Patents

Literature

55 results about "Capillary length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The capillary length or capillary constant, is a length scaling factor that relates gravity and surface tension. It is a fundamental physical property that governs the behaviour of menisci, and is found when body forces (gravity) and surface forces (Laplace pressure) are in equilibrium. The pressure of a static fluid does not depend on the shape, total mass or surface area of the fluid. It is directly proportional to the fluid's specific weight – the force exerted by gravity over a specific volume, and its vertical height.

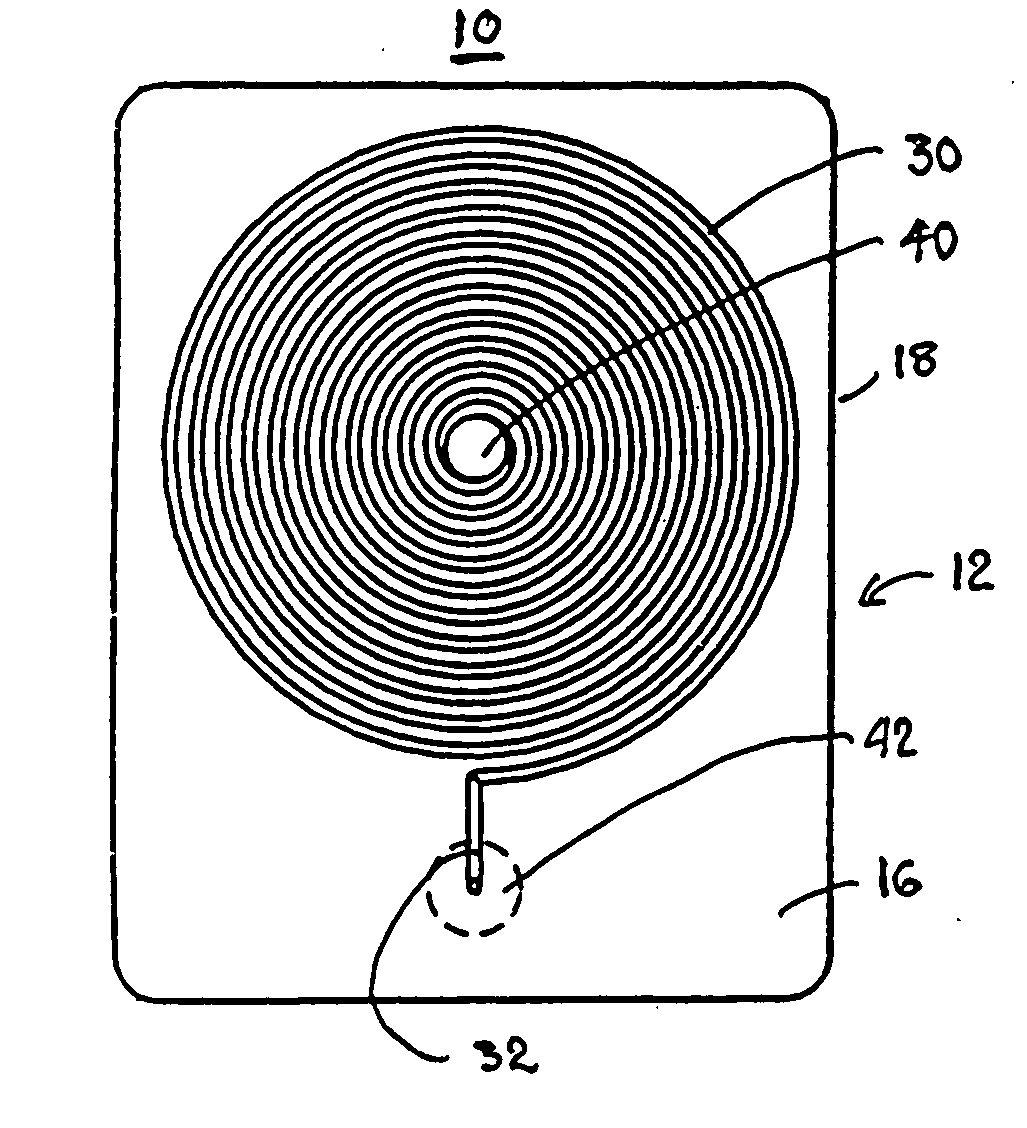

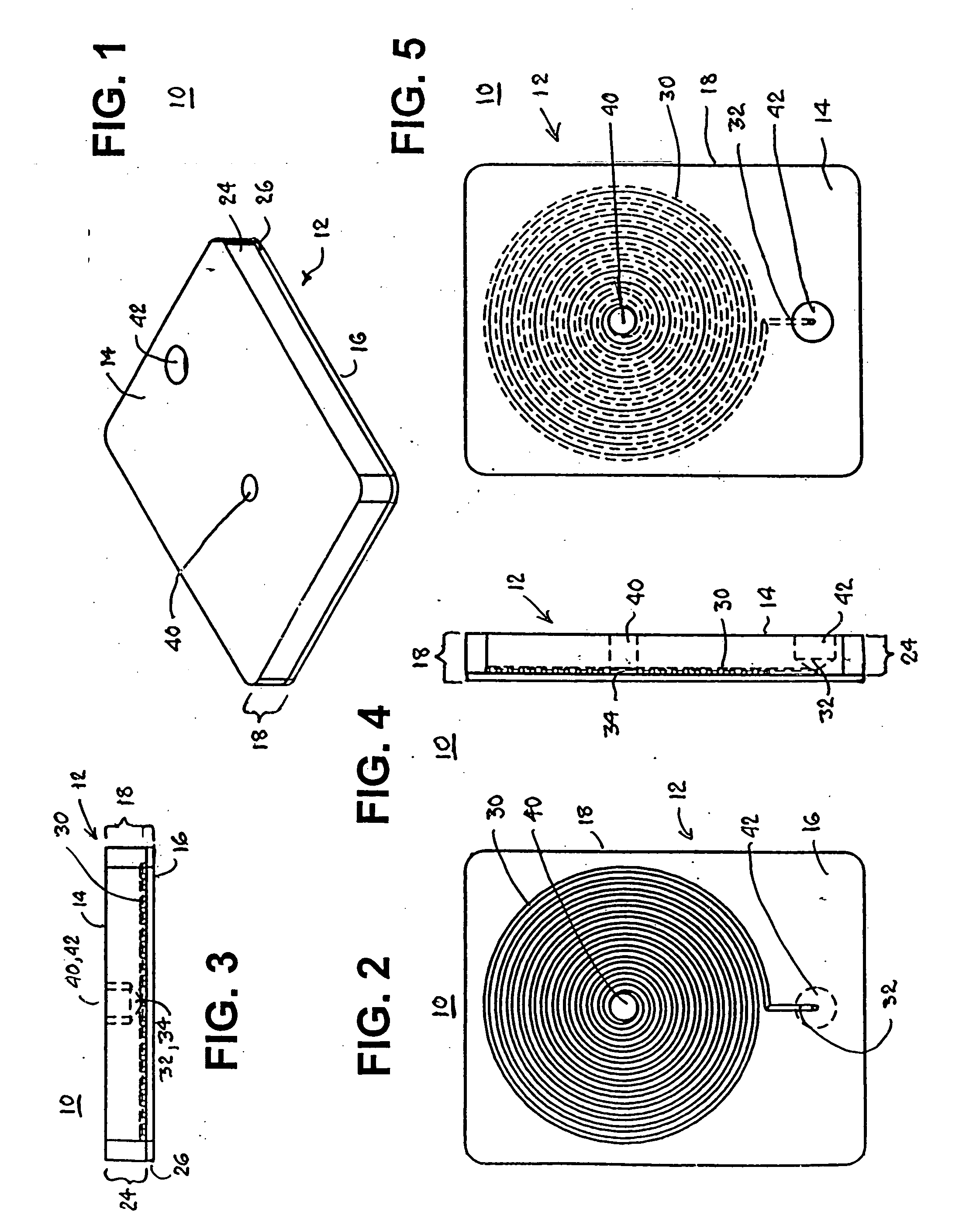

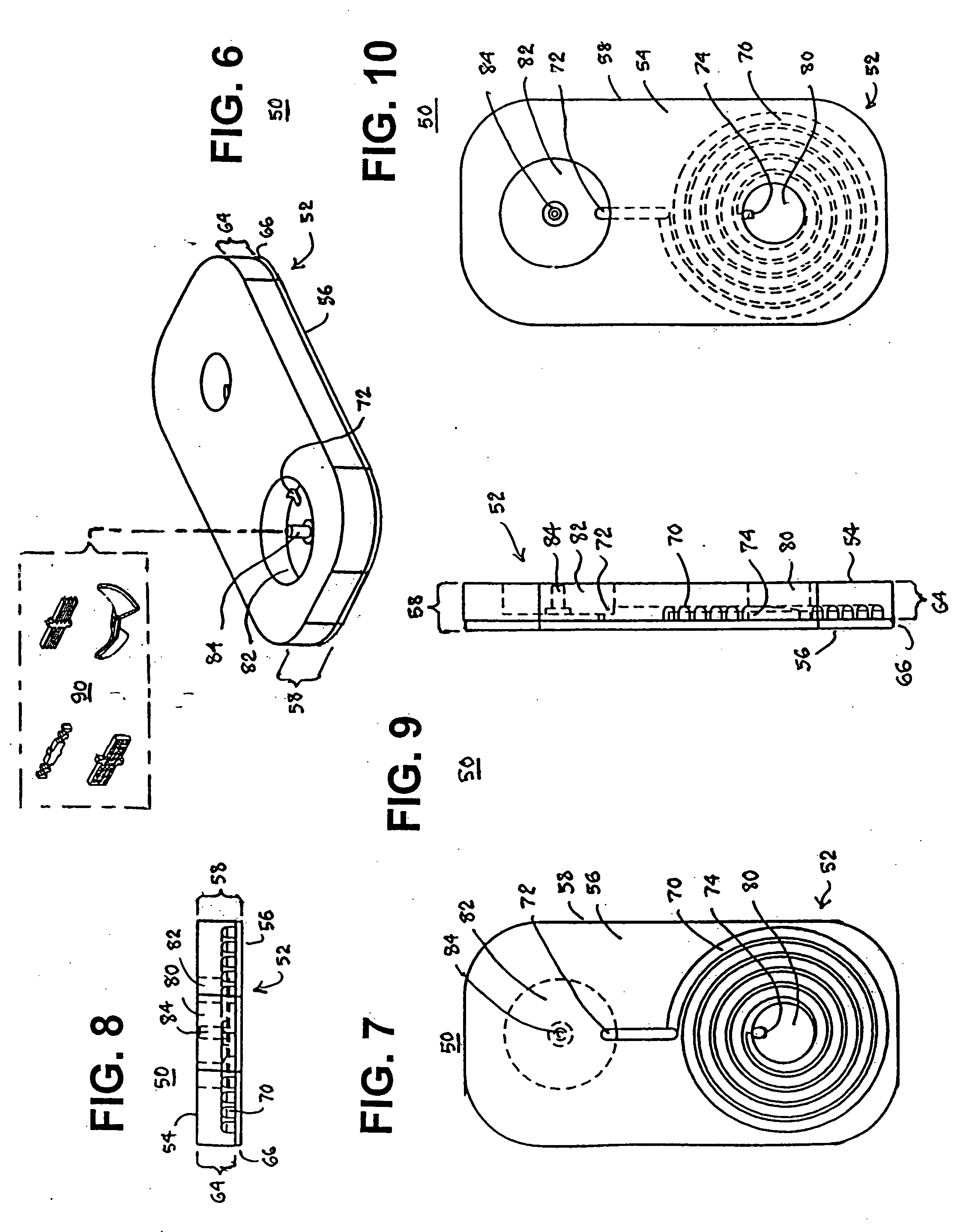

Blood coagulation test cartridge, system, and method

InactiveUS7439069B2Practical and convenientRapid and inexpensiveMicrobiological testing/measurementWithdrawing sample devicesBlood capillaryEngineering

