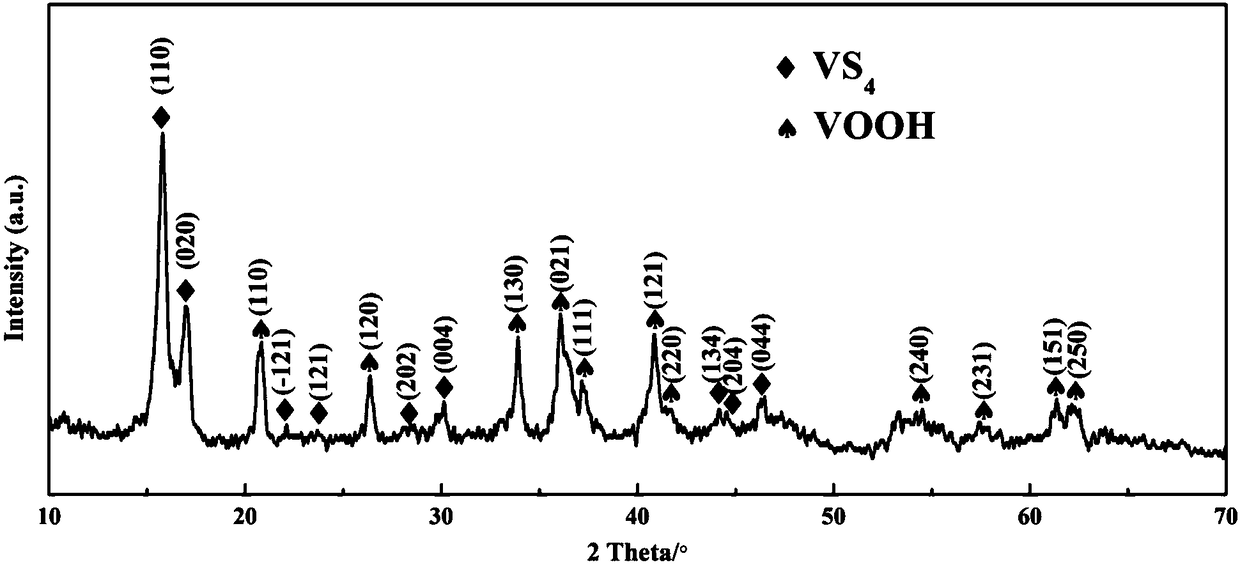

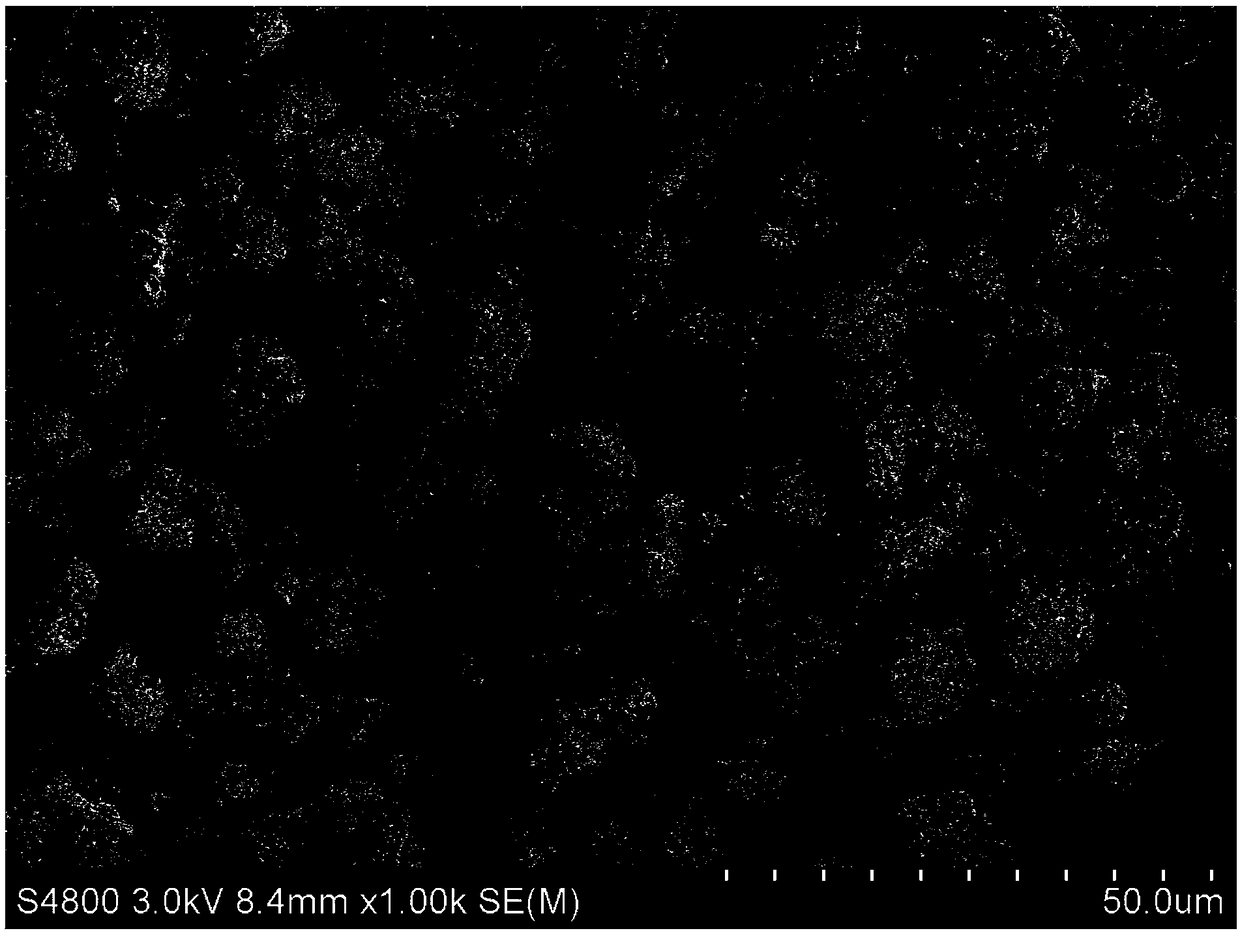

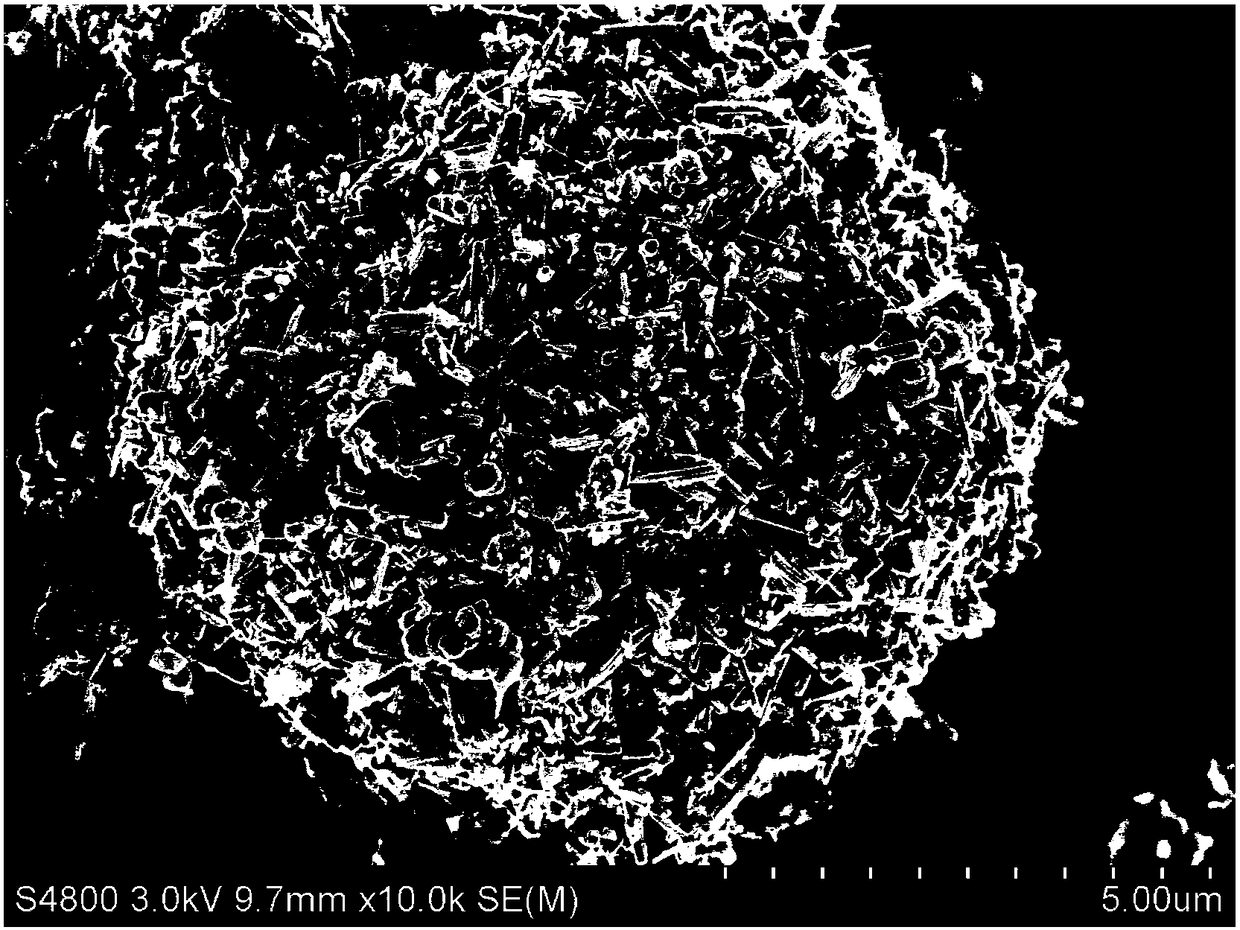

VOOH/VS4 micrometer composite powder as well as preparation method and application of VOOH/VS4 micrometer composite powder

A composite powder and reaction technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of no composite material preparation technology, and achieve excellent catalytic performance, low temperature, and chemical composition. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step 1: Add 2.4g of sodium metavanadate and 3.6g of thioacetamide into 60ml of deionized water at the same time, and magnetically stir for 60min at a speed of 600r / min to obtain a semi-clear solution A;

[0045] Step 2: Then add 0.7mol / L ammonia solution dropwise to solution A, control the drip rate of ammonia solution to 0.15ml / min, after adding one drop of ammonia solution, stir until the pH value of the solution is stable, then drop in Add a drop of ammonia solution until the pH value of the solution reaches 10.6 to obtain solution B;

