Coal slime solidifying and upgrading process and device thereof

A process device and coal slime technology, which is applied in the field of coal slime solidification and upgrading technology and its device, can solve problems such as difficult application in actual production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

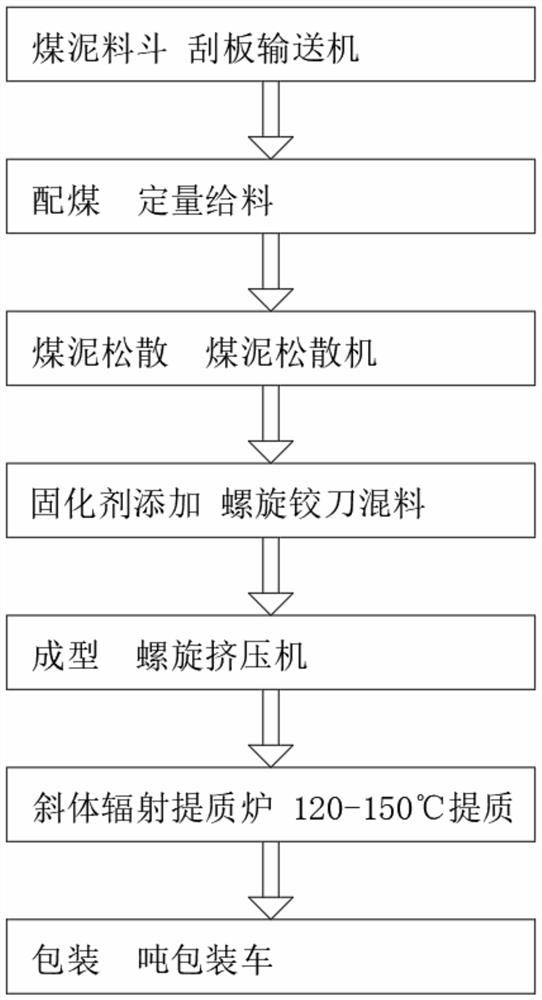

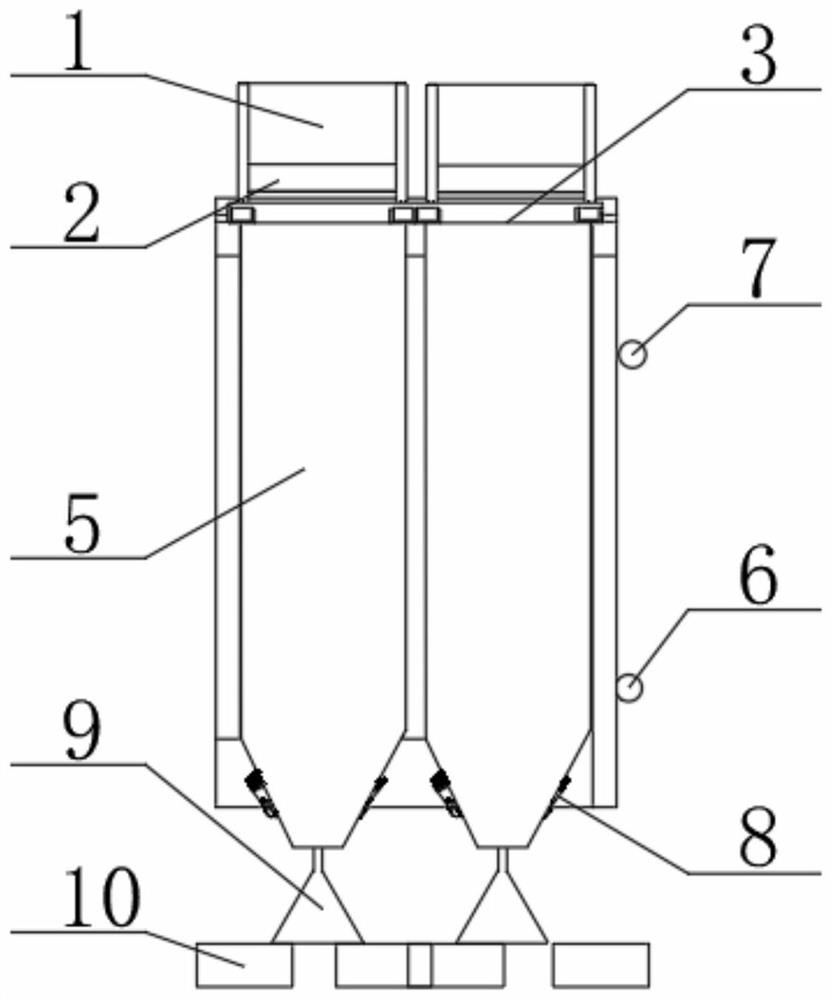

[0040] see Figure 1-6 , the present invention provides a technical solution:

[0041] A coal slime solidification and upgrading process and device thereof, comprising the following steps:

[0042] Step 1: Convey the slime cake to the single-shaft screw through the scraper machine for stirring, and at the same time add additives and sulfur-fixing agents, stir and knead the slime and additives evenly to ensure that the additives fully react with the moisture in the slime;

[0043] Step 2: The coal slime after mixing the additives is formed in the extruder, and extruded into a cylindrical shape of φ25-40mm or a plum blossom shape;

[0044] Step 3: The formed coal slime is transported to the italic radiation upgrading furnace for dehydration at 90-150°C, its water content can be reduced from 35% to 5%, its calorific value can be increased by 1500-2000kcal / kg, and its strength It can be increased from 100N to more than 1000N.

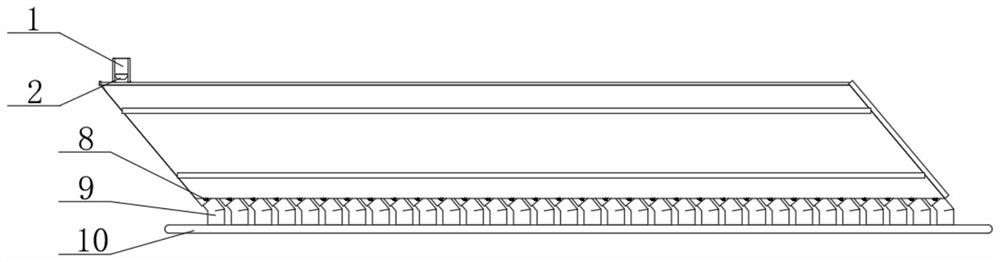

[0045] The italic radiation upgrading furnace includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com