Device for strengthening rapid separation of bubbles on boiling surface and manufacturing method of device

A technology to enhance boiling and rapid detachment, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of deterioration of heat exchange process, difficulty in rehydration, film boiling, etc. The effect of condensation and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

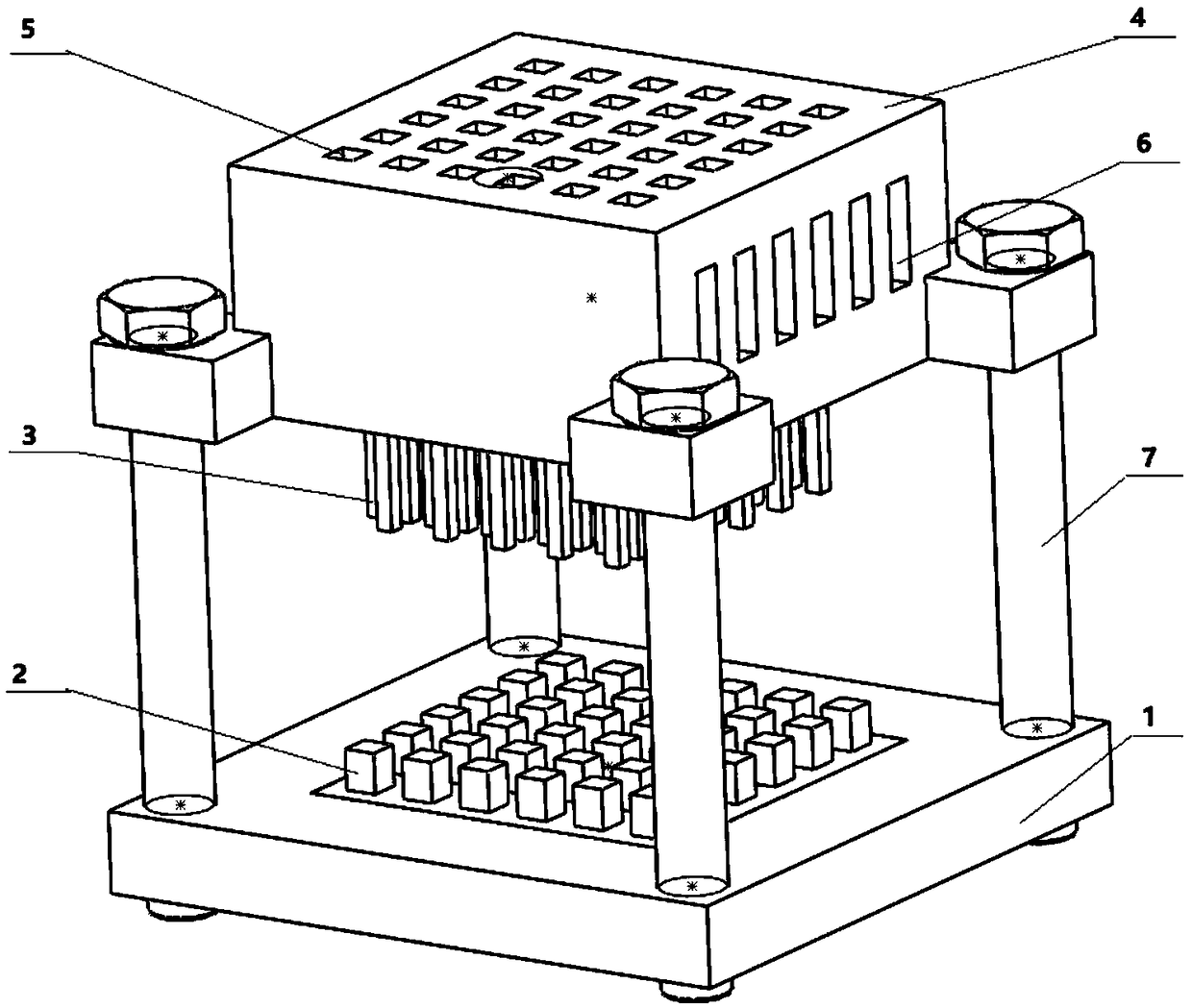

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail:

