Spinning assembly for polyester fibers and assembling device and method thereof

A polyester fiber and spinning component technology, which is applied in the field of polyester fiber spinning component and its assembly device, and can solve the problems of pulp leakage, floating yarn, uneven force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

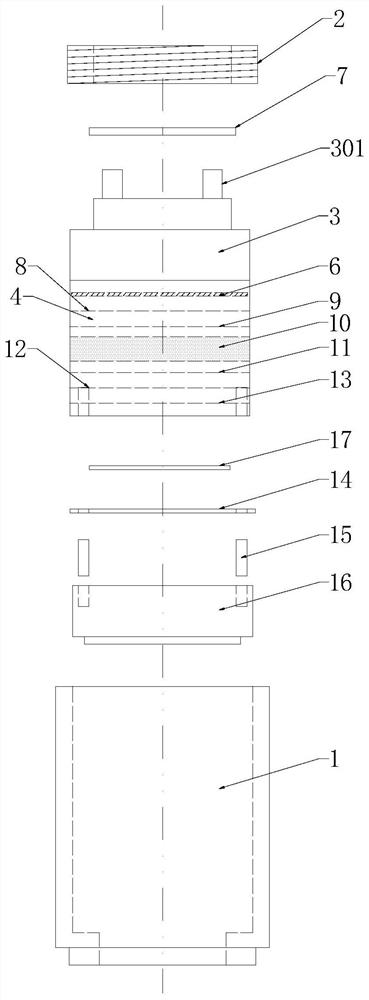

[0080] An automatic integrated device that uniformly stabilizes the internal pressure of components, such as Figure 8 As shown, it includes fixed table top, driving mechanism I, driving mechanism II, fixing mechanism, positioning mechanism and PLC controller;

[0081] Drive mechanism 1 comprises cylinder 22, ascending electromagnetic valve 29, descending electromagnetic valve 33 and table top fixed mount 21; The inner body of cylinder 22 is fixed on the table top fixed mount 21; The outer body of cylinder 22 is slidably connected with table top fixed mount 21; The outer body is connected with the ascending solenoid valve 29 and the descending solenoid valve 33; wherein, the connection between the outer body of the cylinder 22 and the table fixing frame 21 by a sliding mechanism means that the table fixing frame 21 is composed of a beam and columns at both ends thereof, and the columns are fixed On the fixed table; the upper inner side of the column on both sides of the table ...

Embodiment 2

[0088] The assembly method of DIO spinning assembly for polyester fiber is assembled by adopting an automatic integrated device for uniformly stabilizing the internal pressure of the assembly in Example 1. The specific steps are:

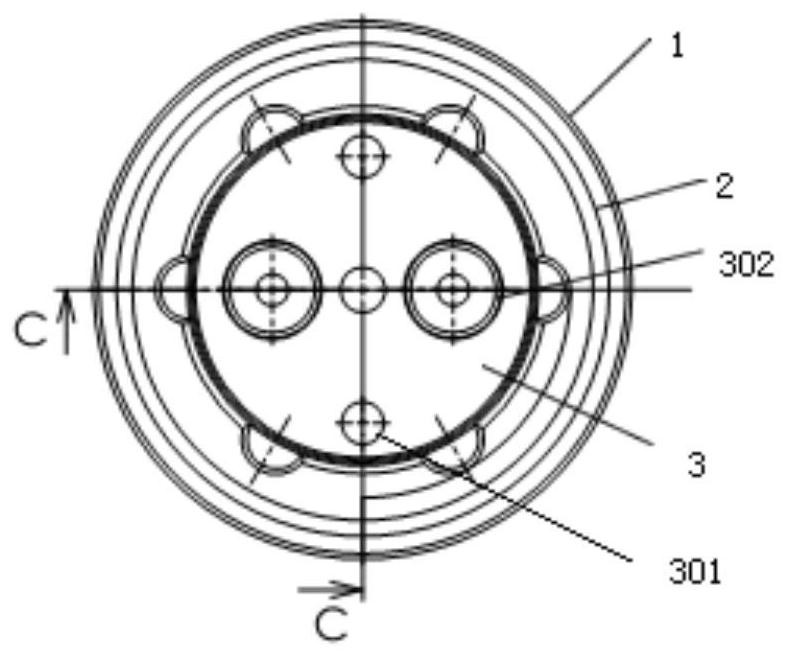

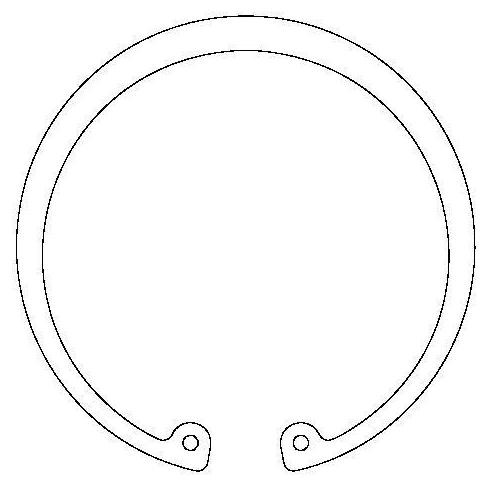

[0089](1) Assembling the sand cup 4: First, put the cleaned single-layer coarse metal mesh sheet 13 and the three-layer aluminum edged filter mesh sheet 12 in the two chambers of the sand cup 4 in sequence, and then put the aluminum Quality extrusion ring 11, use the pressure of 35MPa to seal the mesh and extrusion ring 11 on the step at the bottom of the sand cup 4 and the sand cup 4 at the cup wall; For good filter sand 10, flatten the sand with a double-half-moon flat sander, then place a single-layer fine metal mesh 9 and compact 6 on the filter sand 10, and finally, evenly inlay the sealing ring 8 on the compact 6 Between the sand cup 4 wall and the sand cup 4, the assembled sand cup 4 is obtained; the pressure of 35MPa is to place the device w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com