A counterflow flue gas purification device and its purification unit

A flue gas purification and purification unit technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of uneven material discharge and large floor area, and achieve uniform material discharge, reduce the height of material distribution, The effect of lowering the altitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

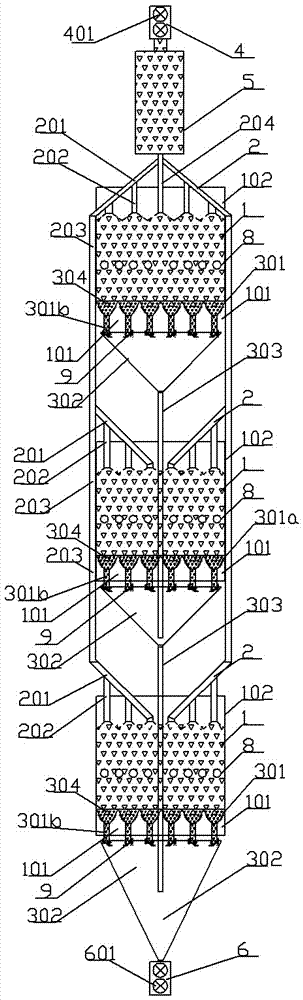

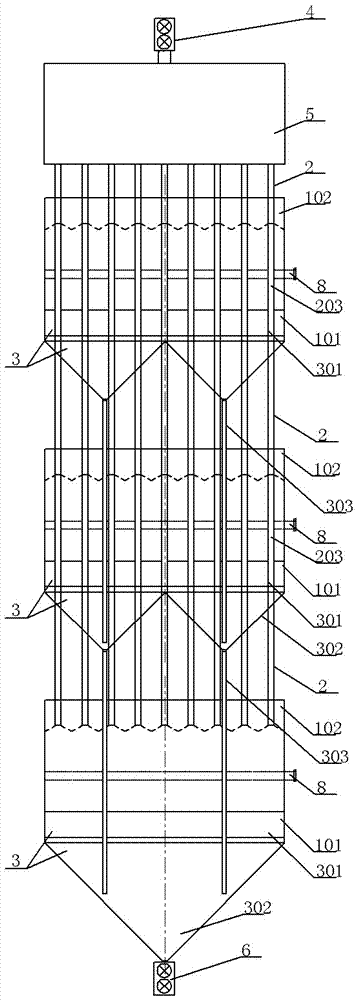

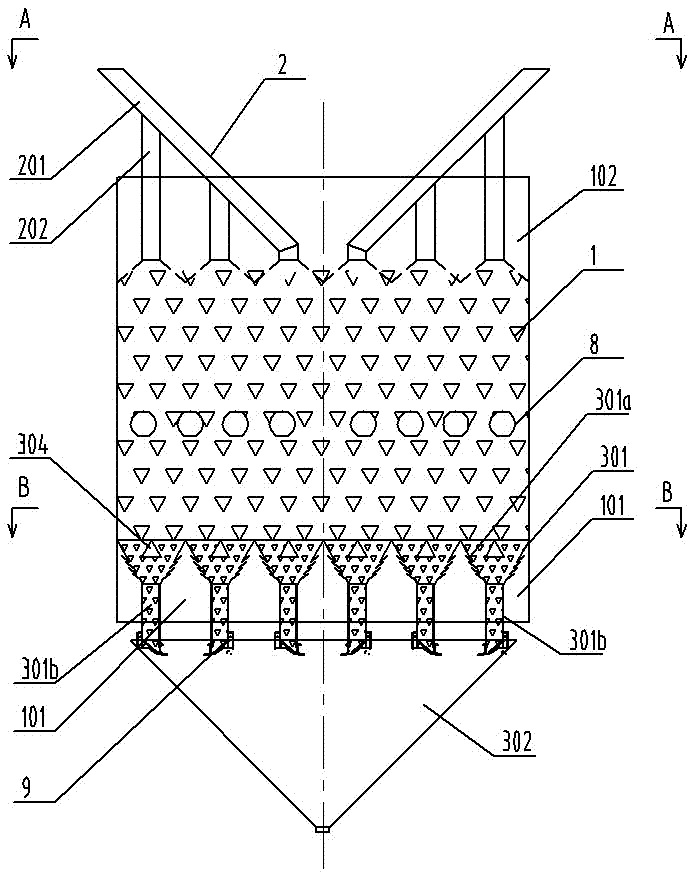

[0033] The structure of an embodiment of the counterflow flue gas purification device of the present invention is as follows: Figure 1 to Figure 6 As shown, the counter-flow flue gas purification device of this embodiment includes three purification units arranged vertically in succession. A storage bin 5 for storing activated carbon raw materials is provided above the top purification unit. The upper part of the storage bin 5 is provided with Feeding mechanism 4, the feeding mechanism 4 adopts a double-spool star feeder 401, and the space between the two valve cores is sealed with an inert gas to realize the feeding of activated carbon, isolate the air, and prevent the leakage of smoke.

[0034] Each purification unit includes a purification tower body 1 respectively. A flue gas inlet chamber 101 and a flue gas outlet chamber 102 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com