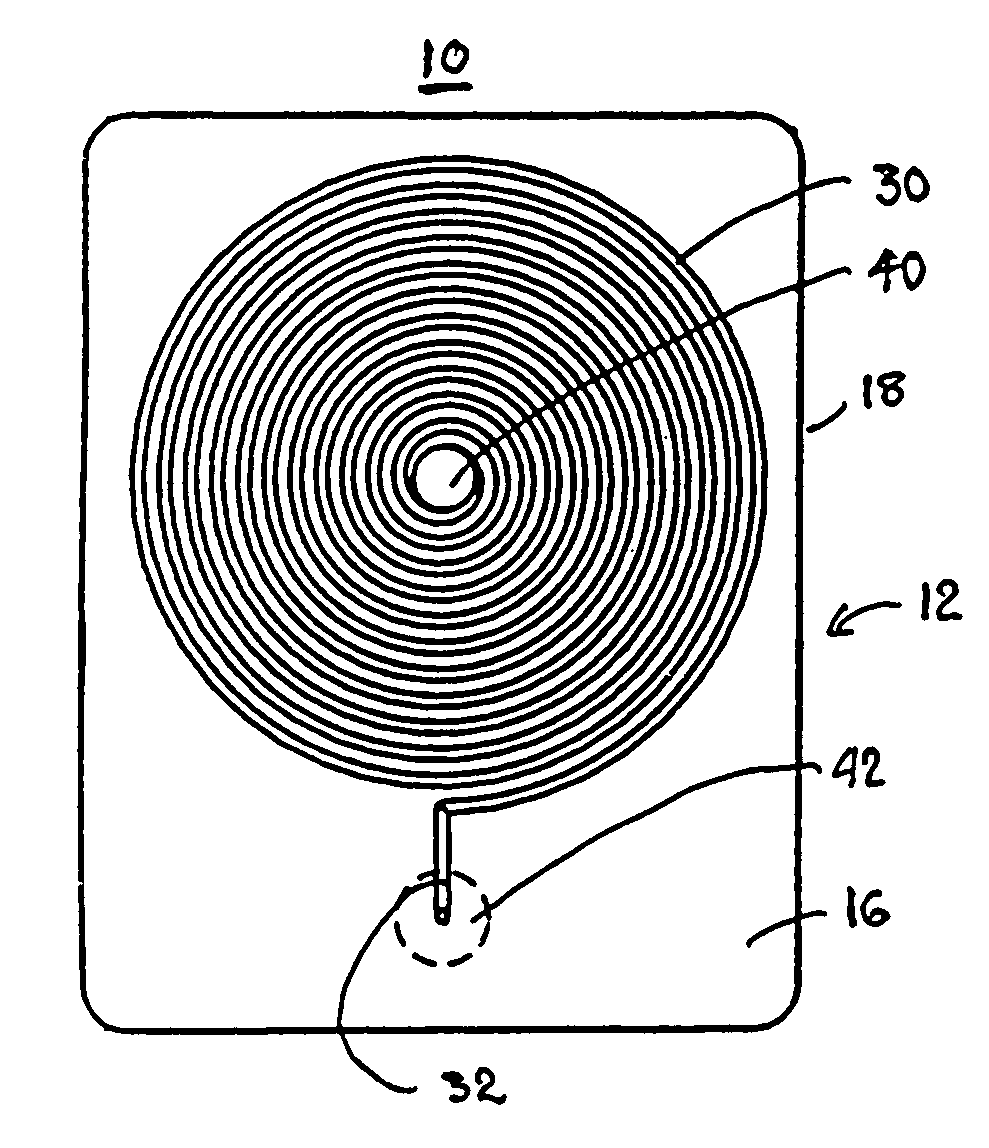

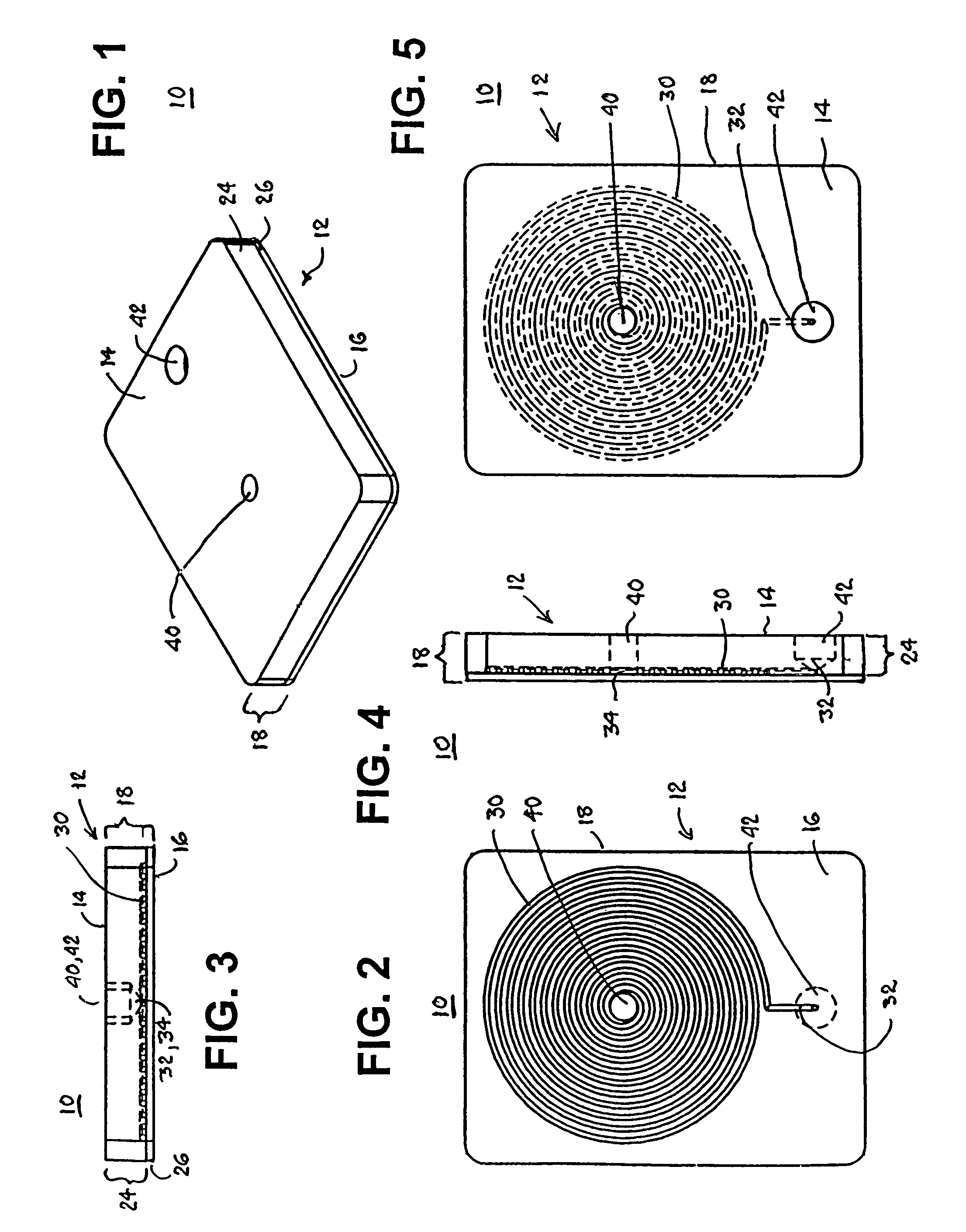

A system and method for determining a coagulation time, e.g., thrombin time, PT, aPTT, and ACT, of a blood sample deposited in a test cartridge is disclosed. The test cartridge includes a blood receptacle that is open to the atmosphere into which a blood sample is to be deposited, a vacuum port that is open to atmosphere, and a spiral capillary within the test cartridge having a capillary length and cross-section area, a first capillary end of the spiral capillary open to the blood receptacle and a second capillary end of the spiral capillary open to the vacuum port, whereby the spiral capillary is closed to atmosphere. When a blood sample is deposited in the blood receptacle, a vacuum is drawn through the vacuum port and the blood is drawn through the spiral capillary until coagulation occurs. A pressure change is detected, and the coagulation time is measured.

Owner:MEDTRONIC INC

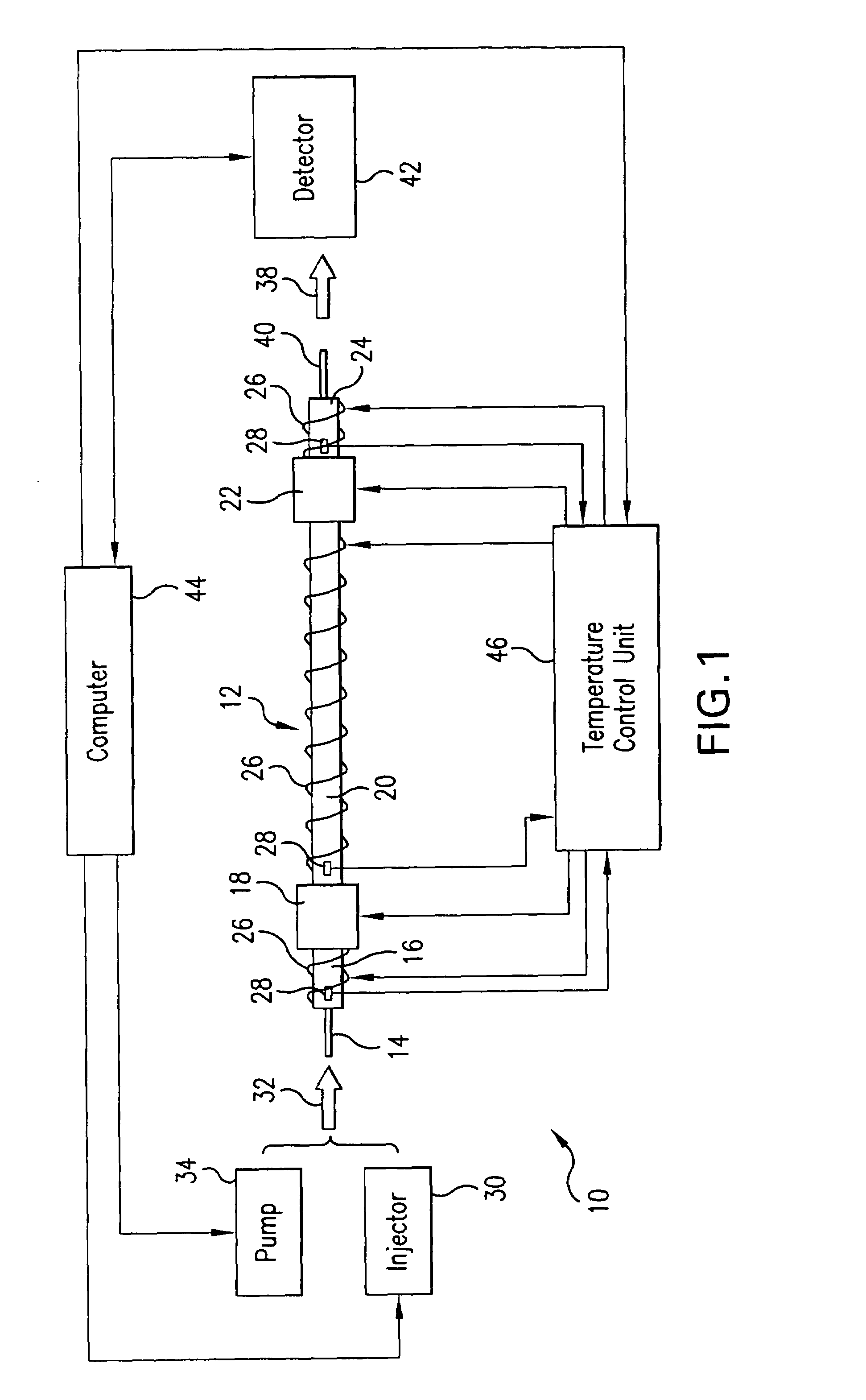

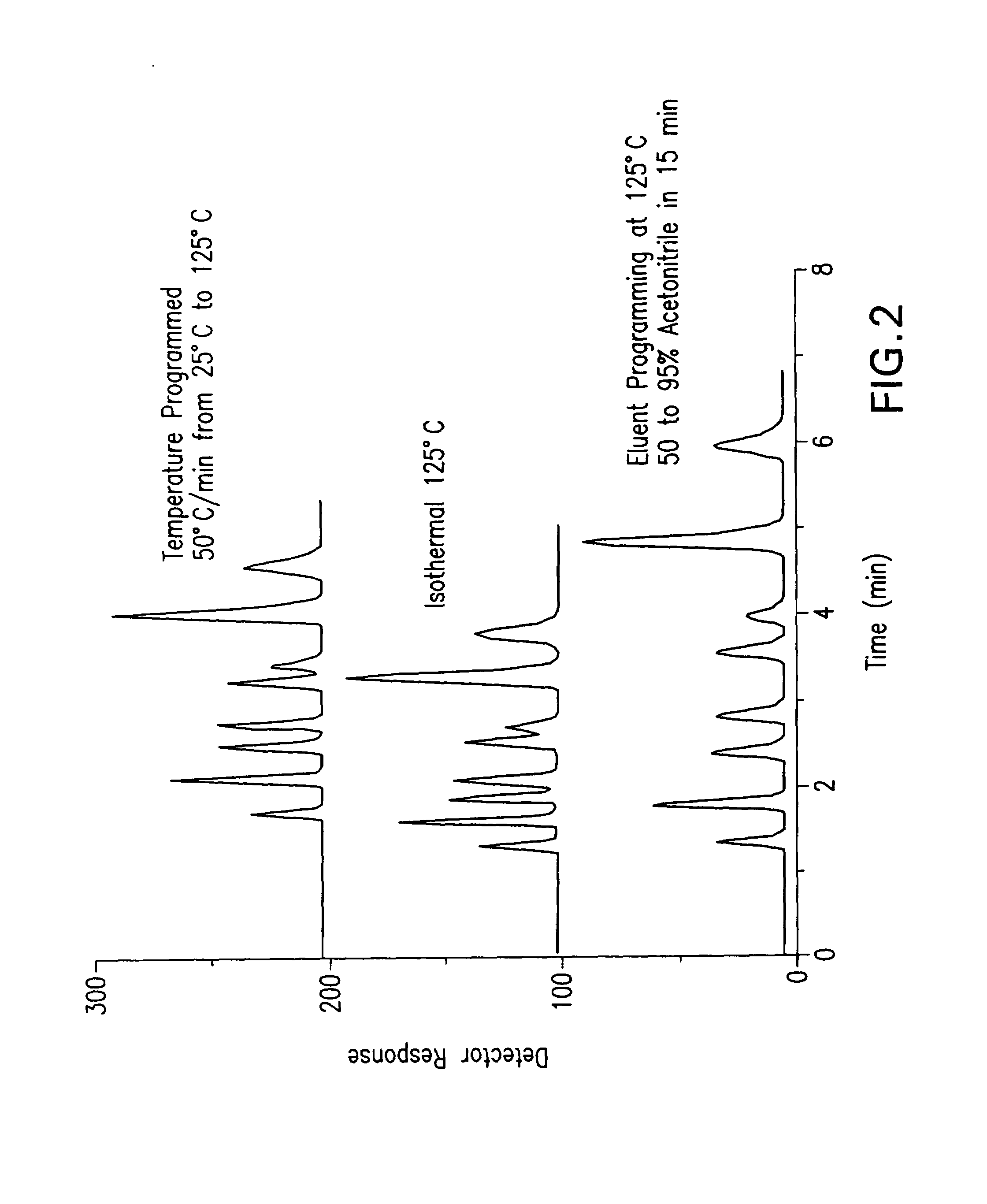

Temperature programmed low thermal mass fast liquid chromatography analysis system

InactiveUS20090173146A1Fast heat exchangeHigh throughput analysis rateComponent separationElectronic temperatureCapillary Tubing

