Design and preparation method of micro-channel structure of efficient enhanced boiling heat transfer surface

A microchannel structure and enhanced boiling technology, applied in the field of phase change heat transfer, can solve the problems that the bubble growth characteristics in the microchannel structure cannot be significantly changed, the surface boiling heat transfer performance cannot be greatly improved, and large-scale commercialization cannot be achieved. , to achieve the effects of reducing thermal expansion coefficient mismatch and heat transfer loss, increasing critical heat flux, and increasing the number of nucleation sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a method for designing and preparing a microchannel structure that efficiently enhances the boiling heat transfer surface, including the following steps:

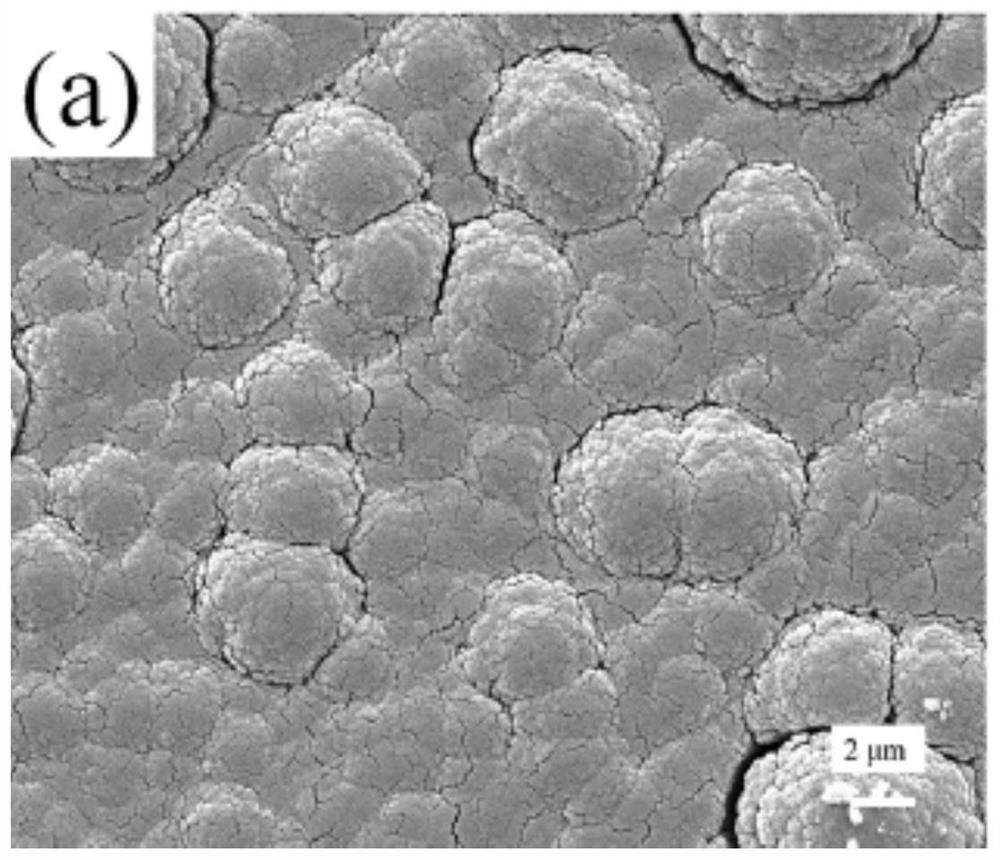

[0037] (1) Take a copper cylinder with a diameter of 10mm and a height of 20mm, and use laser processing to form a microchannel structure on the surface of the copper cylinder;

[0038] The concrete condition of described laser processing is set as:

