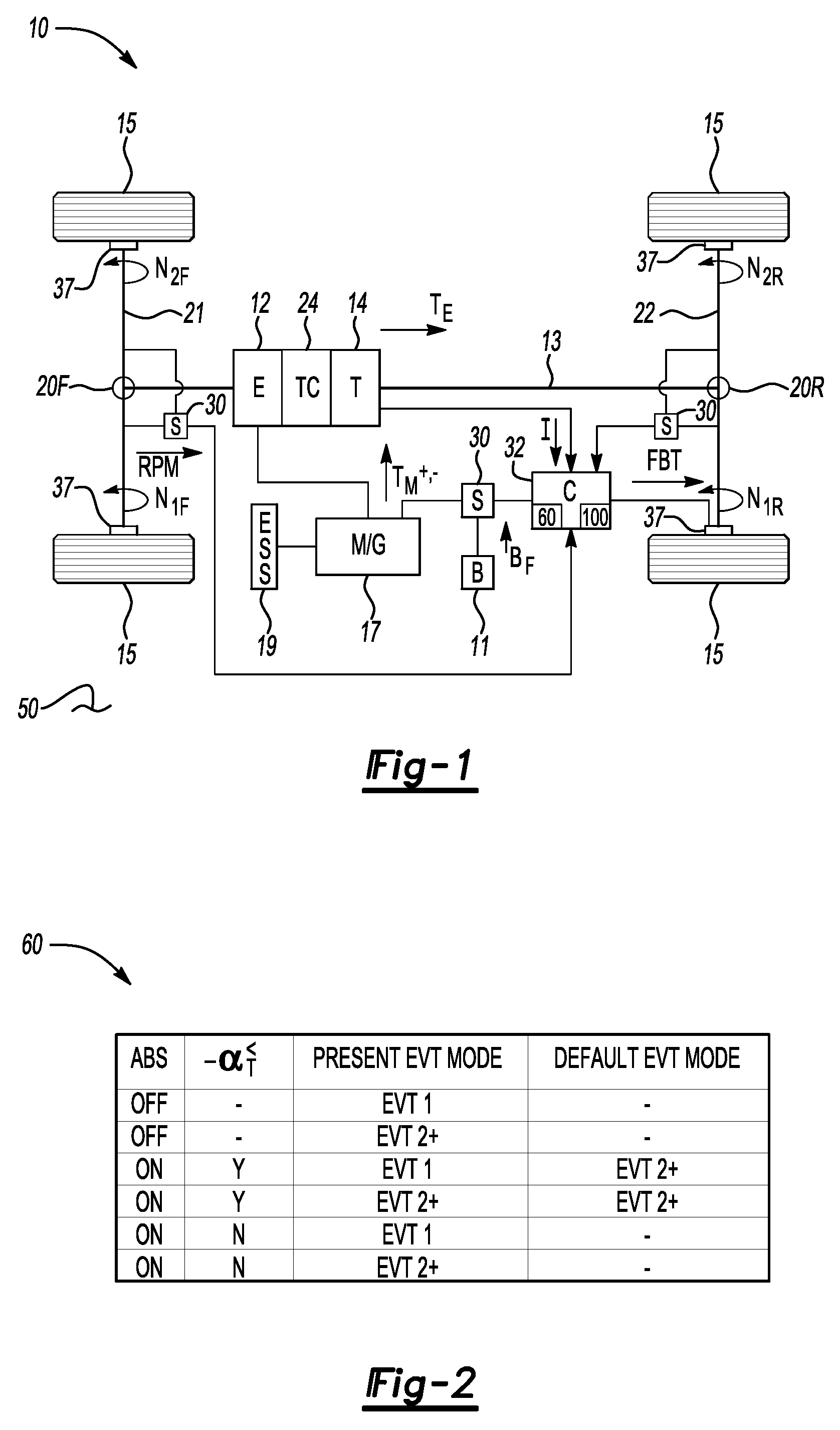

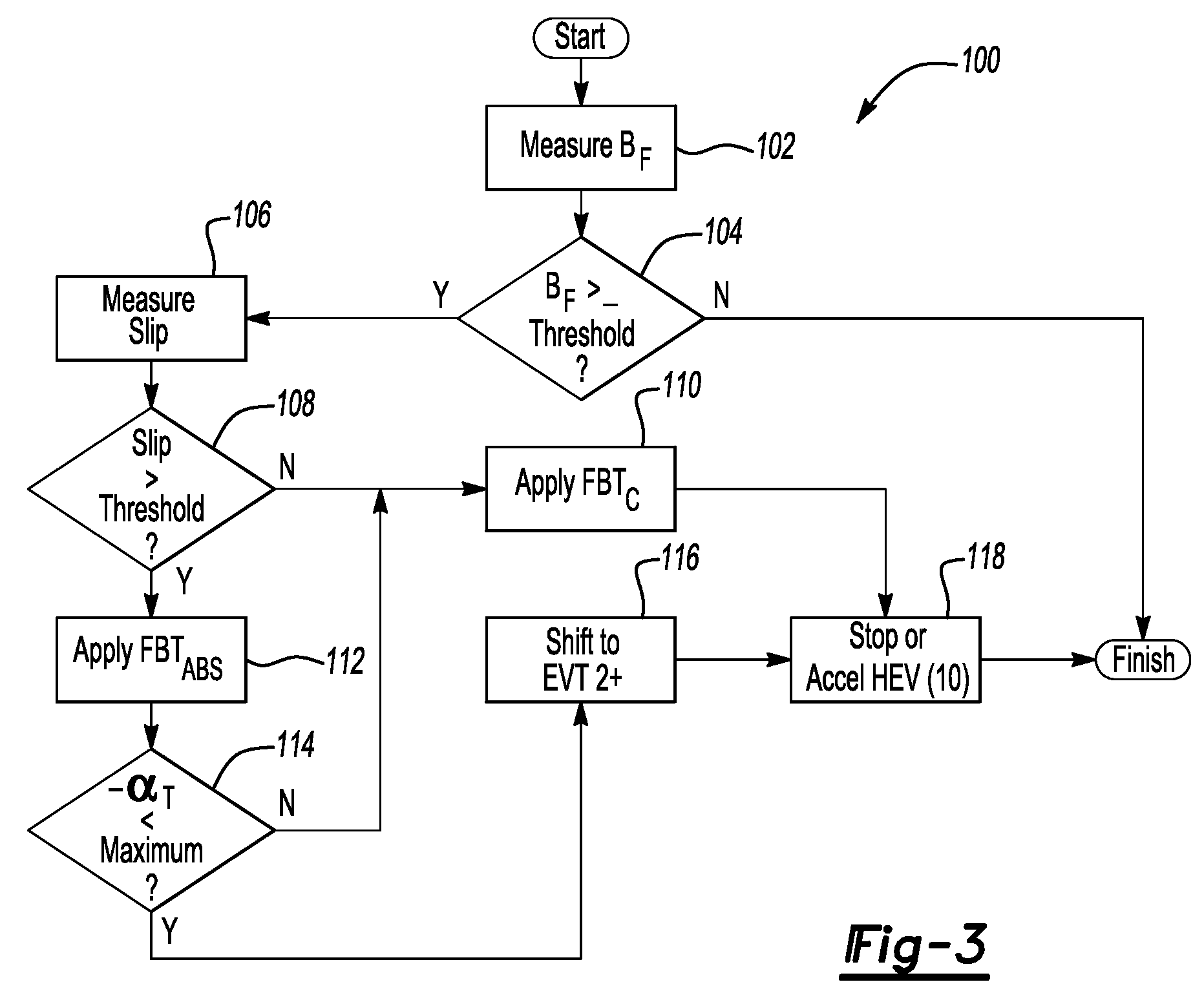

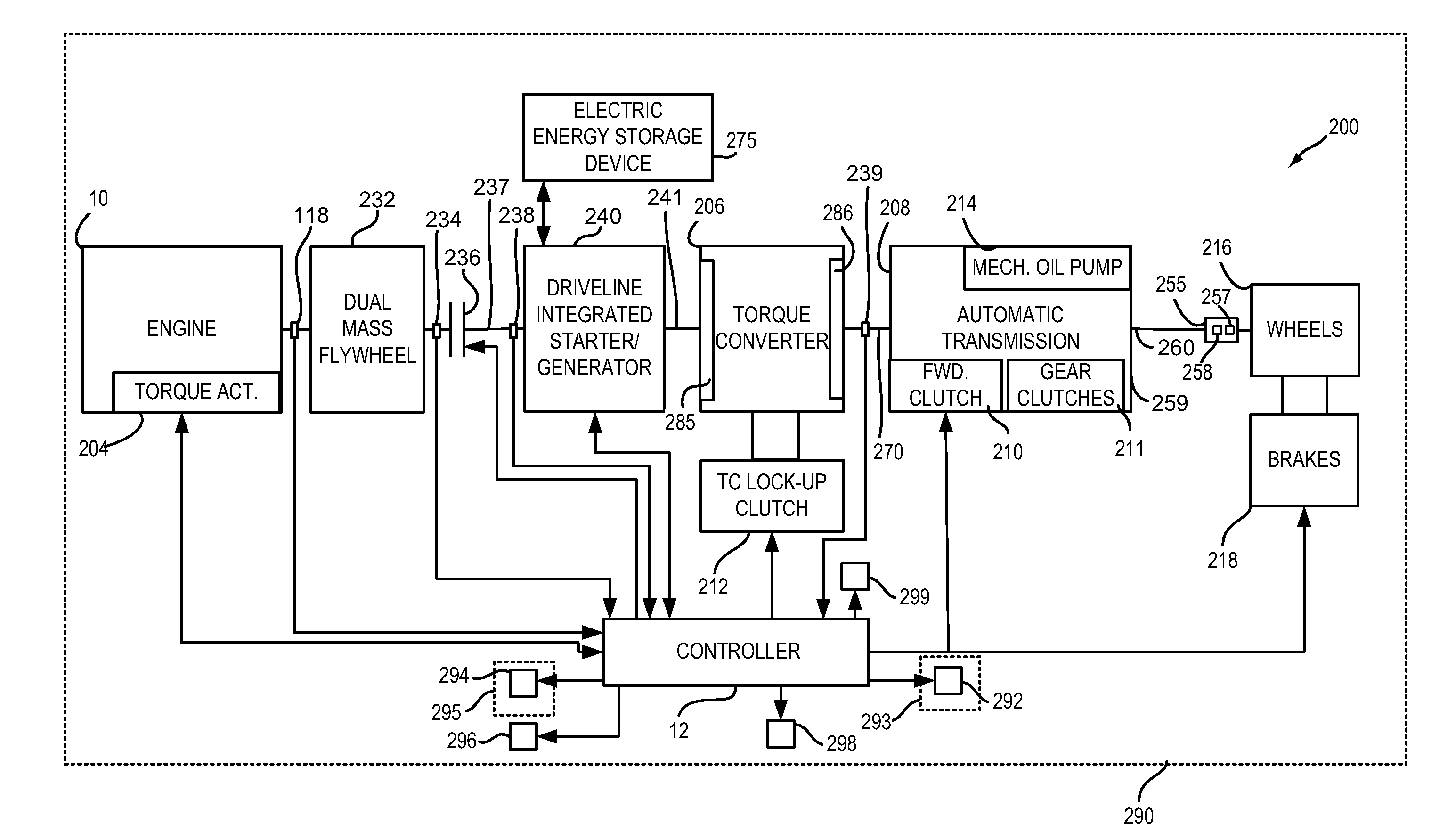

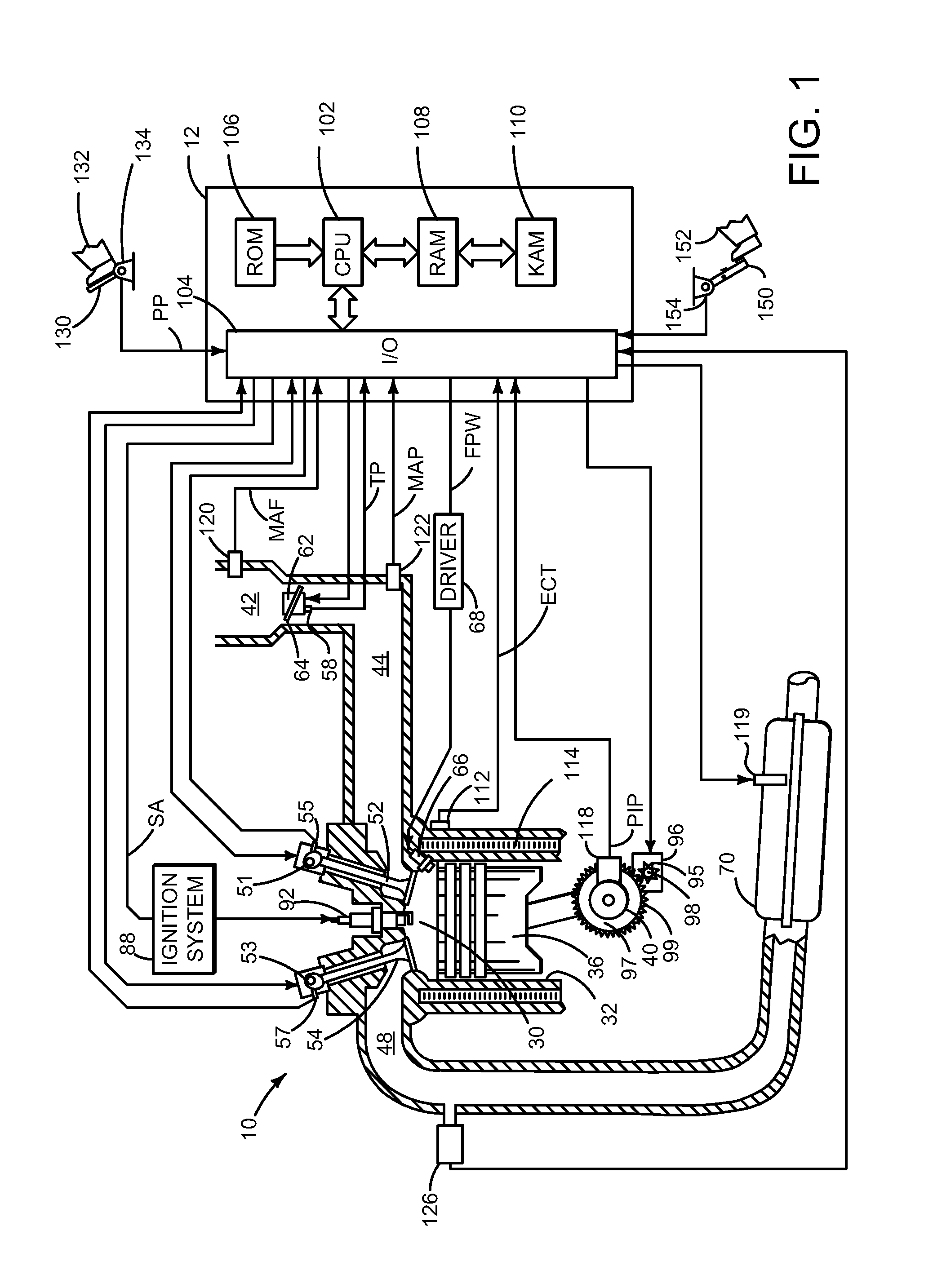

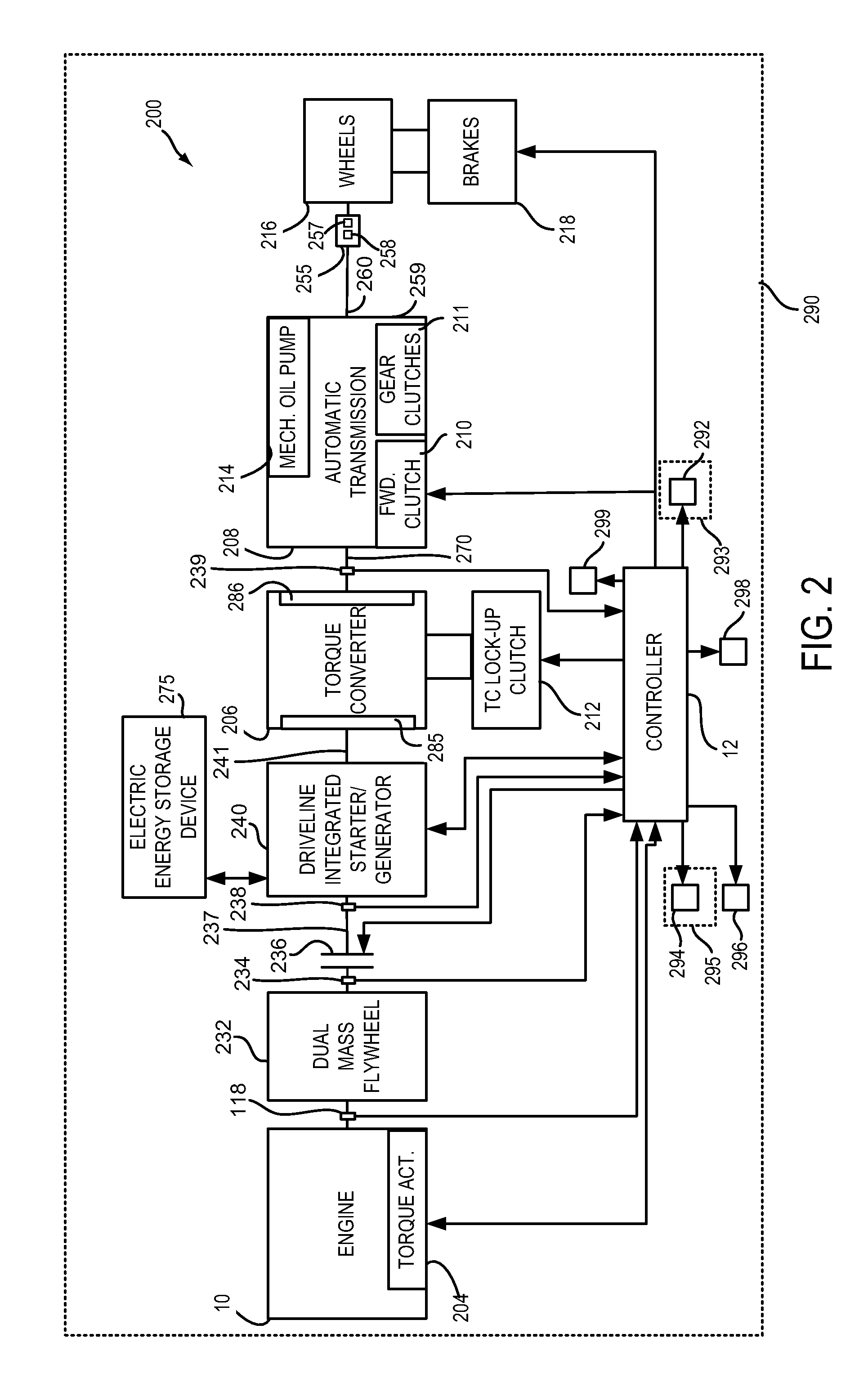

Method and apparatus for optimizing braking control during a threshold braking event

ActiveUS8062175B2Optimizing brake pressure controlMinimize such driveline disturbancesSpeed controllerElectrodynamic brake systemsDrive wheelRoad surface

A method minimizes a driveline vibration and reduces stopping distances in a hybrid electric vehicle (HEV) having a plurality of drive wheels, a friction braking system having antilock braking system (ABS) capability, and an electronically variable transmission (EVT) with two EVT modes. The method automatically shifts the EVT to a predetermined high speed / low torque EVT mode when the ABS is active and when a calibrated maximum deceleration rate is not exceeded. An HEV has a friction braking system with ABS capability and an EVT including a plurality of modes. A controller automatically activates the friction braking ABS in response to a threshold level of slip between the drive wheels and the road surface when the brake pedal is actuated. An algorithm automatically shifts the EVT into one of the high speed / low torque EVT modes when the ABS is activated and the calibrated maximum deceleration rate is not exceeded.