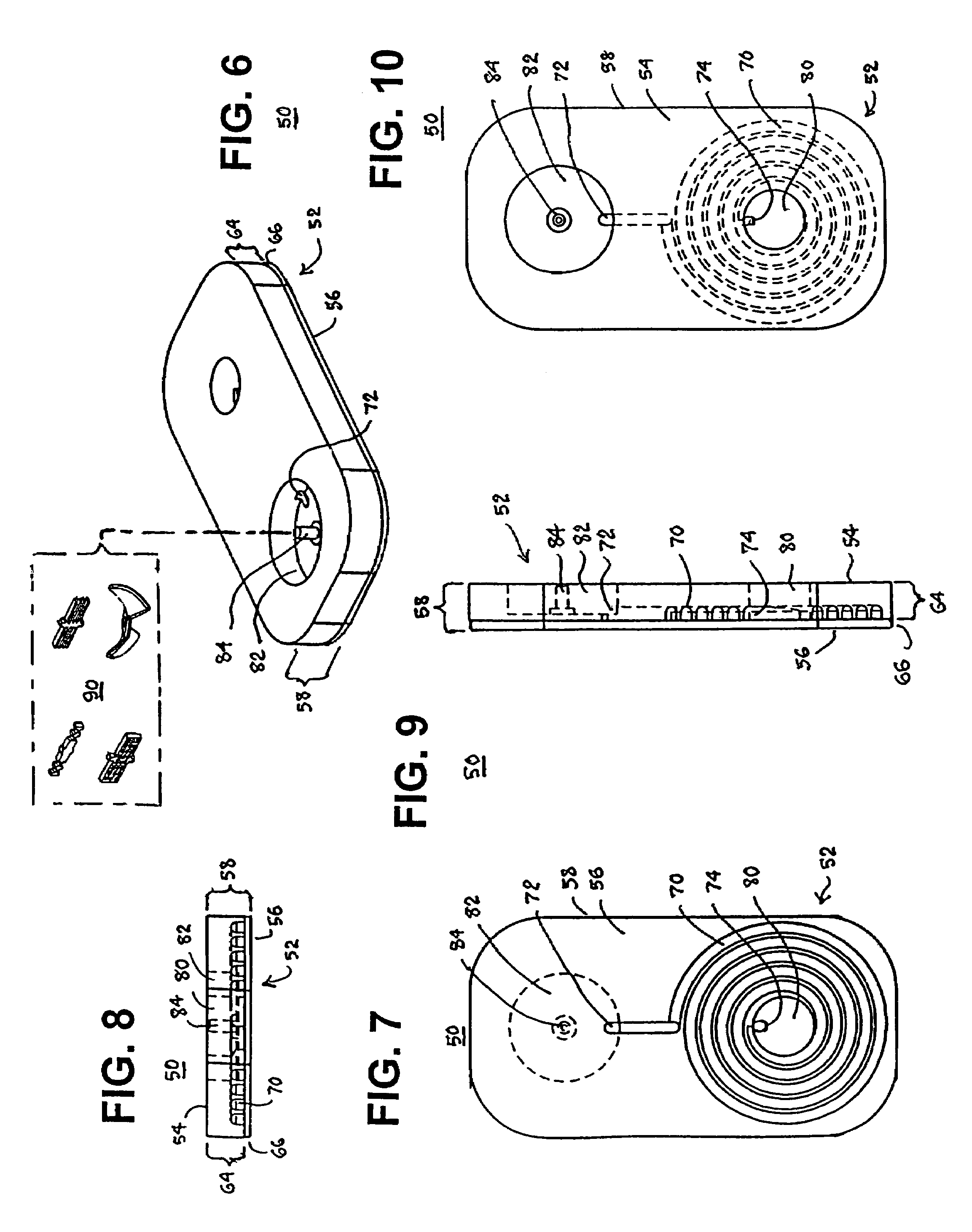

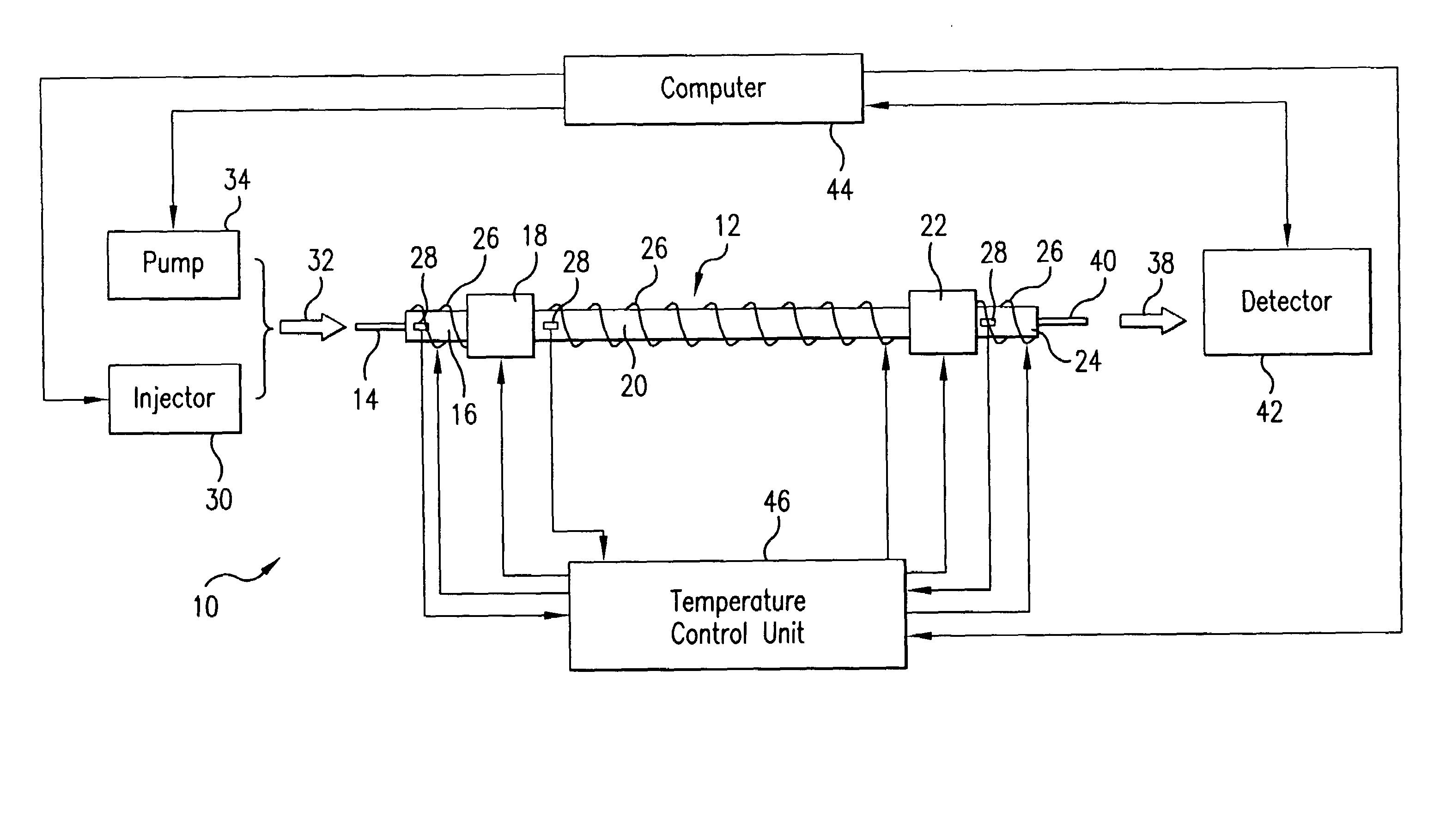

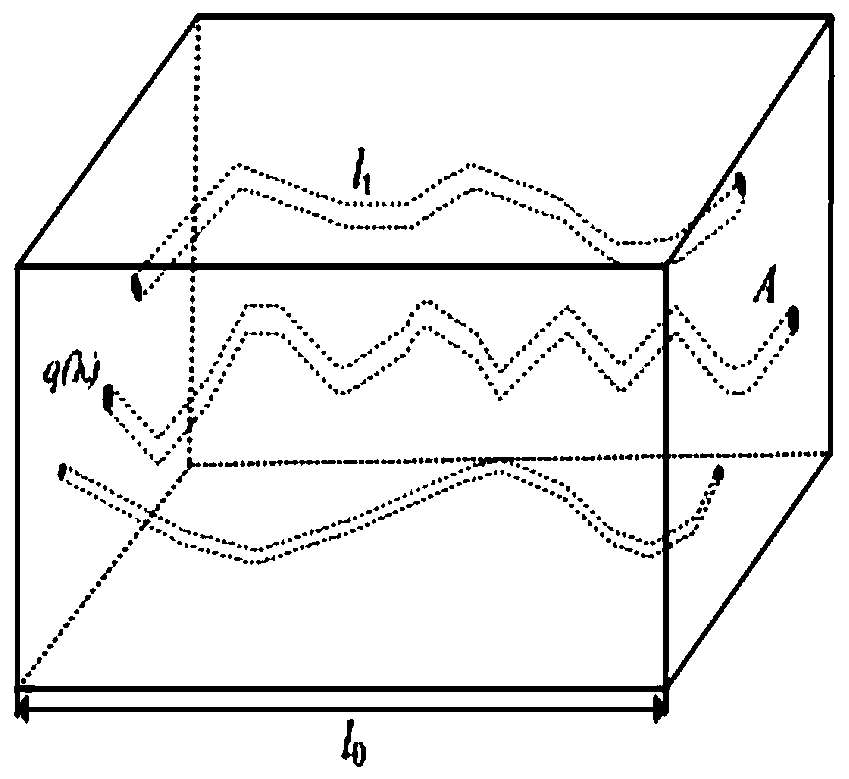

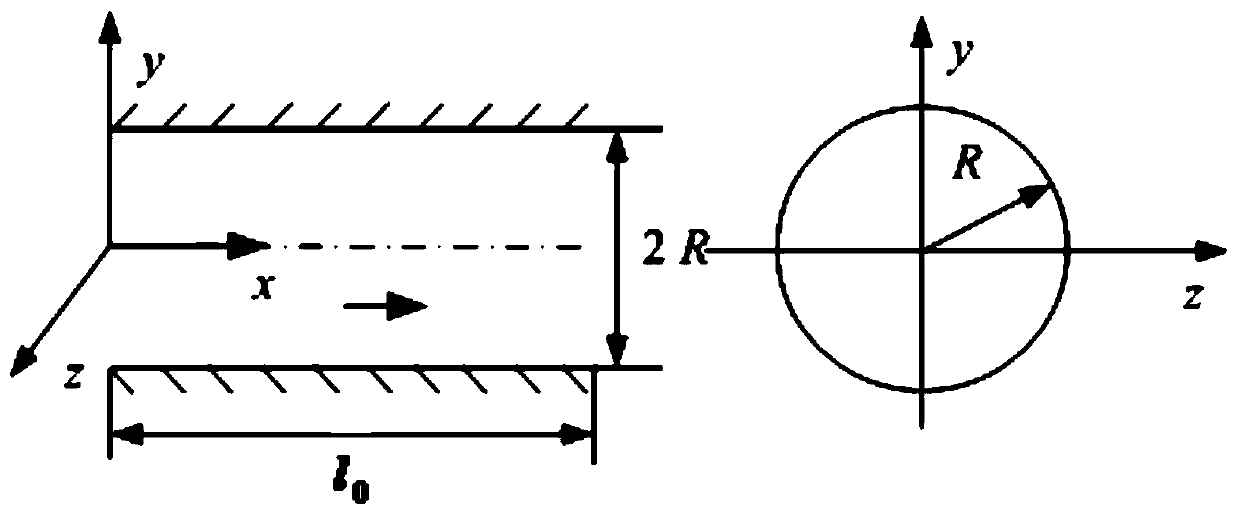

A temperature programmed low thermal mass fast liquid chromatography system capable of high throughput and low power consumption includes a straight or curved short reloadable low-mass tubular heater with a capillary column extending inside. If the capillary column is long enough, it is coiled to form a coiled capillary LC column (the length of which does not exceed 0.2 m-1.0 m) packed in a singular module package with a heating wire and a temperature sensing wire extending along and in proximity to the LC capillary column. A tubular heater, e.g. a steel tubing, incorporates the LC capillary column, along with the heating wire and the temperatures sensor and is coiled to form a miniature power saving LC module which may be attached outside a chromatography oven. Capillary lengths extend inside the oven between the inlet and outlet of the LC column module and mobile phase source and detector, respectively. An electronic temperature control block is positioned outside the oven cavity and controls the heating of the capillary LC column, as well as other heated zones in the system.

Owner:AGILENT TECH INC

Blood coagulation test cartridge, system, and method

InactiveUS20050255601A1Practical and convenientRapid and inexpensiveMicrobiological testing/measurementWithdrawing sample devicesBlood capillaryEngineering

A system and method for determining a coagulation time, e.g., thrombin time, PT, aPTT, and ACT, of a blood sample deposited in a test cartridge is disclosed. The test cartridge comprises a blood receptacle that is open to the atmosphere into which a blood sample is to be deposited, a vacuum port that is open to atmosphere, and a spiral capillary within the test cartridge having a capillary length and cross-section area, a first capillary end of the spiral capillary open to the blood receptacle and a second capillary end of the spiral capillary open to the vacuum port, whereby the spiral capillary is closed to atmosphere. When a blood sample is deposited in the blood receptacle, a vacuum is drawn through the vacuum port and the blood is drawn through the spiral capillary until coagulation occurs. A pressure change is detected, and the coagulation time is measured.

