A preparation system for making floor gypsum powder from construction waste and using method thereof

A preparation system and technology of gypsum powder, which are applied in the directions of climate sustainability, sustainable waste treatment, grain treatment, etc., can solve the problems such as the restriction of reuse of waste gypsum board, the adverse effect of gypsum board strength and shape, etc., and achieve high production efficiency. , the residence time is consistent, and the effect of ensuring the quality of calcination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

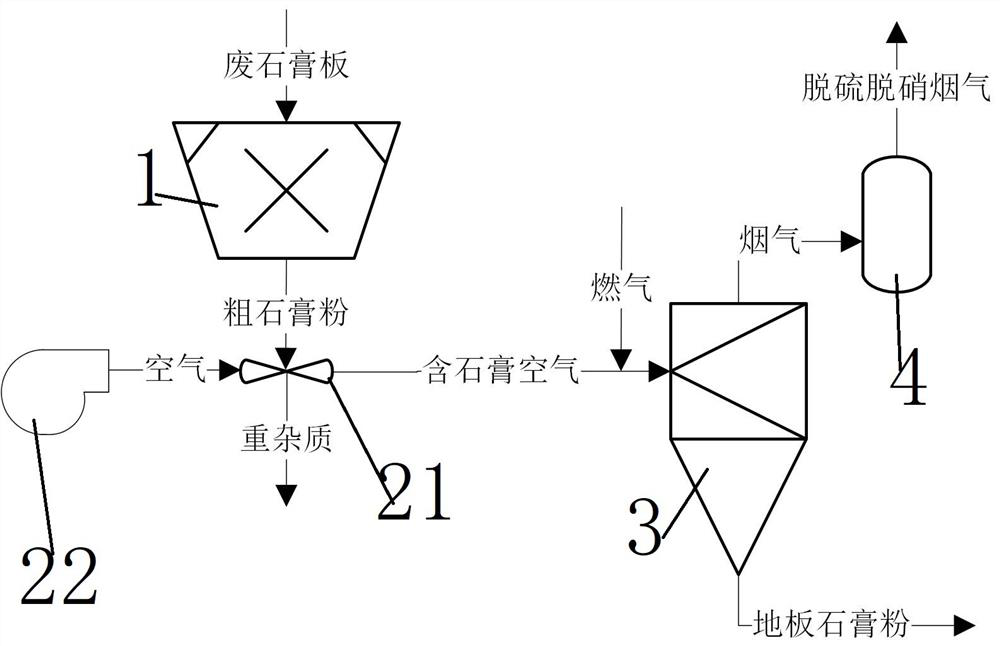

[0030] like figure 1 As shown, a preparation system for making floor gypsum powder from construction waste uses waste gypsum board to prepare floor gypsum powder, including a pulverizing subsystem 1 for pulverizing the waste gypsum board into coarse gypsum powder. The impurities in the coarse gypsum powder are , impurities with a true density greater than gypsum are recorded as heavy impurities, and impurities with a true density less than gypsum are recorded as light impurities; heavy impurities include rust and gravel, and light impurities include organic stains, paper fibers, waste coatings and waste glue; prepared from construction waste The device for cleaning the floor gypsum powder also includes an airflow sorting device for removing heavy impurities in the coarse gypsum powder, and a cyclone boiler 3 for removing light impurities in the coarse gypsum powder.

[0031] The cyclone boiler 3 here is a typical structure of a cyclone separator, including a feed port, a flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com