Owner:GM GLOBAL TECH OPERATIONS LLC

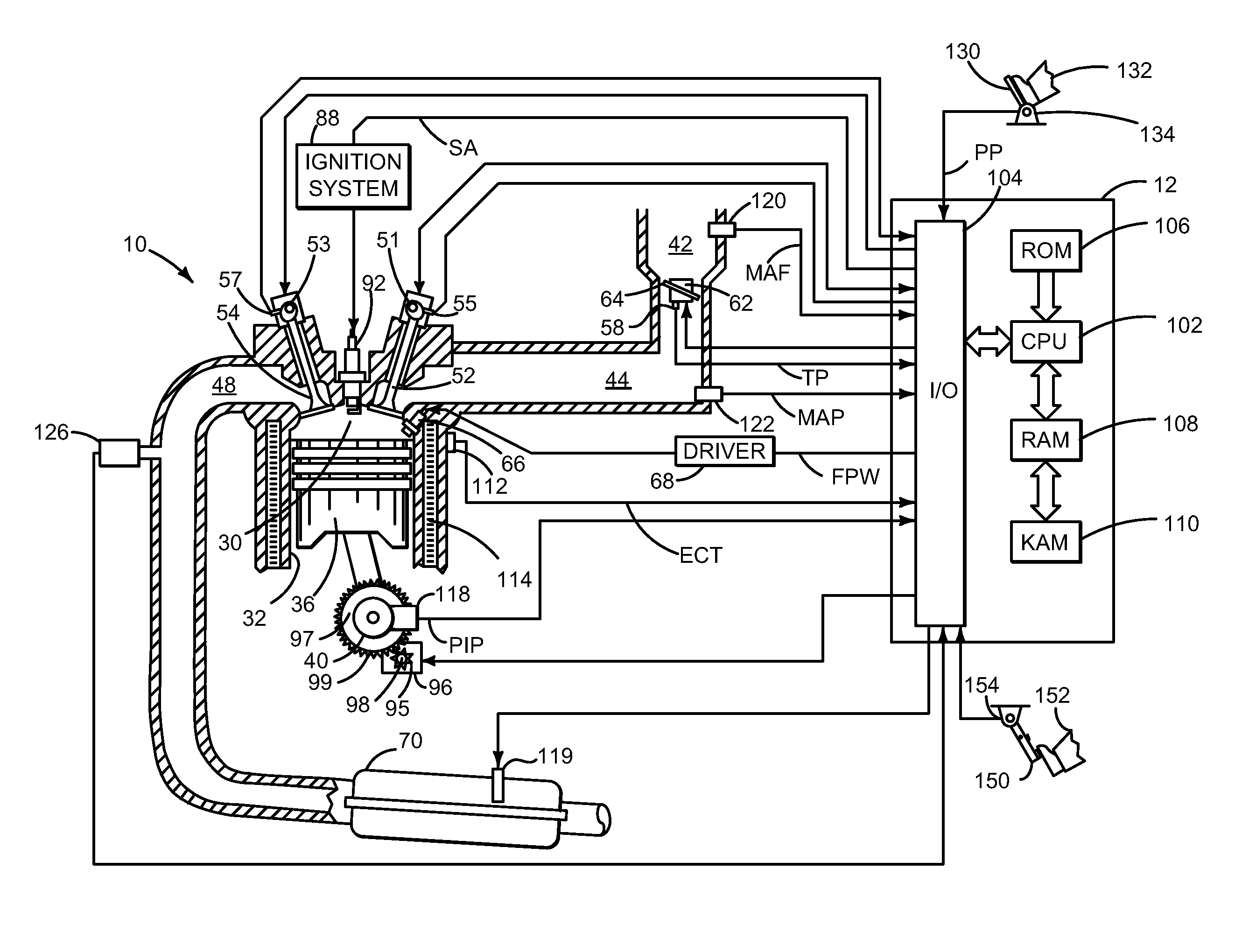

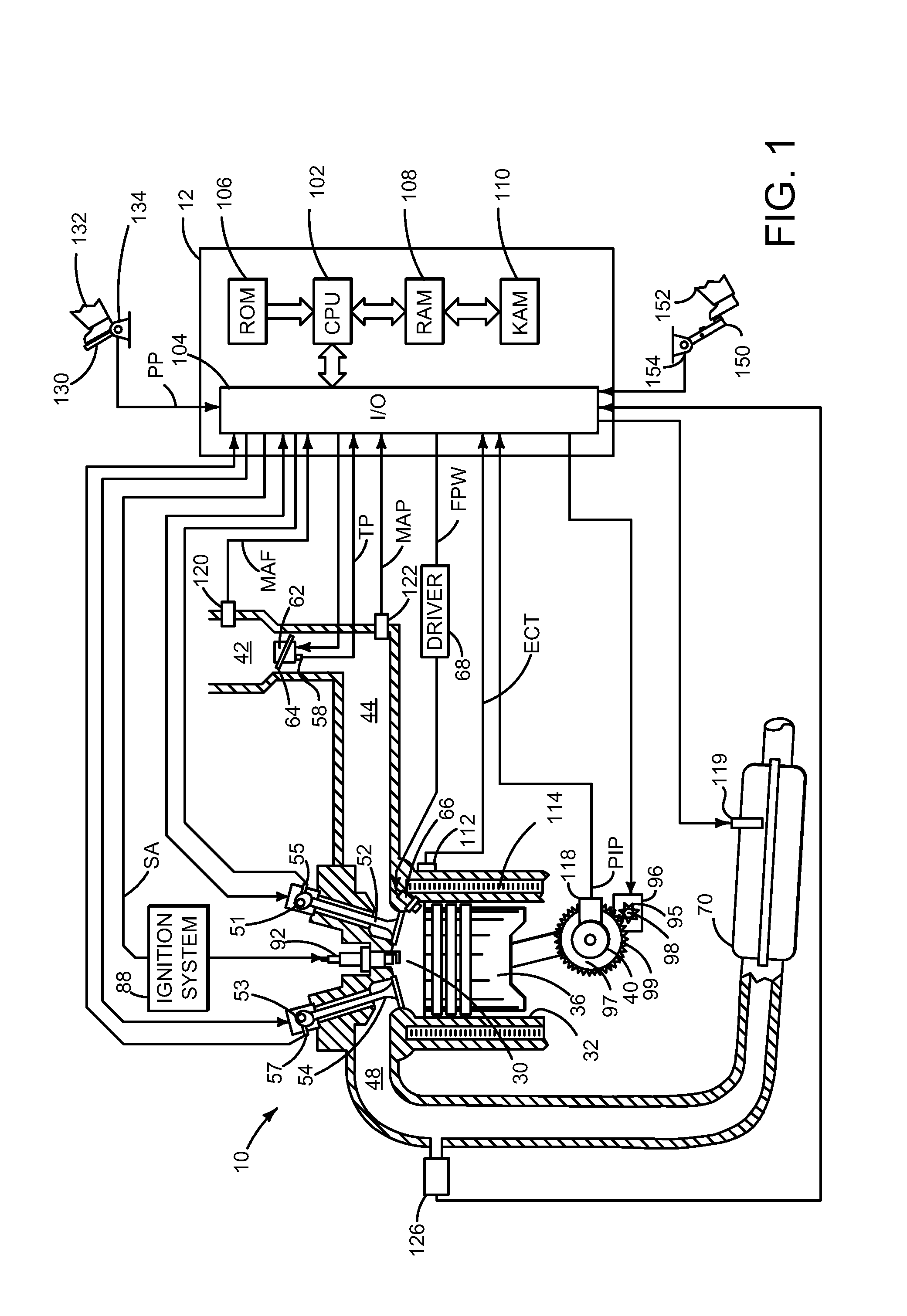

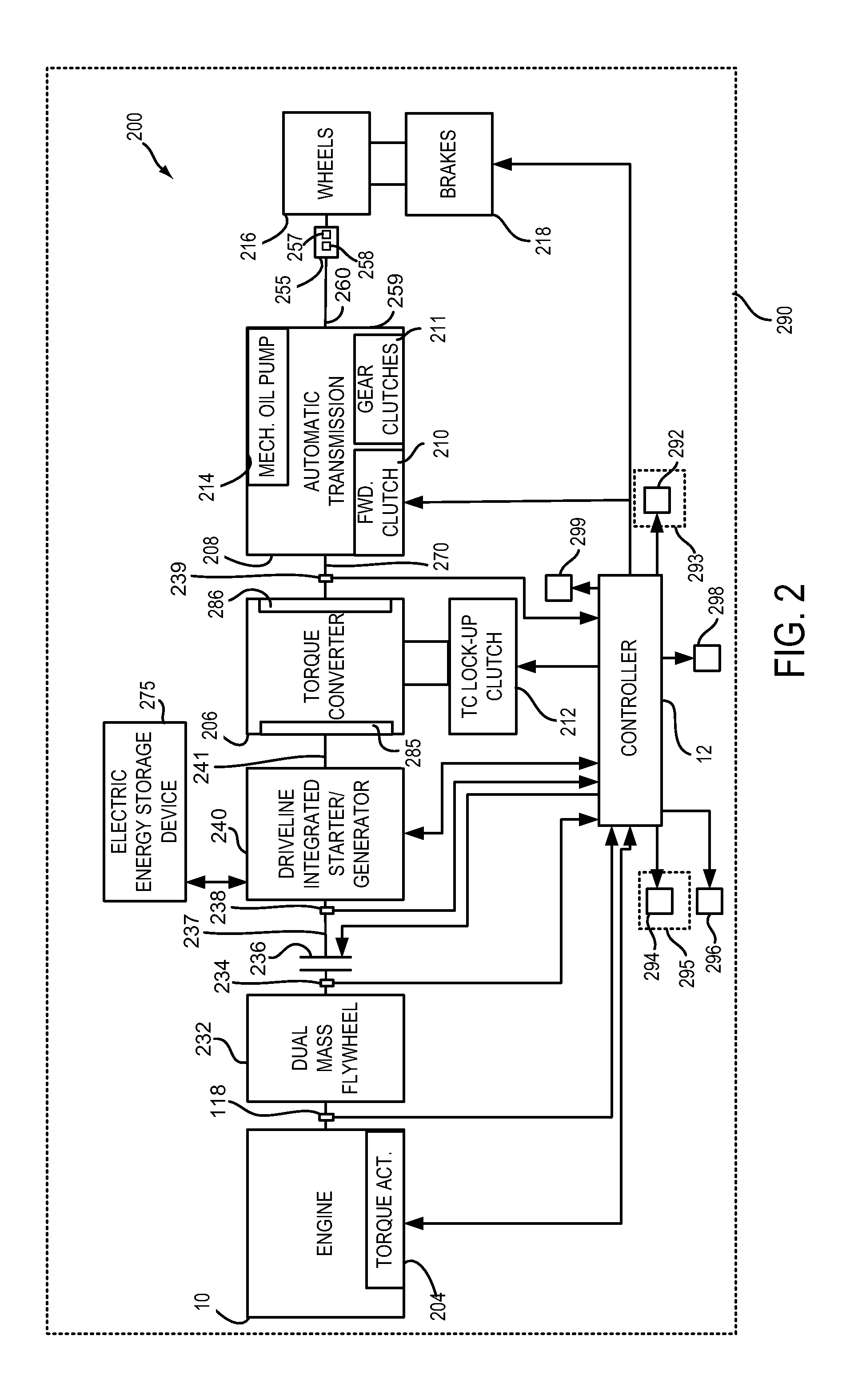

Methods and systems for transitioning between braking modes

ActiveUS8932179B2Reducing driveline braking torqueIncrease frictionHybrid vehiclesEngine controllersHybrid vehicleAutomotive engineering

Systems and methods for improving operation of a hybrid vehicle are presented. In one example, a method for transitioning between driveline braking and wheel brakes is provided.