Owner:MEDTRONIC INC

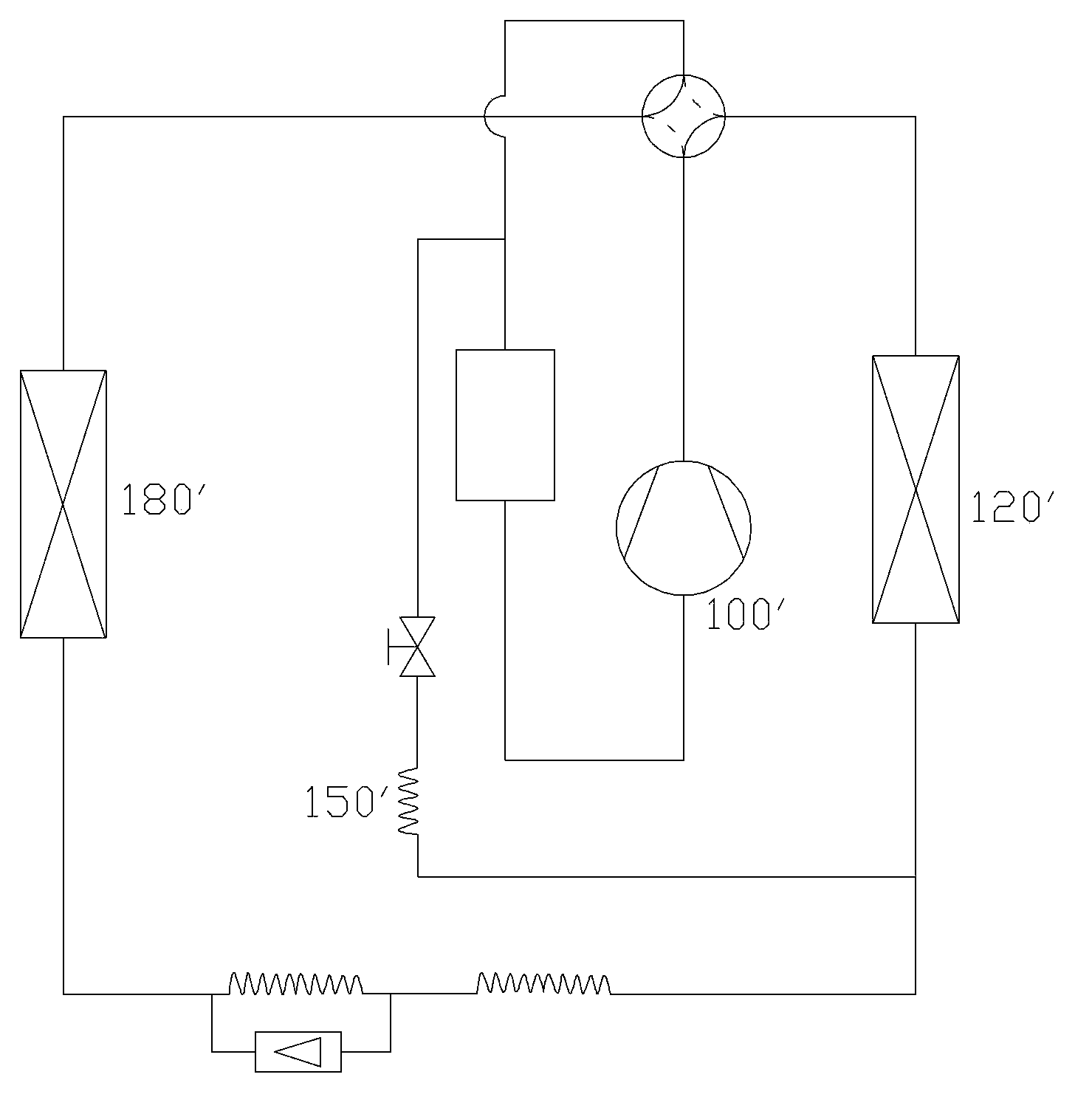

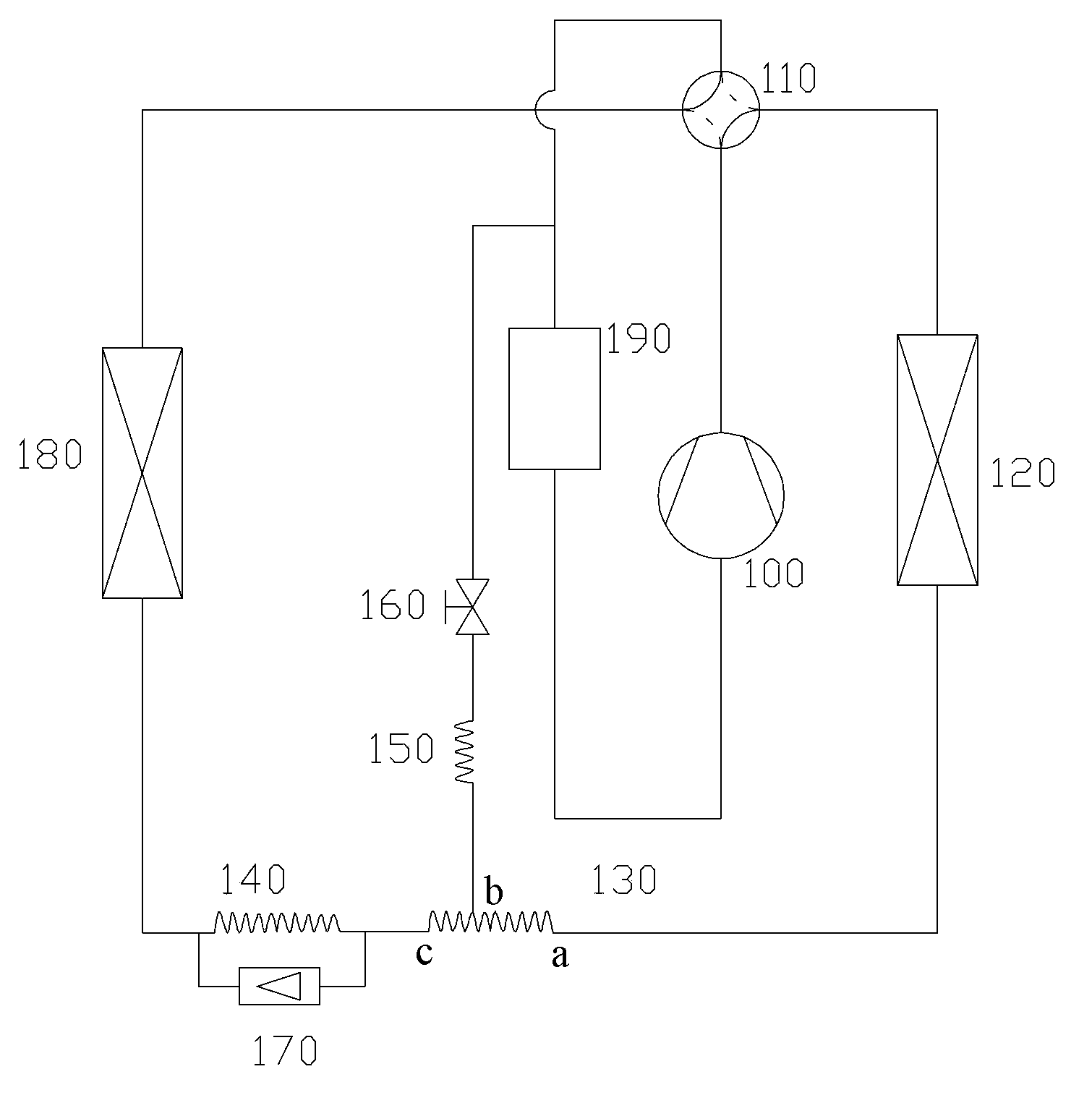

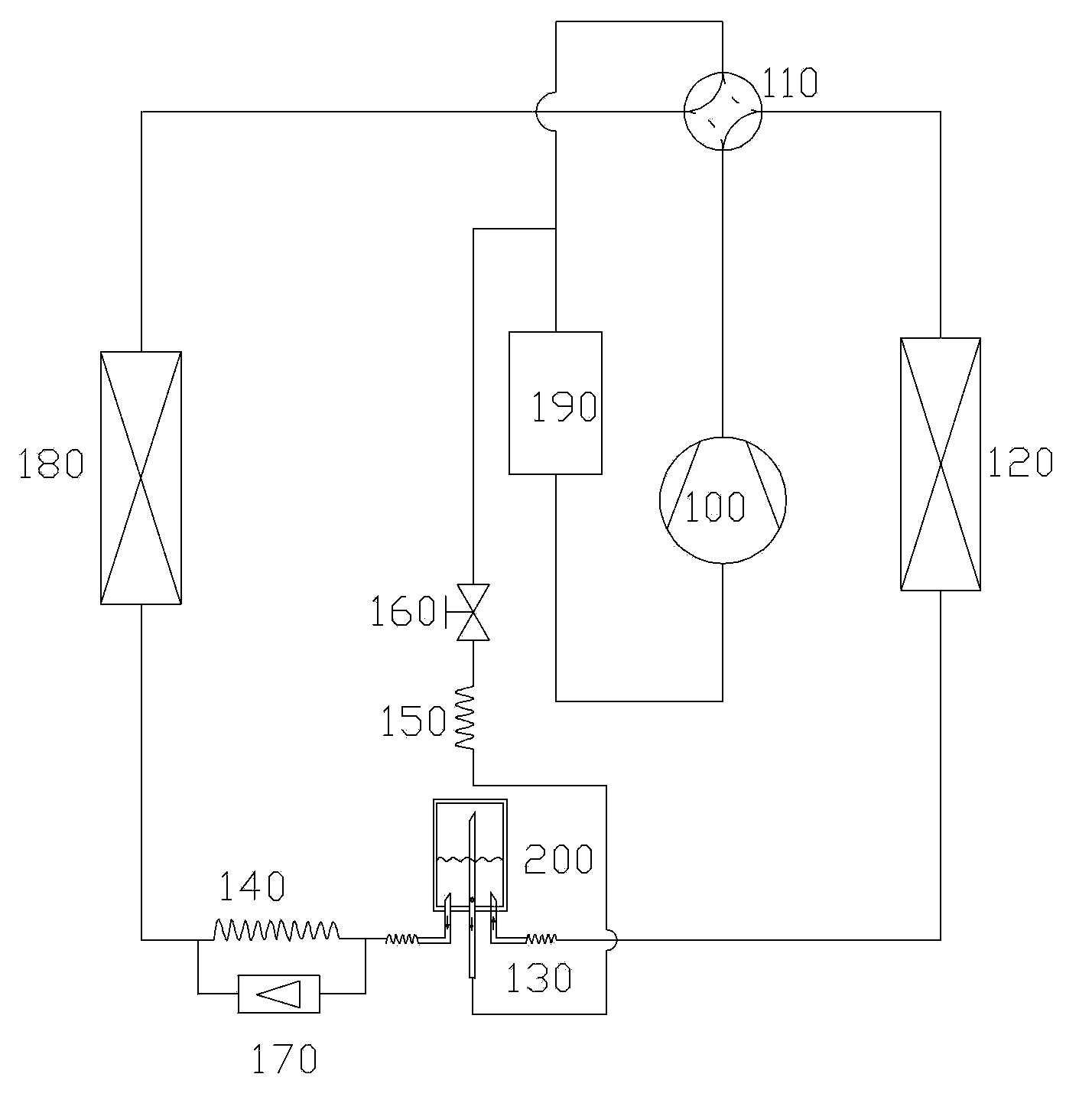

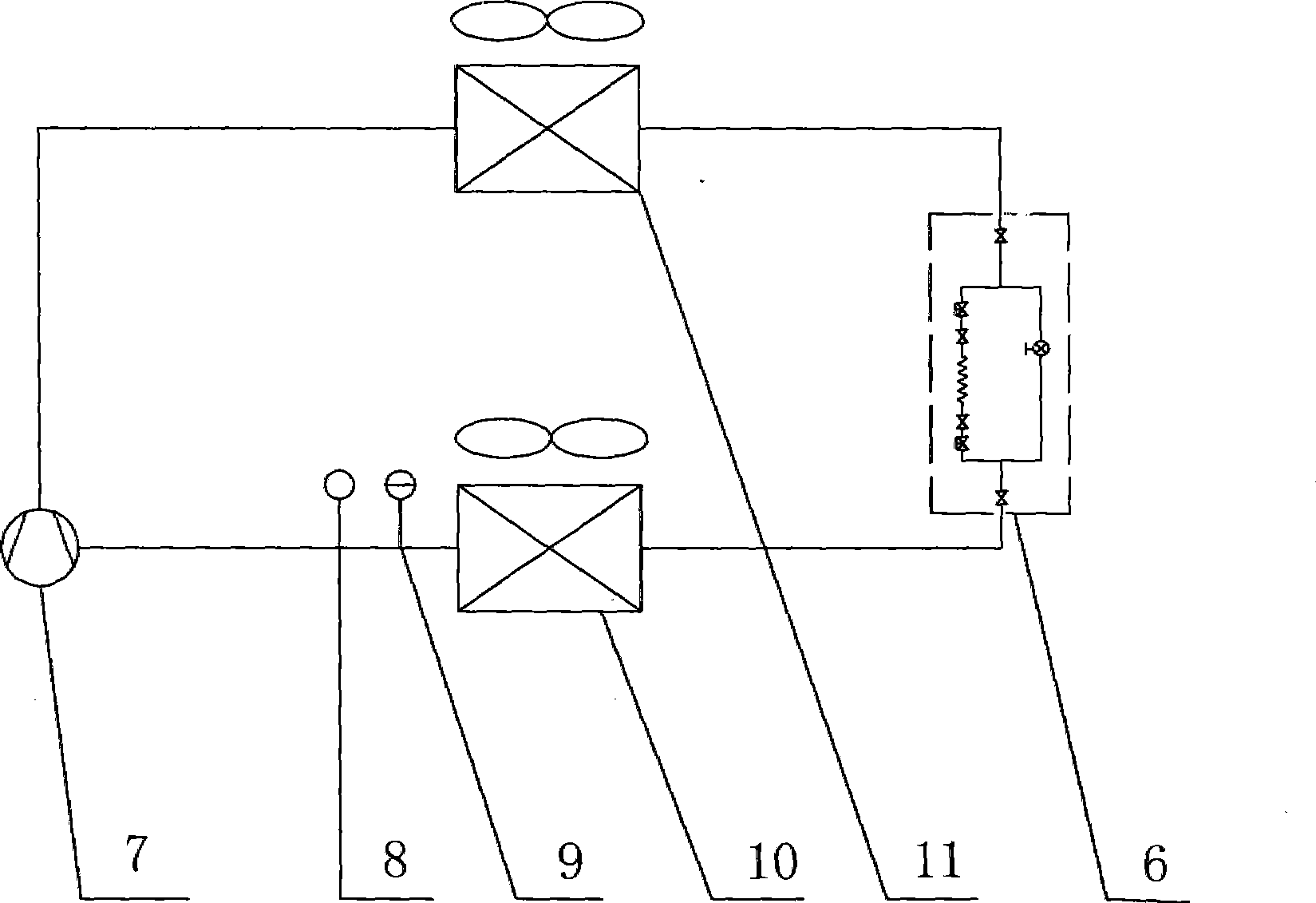

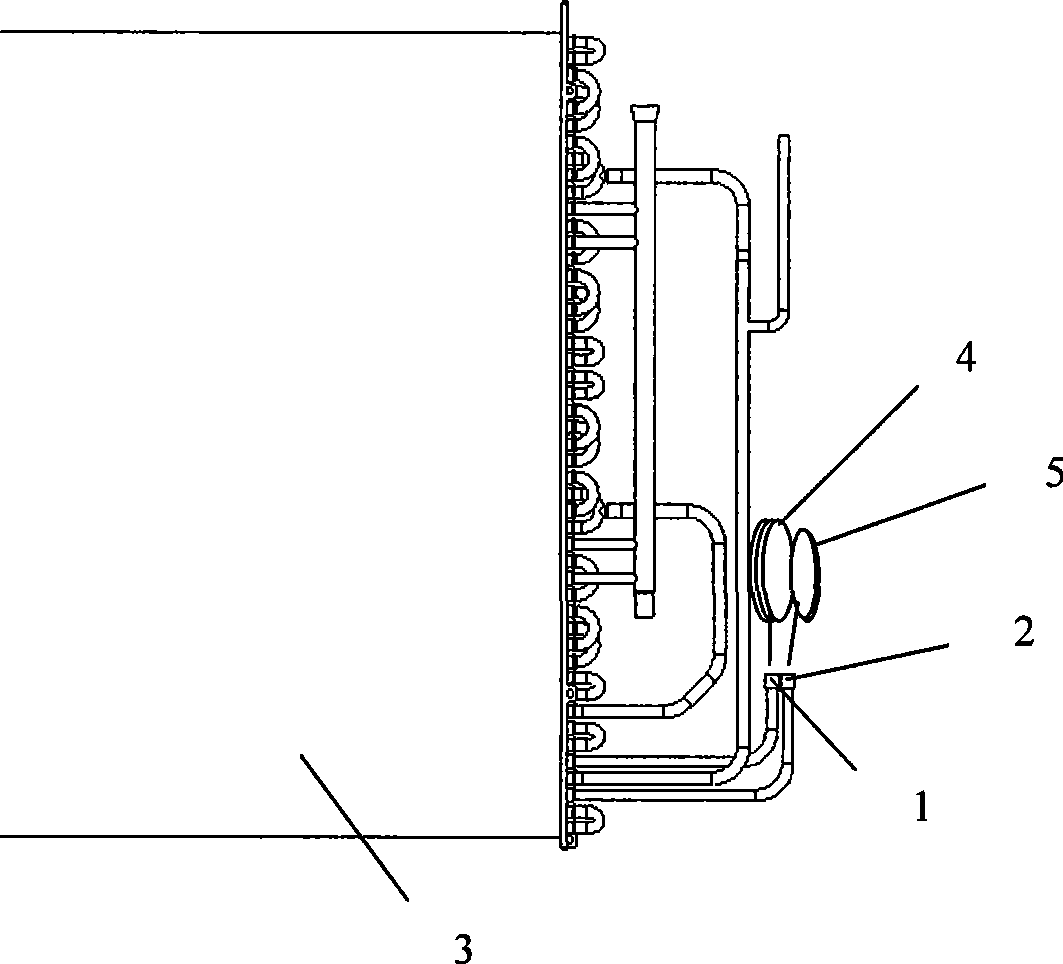

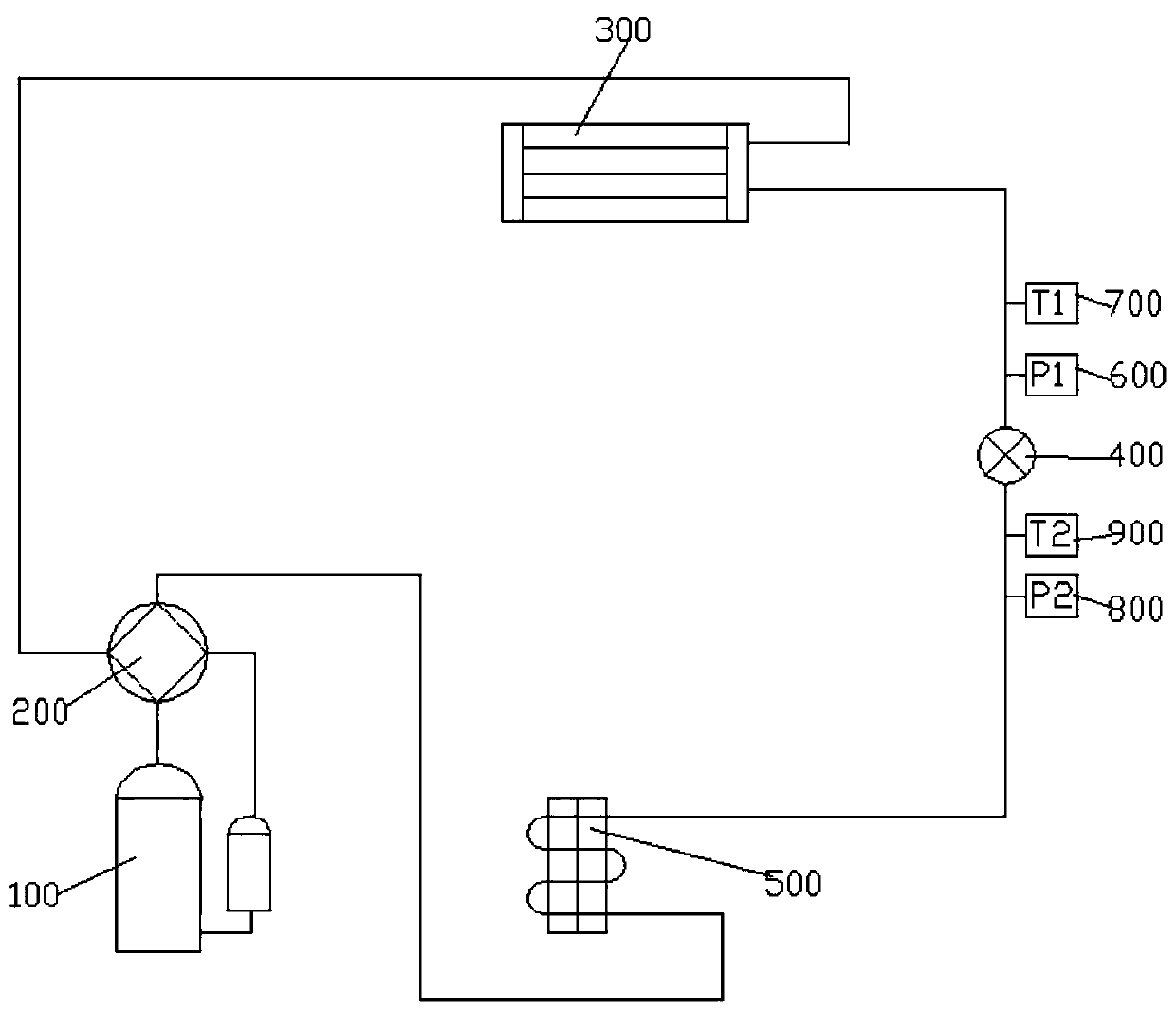

Refrigerating system and air-conditioning system with same

InactiveCN103673424AImprove practicalityReduce exhaust temperatureMechanical apparatusFluid circulation arrangementVapor–liquid separatorEngineering

The invention provides a refrigerating system and an air-conditioning system with the same. The refrigerating system comprises a major refrigerating loop and a liquid injecting cooling loop. The major refrigerating loop comprises a gas-liquid separator, a compressor, a four-way reversing valve, an outdoor heat exchanger, a first capillary pipe and an indoor heat exchanger which are sequentially connected through refrigerating pipelines. The liquid injecting cooling loop comprises a liquid injecting capillary pipe and a valve which are sequentially connected, the first end of the liquid injecting cooling loop is connected between the first end of the first capillary pipe and the indoor heat exchange, the second end of the liquid injecting cooling loop is connected on a pipeline between the four-way reversing valve and the gas-liquid separator or connected on the gas-liquid separator. The refrigerating system effectively solves the problems that a compressor of an existing refrigerating system is too high in exhaust temperature and a liquid injecting capillary pipe is too long in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC

