Efficient gas-liquid reaction kettle and application thereof in esterification reaction of ethylene oxide and carbon dioxide

A gas-liquid reaction and reaction kettle technology, applied in the field of chemical engineering, can solve the problems of incomplete reaction, generation of by-products, raw materials for side reactions, etc., to achieve uniform and complete reaction, ensure product quality and enhance the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

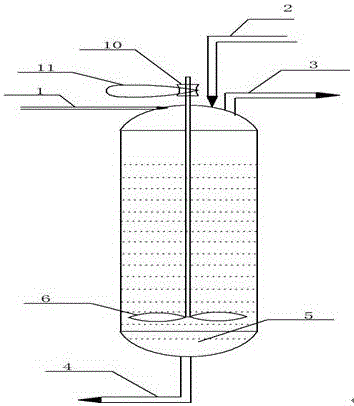

Image

Examples

Embodiment 1

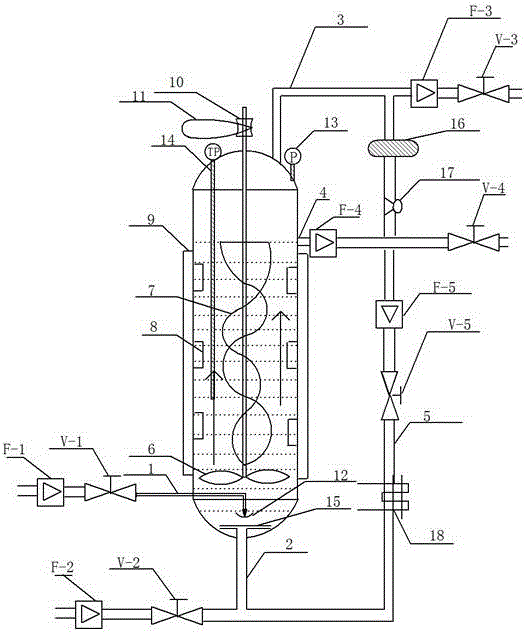

[0026] Such as figure 2 As shown, a high-efficiency gas-liquid two-phase chemical reaction kettle includes more than one liquid-phase raw material feeding pipeline, more than one gas-phase raw material feeding pipeline, gas-phase tail gas pipeline, liquid-phase product discharge pipeline, and circulating gas pipeline , strip-shaped stirring blades, spiral stirring blades, baffles, cooling fins, stirring shafts, motor belts, nozzles, pressure gauges, thermocouples, spiral gas distributors, buffer tanks, circulation pumps, start-up heaters, Liquid-phase raw material feed flowmeter, fresh gas-phase raw material feed flowmeter, gas-phase tail gas flowmeter, liquid-phase product outlet flowmeter, circulating gas flowmeter, liquid-phase raw material feed valve, fresh gas-phase raw material feed valve, gas-phase tail gas discharge Empty valve, liquid phase product outlet valve and cycle gas control main valve.

[0027] One end of the liquid phase raw material feed valve is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com