Owner:FORD GLOBAL TECH LLC

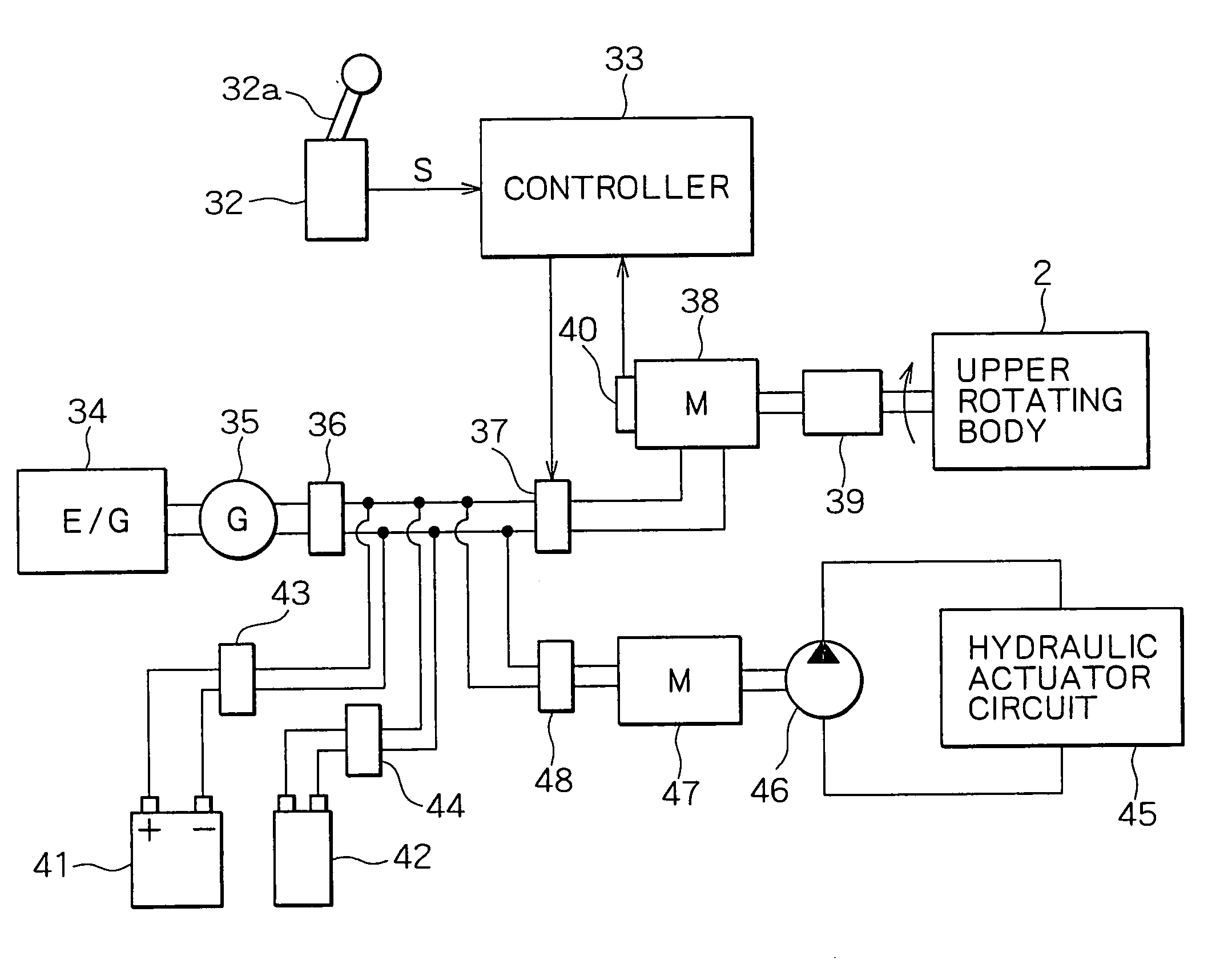

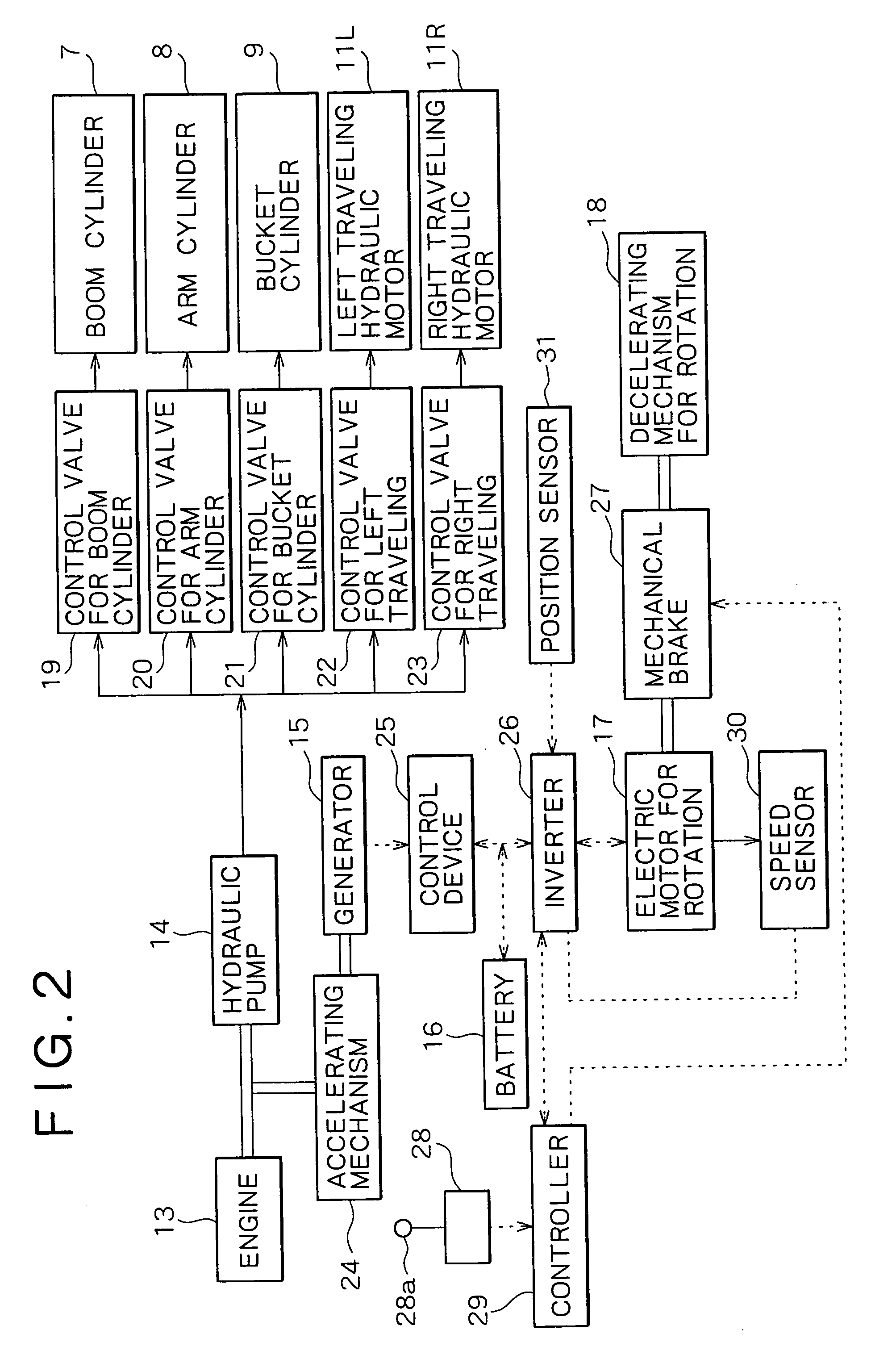

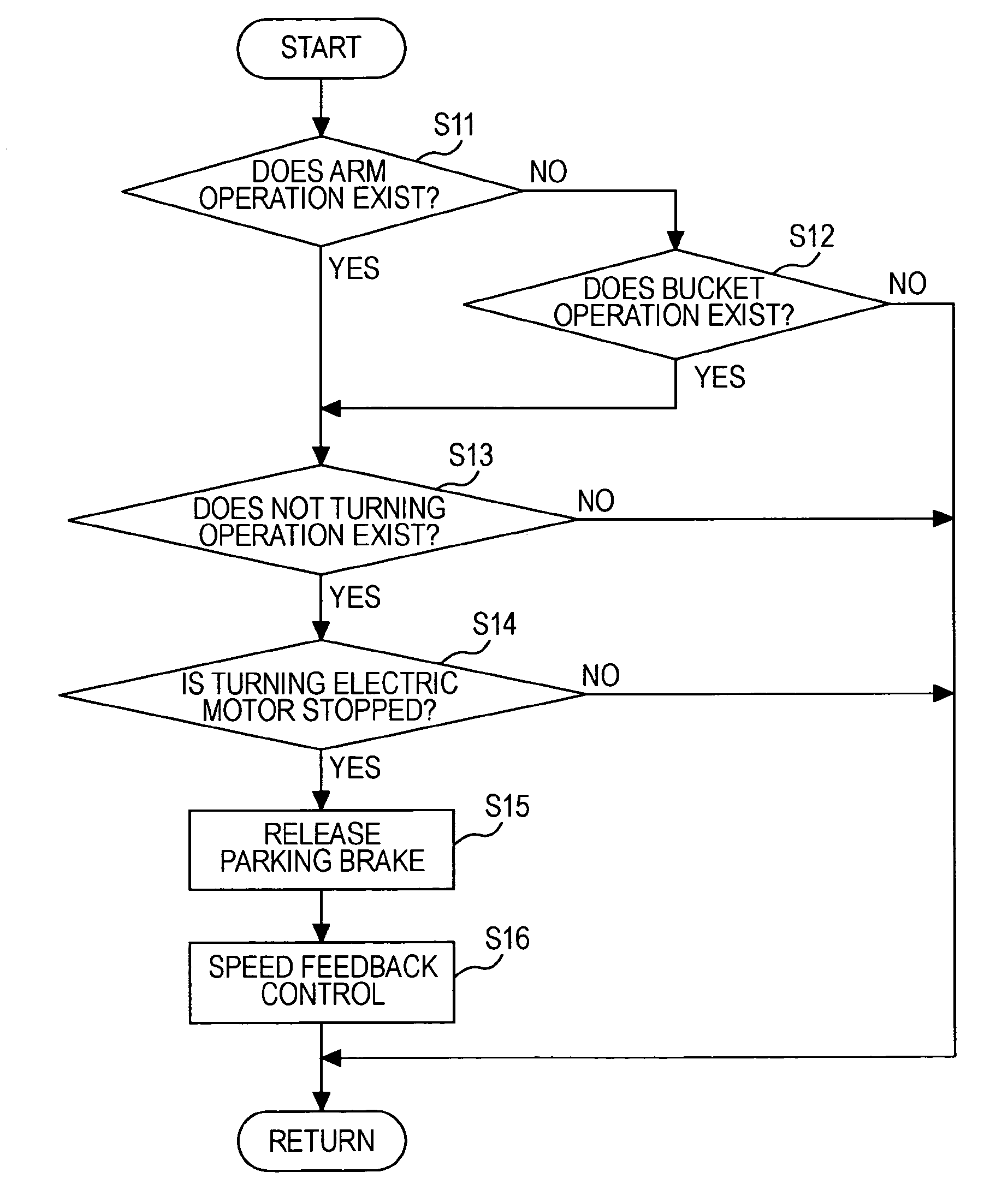

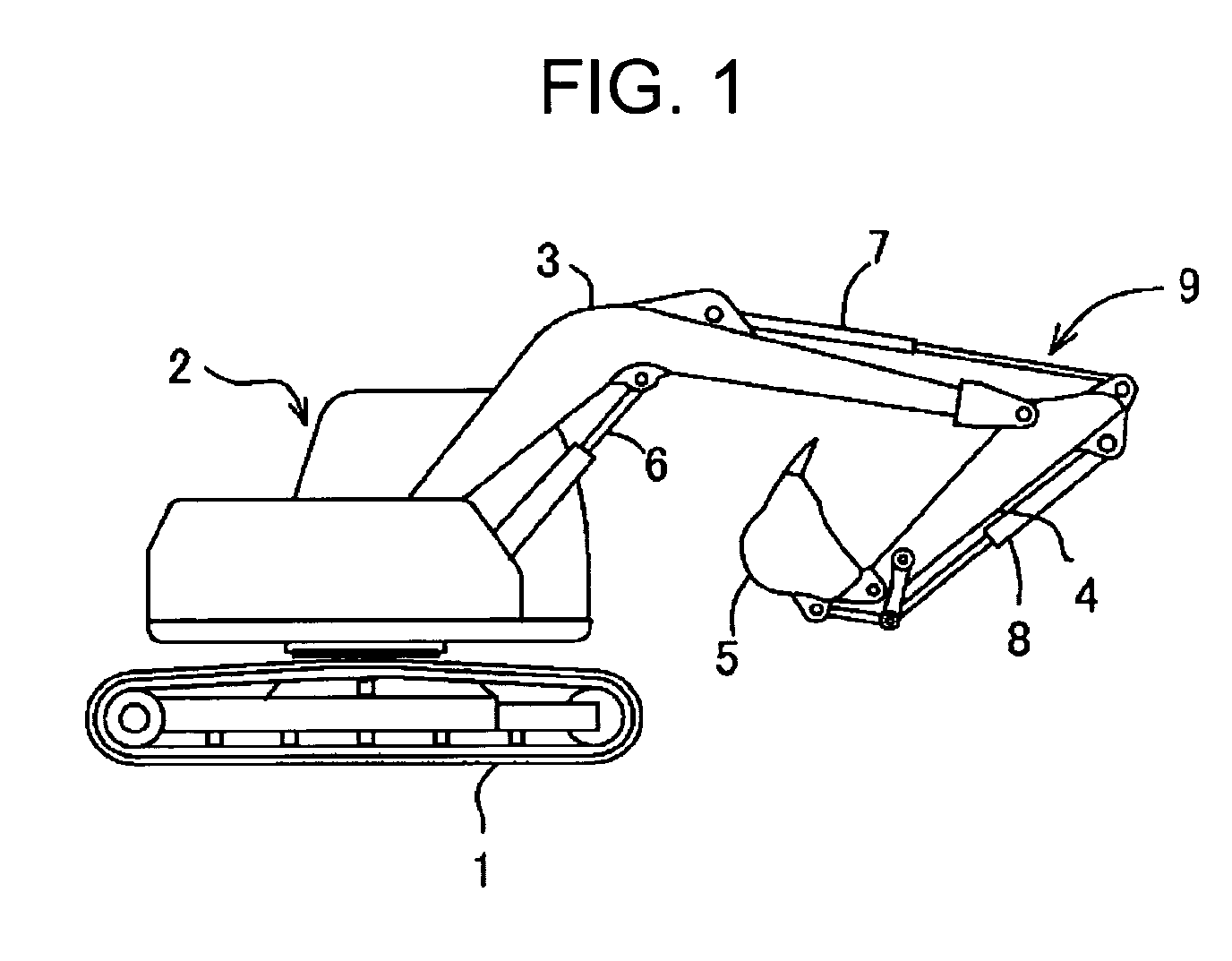

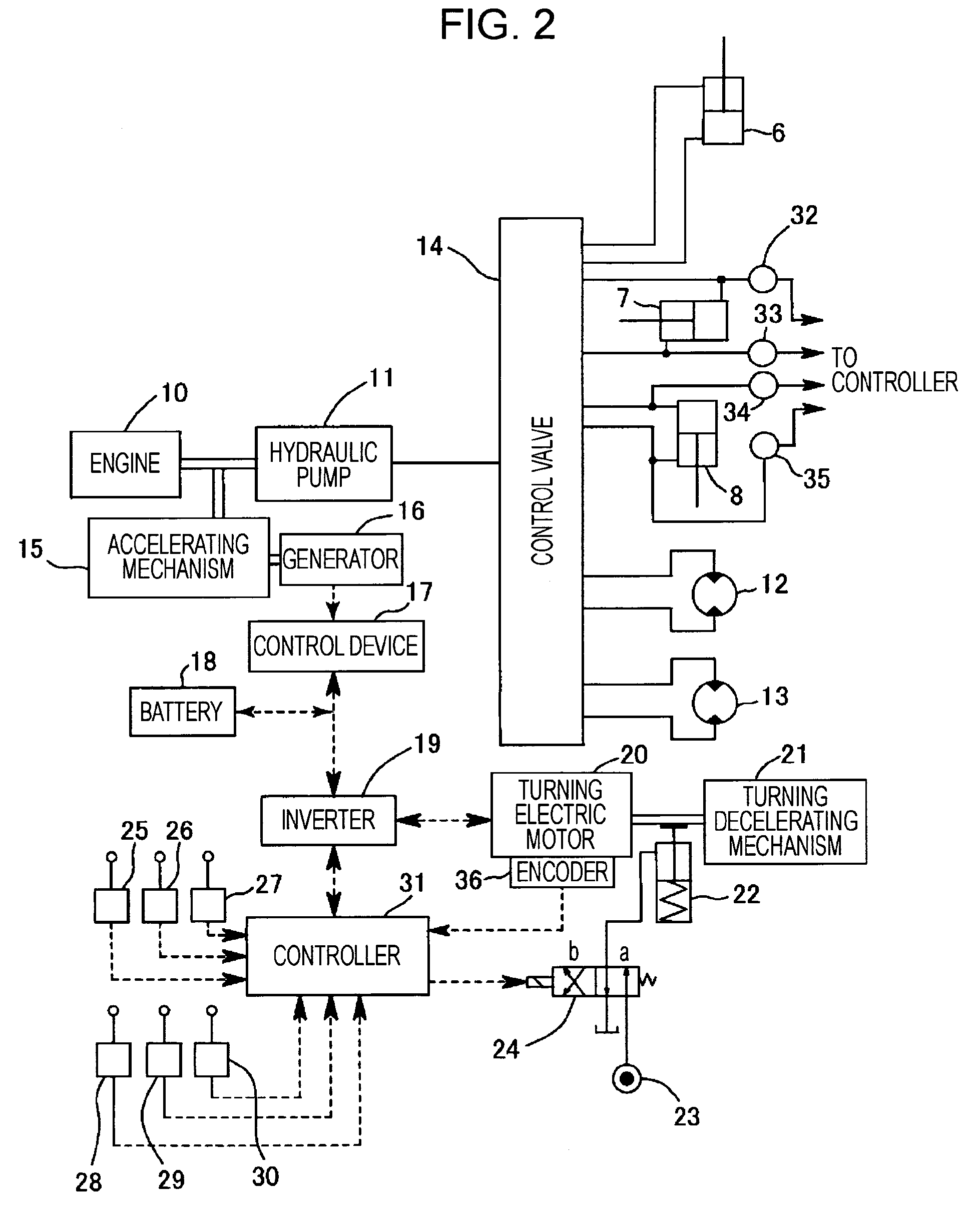

Rotation control device of working machine

InactiveUS7067999B2Single-phase induction motor startersDC motor speed/torque controlStart timeEngineering

In a neutral range preset, there are set a zone for stopping and holding a rotating body only by a mechanical brake, a zone for holding the body only by performing position holding control, and a zone for simultaneously exerting both effects, i.e., the effect of the mechanical brake and the effect of the holding control. On-the-spot holding torque generated when the position holding control is performed is stored. The higher of the on-the-spot holding torque stored and accelerating torque according to an operation amount of the body at a rotation starting time is set as electric motor torque for acceleration. When performing a pressing work including pressing a bucket against an object for work, torque control is carried out according to the operation amount.

Owner:KOBELCO CONSTR MASCH CO LTD +1

Electric Braking Apparatus

InactiveUS20080236964A1Reduce the impact of noiseQuality improvementAsynchronous induction motorsMechanical energy handlingElectricityElectrical conductor

An electric braking apparatus including a motor for pressing brake pads on disks, a metal housing for housing the motor, a positive-polarity power line for transmitting power from a battery to the electric motor, a negative-polarity ground line for connecting the electric motor to the ground of a vehicle, and a conductor for electrically connecting the metal housing to the negative polarity of battery or the negative-polarity of an inverter.

Owner:HITACHI LTD

Downhill vehicle speed control algorithm for electric driven vehicles

A control system that prevents an electric vehicle from increasing its speed on a downhill gradient by providing regenerative braking through a traction motor. The system includes an enable circuit that provides an enable signal if certain criteria are met, such as a brake pedal and an acceleration pedal being inactive. The system further includes a controller that is enabled by the enable signal, and receives a vehicle speed signal of the speed of the vehicle. The system also includes a switch that receives the enable signal and the vehicle speed signal. When the enable circuit provides the enable signal, the switch provides a speed set-point to the controller for the last vehicle speed. If the vehicle speed signal goes above the speed set-point, the controller outputs a regenerative braking torque command to the traction motor to reduce the speed of the vehicle to the speed set-point.