[0046] Step 3: Pour solution B into the reaction liner according to the filling ratio of 60% and seal it, install the liner in the outer kettle and fix it, place it in a homogeneous reactor, and heat it from room temperature to 180℃ hydrothermal reaction for 24h;

[0047] Step 4: After the hydrothermal reaction is completed, the reaction kettle is naturally cooled to room temperature, and then the product cooled after the reaction is...

Embodiment 2

[0061] Step 1: Take 2.0g of sodium metavanadate and 3.5g of thioacetamide and add them to 55ml of deionized water at the same time, and magnetically stir for 65min at a speed of 500r / min to obtain a semi-clear solution A;

[0062] Step 2: Then add 0.9mol / L ammonia solution dropwise to solution A, control the drip rate of ammonia solution to 0.13ml / min, after adding one drop of ammonia solution, stir until the pH value of the solution is stable, then add Add a drop of ammonia solution until the pH value of the solution reaches 10.7 to obtain solution B;

[0063] Step 3: Pour solution B into the reaction liner at a filling ratio of 55% and seal it, place the liner in an outer kettle and fix it in a homogeneous reactor, and heat it from room temperature to 175℃ hydrothermal reaction for 25h;

[0064] Step 4: After the hydrothermal reaction is over, cool the reaction vessel to room temperature naturally, then take out the cooled product after the reaction, and collect it by centr...

Embodiment 3

[0067] Step 1: Add 2.2g of sodium metavanadate and 3.8g of thioacetamide into 65ml of deionized water at the same time, and stir magnetically for 55min at a speed of 800r / min to obtain a semi-clear solution A;

[0068] Step 2: Then add 0.8mol / L ammonia solution dropwise to solution A, control the rate of addition of ammonia solution to 0.16ml / min, after adding one drop of ammonia solution, stir until the pH value of the solution is stable, then add Add a drop of ammonia solution until the pH value of the solution reaches 10.7 to obtain solution B;

[0069] Step 3: Pour solution B into the reaction liner at a filling ratio of 65% and seal it, place the liner in an outer kettle and fix it in a homogeneous reactor, and heat it from room temperature to 185℃ hydrothermal reaction for 23h;

[0070] Step 4: After the hydrothermal reaction is over, cool the reaction vessel to room temperature naturally, then take out the cooled product after the reaction, alternately suction filter 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com