Increasing boiling heat transfer using low thermal conductivity materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

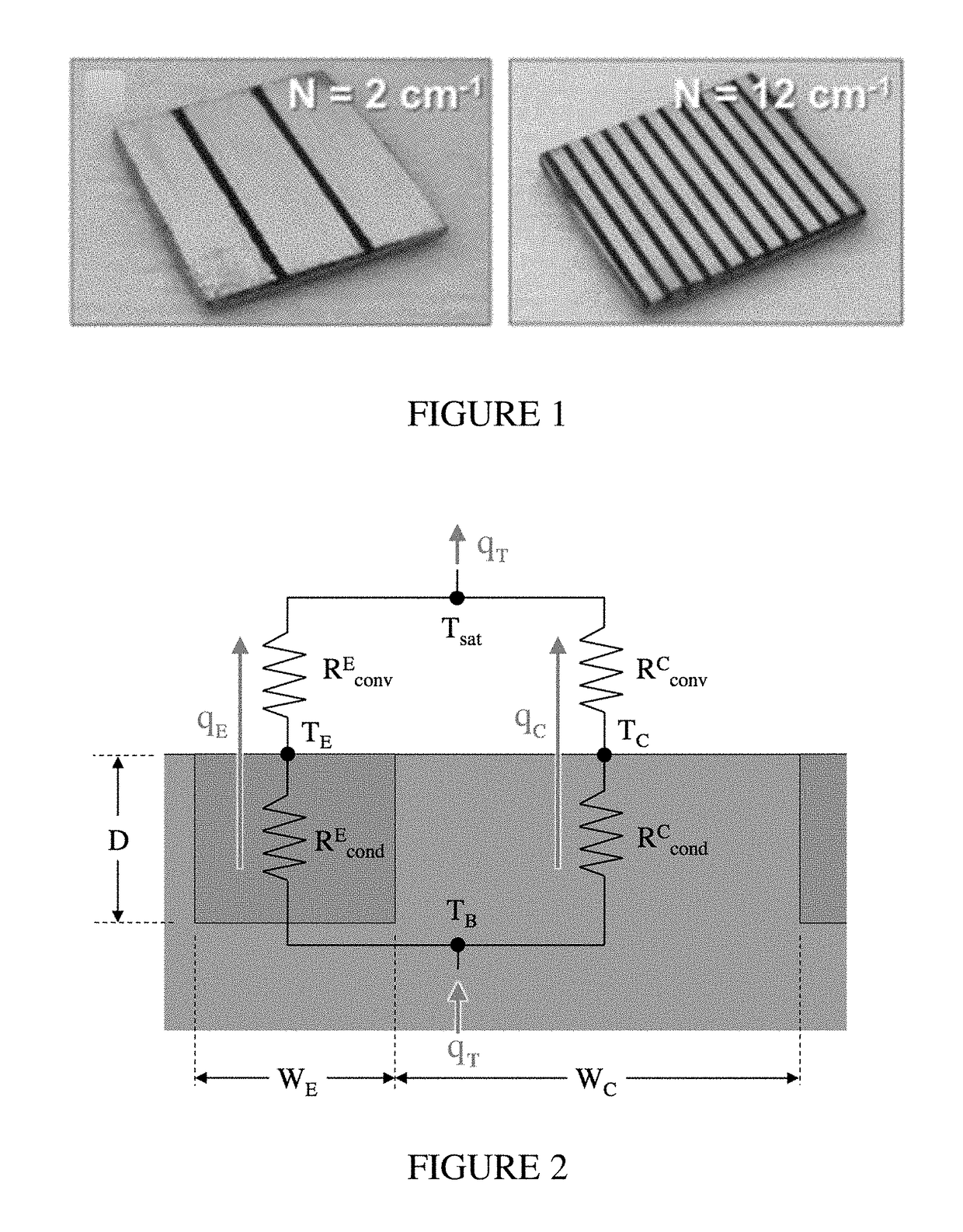

Bi-Conductive Surface Fabrication

[0107]Bi-conductive surfaces were fabricated by embedding lines of a low-conductivity epoxy into a copper substrate. Copper sheets (1 mm thickness) were cut to size and grooves were machined into them using Wire Electrical Discharge Machining (EDM). The EDM wire thickness was 0.254 mm with a reported minimum spark gap of 0.381 mm±0.127 mm. The copper was then treated with an alkaline solution to produce an oxide layer with nanoscale surface roughness to promote adhesion between the copper and epoxy. The surfaces were then coated with a non-conductive high-temperature two-part epoxy (Aremco™ 526N) filling all of the grooves. The epoxy was cured at 93° C. for 2 hours, followed by 163° C. for 12 hours to achieve a maximum strength bond. After curing, the surfaces were manually sanded with 200 grit sandpaper until the bare copper between each epoxy division was exposed. The bare copper surfaces (with no epoxy divisions) were also sanded using the same me...