Owner:GM GLOBAL TECH OPERATIONS LLC

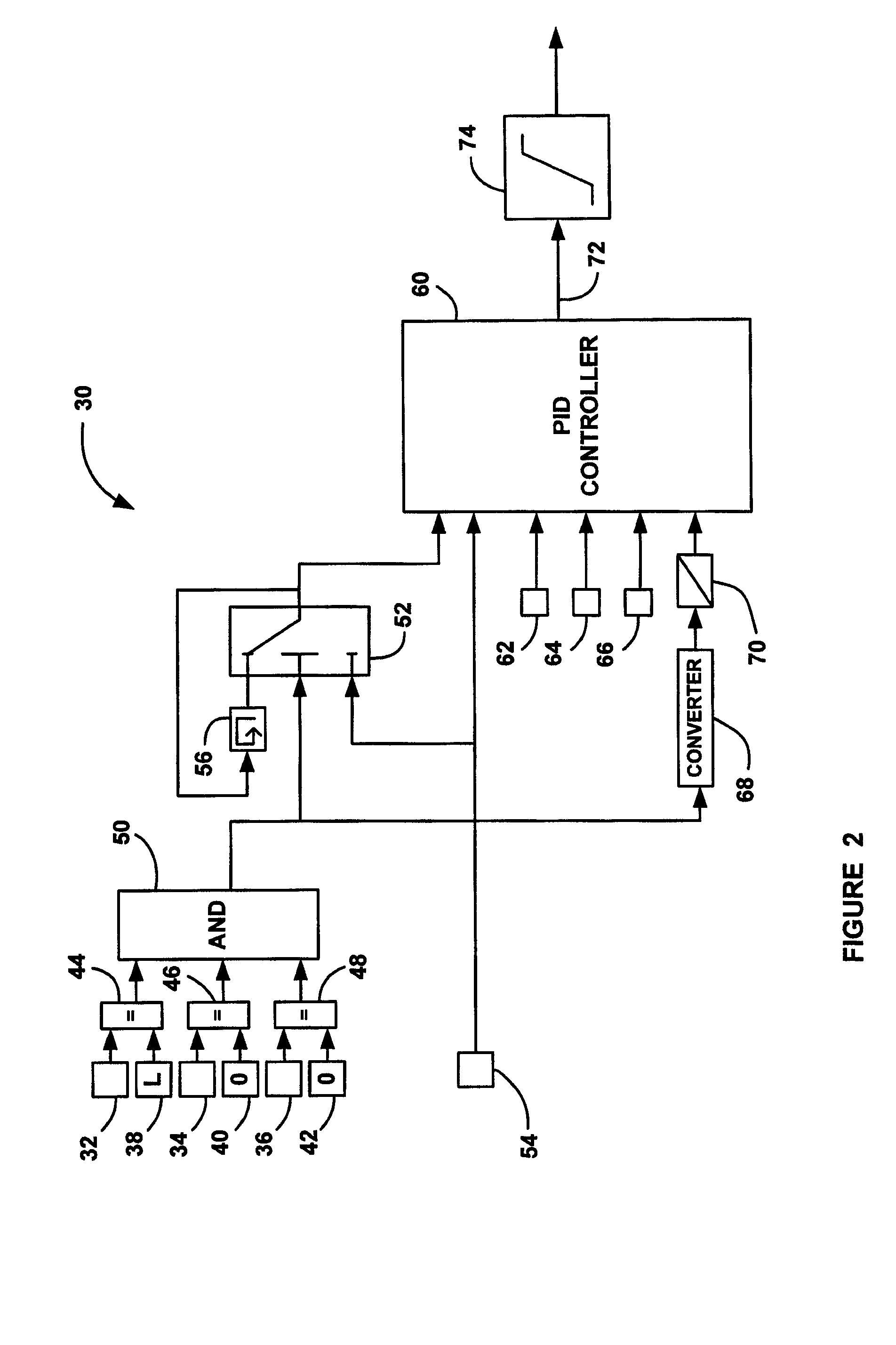

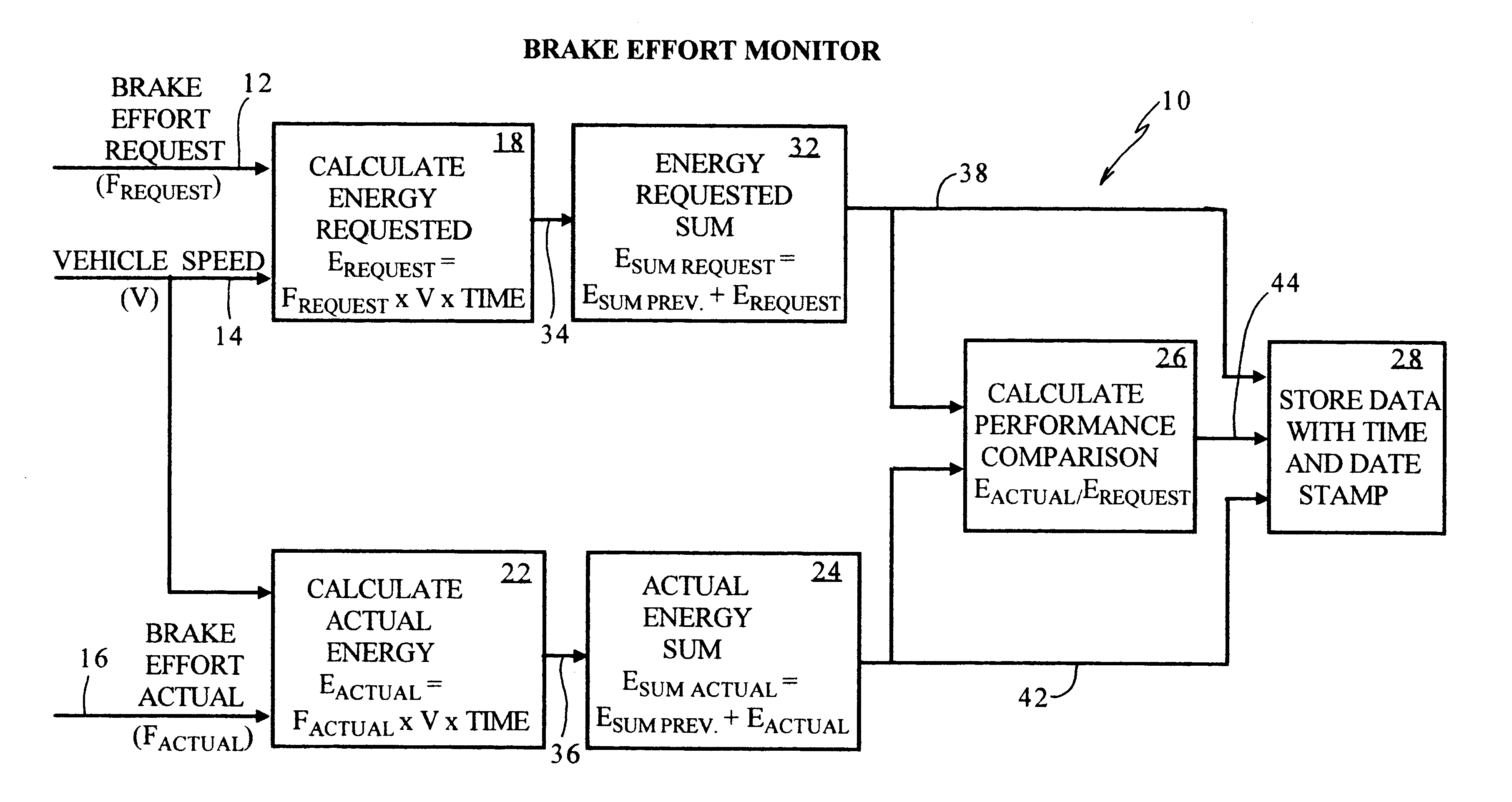

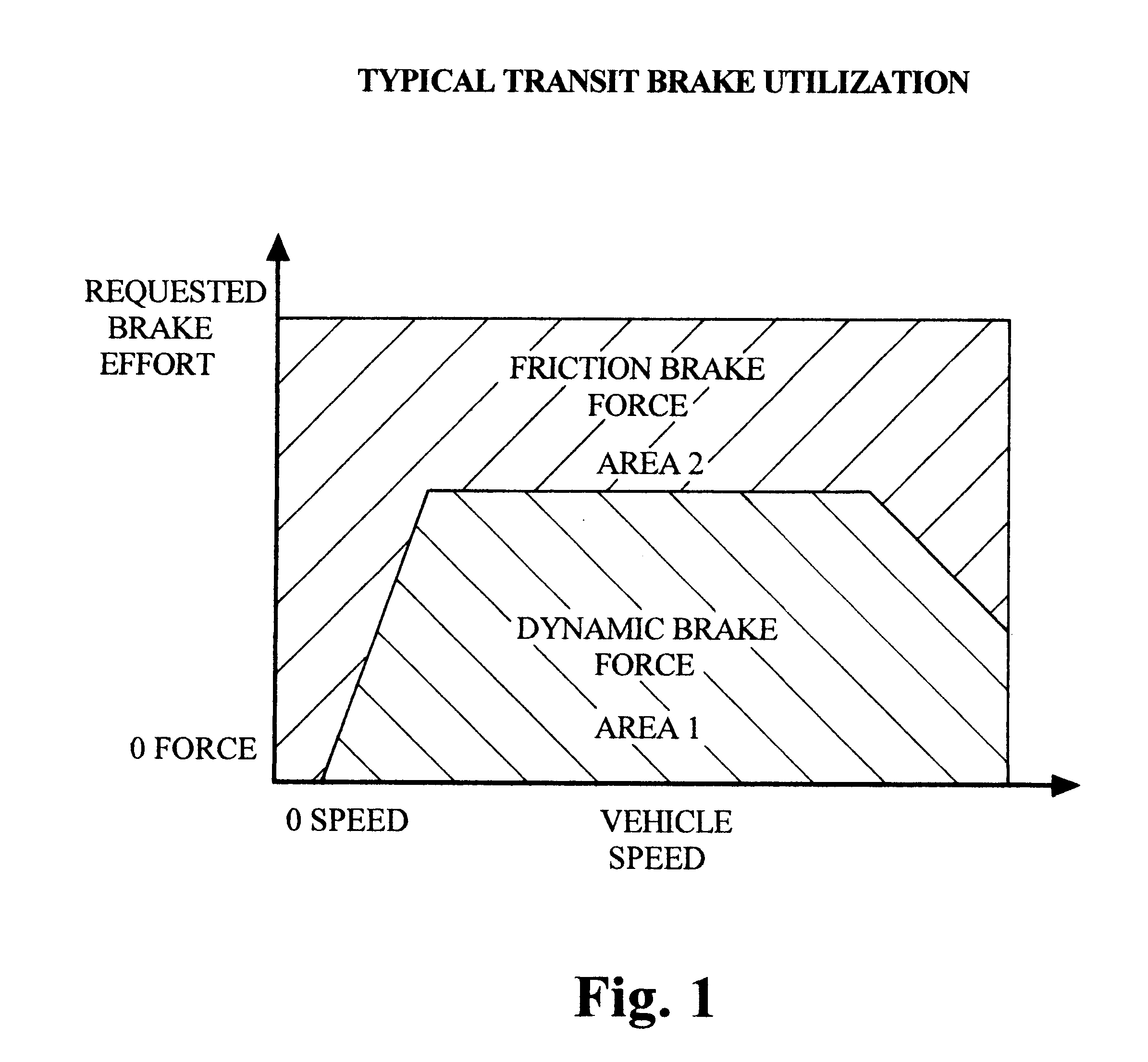

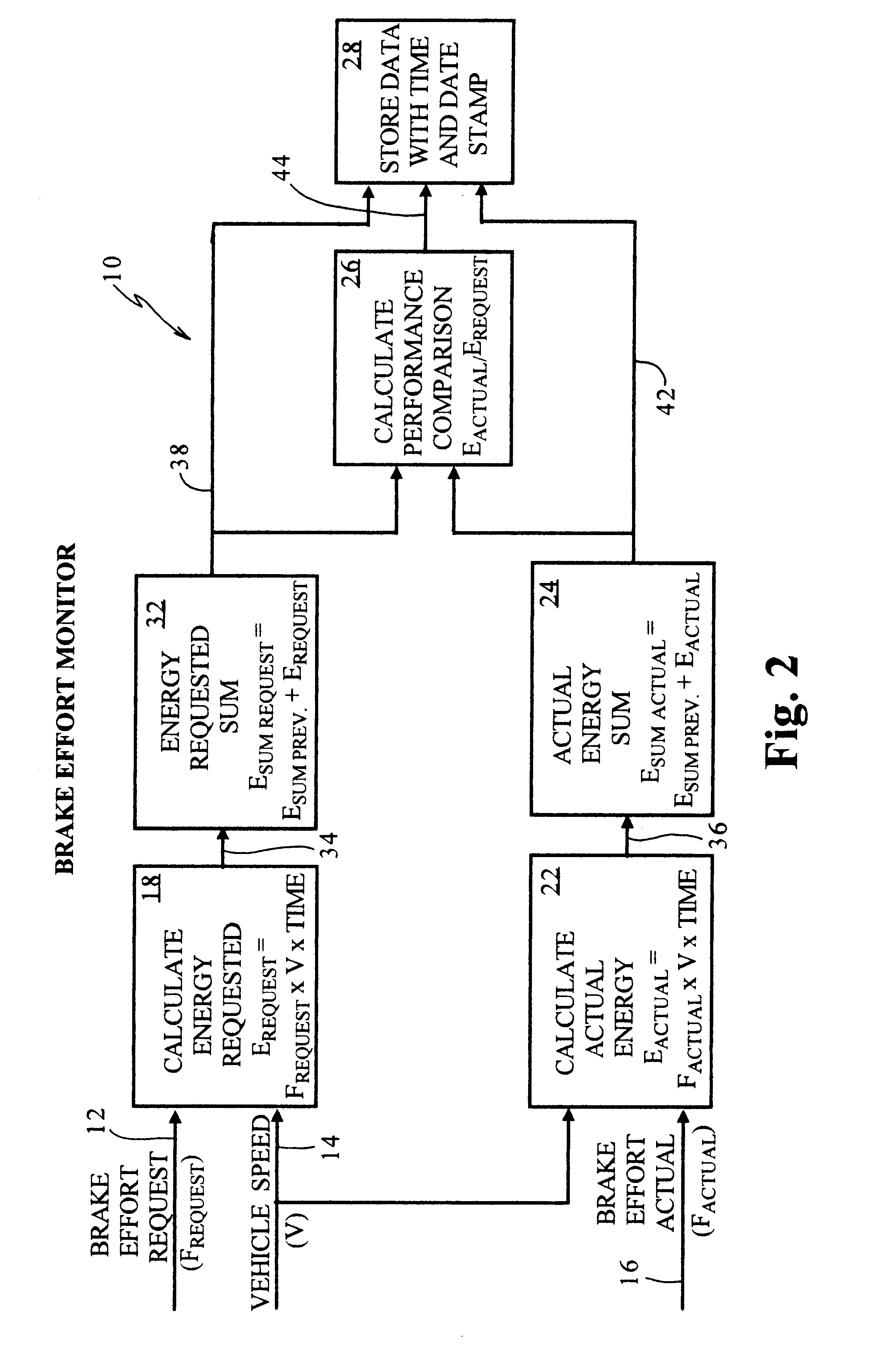

Brake effort monitor

InactiveUS6739675B1Low costMaximize useDynamo-electric brakes/clutchesElectric motor controlComparatorBraking system

A brake effort monitor for railcar braking systems includes means connected to receive a brake effort request signal and a vehicle speed signal for generating an energy requested signal. Another device is connected to receive a brake effort actual signal and a vehicle speed signal for generating an actual energy signal. There is a mechanism connected to receive the energy requested signal and add it to one of a previous energy requested signal and a predetermined value for generating an energy requested sum signal. A device is connected to receive the actual energy signal and add it to one of a previous actual energy signal and a predetermined value for generating an actual energy sum signal. A comparator is connected to receive the energy requested sum signal and the actual energy sum signal for generating a performance comparison signal and a storage device is connected to receive at least one of an energy requested sum signal and an actual energy sum signal and a performance comparison signal for storing at least one signal.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

