Device for continuously preparing high-purity polyisophthaloyl metaphenylene diamine resin solution

A technology of polym-phenylene isophthalamide and isophthaloyl chloride, which is applied in the direction of feeding device, chemical/physical/physical chemical fixed reactor, chemical/physical/physical chemical process, etc., can solve the problem of Corrosion, narrow molecular weight distribution of polym-phenylene isophthalamide polymer, large engineering investment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

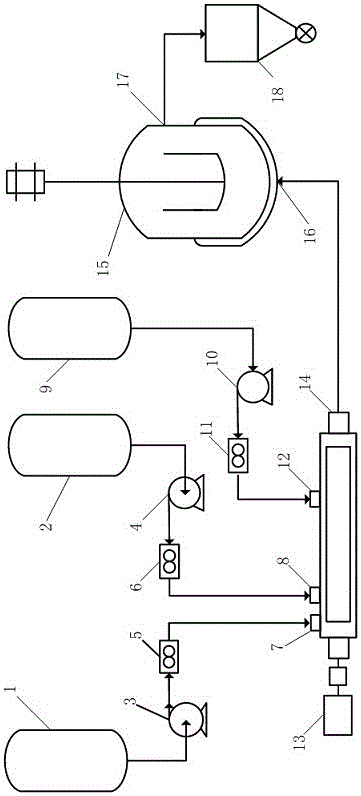

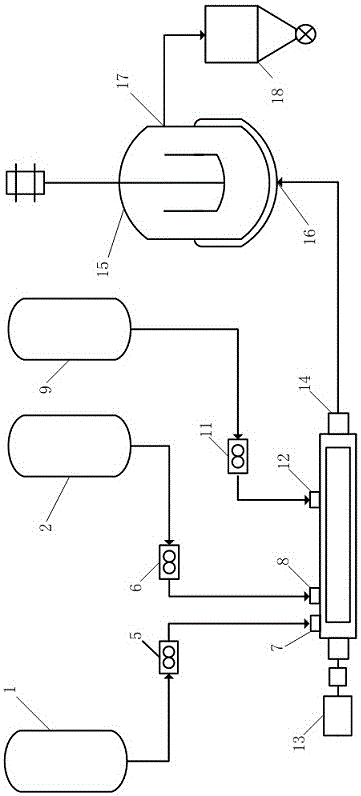

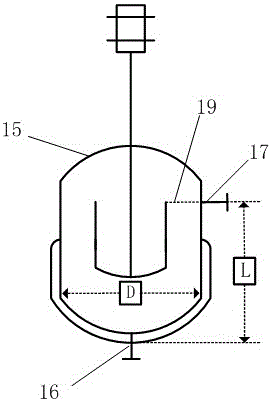

[0016] The first embodiment of the present invention is as figure 1 shown. The device includes solvent metering delivery system, m-phenylenediamine metering delivery system, isophthaloyl chloride metering delivery system, twin-screw mixer 13, polymerization reactor 15 and resin solution storage tank 18, etc.; solvent metering delivery system includes solvent storage tank 1. Solvent delivery pump 3 and solvent mass flowmeter 5; m-phenylenediamine metering delivery system includes m-phenylenediamine storage tank 2, m-phenylenediamine delivery pump 4 and m-phenylenediamine mass flowmeter 6; m-phenylenediamine The acid chloride metering delivery system comprises an isophthaloyl chloride storage tank 9, an isophthaloyl chloride delivery pump 10 and an isophthaloyl chloride mass flowmeter 11; their connection relationship is: the output port of the solvent storage tank 1 and the solvent delivery pump 3 is connected to the input port, the output port of the solvent delivery pump 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com