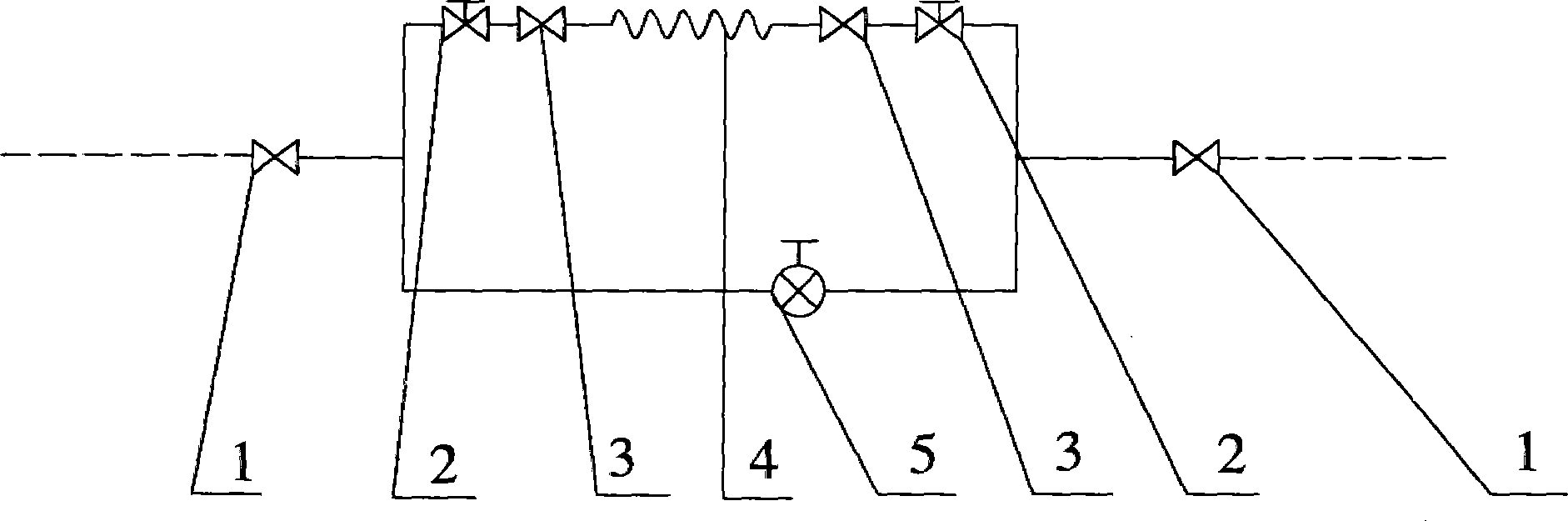

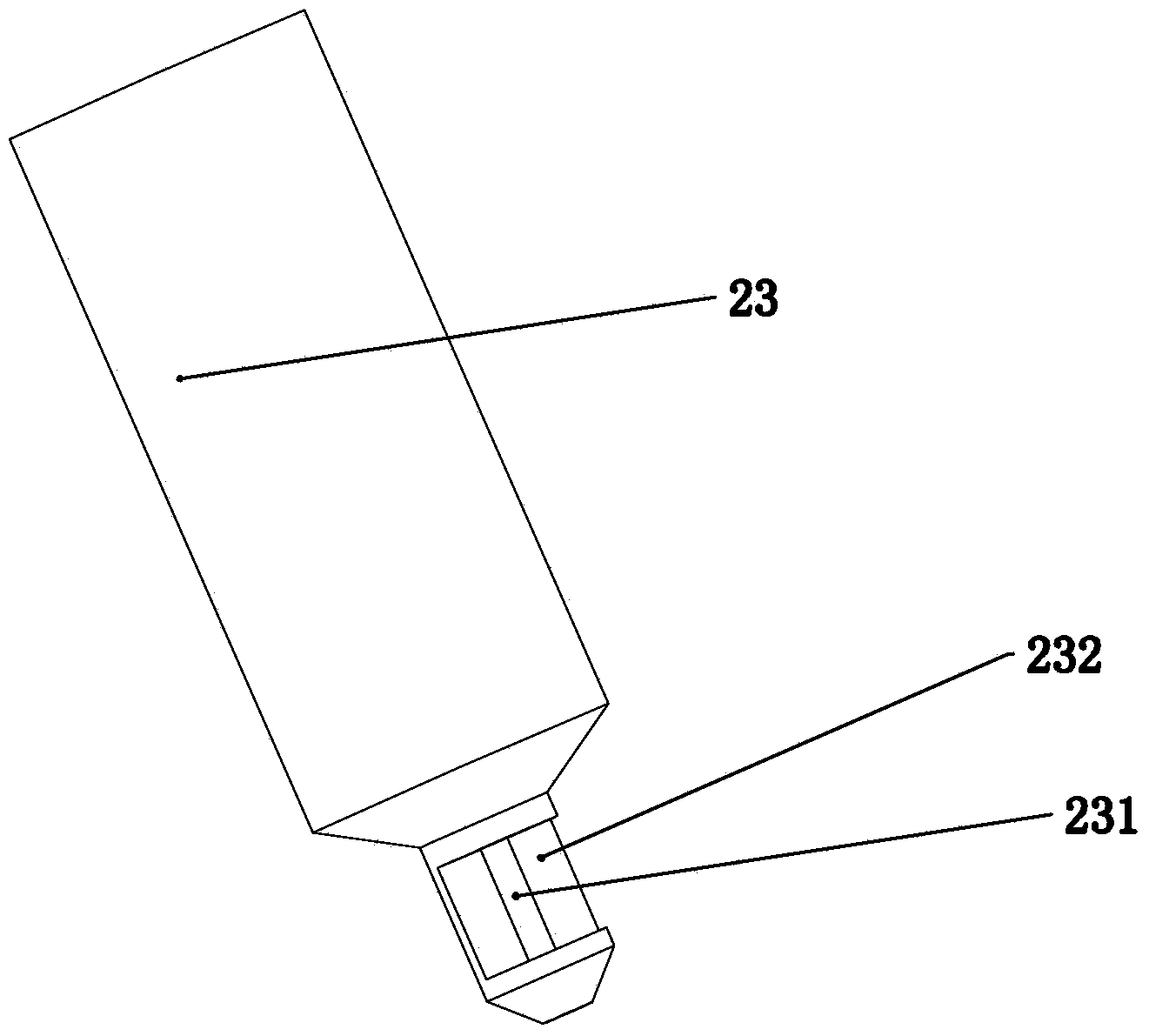

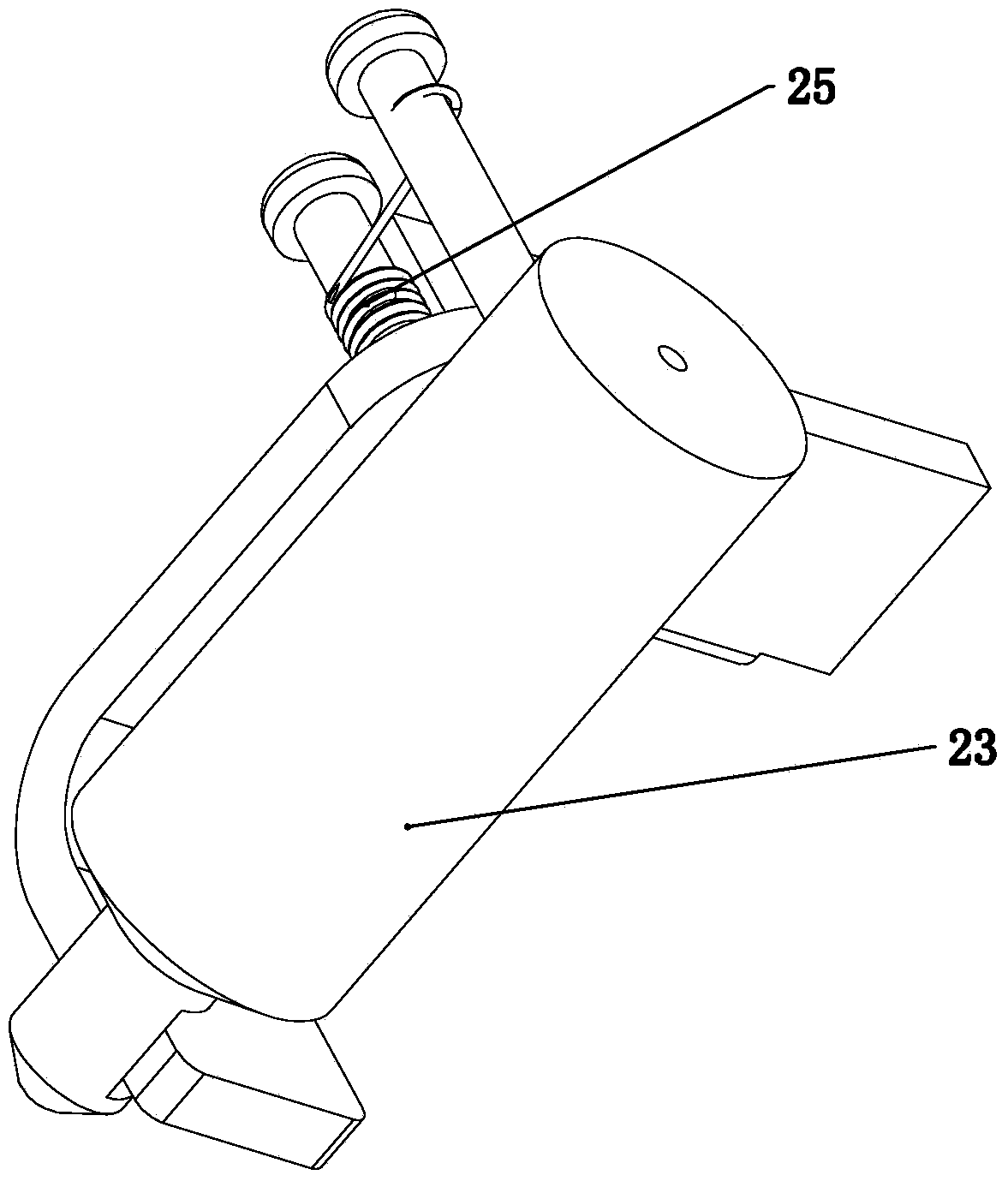

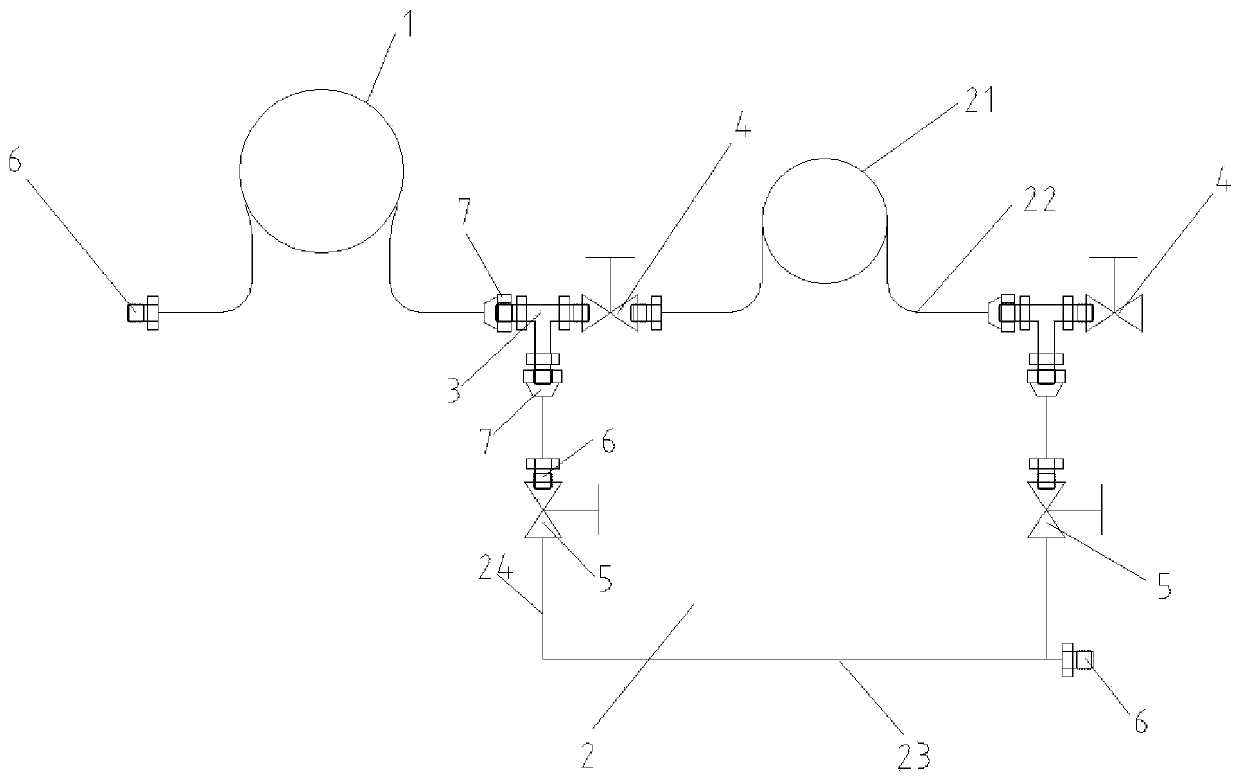

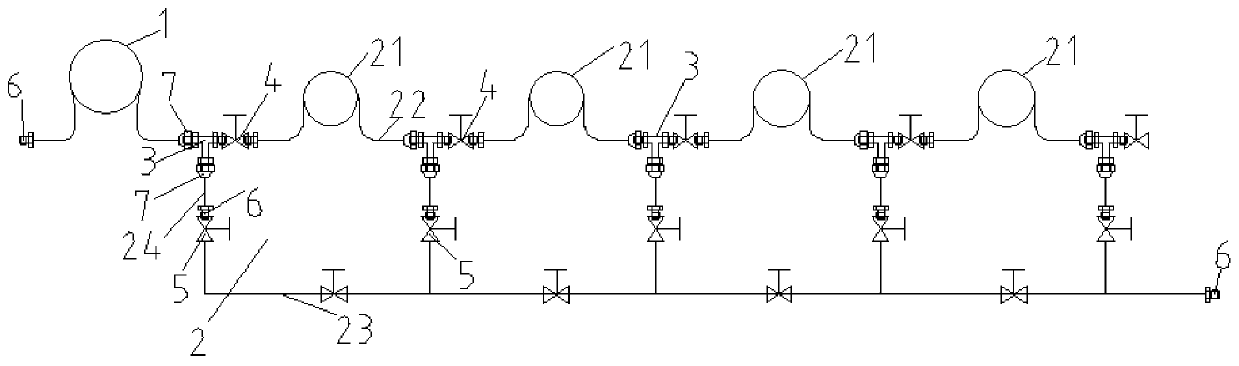

Rapid matching apparatus for capillary pipe length for air conditioner

InactiveCN101382363AQuick implementation of match testingImplement match testEfficient regulation technologiesFluid circulation arrangementEngineeringElectronic expansion valve

The invention relates to a fast matching device of the length of a capillary for an air-conditioner, comprising an electronic expansion valve and a capillary component branch to be tested; the capillary component branch to be tested consists of a capillary component and stop valves which are respectively connected with the two ends thereof in series, and the capillary component branch to be tested is connected with the electronic expansion valve in parallel. The fast matching device can not only fast determine the capability of throttling and reducing pressure of the capillaries with the different lengths with the help of the electronic expansion valve, but can also carry out the on-line fast replacement of the capillary component with the help of the stop valves which are arranged at the two ends of the capillary component, thereby greatly improving the efficiency and the accuracy of the matching of the length of the capillary.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

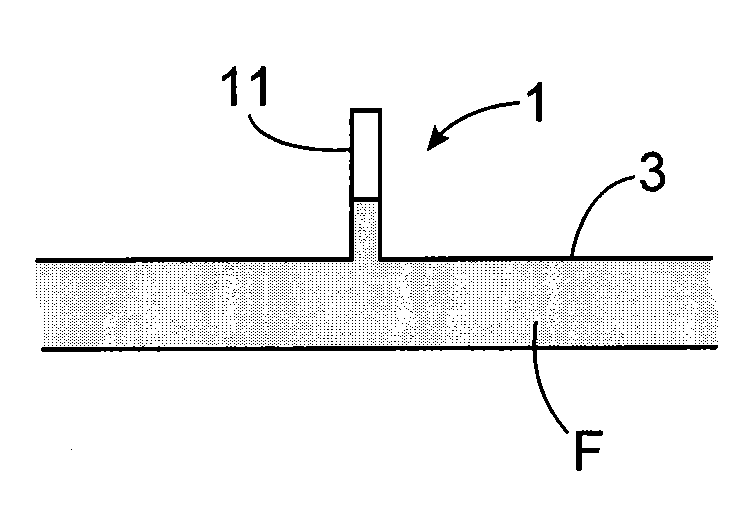

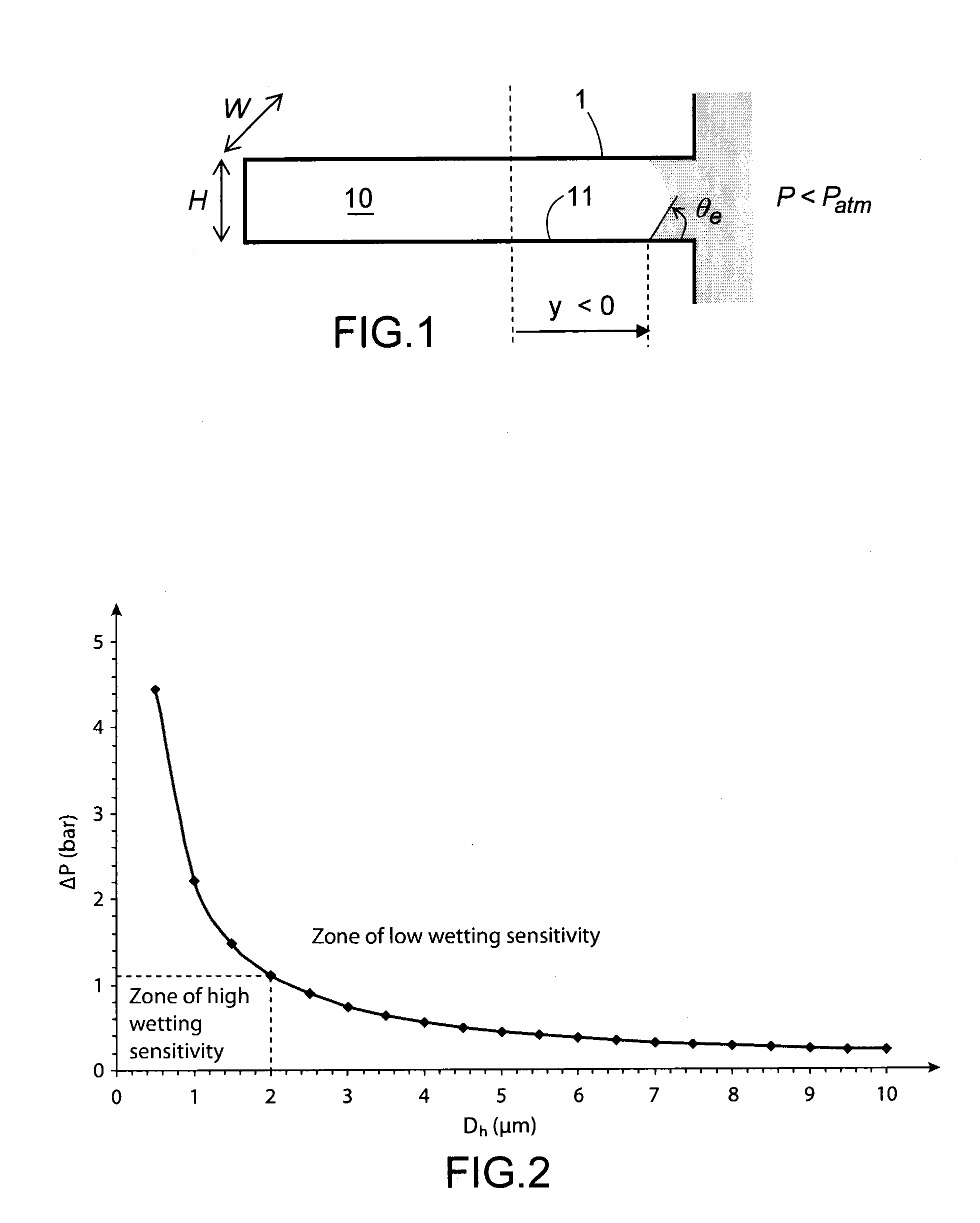

Device forming a manometer intended for measuring biphasic fluid pressure, associated method of manufacture and fluidic network