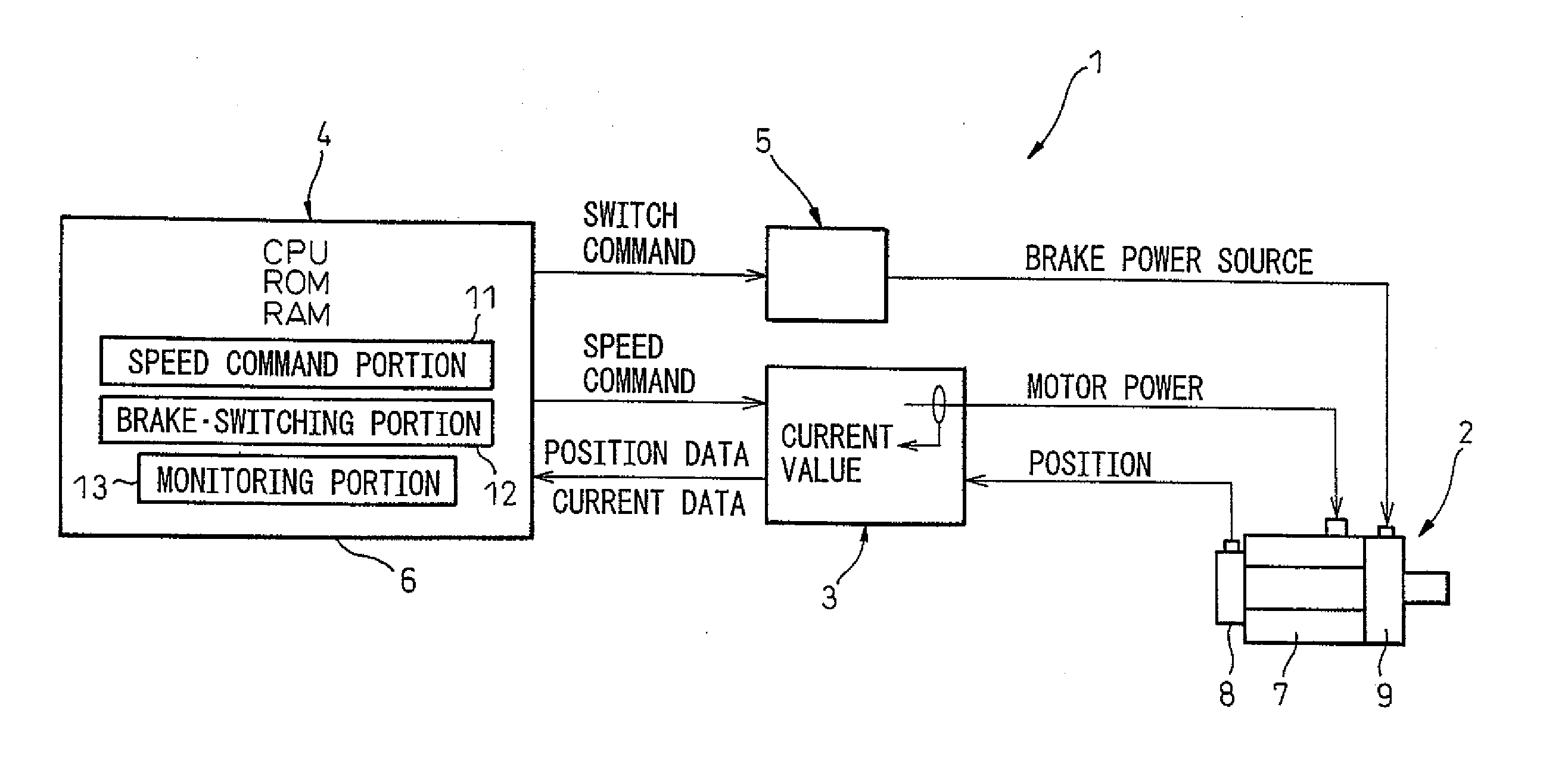

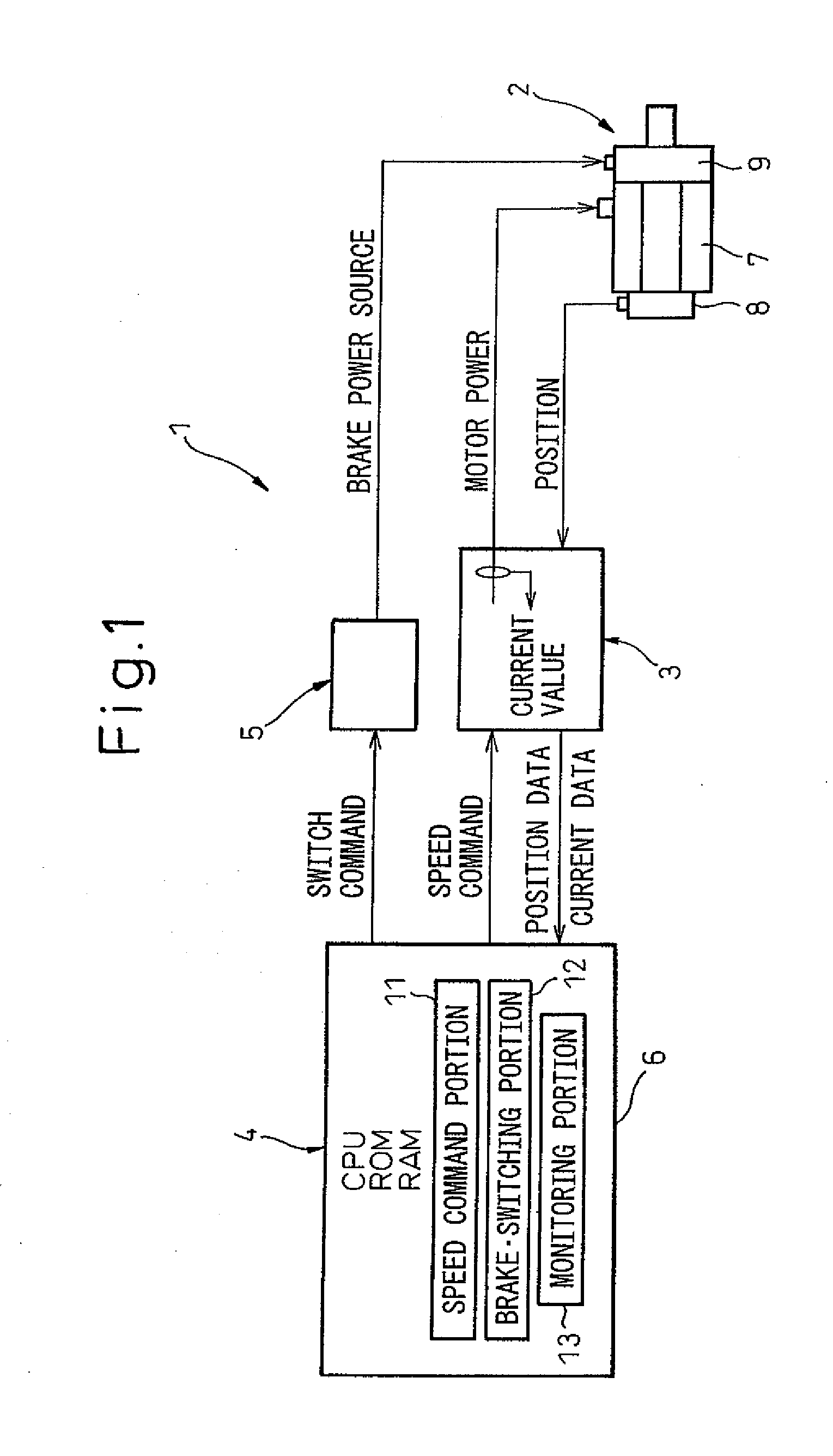

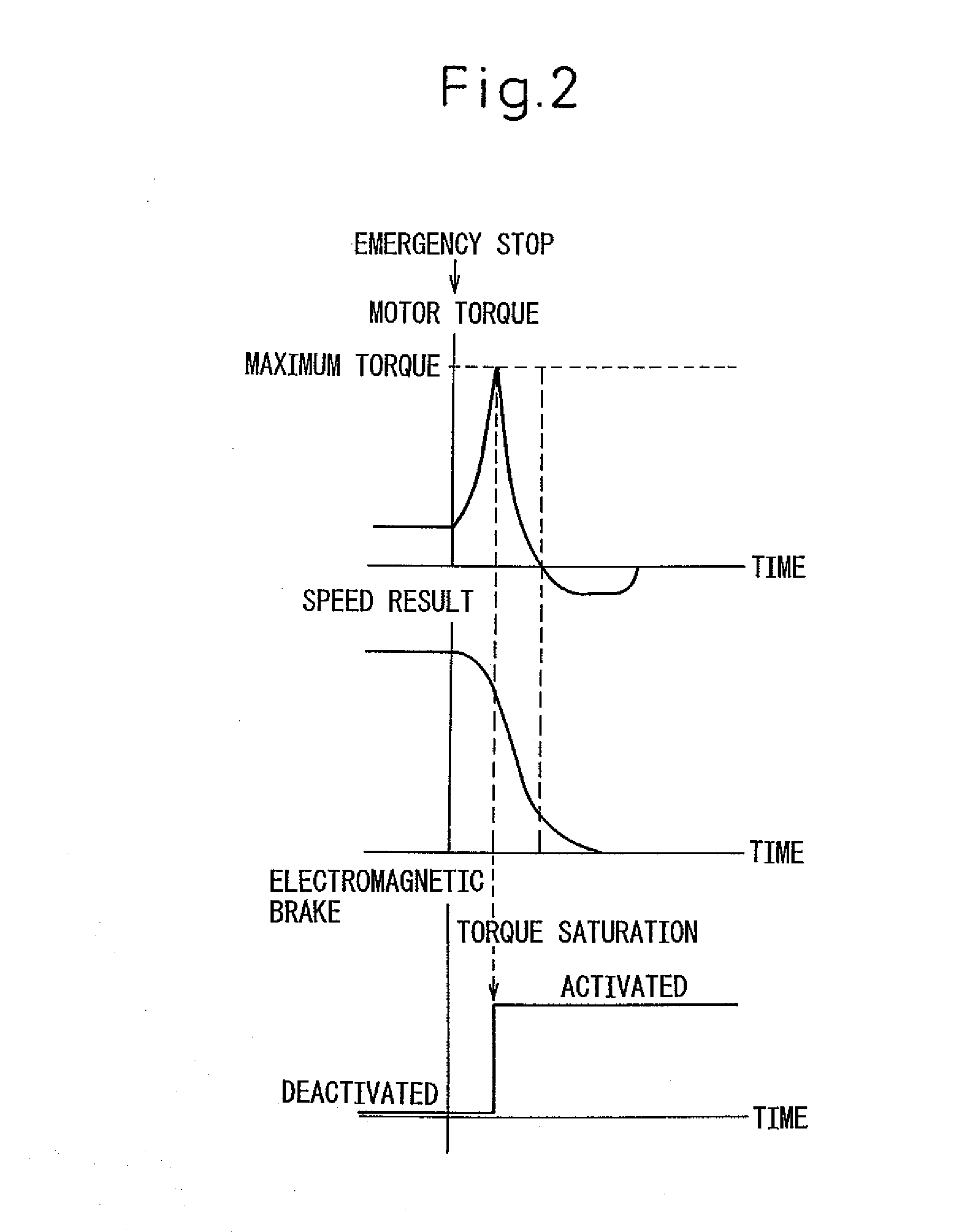

Servo motor stop controlling method and servo motor controller

InactiveUS20070096670A1Short stayShorten the stopping distanceAC motor controlElectric motor controlMotor controllerMotor control

A servo motor controller is provided with a motor control section for controlling a servo motor provided with a brake. The motor control section includes a speed command portion for outputting a speed command to increase or reduce the rotation of the servo motor, and a brake switching portion for outputting switch command for a braking circuit to switch the brake, wherein the brake is activated during speed reduction of the servo motor by the speed command portion, whereby a rotation of the servo motor is stopped. The motor control section further includes a monitoring portion for monitoring whether or not the decelerating torque of the servo motor during speed reduction exceeds a set value that has been set equal to or lower than a maximum allowable torque of the servo motor in the motor control section.