example 2

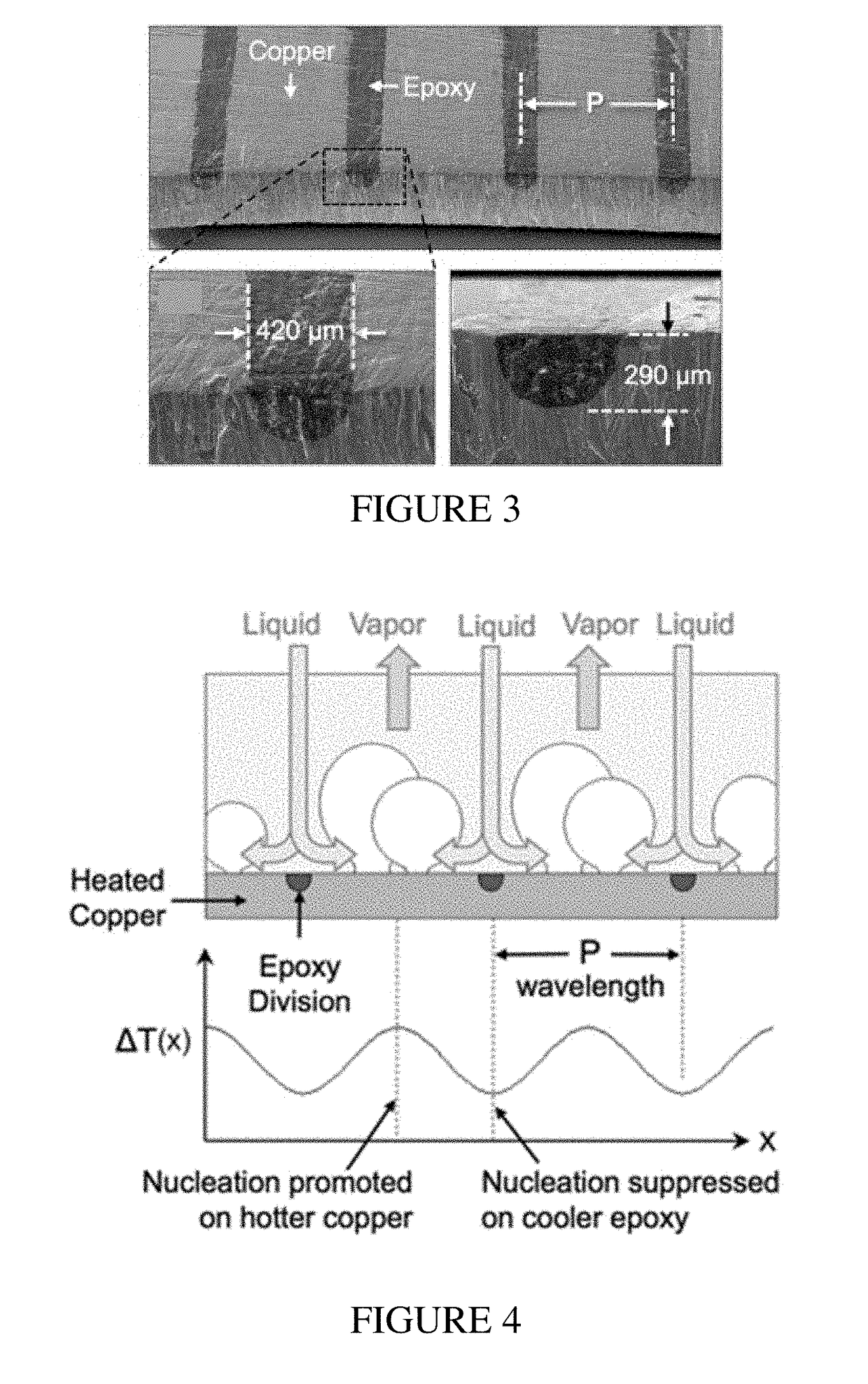

[0109]Evaluating equation S8 using the experimentally measured heat transfer coefficients during nucleate boiling, h=50-210 kW / m2K (FIG. 3), results in qE / qT=0.2%-2% for the highest performing surfaces (P=3.7-1.8 mm). For the lower performing surfaces (P=1.39-0.96 mm) this increases to qE / qT=0.8%-5%. Similarly, by evaluating equation S10 it can be shown that the ratio of the superheats between the epoxy and fluid to the copper and fluid is ΔTsat,E / ΔTsat,C=1.9%-6.7%, over the same range of h.