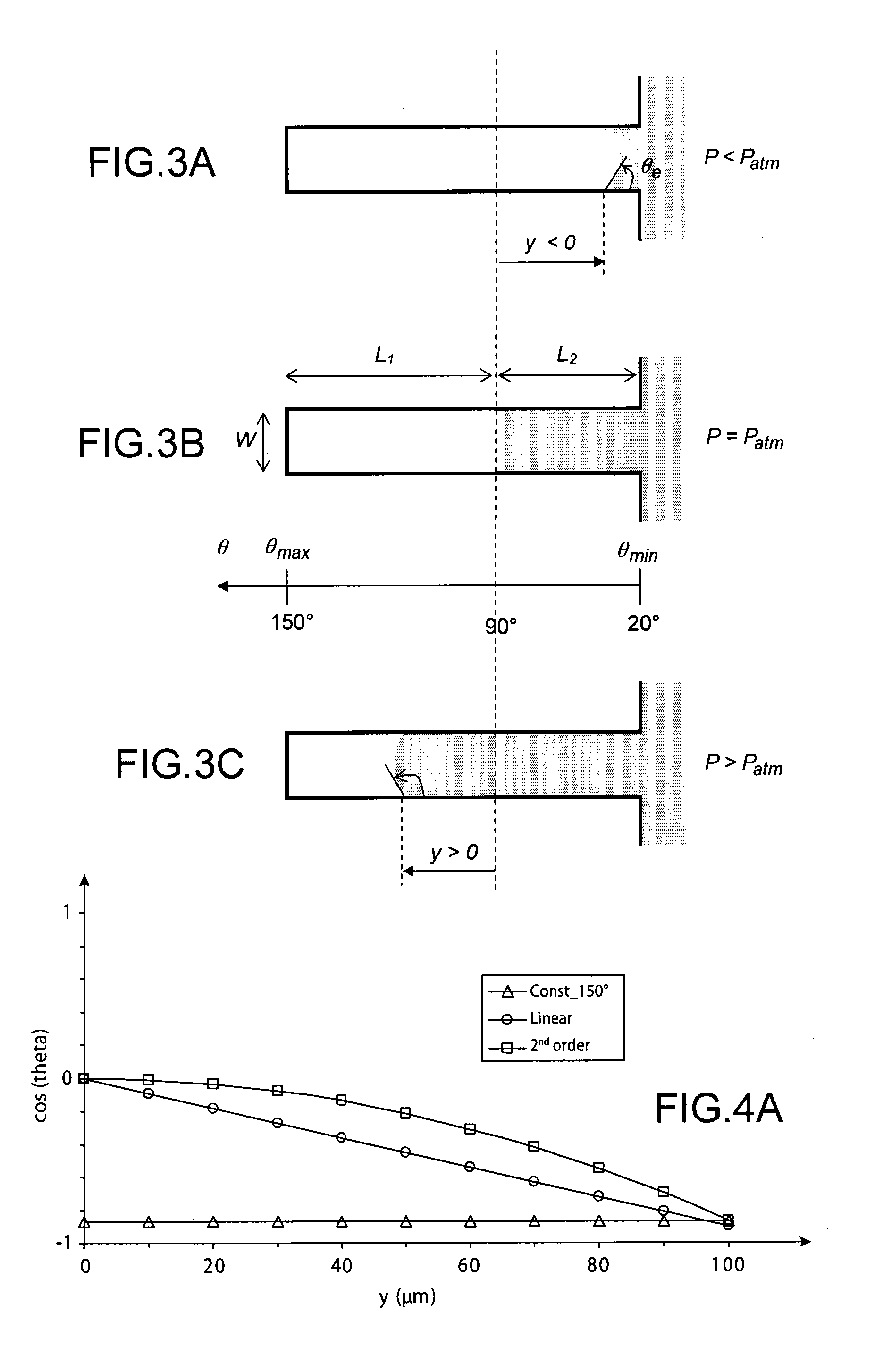

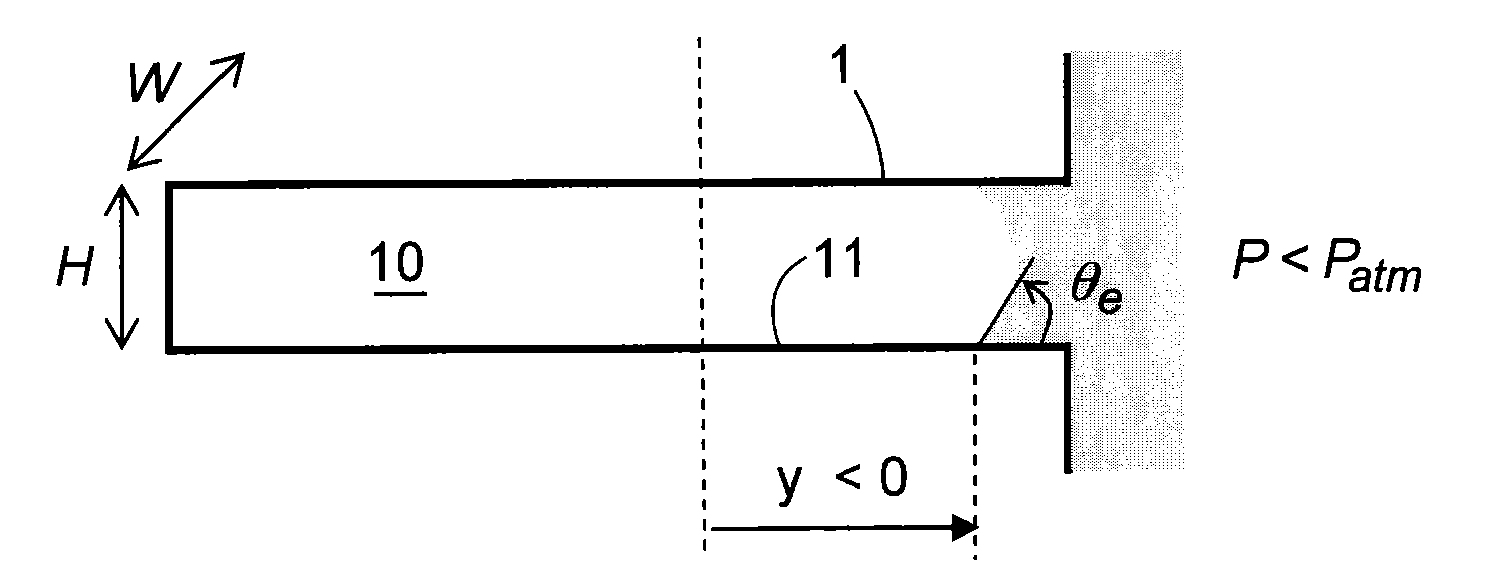

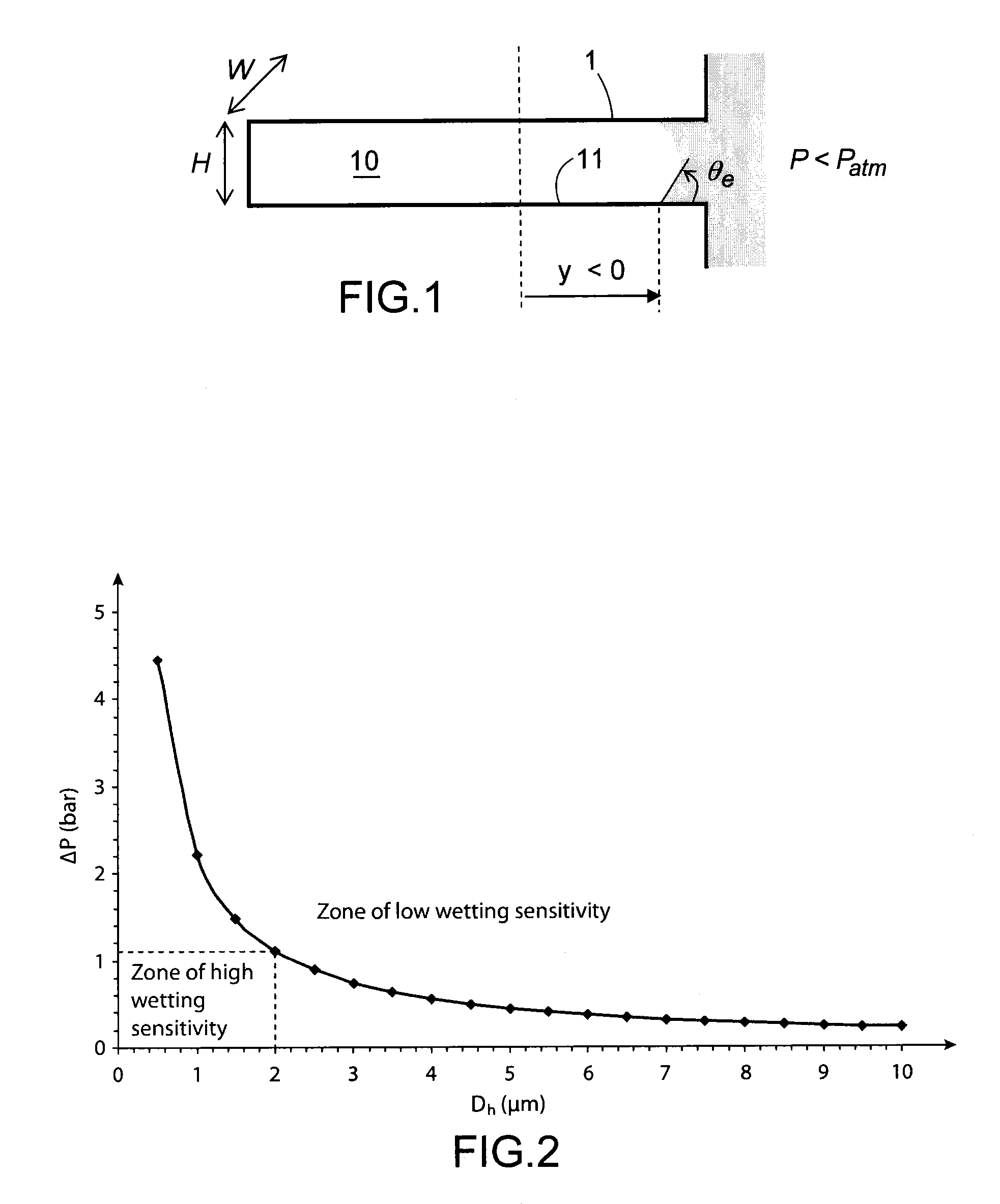

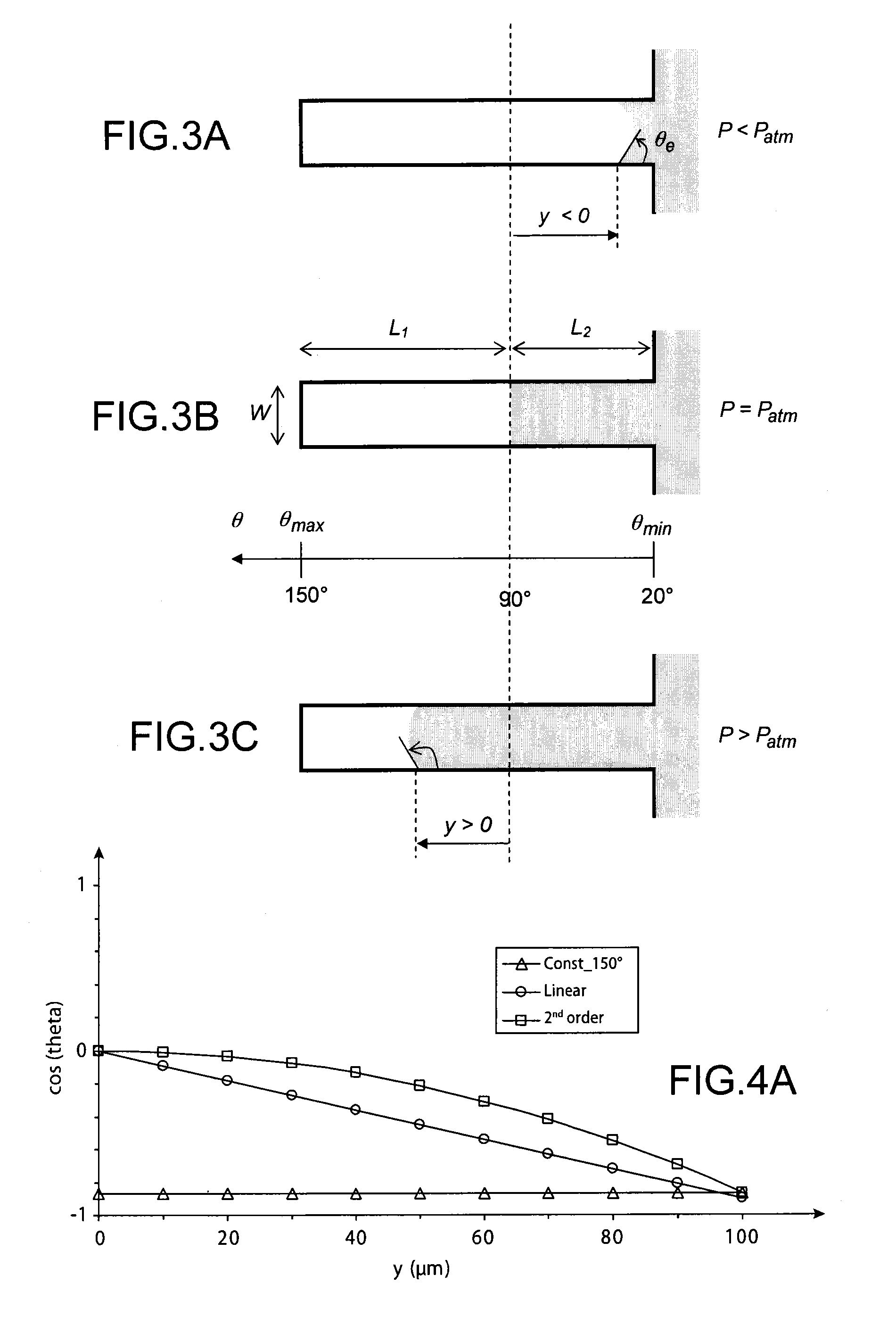

InactiveUS20130052552A1High measurement sensitivityWithout impairing its compactness and its operationFixed microstructural devicesVolume/mass flow measurementFuel cellsDevice form

A device forming a manometer, configured to measure pressure of a biphasic fluid in a fluidic network, including: a first channel inside which a biphasic fluid is able to flow; a second channel emerging into the first channel, wherein the second channel is blind, with each of its dimensions less than capillary length of the fluid's liquid phase, and with at least one of its lengthways wall having a surface energy gradient that decreases from its inlet to the end. The surface energy gradient enables the wetting angle of the meniscus of the fluid's liquid phase to be increased in the blind channel from its inlet to the end. Such a device may find application to measurement of pressure of a biphasic fluid in a heat exchanger or in a fuel cell.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

