A kind of extruder raw material quantitative blanking equipment

An extruder and raw material technology, which is applied in the field of extruder raw material quantitative feeding equipment, can solve the problems of difficult mixing and quantitative feeding of plastic particles, difficulty in quantitative feeding, and the amount of feeding is not fixed. Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

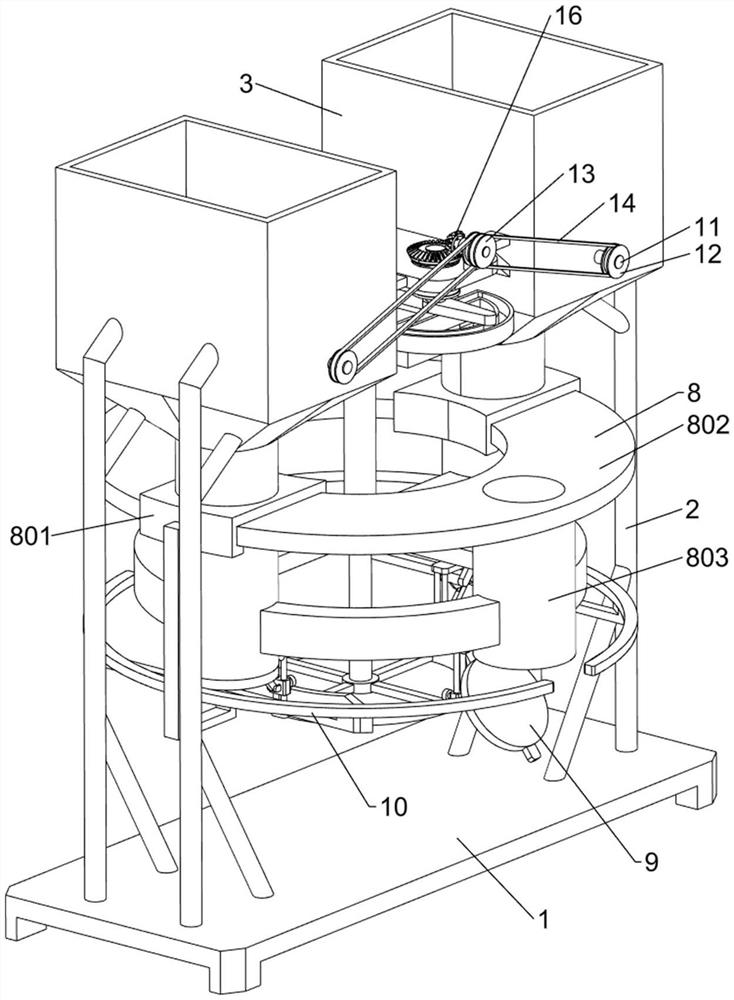

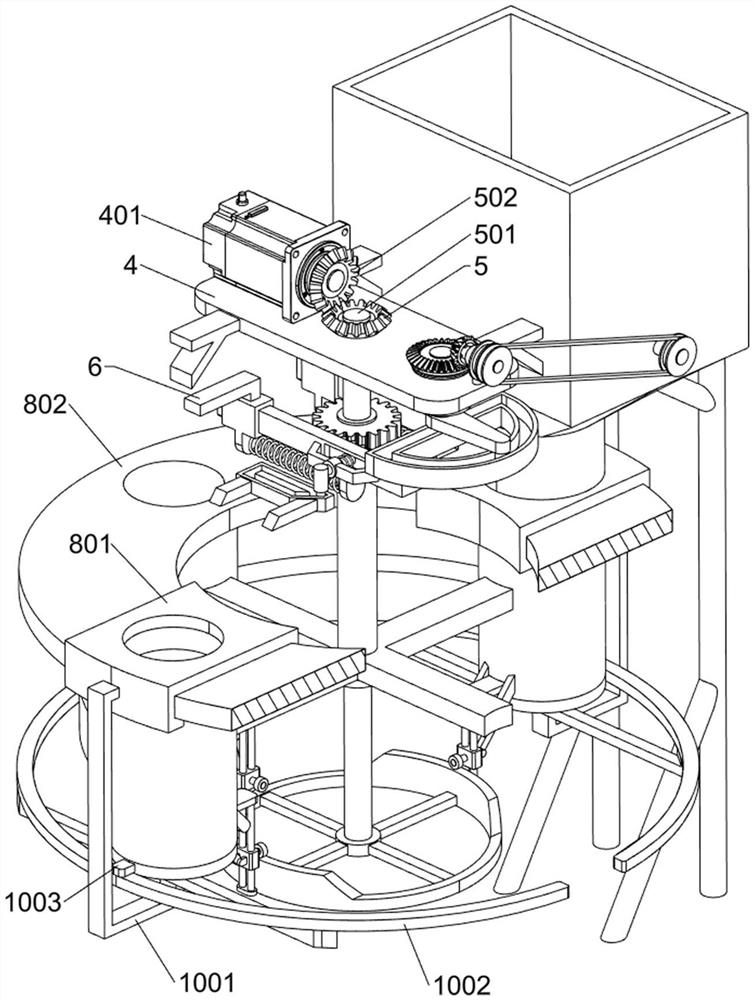

[0026] An extruder raw material quantitative cutting equipment, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, it includes a base plate 1, a bracket 2, a storage box 3, a support plate 4, a servo motor 401, a drive assembly 5, a movable assembly 6, a rotation assembly 7, a blanking assembly 8, a cover opening assembly 9 and a limit assembly 10 , the bottom plate 1 is fixedly connected to the left and right symmetrically with the support 2, the upper part of the support 2 is connected with the storage box 3 by bolts, the support plate 4 is fixedly connected between the storage boxes 3, and the back side of the top of the support plate 4 is fixed with a servo motor 401 , a drive assembly 5 is arranged between the support plate 4 and the output shaft of the servo motor 401, a movable assembly 6 and a rotating assembly 7 are arranged between the storage box 3, the movable assembly 6 is connected with the drive assembly 5, and the bottom ...

