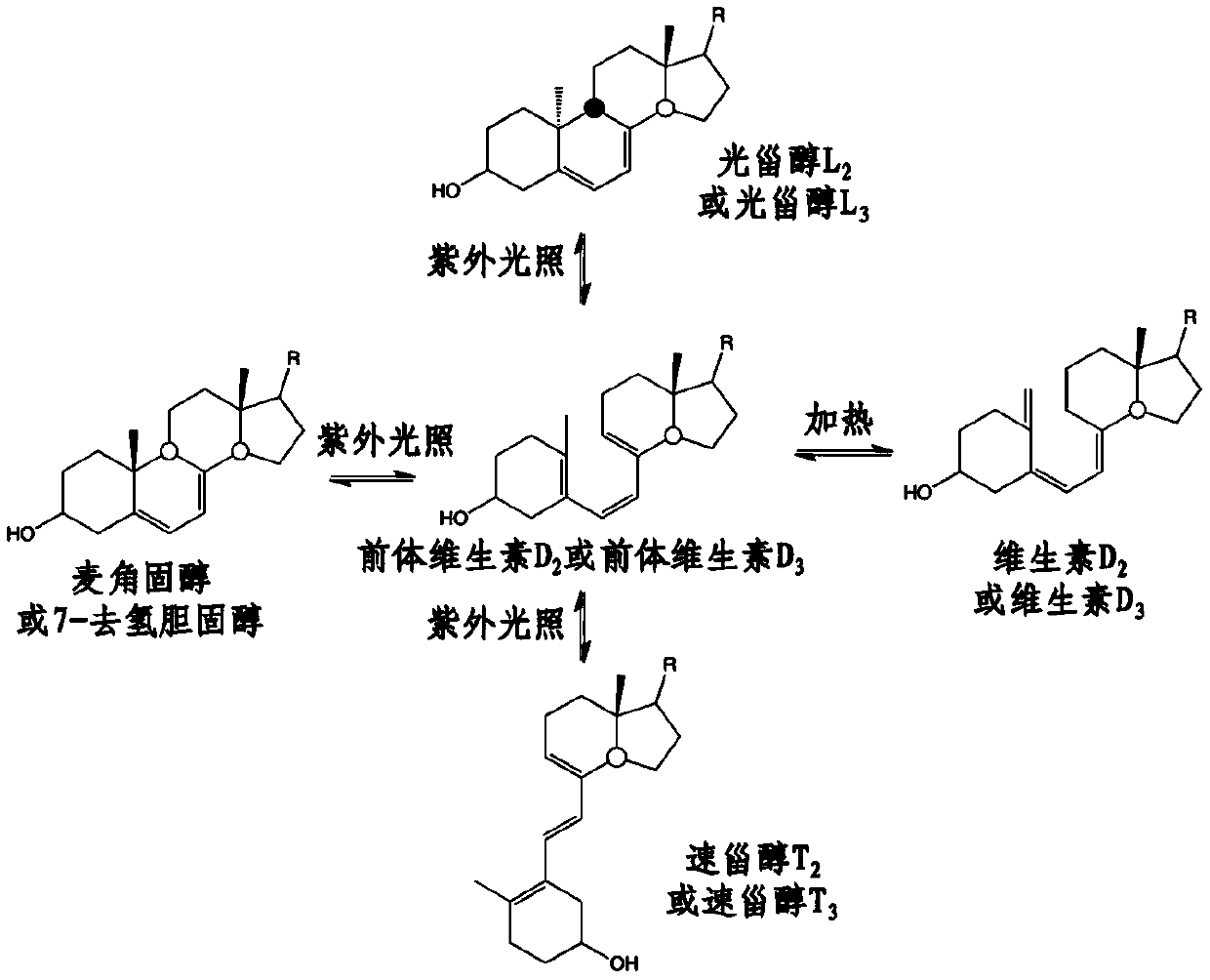

Photochemical synthesis of vitamin D in a tubular reactor 2 、d 3 Methods

A tubular reactor and photochemical synthesis technology, applied in the direction of organic chemistry, can solve the problems of waste gas emission, high requirements, fusion and total flow rate acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

