Device for continuously preparing high-purity meta-position aramid fiber resin solution

A technology of resin solution and aramid fiber, which is applied in the field of polymer material production equipment and industrial continuous preparation of high-purity meta-aramid resin solution, which can solve the problem of high production cost and polym-phenylene isophthalamide polymerization Problems such as narrow molecular weight distribution and large engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

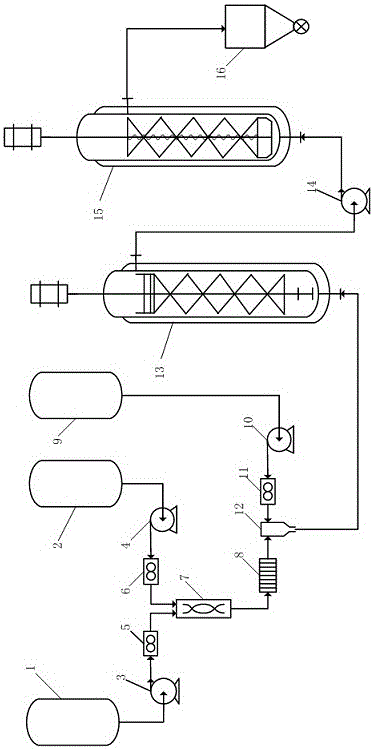

Method used

Image

Examples

Embodiment 1

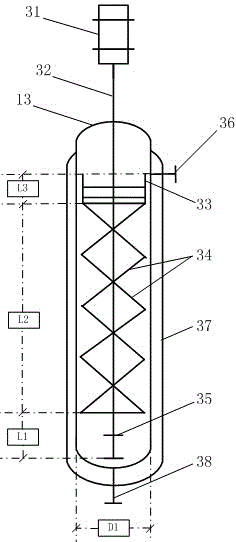

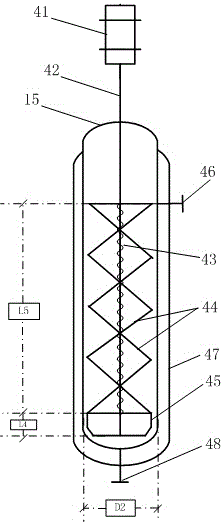

[0022]The solid m-phenylenediamine (MPD) raw material is heated and melted at 80°C into a fluid liquid molten state, and placed in the m-phenylenediamine storage tank 2 for standby; the solid isophthaloyl dichloride (IPC) raw material is in Heating and melting at a temperature of 60°C into a liquid molten state with fluidity, and placing it in the isophthaloyl chloride storage tank 9 for standby; the N,N-dimethylacetamide (DMAc) in the solvent storage tank 1 has a water content of 80ppm, measured by the solvent delivery pump 3 and the solvent mass flowmeter 5, enters from an input port of the static mixer 7 at a flow rate of 401.69 mass parts per hour; m-phenylenediamine (MPD) in the m-phenylenediamine storage tank 2 The melt enters from another input port of the static mixer 7 at a flow rate of 27.29 parts by mass per hour after being metered by the m-phenylenediamine delivery pump 4 and the m-phenylenediamine mass flowmeter 6; the m-phenylenediamine coming out of the static m...

Embodiment 2

[0025] The solid m-phenylenediamine (MPD) raw material is heated and melted at 80°C into a fluid liquid molten state, and placed in the m-phenylenediamine storage tank 2 for standby; the solid isophthaloyl dichloride (IPC) raw material is in Heating and melting at a temperature of 60°C into a liquid molten state with fluidity, and placing it in the isophthaloyl chloride storage tank 9 for standby; the N,N-dimethylacetamide (DMAc) in the solvent storage tank 1 has a water content of 120ppm, measured by the solvent delivery pump 3 and the solvent mass flowmeter 5, enters from an input port of the static mixer 7 at a flow rate of 322.44 mass parts per hour; m-phenylenediamine (MPD) in the m-phenylenediamine storage tank 2 The melt enters from another input port of the static mixer 7 at a flow rate of 27.29 parts by mass per hour after being metered by the m-phenylenediamine delivery pump 4 and the m-phenylenediamine mass flowmeter 6; the m-phenylenediamine coming out of the static...

Embodiment 3

[0028] The solid m-phenylenediamine (MPD) raw material is heated and melted at 80°C into a fluid liquid molten state, and placed in the m-phenylenediamine storage tank 2 for standby; the solid isophthaloyl dichloride (IPC) raw material is in Heating and melting at a temperature of 60°C into a liquid molten state with fluidity, and placing it in the isophthaloyl chloride storage tank 9 for standby; the N,N-dimethylacetamide (DMAc) in the solvent storage tank 1 has a water content of 150ppm, measured by the solvent delivery pump 3 and the solvent mass flowmeter 5, enters from an input port of the static mixer 7 at a flow rate of 227.11 parts by mass per hour; m-phenylenediamine (MPD) in the m-phenylenediamine storage tank 2 The melt enters from another input port of the static mixer 7 at a flow rate of 27.29 parts by mass per hour after being metered by the m-phenylenediamine delivery pump 4 and the m-phenylenediamine mass flowmeter 6; the m-phenylenediamine coming out of the sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com