Micro-mixing system and method for photochemical reaction in tubular reactor

A photochemical reaction, tubular reactor technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical processes using energy, etc. There is no targeted solution to the problems of illumination and low degree of internal disturbance, so as to achieve the effect of basically consistent residence time, reduced boundary layer thickness, and consistent residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

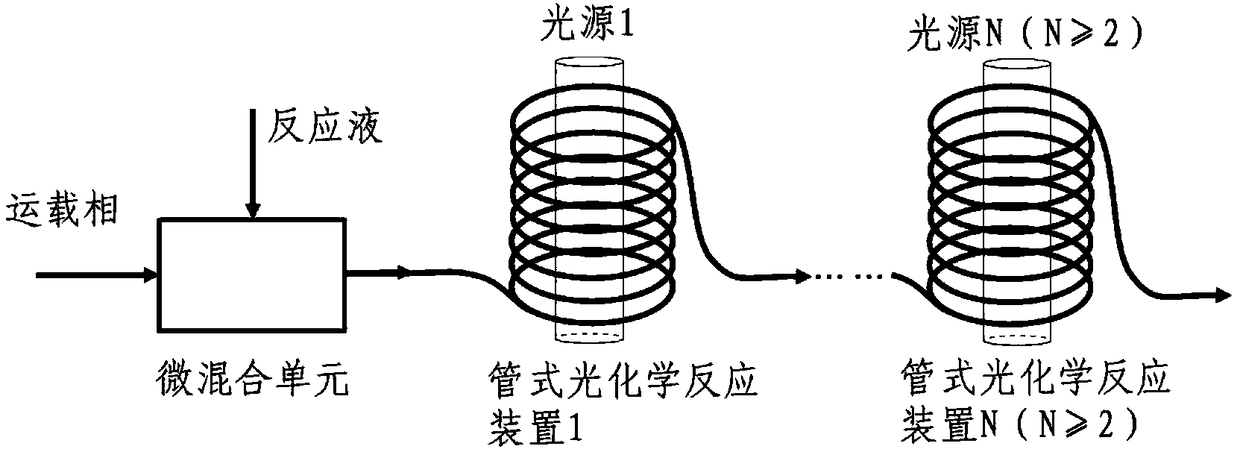

[0050] The micro-mixing system for photochemical reaction in a tubular reactor with an inverted structure in Example 1 of the present invention is composed of a micro-mixing unit and a tubular photochemical reaction device (including a tubular reactor and a light source).

