Hydrolysis reactor

A hydrolysis reactor and heater technology, applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problems of increasing the burden on the phenol cyanide wastewater treatment unit, and the purification effect is difficult to meet, so as to achieve hydrolysis Thorough reaction, uniform heat exchange, and reduced burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

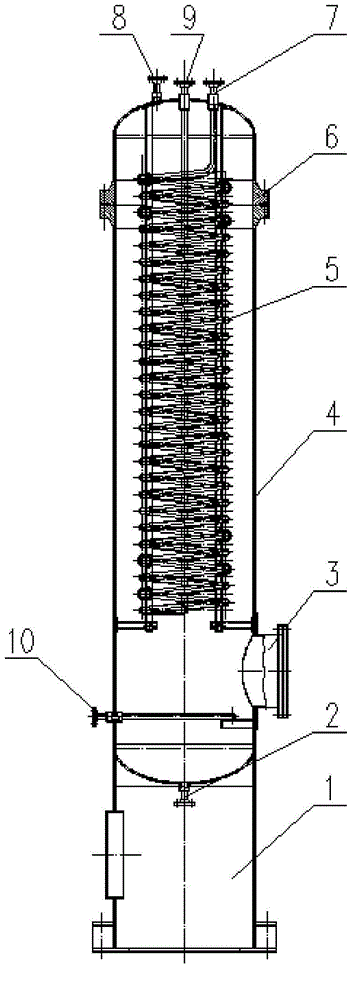

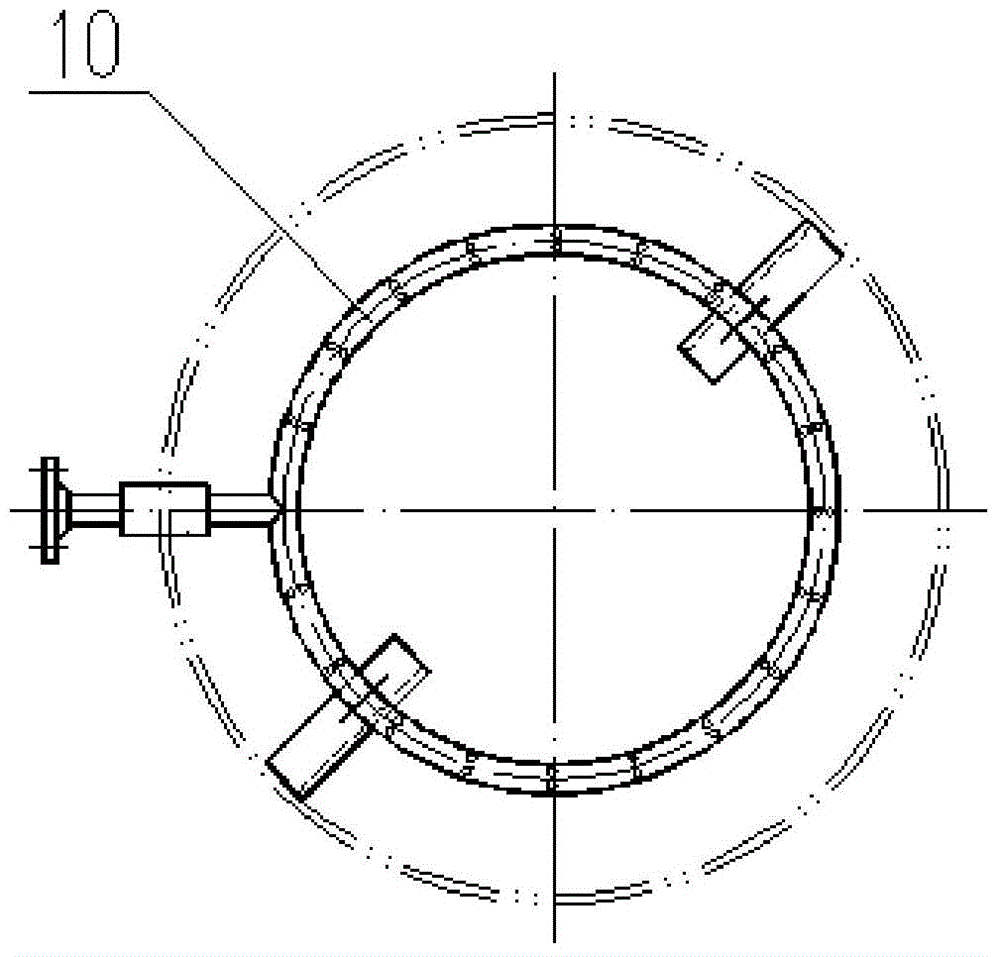

[0018] Such as figure 1 As shown, the hydrolysis reactor includes a tower body (4), a skirt (1), a heater (5) and a waste liquid inlet (10), the tower body (4) is a split type, and the tower body is connected by a flange (6). The two parts are connected, the skirt (1) is installed under the tower body (4), the vent (2) is arranged at the bottom of the tower body (4), the waste liquid inlet (10) is arranged above the vent (2), and the waste liquid inlet (10 ) adopts an annular pipe, a number of small holes are distributed at the bottom of the annular pipe, manholes (3) are installed in the lower part of the tower body (4), and a heater (5) is installed inside the tower body (4), and the heater (5) adopts a serpentine heater. The heating medium inlet (7) and the heating medium outlet (9) of the heater (5) are both arranged on the top of the tower body (4), and the waste liquid outlet (8) is arranged on the top of the tower body (4).

[0019] Embodiment 1 is a hydrolysis reactor...

Embodiment 2

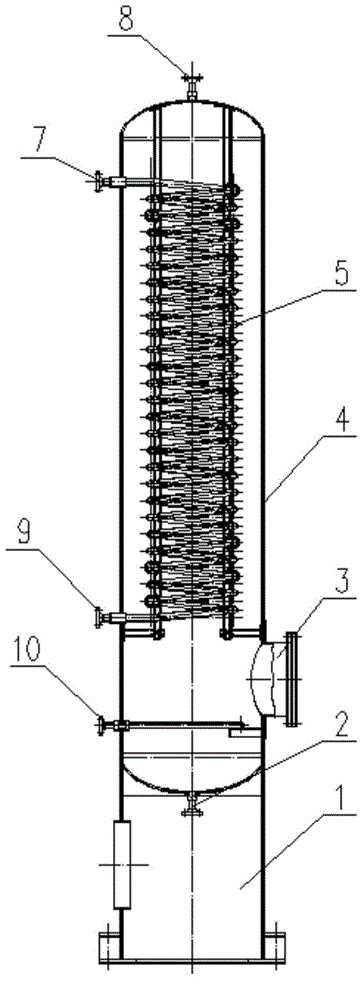

[0024] Such as figure 2 As shown, the hydrolysis reactor includes a tower body (4), a skirt (1), a heater (5) and a waste liquid inlet (10), and the skirt (1) is installed below the tower body (4), and the tower body (4) A vent (2) is arranged at the bottom, and a waste liquid inlet (10) is arranged above the vent (2). The waste liquid inlet (10) adopts an annular pipe, and several small holes are distributed at the bottom of the annular pipe. Manholes ( 3), the heater (5) is installed inside the tower body (4), and the heater (5) adopts a serpentine heater, and the heating medium inlet (7) and the heating medium outlet (9) of the heater (5) are all arranged in the tower The side of the body (4), and the top of the tower body (4) are provided with a waste liquid outlet (8).

[0025] Embodiment 2 is a top-entry hydrolysis reactor heating medium, and there is a large space in the tower body, and the heater can be repaired and maintained by entering the tower from a manhole.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com