Preparation method of polymer micro-foaming film

A polymer film and polymer technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of residual solubles and chemical solvents, large environmental and product pollution, and uneven pore size distribution. Equal problem, to achieve the effect of increased pore density, shortened saturation time, and increased nucleation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

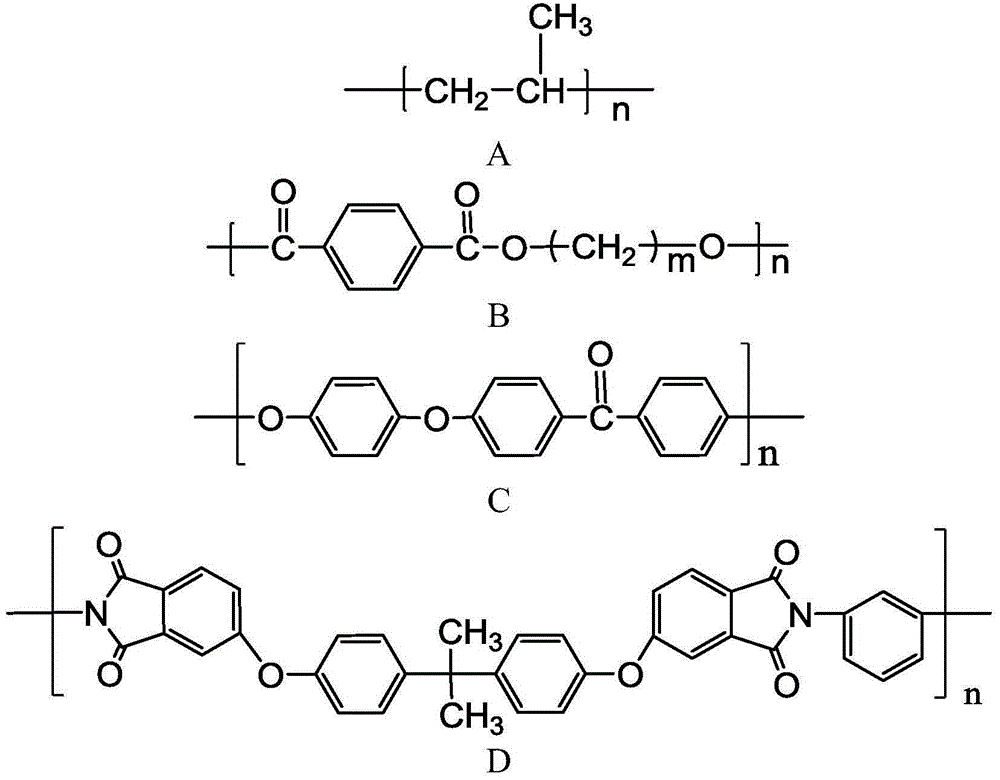

[0037] First, a polypropylene film with an average thickness of 300 μm and a polypropylene non-woven fabric are combined into a roll. Then the composite coil was placed in a high-pressure reactor, filled with 15MPa of carbon dioxide, and the temperature in the kettle was maintained at 80°C for 36 hours. Then start 20MHz ultrasonic vibration, and at the same time reduce the temperature in the kettle to 0°C, release the pressure to normal pressure, and take out the coil after the vibration is over.

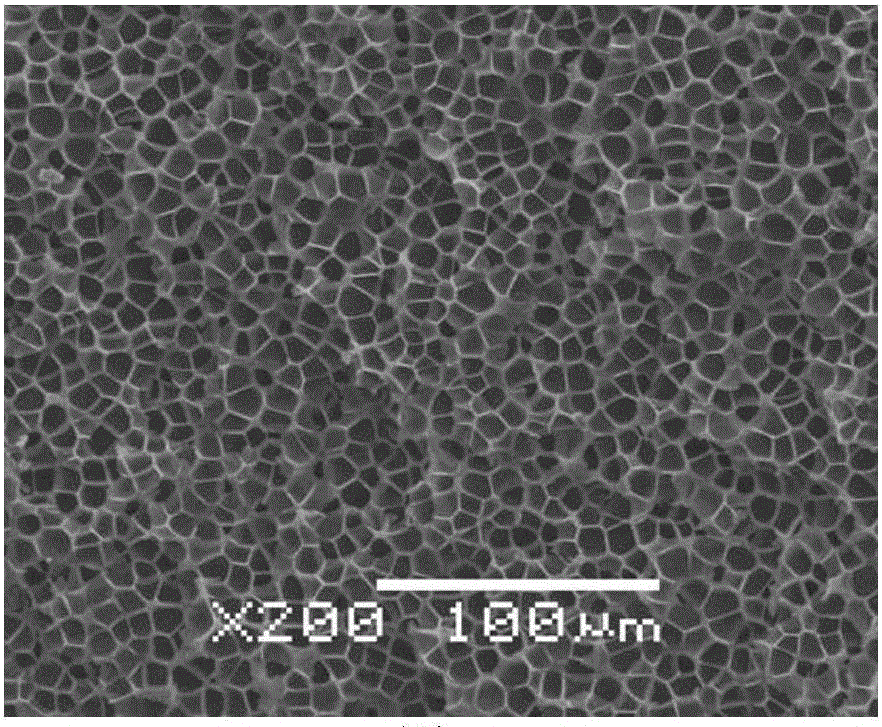

[0038] Finally, the composite coil is placed on a steam forming machine, the temperature is controlled at 120-150° C., and the foaming time is 30 seconds to obtain a reflectivity of 99.5%. The density is 0.25g / cm 3 The uniform foaming film, the scanning electron micrograph of its slice is attached figure 1 As shown, the cell diameter is between 5-20 μm.

Embodiment 2

[0040] First, a polypropylene film with an average thickness of 300 μm and a polypropylene non-woven fabric are combined into a roll. Then place the composite coil in a high-pressure reactor, fill it with 7.5MPa of carbon dioxide, and keep the temperature in the kettle at 80°C for 40 hours. Then start 20MHz ultrasonic vibration, and at the same time reduce the temperature in the kettle to 0°C, release the pressure to normal pressure, and take out the coil after the vibration is over.

[0041] Finally, the composite coil is placed on a steam forming machine, the temperature is controlled at 120-150° C., and the foaming time is 30 seconds to obtain a reflectivity of 99.1%. The density is 0.33g / cm 3 uniform foam film.

Embodiment 3

[0043] First, a polyester film with an average thickness of 350 μm and a polyester non-woven fabric are combined into a roll. Then place the composite coil in the autoclave, fill it with 15MPa carbon dioxide, and keep the temperature in the autoclave at 120°C for 40 hours. Then start 30MHz ultrasonic vibration, and at the same time reduce the temperature in the kettle to 0°C, release the pressure to normal pressure, and take out the coil after the vibration is over.

[0044] Finally, the composite coil is placed on a hot roll forming machine, the temperature is controlled at 200-240° C., and the foaming time is 10 seconds to obtain a reflectivity of 99.8%. The density is 0.35g / cm 3 uniform foam film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com