Owner:FANUC LTD

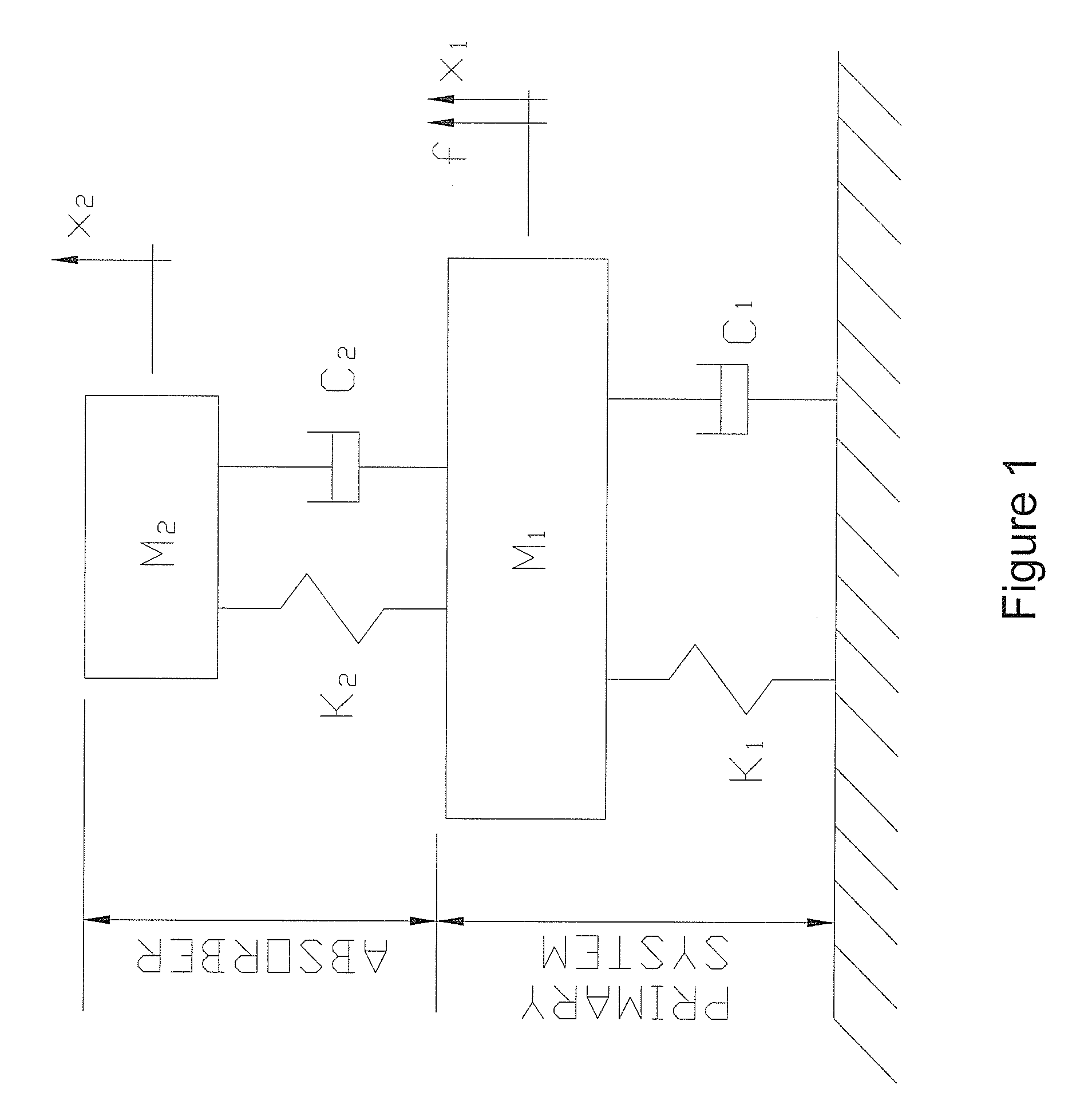

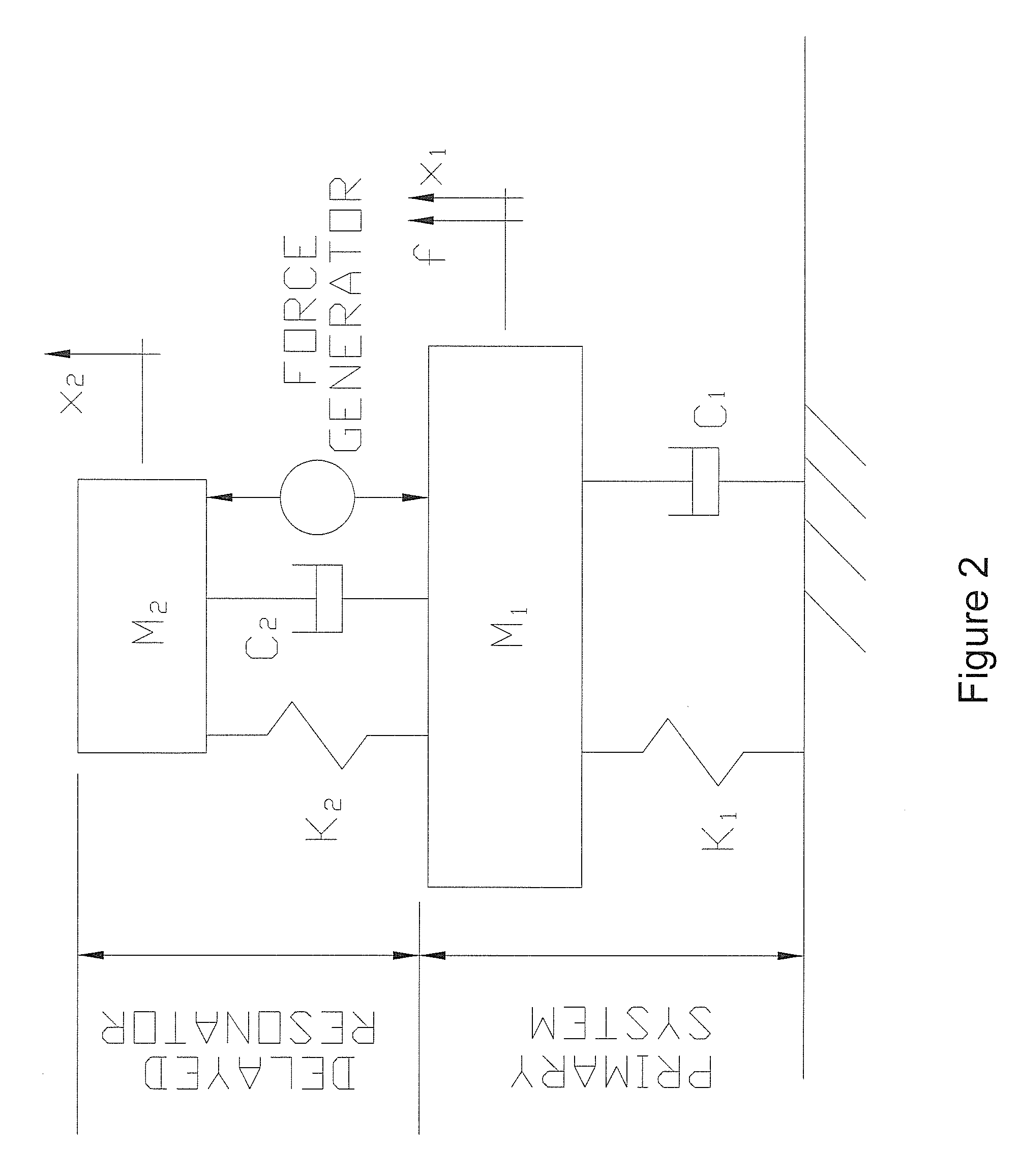

Self-tuning vibration absorber

InactiveUS20100057260A1Reduce vibrationReduce relative motionTemperatue controlStatic/dynamic balance measurementElectricitySelf-tuning

A self-tuning vibration absorber including a carrier rod assembly having operatively connected thereto a mounting mechanism for mounting the carrier rod assembly to a primary system and a hollow shafted motorized tuning mechanism for tuning a phase difference between vibration of the primary system and vibration of the carrier rod assembly to 90 degrees, the carrier rod assembly further including a detecting mechanism for detecting the vibration of the primary system and the vibration of the carrier rod assembly, and a controller in electrical connection with the detecting mechanism and the tuning means for controlling the tuning mechanism based on the vibration of the primary system and the vibration of the carrier rod assembly detected. A method of vibration dampening, a method of controlling a self-tuning vibration absorber, and a method of reducing hunting motion in railcars.

Owner:NORTHERN ILLINOIS UNIVERSITY

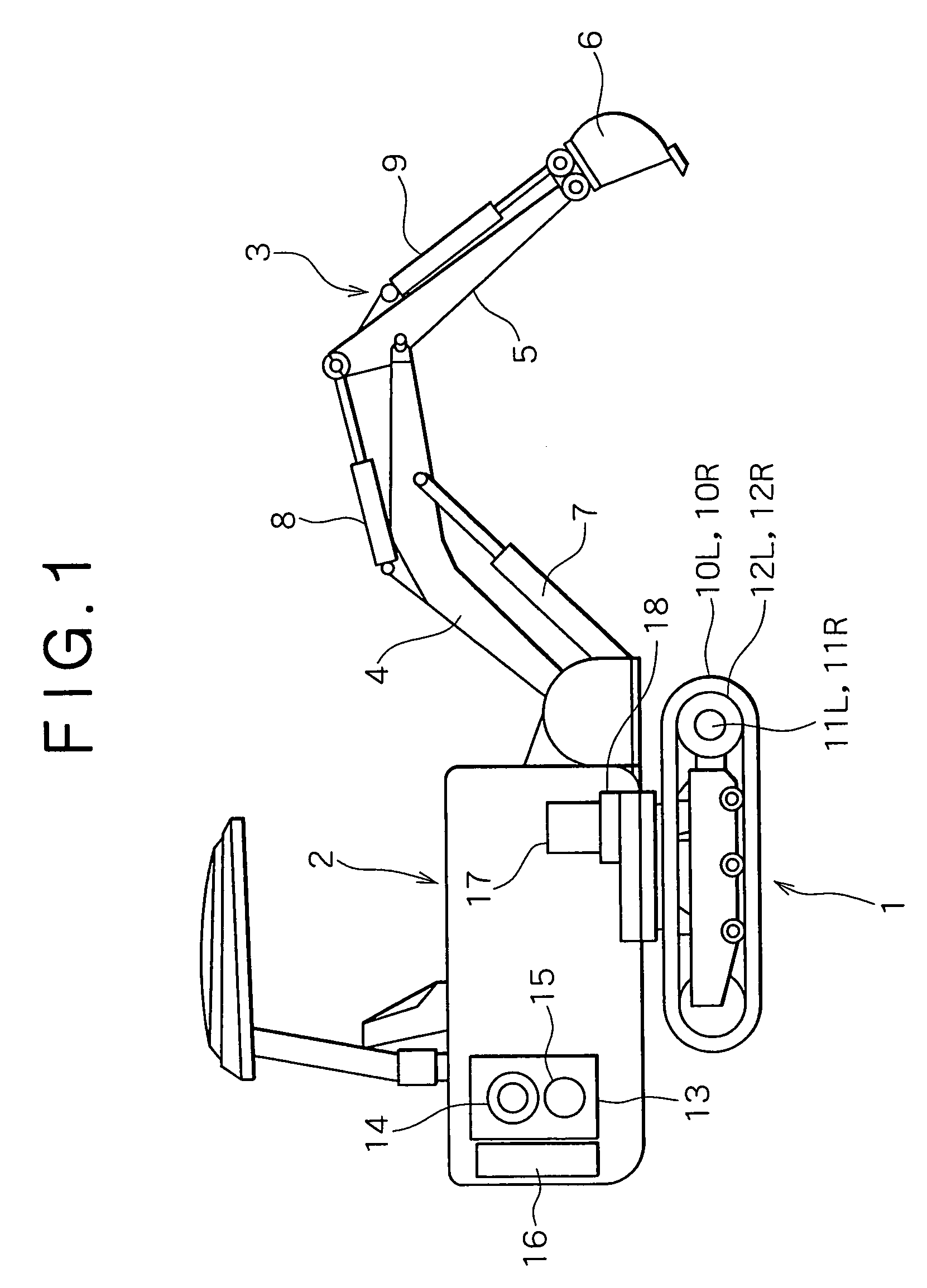

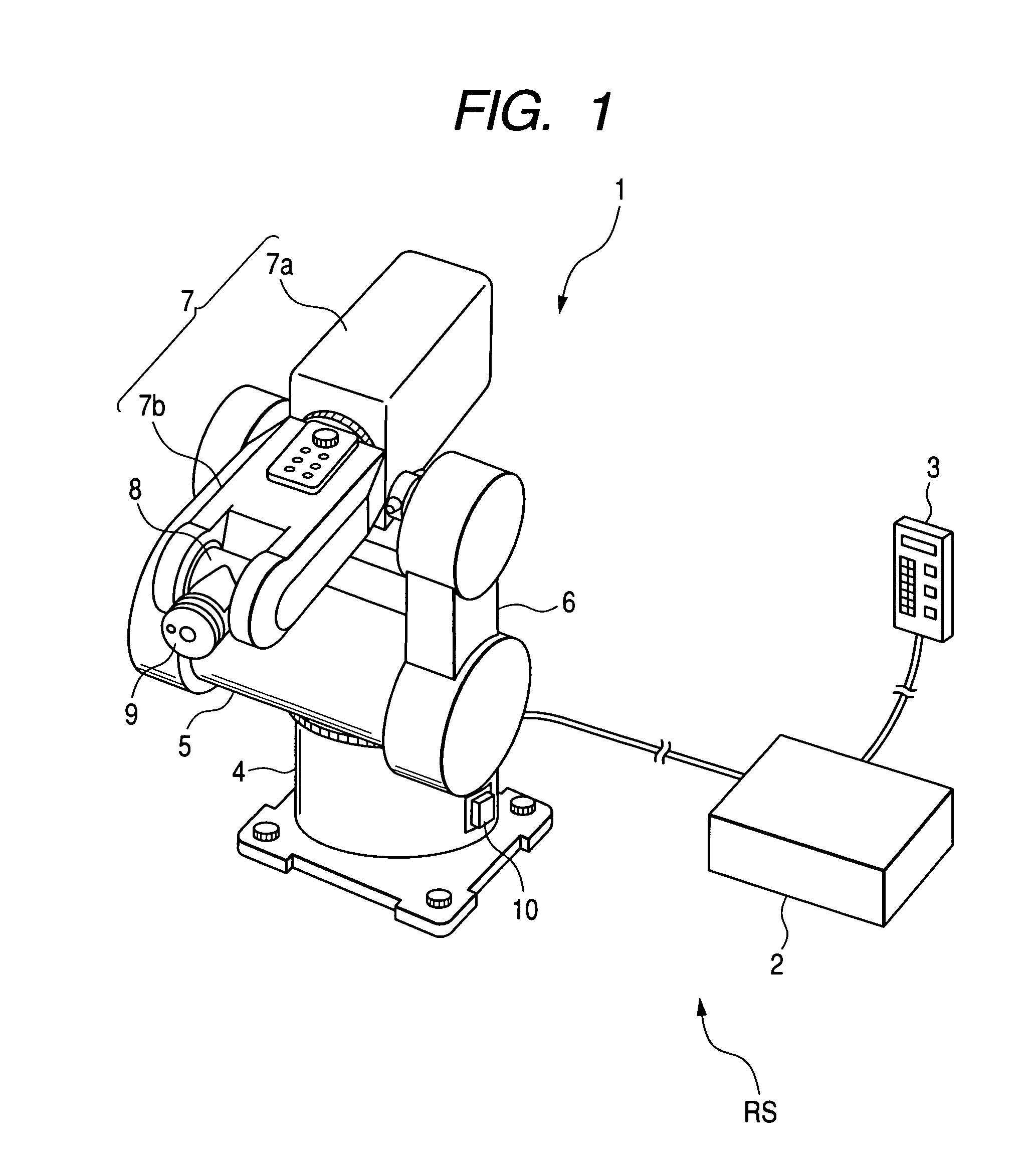

Rotation-type working machine

ActiveUS7345441B2Easy to operateWork lessElectric motor controlServomotorsEngineeringFeedback control

A parking brake is released by a controller and a rotating electric motor is speed-feedback-controlled or position-feedback-controlled to stop and hold an upper rotating body if at least one of arm operation, bucket operation, and travel operation is carried out in a rotating stopped state and with respect to the arm operation and the bucket operation, cylinder thrust of an arm cylinder or a bucket cylinder is greater or equal to a set value. Thereby, a parking brake and a rotating driving part can be prevented from being damaged by rotating external force generated by excavation reaction force or the like and a rotating body can be stopped and held.

