Bolt fastening type high-productivity compact top-mounted spinning assembly

A spinning assembly, fastening technology, which is applied in the field of bolt fastening, high-capacity and compact top-loading spinning assembly, which can solve the problems of inability to test product quality, high risk of spinning assembly, and short service life of the machine. Achieve the effect of reducing deformation, consistent residence time and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

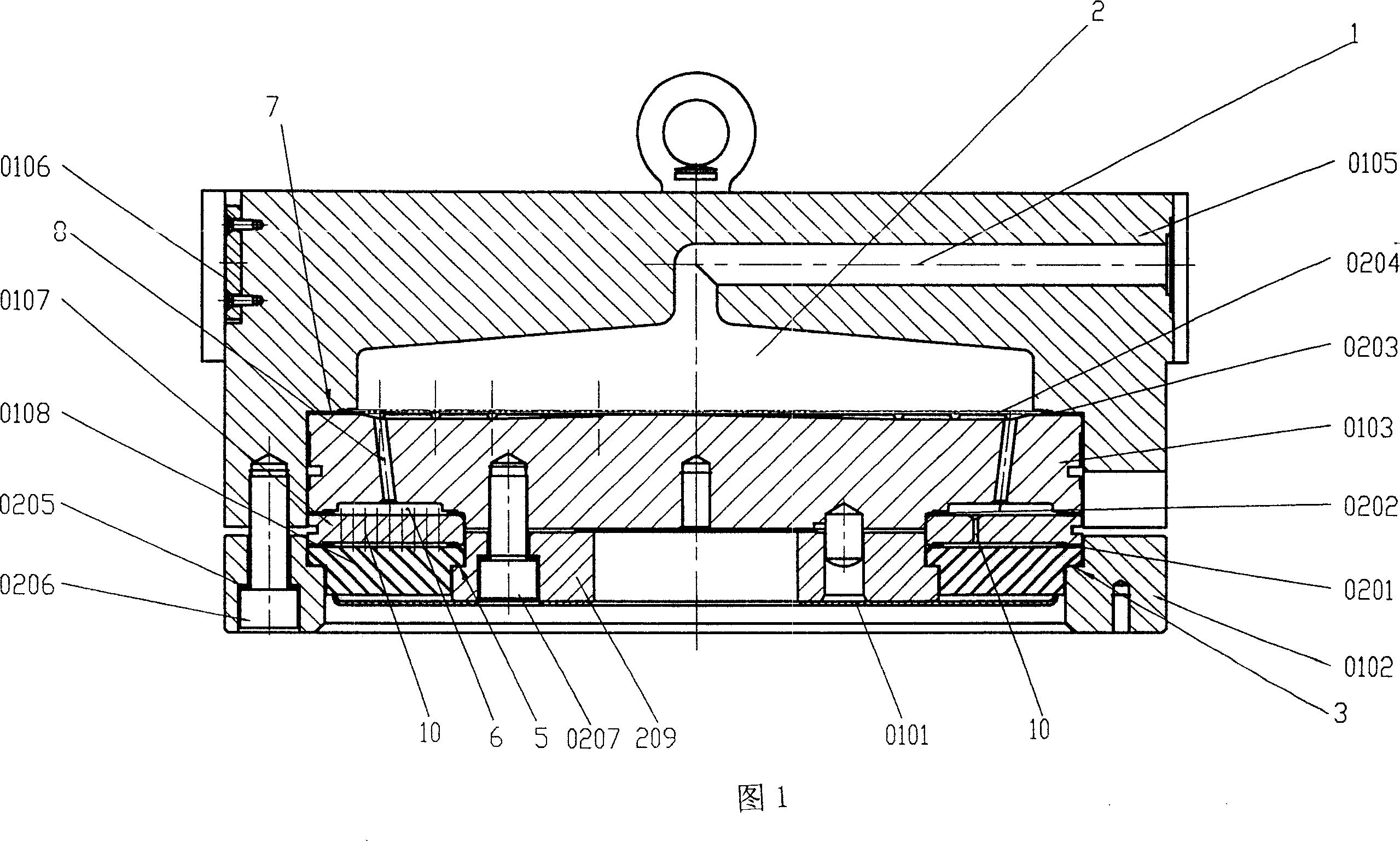

[0030] As shown in Figures 1-9.