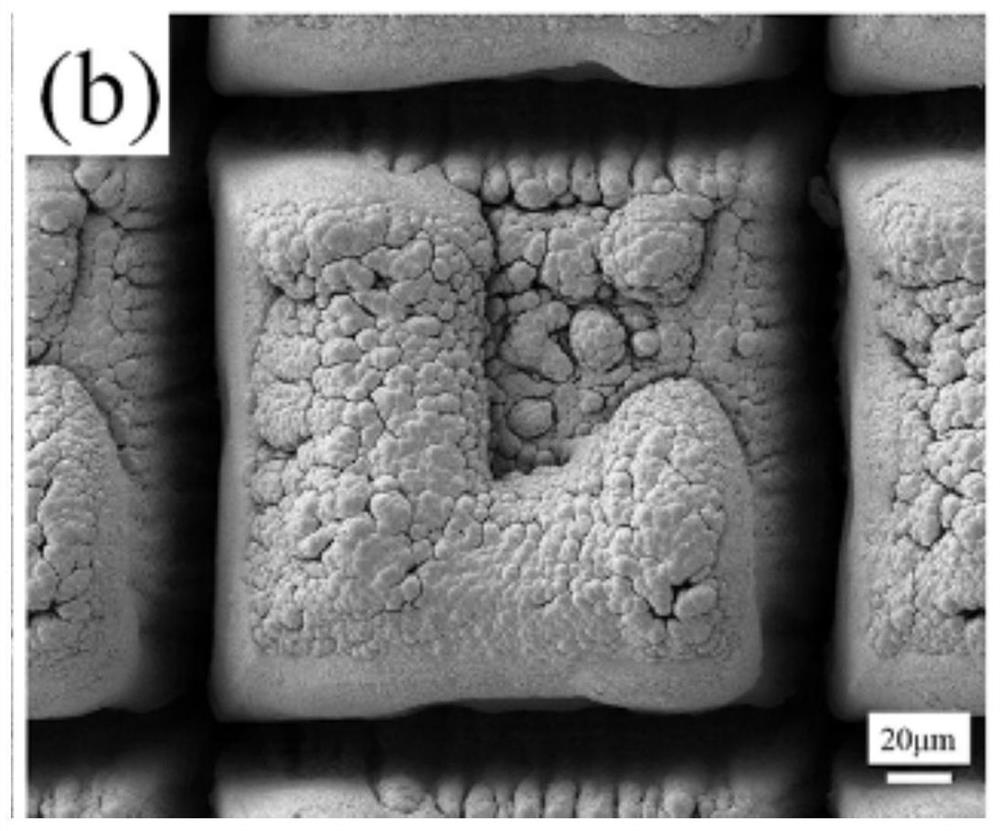

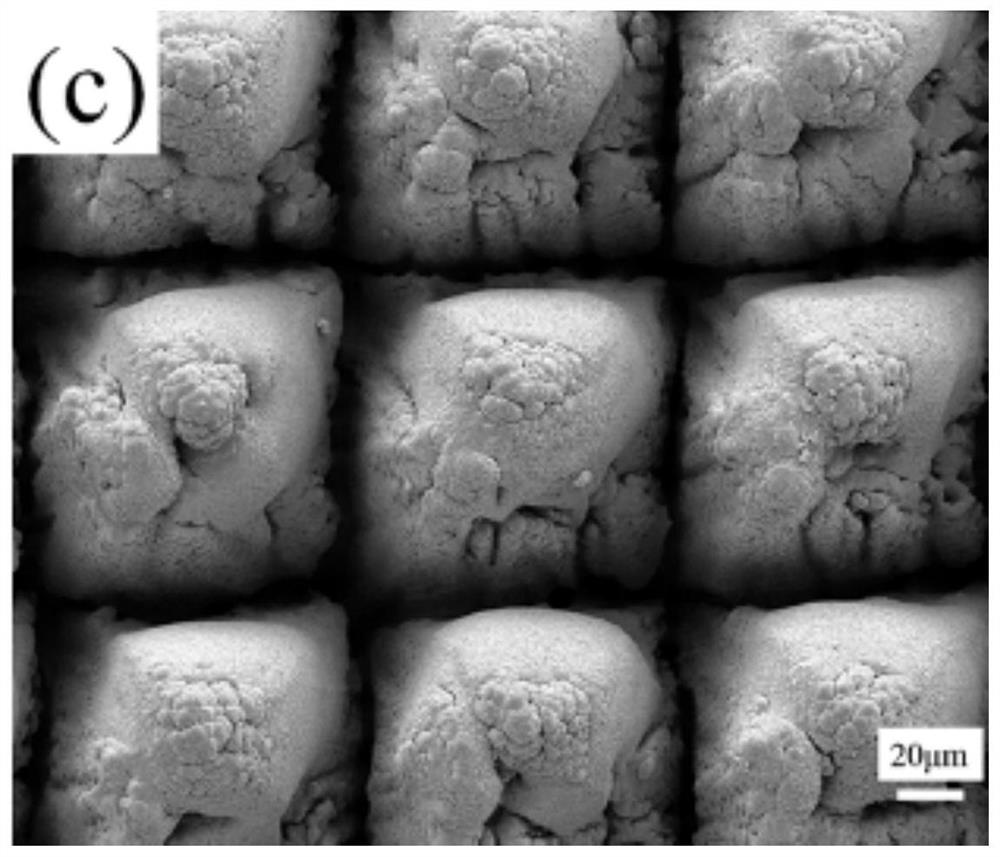

[0039] Design a "well" shape structure on the laser platform (Wuhan Anyon Laser, model PicoYL-15), the distance between the two nearest laser processing lines is 0.2mm; the laser wavelength is 1064nm, the spot diameter is 50μm, and the total power 15W;

[0040] The cross-section of the microchannel structure is a rectangle, and the width of the rectangle is 0.2mm (corresponding to the interval between two lines of the "well" shape structure), and the channel (groove) width of the microchannel structure is 0.2mm, The depth is 312 μm;

[0041](...

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is only: in step (1), when laser processing is adopted, the interval between the two lines of the "well"-shaped structure is 0.1mm, and others are the same as embodiment 1; correspondingly, this The cross-section of the microchannel structure obtained in the embodiment is rectangular, and the width of the rectangle is 0.1 mm. The channel (groove) of the microchannel structure has a width of 0.1 mm and a depth of 367 μm.

Embodiment 3

[0045] The difference between this embodiment 3 and embodiment 1 is that in step (1), when laser processing is used, the interval between the two lines of the "well"-shaped structure is 0.03 mm, and the others are the same as in embodiment 1. Correspondingly, the cross-section of the microchannel structure obtained in this embodiment is rectangular, the width of the rectangle is 0.03 mm, the channel (groove) width of the microchannel structure is 0.03 mm, and the depth is 256 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com