Suction-type electronic chip cooling boiling enhanced heat transfer experiment device and method

A technology for strengthening heat exchange and experimental equipment, applied in the direction of material thermal development, etc., can solve the problems of reducing the critical heat flux density of boiling heat transfer, and the rapid separation of bubbles on the chip surface cannot be well combined, so as to improve the critical heat flux density, The pipeline layout is compact and simple, and the effect of reducing the superheat on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

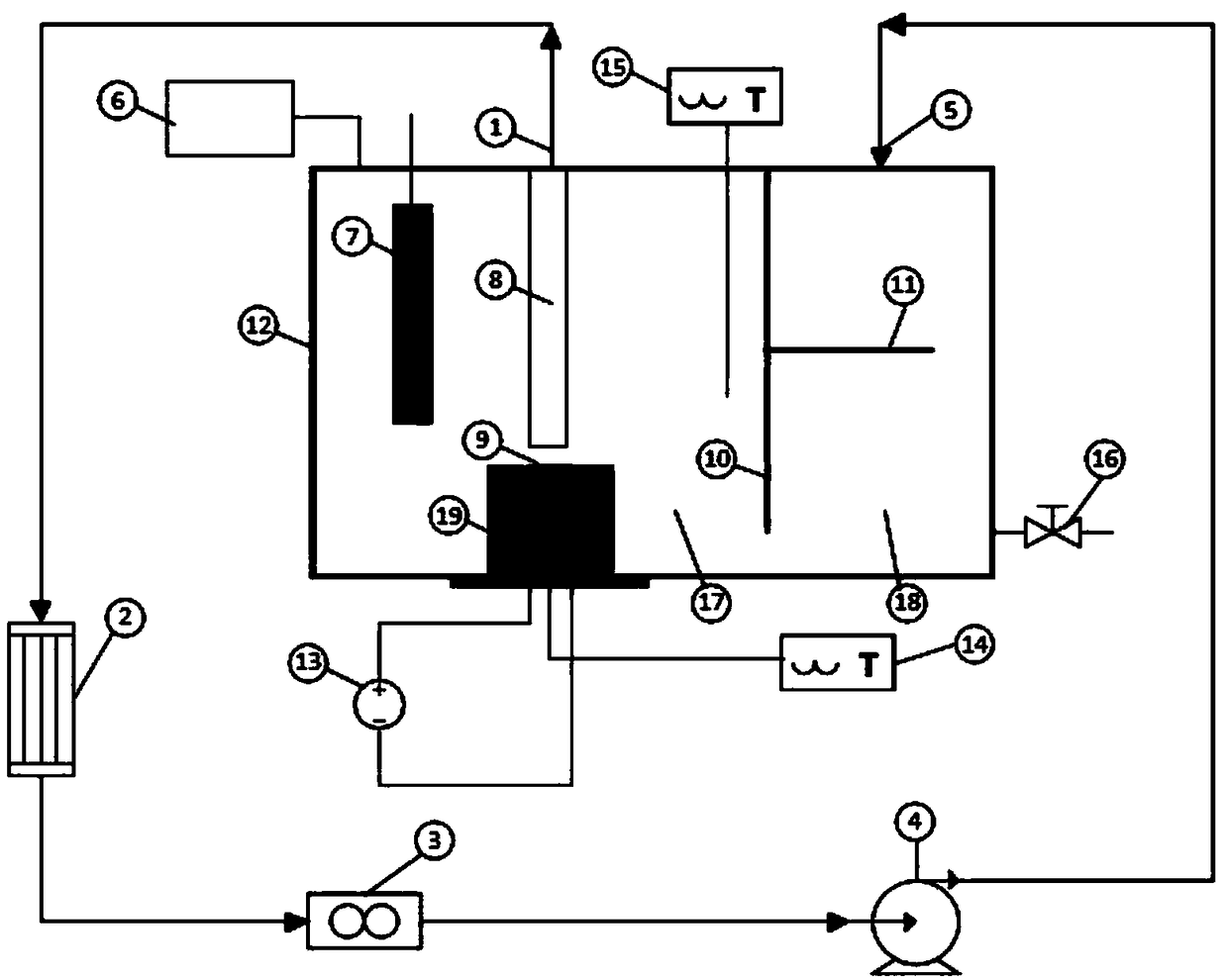

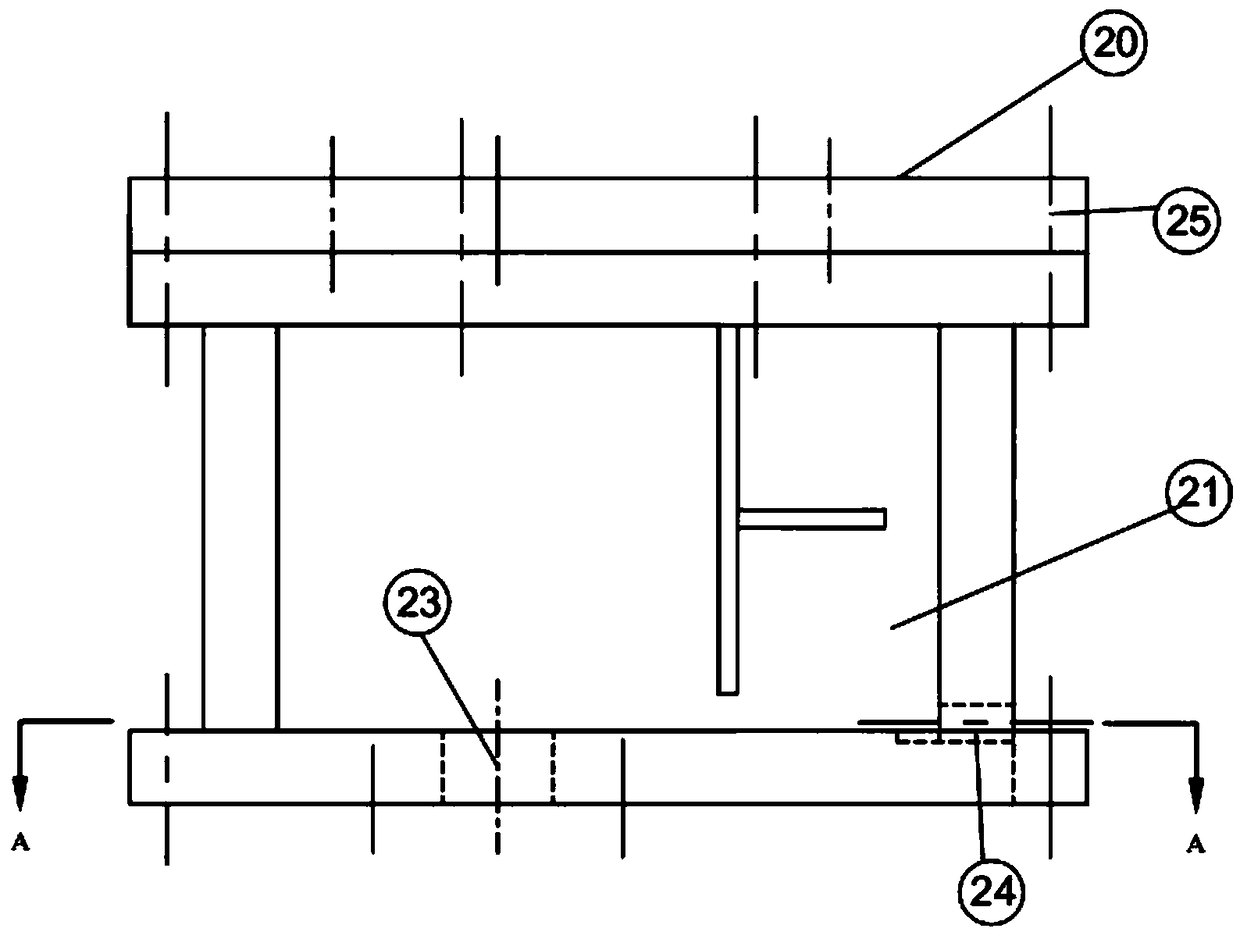

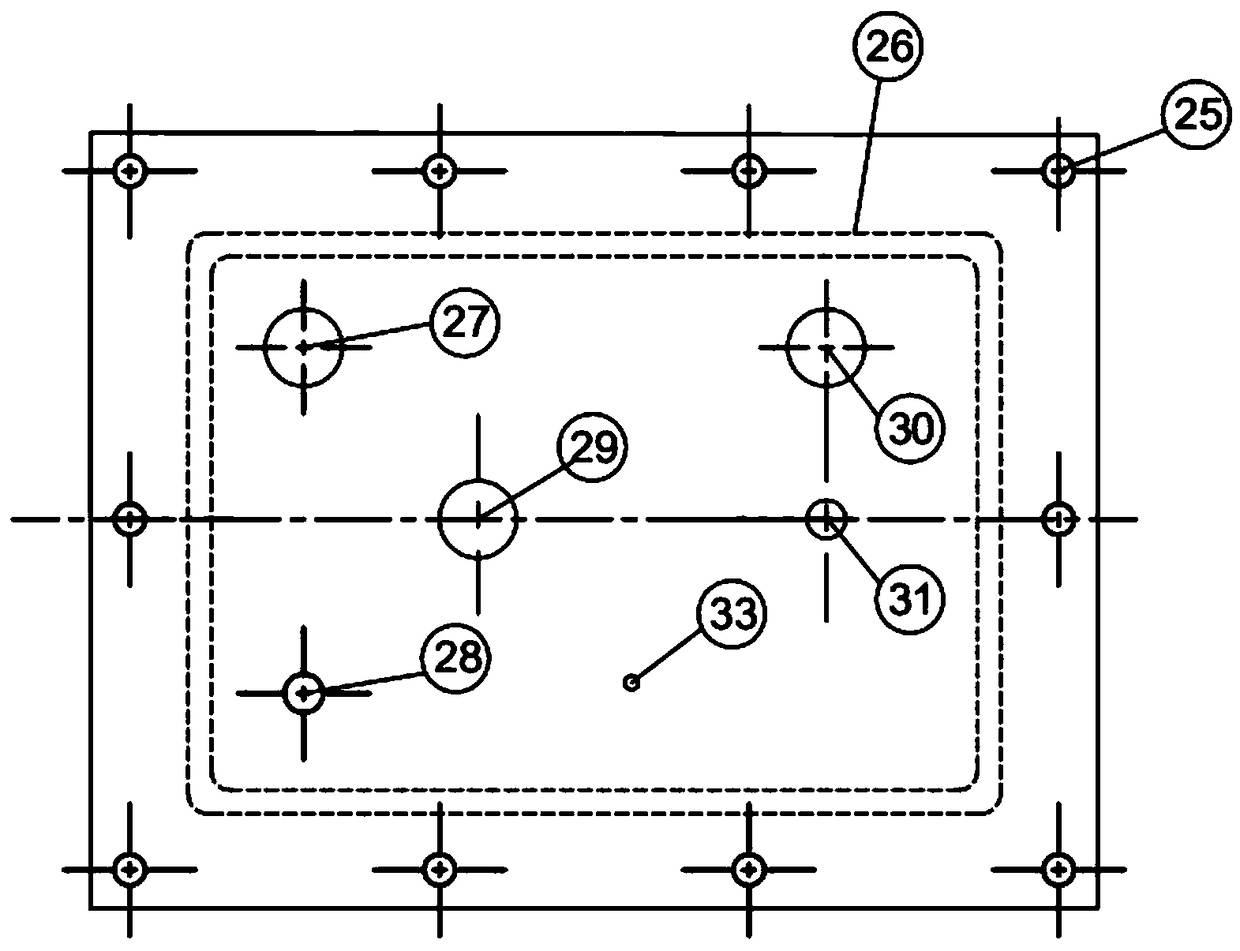

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0030] refer to figure 1 and Figure 3-1 , a pumping type electronic chip cooling enhanced boiling heat transfer experimental device, comprising a DC pump 4, a potentiometer for adjusting the speed of the DC pump, a flow meter 3, a condenser 2 and a suction experiment boiling pool 12; the suction experiment boiling The bottom of the pool 12 is embedded with a loading boss 23, the test chip 9 is fixed on the groove 34 above the loading boss 23, and the test chip 9 is pasted in the groove 34 by heat-insulating silica gel; Divided into two cavities, the two cavities are separated by a partition 10 with a bottom opening of 10 mm, one is a suction cavity 17, and a suction tube bundle 8 is arranged directly above the test chip 9 to extract the surrounding air bubbles and working medium mixture, and the other is a suction cavity 17. One is the liquid discharge chamber 18. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com