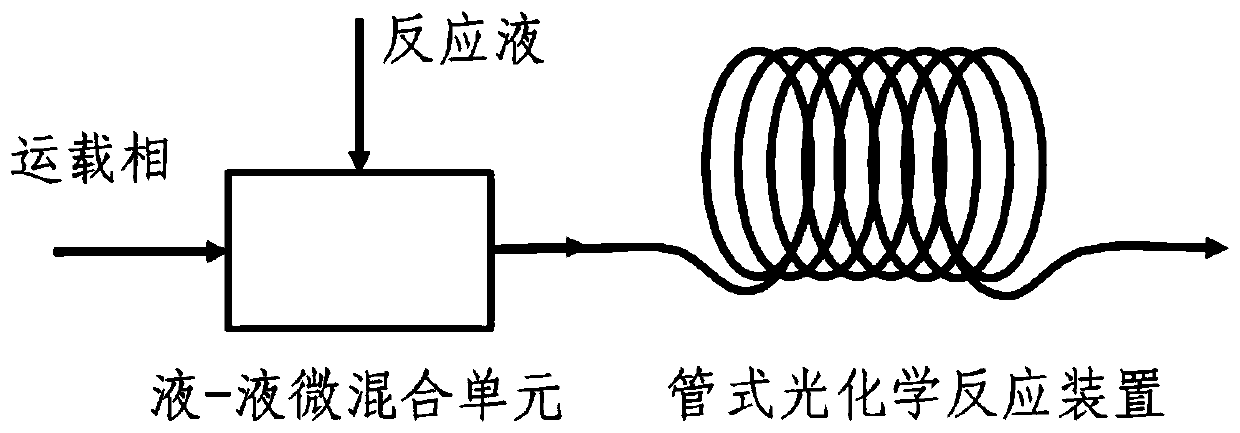

[0044] Photochemical reaction synthesis of vitamin D in the tubular reactor of Example 1 of the present invention 3 The method of the method, wherein the tubular photochemical reaction device comprises a tubular reactor, a light source and a cold trap.