Embodiment 2

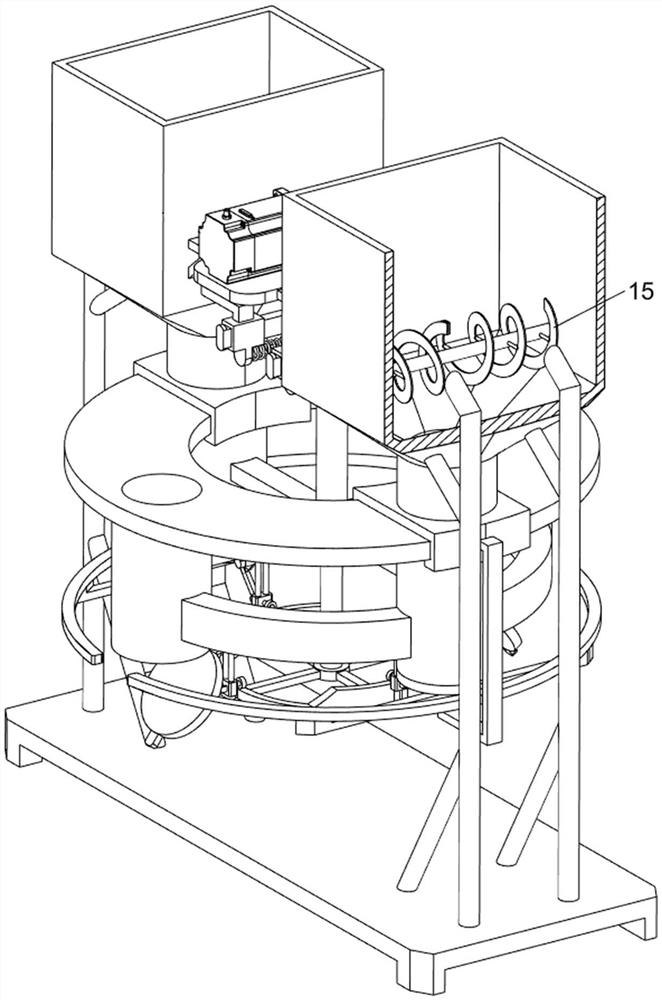

[0037] On the basis of Example 1, as figure 1 As shown, it also includes a third rotating shaft 11, a second transmission wheel 12, a double-groove transmission wheel 13, a second belt 14, a two-way spiral belt 15 and a second bevel gear set 16. The lower part of the front side of the storage box 3 is a rotary type A third rotating shaft 11 is provided. The front side of the third rotating shaft 11 is connected with a second transmission wheel 12. The front side of the top of the support plate 4 is rotatably provided with a double-slotted transmission wheel 13. The double-slotted transmission wheel 13 is connected with the second transmission wheel on both sides A second belt 14 is connected between the wheels 12, a second bevel gear set 16 is connected between the rear end of the double-slot drive wheel 13 and the top of the second shaft 504, and a bidirectional spiral belt 15 is connected to the rear of the third shaft 11. The two-way spiral belts 15 are all located in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com