[0110]Prior to the onset of nucleate boiling, the measured heat transfer coefficients reach values of h˜5 kW / m2K. During this convection-dominated region, the lower heat transfer coefficients result in higher convective resistances that become comparable to the conductive resistances in the epoxy. Because of this, the percentage of heat transfer over the epoxy increases to qE / qT=5%-11% for the highest performing surfaces (P=3.7-1.8 mm), and qE / qT=15%-24% for the lower performing surfaces (P=1.39-...

example 3

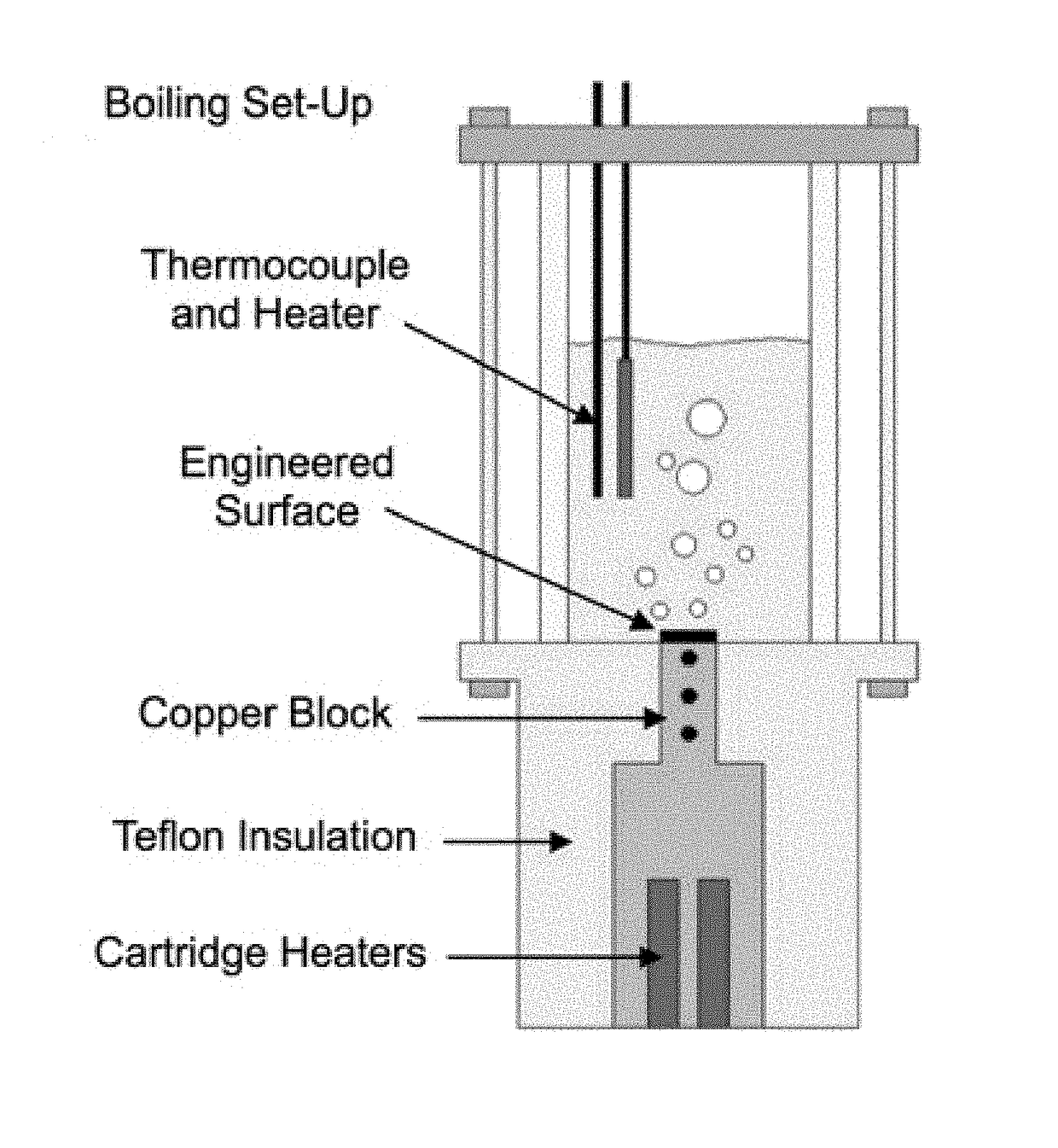

Pool Boiling Characterization and Imaging

[0111]Surfaces were characterized using a custom-built test set-up as previously reported by Rahman et al. See, Rahman, M. M., Ölçero{hacek over (g)}lu, E. & McCarthy, M. Role of Wickability on the Critical Heat Flux of Structured Superhydrophilic Surfaces. Langmuir 30, 11225-11234 (2014) and Rahman, M. M., Ölçero{hacek over (g)}lu, E. & McCarthy, M. Scalable Nanomanufacturing of Virus-templated Coatings for Enhanced Boiling. Advanced Materials Interfaces 1, 1300107 (2014). The setup consists of a copper heater block with PTFE insulation embedded with two cartridge heaters allowing for a maximum power of 1,000 W. Five T-type thermocouples were inserted into the copper block equally spaced 6 mm apart with the topmost thermocouple located directly beneath the sample.

[0112]The temperature measurements were recorded using NI DAQ system, where the average heat flux in the copper block was calculated using Fourier's conduction law. The sample surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com