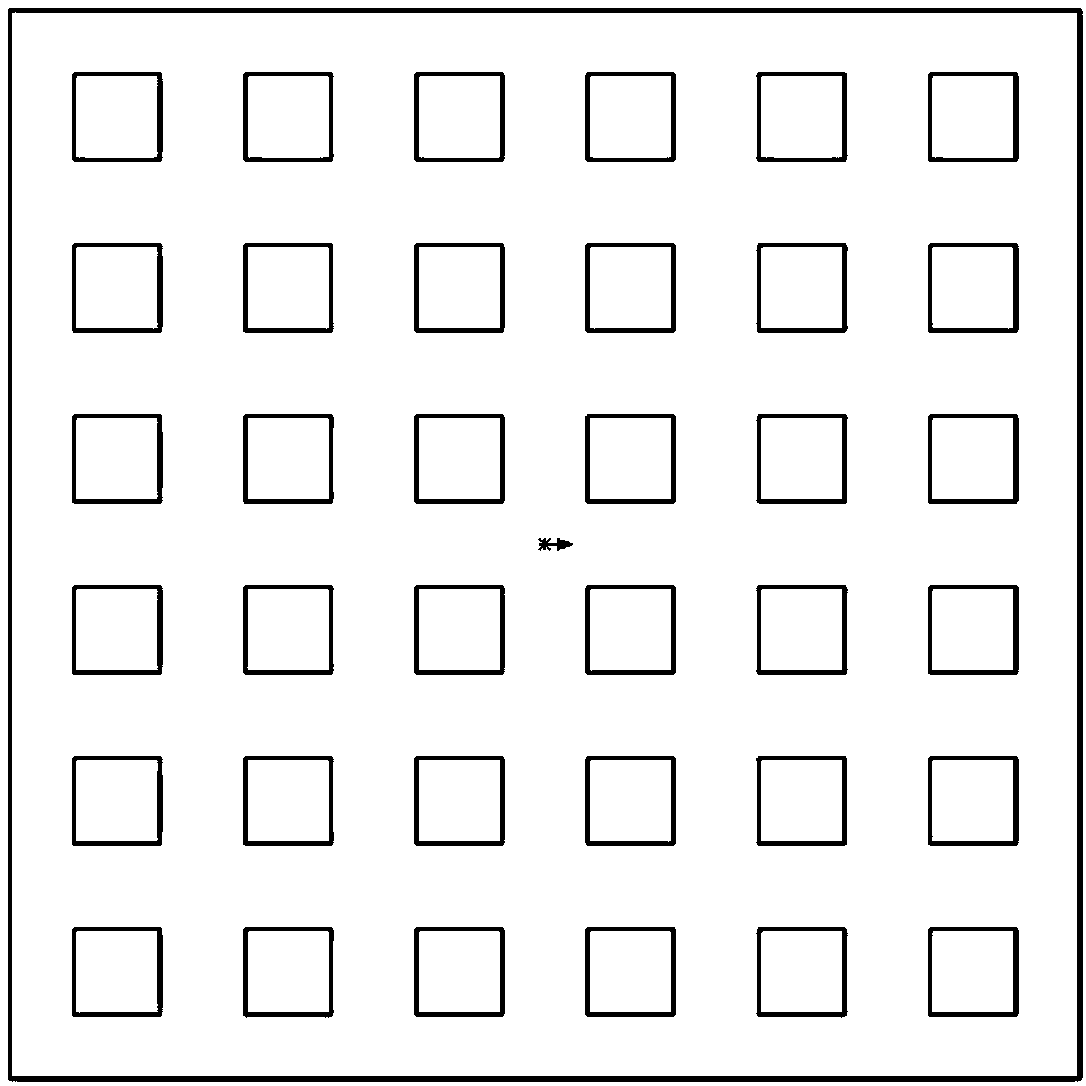

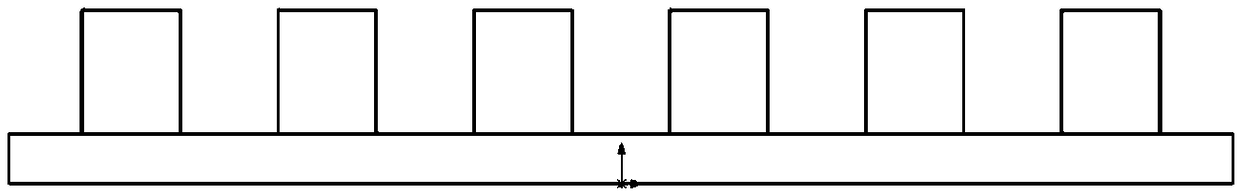

[0032] Referring to the accompanying drawings, a device for enhancing the rapid detachment of bubbles on the surface of boiling, in which a multi-scale enhanced boiling heat transfer structure 2 is arranged on the base 1, and a hydrophobic and aerophilic bubble assisted detachment structure is added vertically above the enhanced boiling heat transfer structure 2 3. Through the bubble-assisted detachment structure 3, the vertical detachment of the bubbles from the heat exchange surface is accelerated. At the same time, the bubble-assisted detachment structure 3 is equipped with a condenser 4, and the built-in gas channel 5 of the condenser 4 is still a hydrophilic surface, which is conducive to non-condensation The rapid detachment of the gas enhances the effect of liquid replenishment during heat exchange; at the same time, the outer surface of the condenser 4 is a hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com