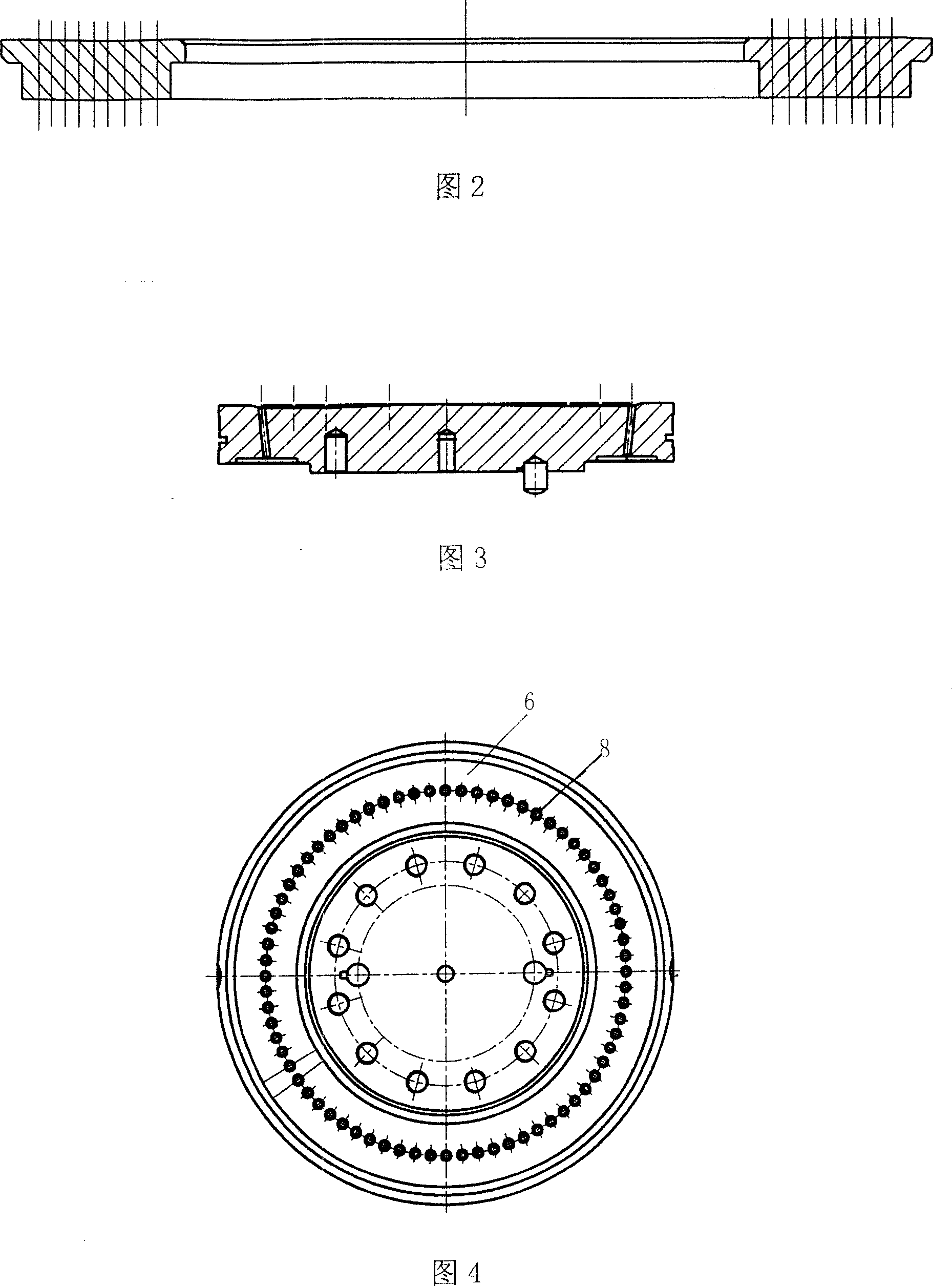

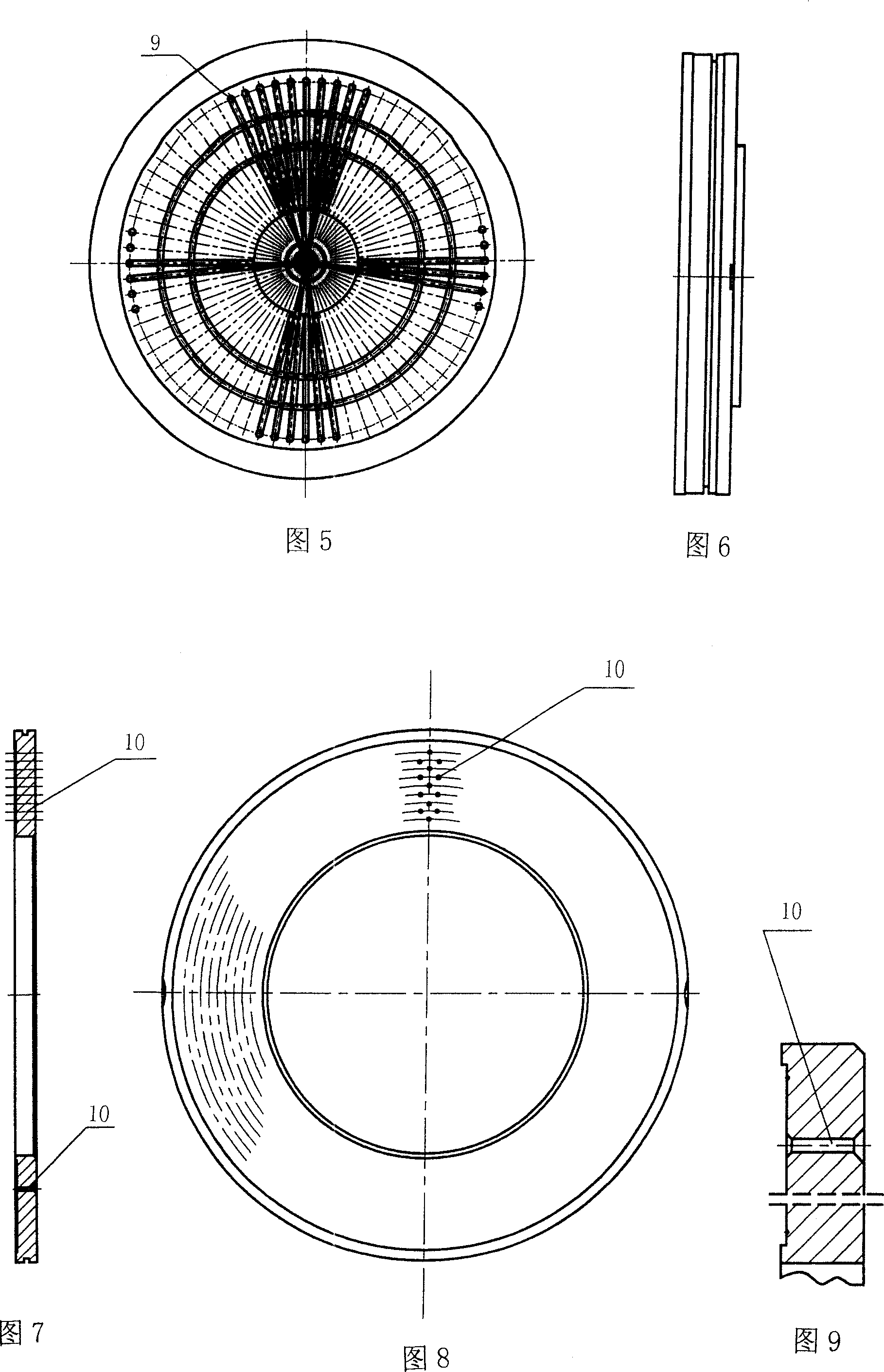

[0031] A bolt-fastened high-capacity compact top-loading spinning assembly, including a headgear seat 0105, an outer pressure ring 0102, the outer ring of the headgear seat 0105 and the outer pressure ring 0102 are connected by high-strength bolts 206, and the headgear seat 0105 is also connected with a positioning block 0106, a melt channel 1 and a distribution chamber 2 communicating with the melt channel 1 are opened on the headgear seat 0105, and a melt inlet copper gasket 0210 is installed at the entrance of the melt channel 1, as shown in Figure 1 . The outer ring of the spinneret 0108 (as shown in Figure 2) is press-fitted on the inner step surface 3 of the outer pressure ring 0102, and the inner ring of the spinneret 0108 is press-fitted on the step surface 5 of the inner pressure ring 209. A protection plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com