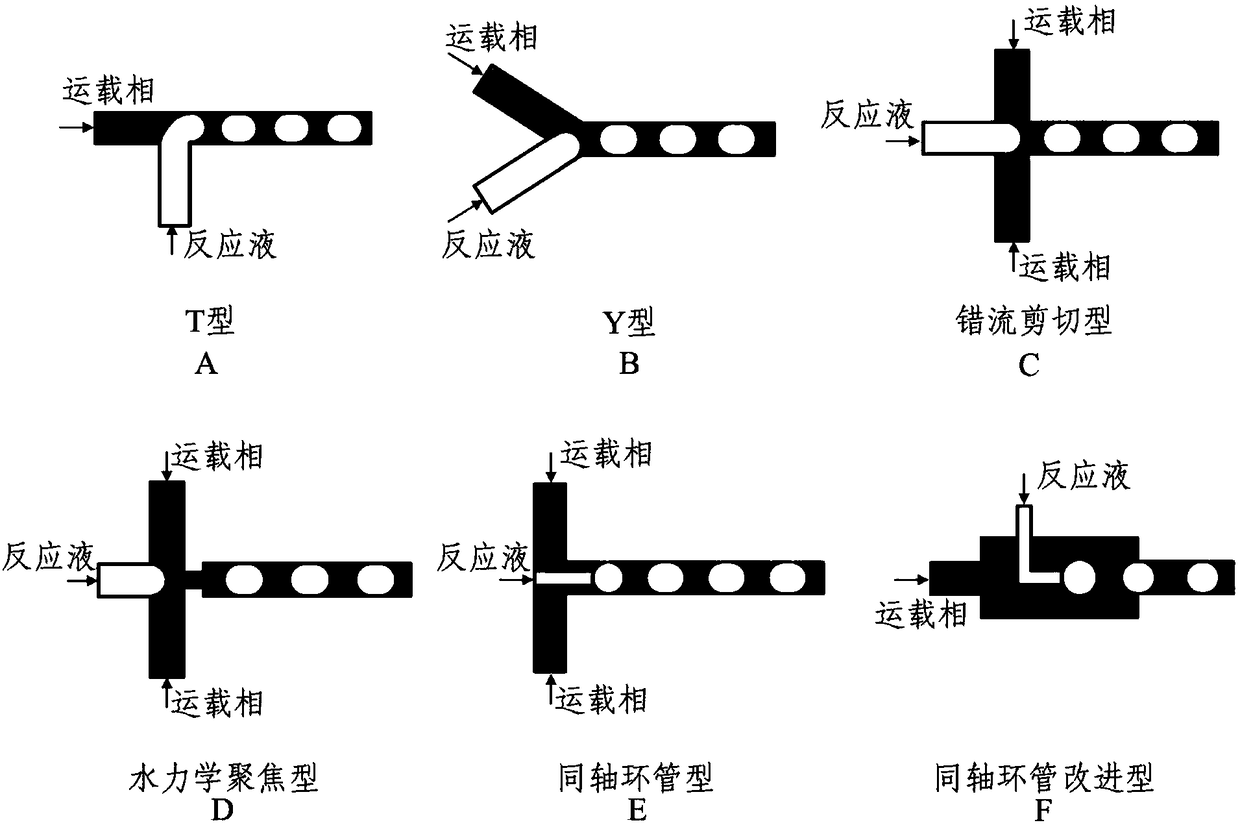

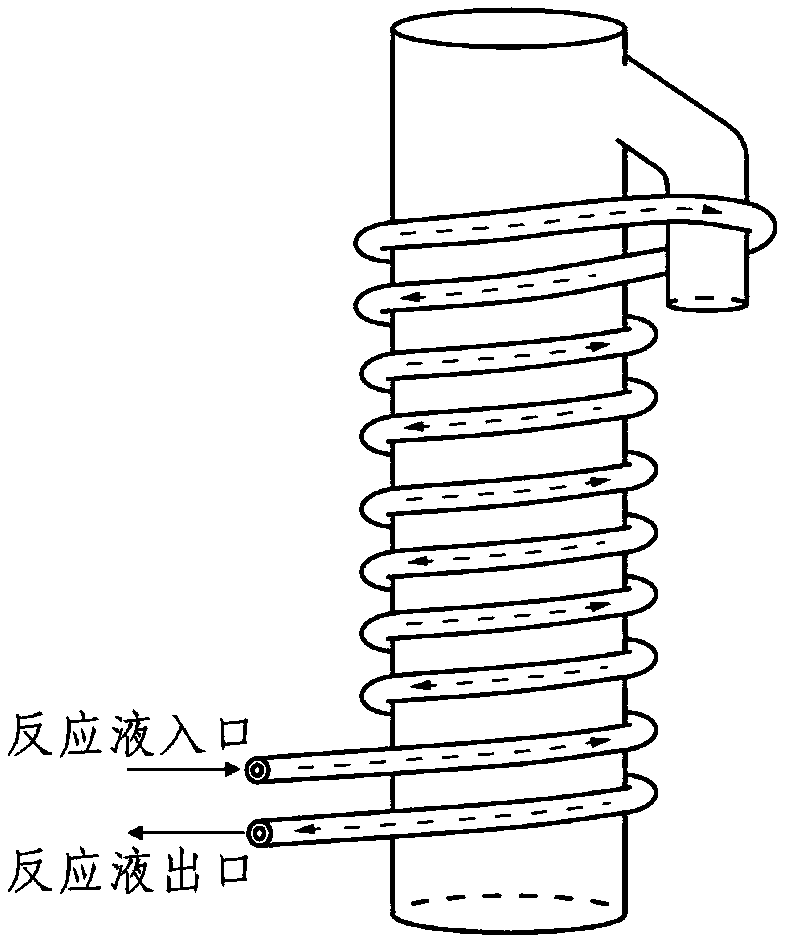

[0051] The micro-mixing unit is a T-shaped structure, the inner diameter of the main channel is 1mm, and the inner diameter of the side channel is 0.05mm; the light source is a light strip formed by a 50-watt LED lamp bead array, and the wavelength is 475nm; the tubular reactor has an inner diameter of 1mm and an outer diameter of 2mm. Perfluoroethylene propylene copolymer tubes, tubular reactors according to image 3 The light source light belt is on the outside of the tubular reactor, the two are coaxial, and it is also a spiral winding method, and the distance between the control tube wall and the LED light belt is 1cm (the tube reactor that does not surround the axis) There is no LED light strip winding...

Embodiment 2

[0057] The micro-mixing system of the photochemical reaction in the tubular reactor with inverted structure of the embodiment 2 of the present invention is composed of a micro-mixing unit and a tubular photochemical reaction device, that is, a micro-mixing unit and a tubular photochemical reaction device (comprising a tube type reactor and light source).

[0058] The micro-mixing unit is a cross-flow shear structure, the inner diameter of the main channel is 0.5mm, and the inner diameter of the two side channels is 1mm; the light source is a light strip formed by a 50-watt LED lamp bead array, and the wavelength is 475nm; the inner diameter of the tubular reactor is 1mm , perfluoroethylene propylene copolymer tube with an outer diameter of 2mm, and the tubular reactor is in accordance with Figure 4 Winding in the way of A; the light source light belt is on the outside of the tubular reactor, the two are coaxial, and it is also a spiral winding method, and the distance between...

Embodiment 3

[0064] The micro-mixing system of the photochemical reaction in the tubular reactor with reverse structure of the embodiment of the present invention 3, it is by micro-mixing unit and 2 casing type photochemical reaction devices (comprising 2 tubular reactors, 2 cold traps and 2 light sources).

[0065] The micro-mixing unit is an improved coaxial annular tube structure, the inner diameter of the droplet forming chamber is 2.5mm, the inner diameter of the reaction solution channel is 1mm, the inner diameter d of the output channel is 1.5mm, and the inner tube is the inner wall of the superhydrophobic coating (with the dispersion The contact angle of the phase liquid is 151°); the first and second light sources are both 100-watt high-pressure mercury lamps; the first and second cold traps are made of high borosilicate glass, which filter out ultraviolet light below 300nm, and the mercury lamp is placed in a cold trap In the trap; the tubular reactor is a perfluoroethylene propy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com