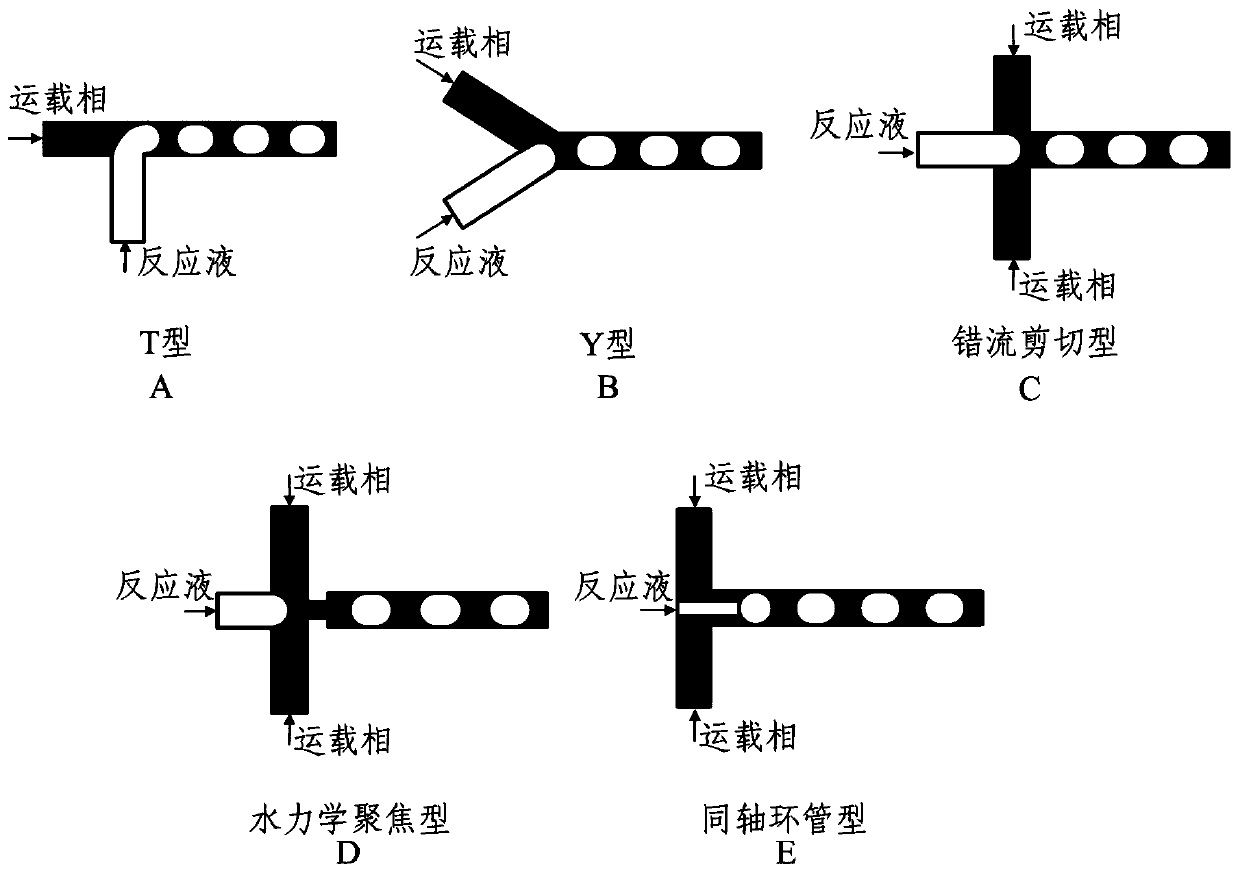

[0045] The liquid-liquid micro-mixing unit is a coaxial ring tube structure, the inner diameter of the inner channel is 0.2mm, and the inner diameter of the outer channel is 2mm; the light source is a 1000-watt high-pressure mercury lamp; the cold trap is made of quartz glass, which filters out ultraviolet light below 200nm. Cover the high-pressure mercury lamp; the tubular reactor is a quartz glass tube with an inner diameter of 2mm and an outer diameter of 4mm, and the tubular reactor is spirally wound outside the quartz glass tube.

[0046] Synthesis of vitamin D by photochemical reaction using the above-mentioned device 2 The steps are:

[0047] 1) Using ethanol as a solvent, prepare 150 mL of an ergosterol solution with...

Embodiment 2

[0051] Photochemical reaction synthesis of vitamin D in the tubular reactor of Example 2 of the present invention 2 The method, the device is composed of a liquid-liquid micro-mixing unit and a tubular photochemical reaction device, that is, a liquid-liquid micro-mixing unit and a tubular photochemical reaction device (including a tubular reactor, a light source and a cold trap).

[0052] The liquid-liquid micro-mixing unit has a Y-shaped structure, and the inner diameter of the two branch channels is 1mm; the light source is a 100-watt high-pressure mercury lamp; the cold trap is made of silicate glass, which filters out ultraviolet light below 280nm and covers the high-pressure mercury lamp The tubular reactor is a quartz glass tube with an inner diameter of 2 mm and an outer diameter of 4 mm, and the tubular reactor is spirally wound outside the quartz glass tube.

[0053] Synthesis of vitamin D by photochemical reaction using the above-mentioned device 2 The steps are:

...

Embodiment 3

[0058] Photochemical reaction synthesis of vitamin D in the tubular reactor of Example 3 of the present invention 3 The method, the device is composed of a liquid-liquid micro-mixing unit and a tube-type photochemical reaction device, that is, a liquid-liquid micro-mixing unit and a tube-type photochemical reaction device (including a tube reactor and a light source).

[0059] The liquid-liquid micro-mixing unit is a T-shaped structure, the inner diameter of the main channel is 1mm, and the inner diameter of the side channel is 0.05mm; the light source is an 8-watt low-pressure mercury lamp, and the main wavelength is 308nm; Fluoroethylene propylene copolymer tube, the tubular reactor is spirally wound outside the low-pressure mercury lamp, and the distance between the control tube wall and the mercury lamp is 3cm.

[0060] Use the above-mentioned device to carry out photochemical reaction to synthesize vitamin D 3 The steps are:

[0061] 1) Using methyl tert-butyl ether as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com