Toughening and heat-resistant PET material for 3D printing and preparation method thereof

A 3D printing and toughening technology, applied in the direction of additive processing, etc., can solve the problems of product application range limitation, low thermal deformation temperature, low impact strength, etc., achieve low production cost, suitable thermal deformation temperature, and speed up molding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method of the above-mentioned toughened heat-resistant PET material for 3D printing comprises the following steps:

[0058] 1) Drying the PET;

[0059] 2) Mix PET, chain extender, nucleating agent, nucleating accelerator, toughening agent, inorganic reinforcing agent, antioxidant, lubricant and nanoparticles, and stir evenly;

[0060] 3) Add the materials in step 2) into an extruder, knead, extrude, and granulate to obtain a toughened heat-resistant PET material for 3D printing.

[0061] Preferably, the preparation method of the above-mentioned toughened heat-resistant PET material for 3D printing comprises the following steps:

[0062] 1) Dry the PET at 130-140°C for 3-4 hours;

[0063] 2) Add PET, chain extender, nucleating agent, nucleating accelerator, toughening agent, inorganic reinforcing agent, antioxidant, lubricant and nanoparticles into the high-speed mixer, mix for 3 to 5 minutes, and stir well ;

[0064] 3) Add the materials in step 2) i...

Embodiment 1

[0068] 1) Weigh the following raw materials in parts by mass: PET Dayouguang slice 03: 86 parts; multi-epoxy chain extender CE-3: 2 parts; nucleating agent NAV-101: 0.7 parts; nucleating accelerator SURLYN 8920: 1.2 parts; toughening agent AX-8900: 4 parts; superfine talc powder: 3 parts; antioxidant 3114: 0.5 parts; lubricant pentaerythritol stearate: 0.6 parts; nano silicon oxide TSP-F09: 2 share;

[0069] 2) Put the PET chips into the blower dryer first, dry at 130-140°C for 3-4 hours, then put all the raw materials into the high-speed mixer, mix for 3-5 minutes, and mix well;

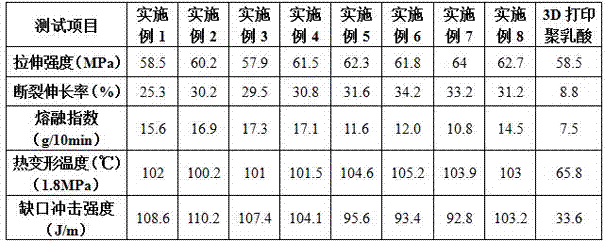

[0070] 3) Put the mixed raw materials into the twin-screw extruder, melt, extrude, and granulate to obtain a toughened heat-resistant PET material for 3D printing. The performance test of the toughened heat-resistant PET material for 3D printing in this example The data are shown in Table 1.

Embodiment 2

[0072] 1) Weigh the following raw materials in parts by mass: PET Dayouguang slice 03: 85.1 parts; multi-epoxy chain extender CE-3: 2 parts; nucleating agent NAV-101: 0.5 parts; nucleating accelerator SURLYN 8920: 1.4 parts; toughening agent AX-8900: 4 parts; aluminum hydroxide: 3.5 parts; antioxidant B215: 0.5 parts; lubricant silicone powder: 0.5 parts; nano silicon oxide TSP-F09: 2.5 parts;

[0073] 2) Put the PET chips into the blower dryer first, dry at 130-140°C for 3-4 hours, then put all the raw materials into the high-speed mixer, mix for 3-5 minutes, and mix well;

[0074] 3) Put the mixed raw materials into the twin-screw extruder, melt, extrude, and granulate to obtain a toughened heat-resistant PET material for 3D printing. The performance test of the toughened heat-resistant PET material for 3D printing in this example The data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com