Condensation pipeline vibration damper and vibration damping method

A technology for condensing pipes and shock absorbers, which is applied in the directions of pipe elements, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of installation and construction difficulties, influence attenuation effect, parameter selection difficulties, etc., and achieve convenient installation and disassembly. , Improve the utilization efficiency and enhance the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

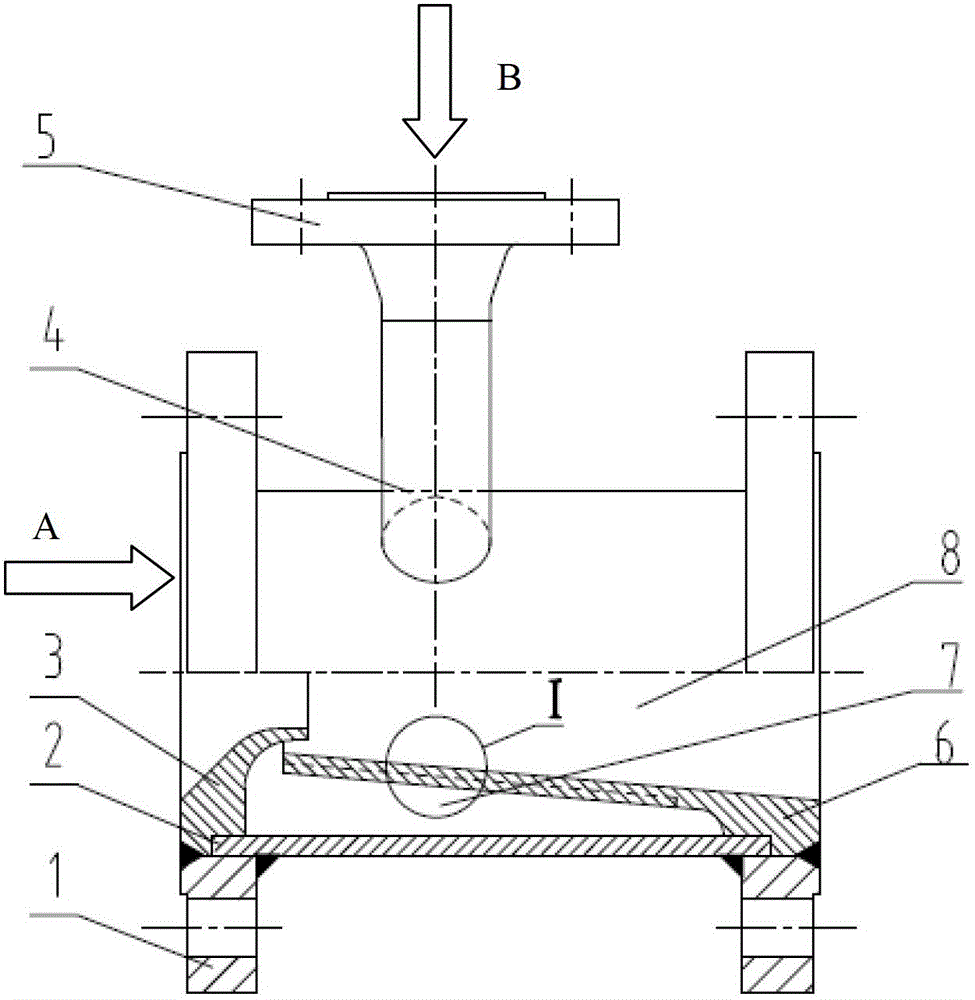

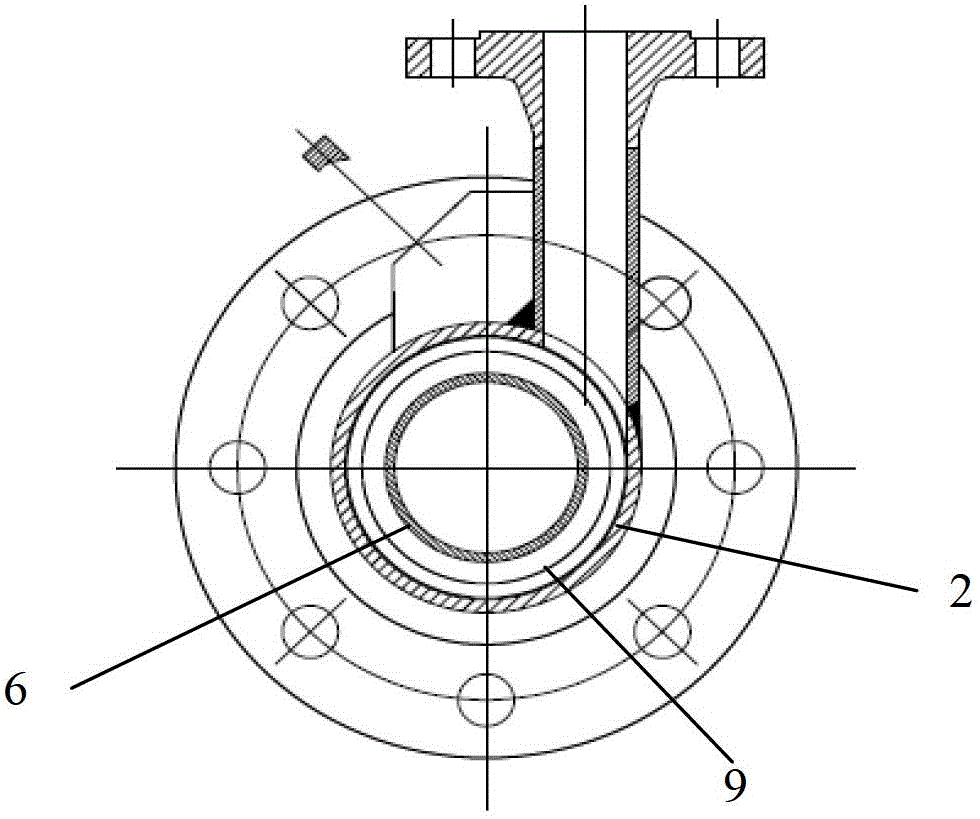

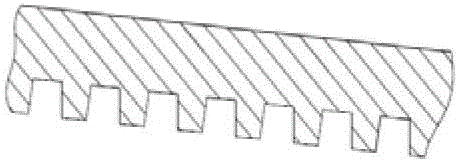

[0040] Such as figure 1 As shown, a condensate pipeline shock absorber includes a main liquid inlet, and the main liquid inlet communicates with a branch pipe 4 for two-phase flow; the shock absorber includes an inner chamber 8 that communicates with the main liquid inlet. , and the outer cavity 7 communicated with the branch pipe 4, the inner cavity 8 is sleeved in the outer cavity 7, and the inner cavity 8 is provided with a gap at the communication part with the outer cavity 7; the inner wall of the outer cavity 7 A threaded groove 9 is provided. The entrance of the inner chamber 8 is a tapered mouth structure, and the diameter of the inner chamber 8 at the communication point with the outer chamber 7 is smaller than that at the entrance of the inner chamber 8 . The outer edge of the inner cavity 8 is the inner cylinder 6, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com