Owner:KOBELCO CONSTR MASCH CO LTD

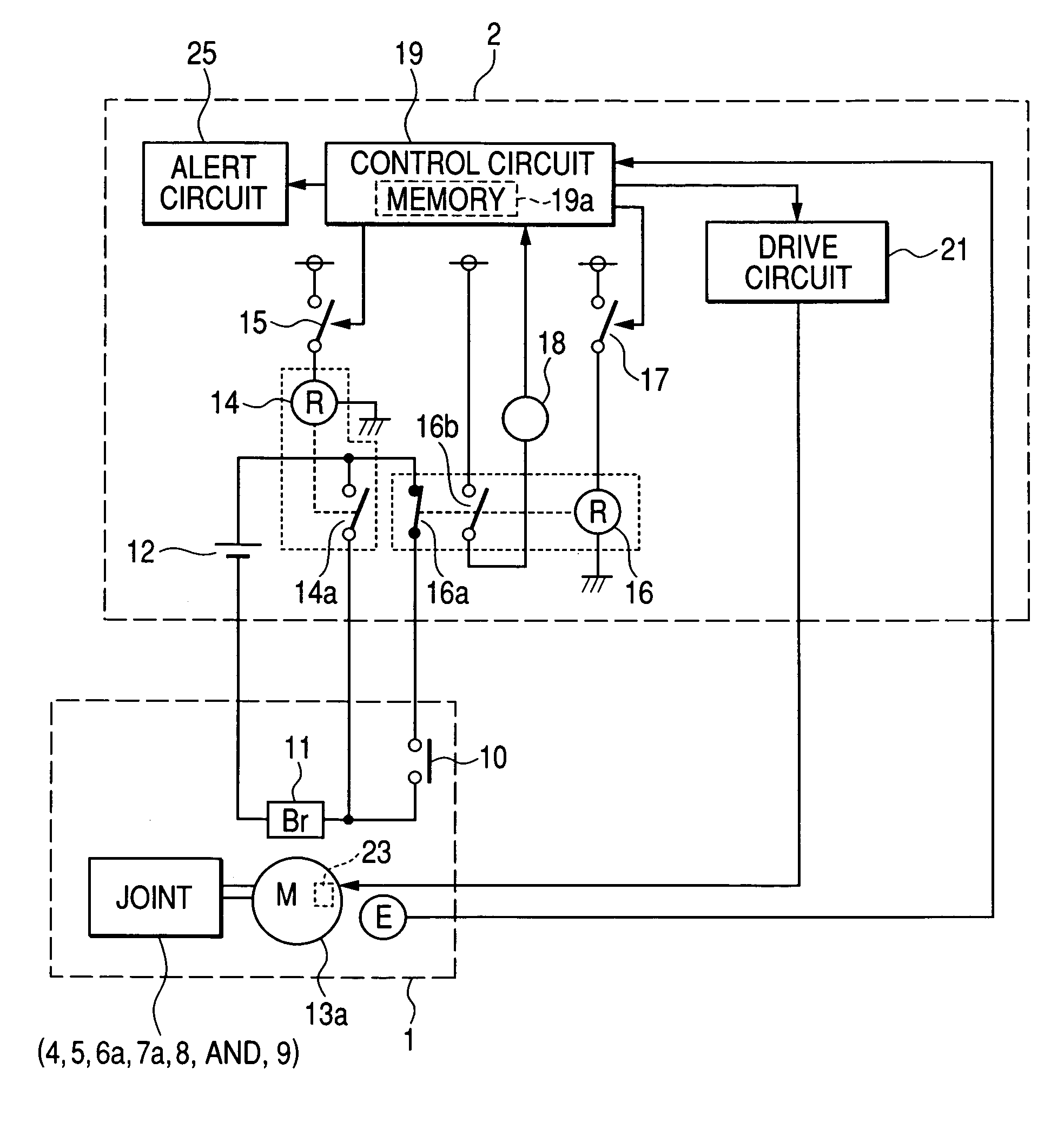

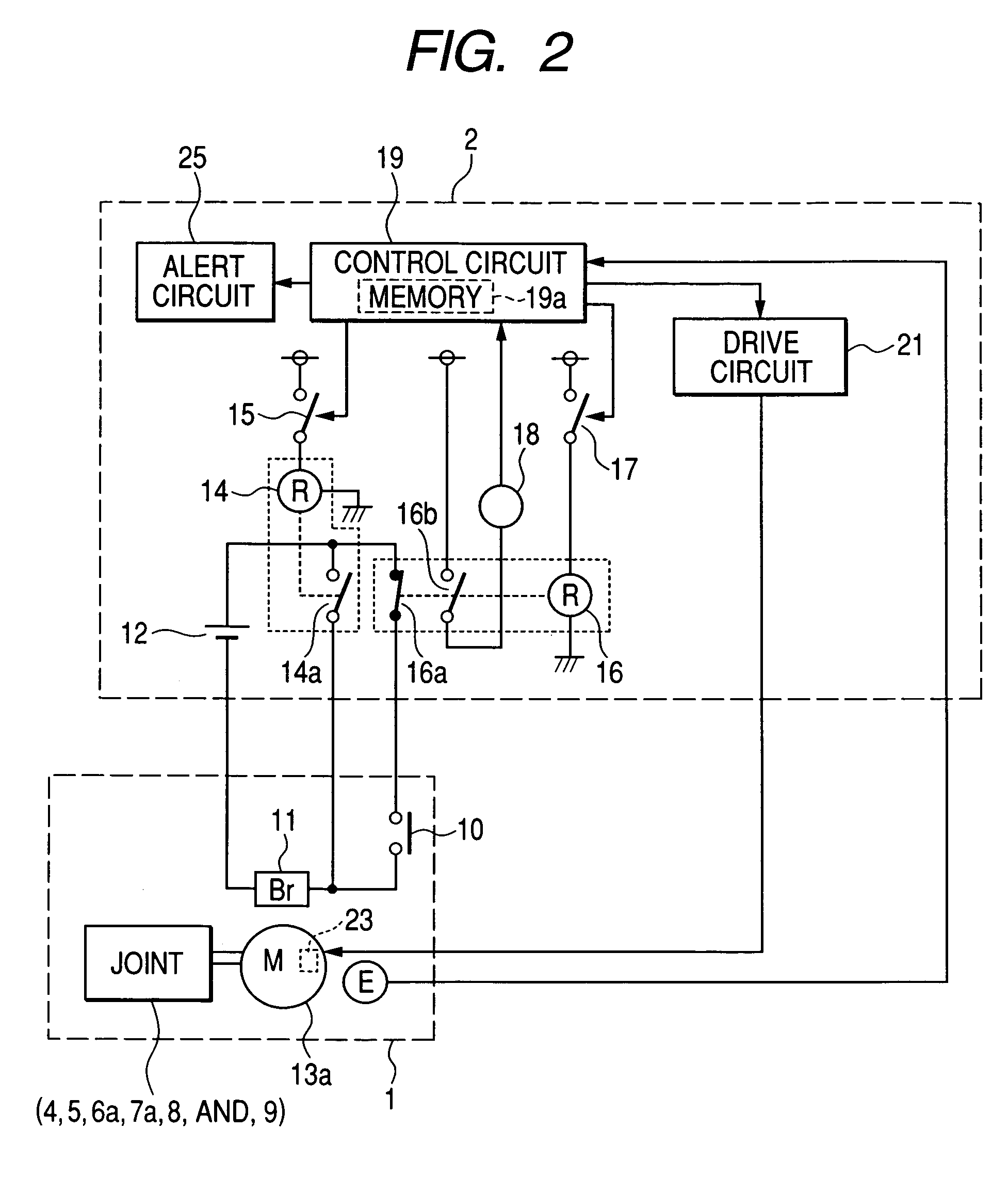

Controller for controlling robot body with power-off brake

InactiveUS7852030B2Reducing high-speed movementIncreased complexityProgramme-controlled manipulatorDC motor speed/torque controlElectricityElectrical connection

In a controller, a first switch unit establishes electrical connection between a power-off brake and a power source when a servomotor is energized. The electrical connection causes the power-off brake to be released. A second switch unit is provided between the power-off brake and the power source. The second switch unit establishes electrical connection between the power-off brake and the power source upon being manually operated during the servomotor being deenergized. A calculating unit calculates a driving speed of the joint by the servomotor. A determining unit determines whether the calculated driving speed of the joint is greater than a predetermined threshold speed. An interrupting unit interrupts a supply of electrical power from the power source to the power-off brake through the electrical connection established by the second switch unit when it is determined that the calculated driving speed of the joint is greater than the predetermined threshold speed.

Owner:DENSO WAVE INC

Methods and systems for transitioning between braking modes

ActiveUS20130296130A1Reducing driveline braking torqueIncrease friction brakingHybrid vehiclesEngine controllersHybrid vehicleAutomotive engineering

Systems and methods for improving operation of a hybrid vehicle are presented. In one example, a method for transitioning between driveline braking and wheel brakes is provided.

Owner:FORD GLOBAL TECH LLC

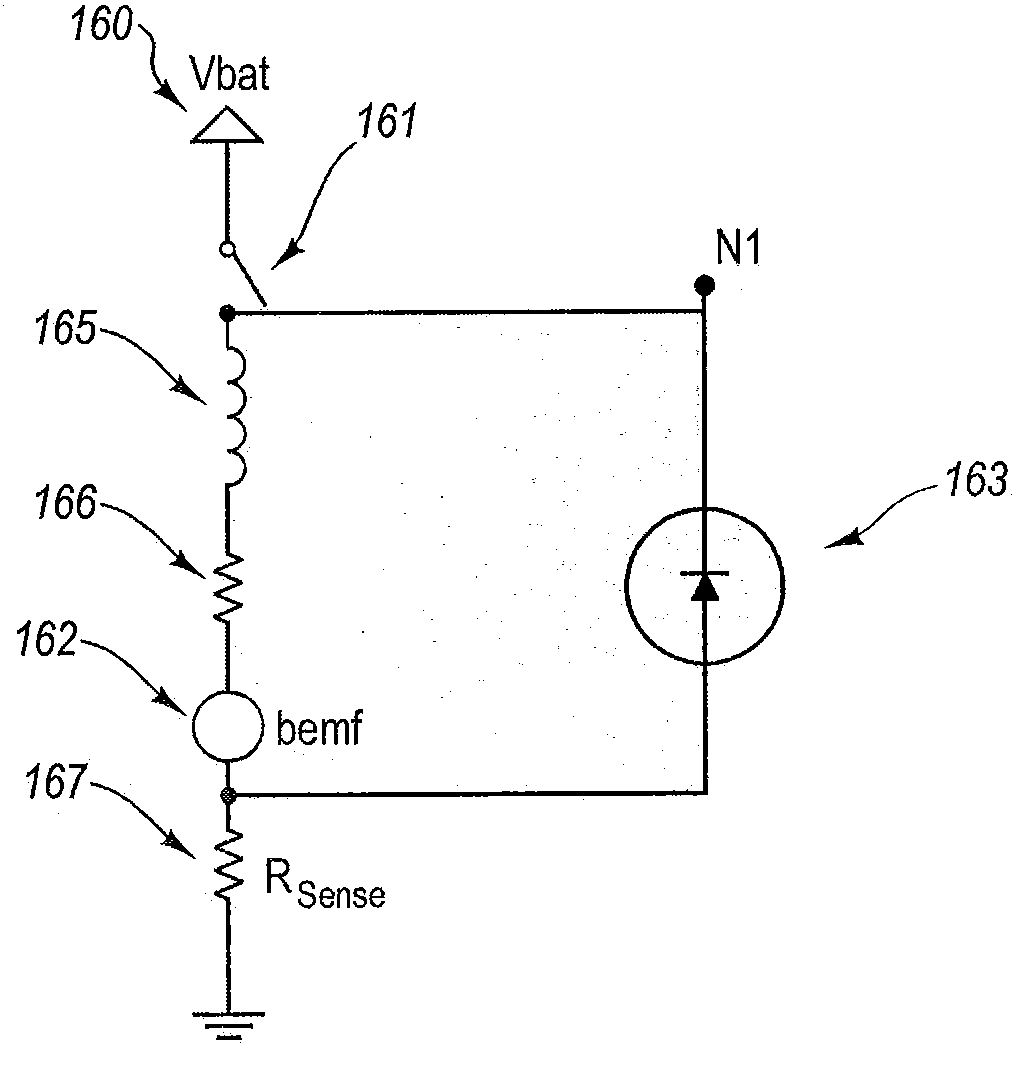

Method and apparatus for driving a DC motor

ActiveUS20080197794A1Synchronous motors startersDC motor speed/torque controlControl signalEngineering

A circuit for determining a direction of rotation of an electric motor, the motor having asymmetry and / or eccentricity in a profile of back electromotive force as a function of angular position of a rotor with respect to a stator, the circuit receiving a signal representing the BEMF, and use the corresponding asymmetry and / or eccentricity in the signal to derive the direction of rotation. The signal representing the back emf can be generated by a control circuit. The control circuit can have a feedback loop regulator to generate a control signal (TL or TR) to control a current drive circuit (11,12) to control an amplitude of current (iw) in the windings, the feedback loop regulator being arranged to compare the amplitude of the current (iw) in the windings with a reference value (iset), and use the control signal to provide the signal representing the back electromotive force.

Owner:AMI SEMICON BELGIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com