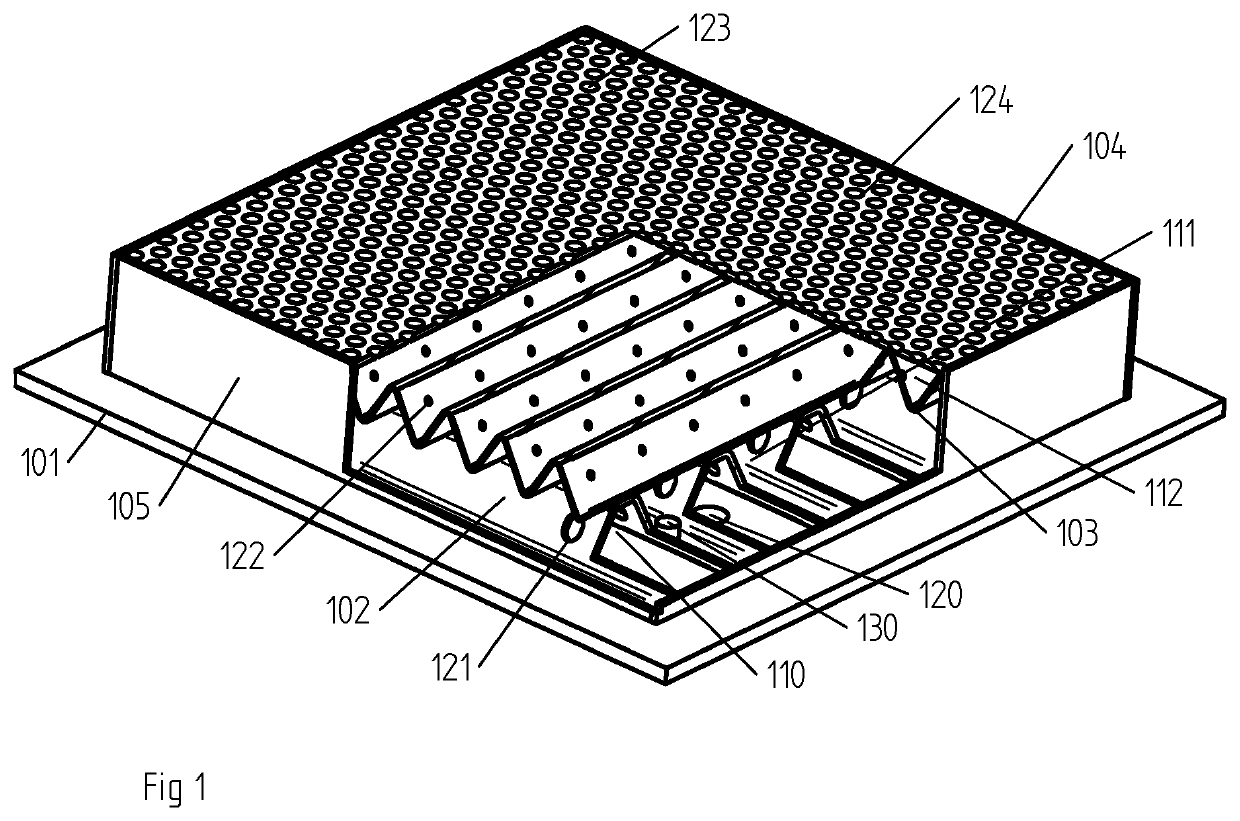

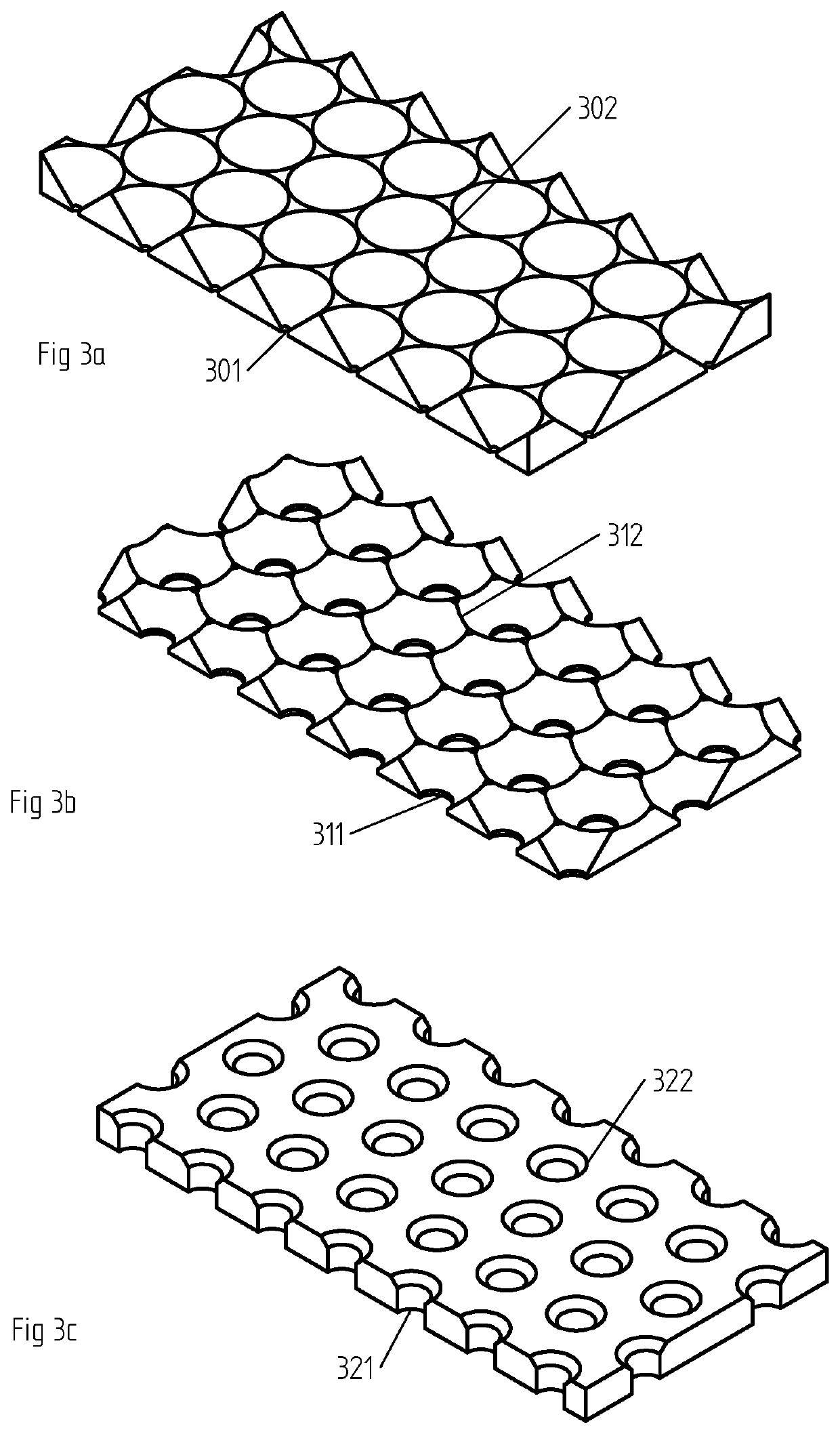

Plate type heat exchanging element for evaporation and condensation

ActiveCN101639332ASolve poor mechanical sealReduce thermal resistanceHeat exchanger casingsLaminated elementsEvaporationEngineering

The invention discloses a plate type heat exchanging element for evaporation and condensation, belonging to the technical field of engineering thermophysics and energy and utilization. The heat exchanging element is characterized in that a specially designed strengthening heat transfer structure is arranged on the heat transfer zone of the element; a structure protruding to the condensation side plays a role of fixing and turbulence and a structure protruding to the evaporation side is in an inward depression configuration so as to form more corning points; a narrow seam with microscale effect, which is designed aiming at working liquid, is arranged between the structure and a flat bar; the height of the structure is an optimized value which is calculated according to characteristic valuesof detached diameter and capillary length of the working liquid, so as to cause generated bubbles to continuously absorb heat to grow up in the process of sliding between the flat bars after detaching from the coring points, thereby taking more heat away, updating the passed surfaces and accelerating liquid convection. The invention has the effects and benefits that the evaporative condenser consisting of the provided elements is in direct immersion type, and has the advantages of high heat transfer coefficient, convenient unpick and wash, uneasy corrosion and low energy consumption.

Owner:DALIAN UNIV OF TECH

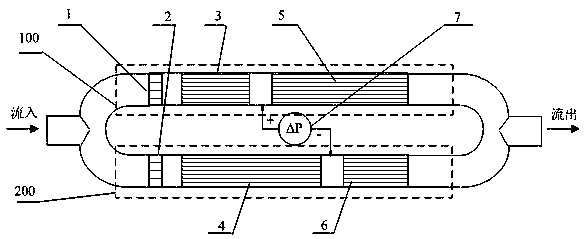

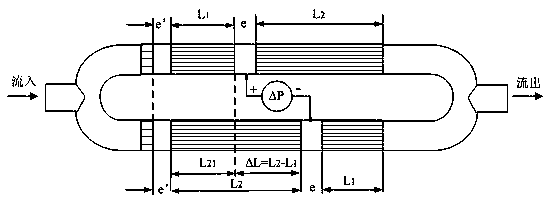

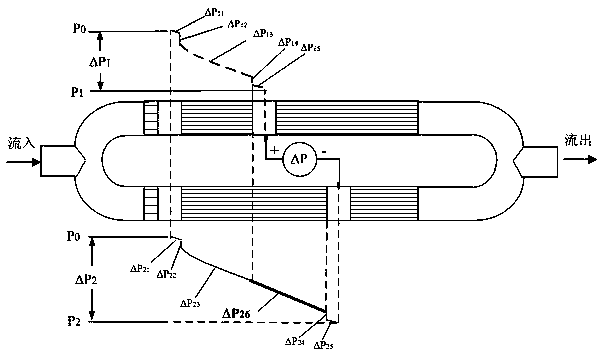

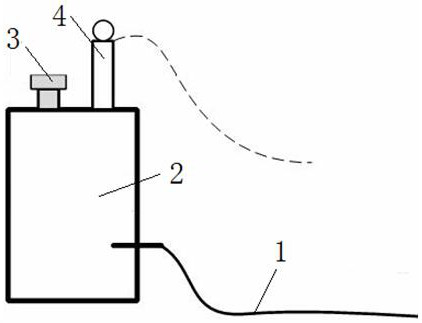

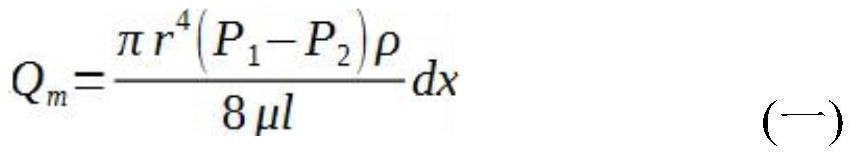

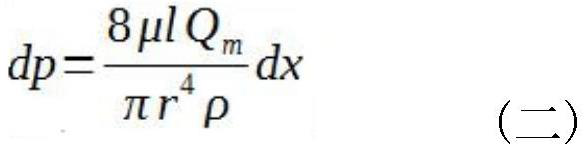

Differential pressure type laminar flow measuring method and device

PendingCN109738030ANon-linear component reductionSubsequent corrections are easyVolume/mass flow by differential pressureDifferential pressureEngineering

The invention discloses a differential pressure type laminar flow measuring method and device. A measuring pipeline consists of two parallel branch circuits with the same pipe diameter, each branch circuit is in series connection with two laminar flow elements of different lengths, the laminar flow elements on the two branch circuits are identical in pairs,themounting positions of the laminar flowelements are symmetric in a crossedmode, and the two branch circuits which are identical except for the relative positions of a long laminar flow element and a short laminar flow element; and a pressure tappingport is formed in the middle of a pressure tappingcavity between the two laminar flow elements on each branch circuit, the pressure difference between the two pressuretapping cavities is measured and is called as the differential pressure, the differential pressure value isdirectly proportional to the volume flow flowing through the measuring pipeline, the measured volume flow is calculated through the differential pressure by adopting a Hagen-Poiseuille law, and during specific implementation, the requirements that the capillary length of each laminar flow element exceeds the length of a flow inlet section and flowing is in a laminar state are met. According to the differential pressure type laminar flow measuring method, the nonlinear influence of the pressure loss of inlets and outlets and the flow pressure loss of the inlet section of the laminar flow elements of a traditional laminar flowmeter is avoided, and accurate measurement and the wider measuring range are easy to realize.

Owner:CHINA JILIANG UNIV +1

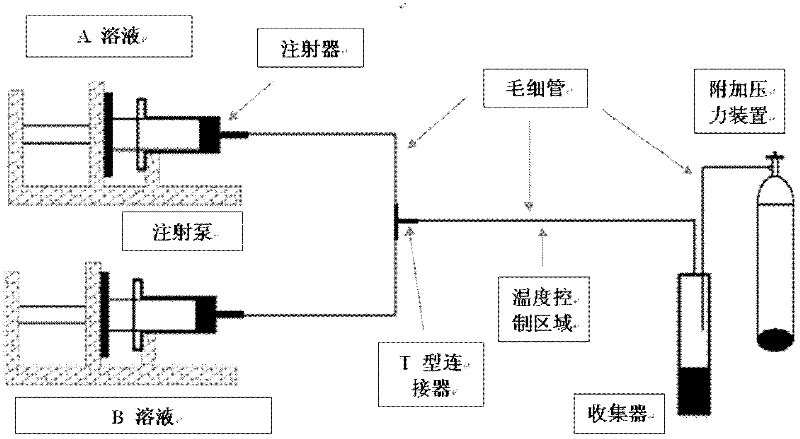

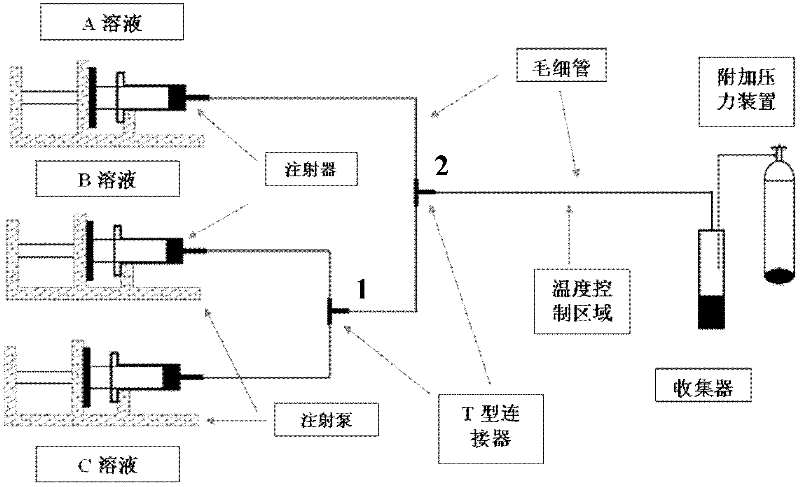

Preparation method for lithium ion battery electrode material

The invention discloses a preparation method for a lithium ion battery electrode material, belonging to the technical field of the lithium ion battery electrode material. The preparation method comprises the following steps of: adopting microfluidics for a primary or secondary structure, a solution containing Fe (2+) ion and Li(+) ion and a precursor solution containing PO43- ion; using an injector to respectively extract the solutions and then installing the injector on an injection pump; connecting the injector by a T-shaped connector, connecting the third end vertical end with a capillary tube as a reaction region (if the reaction region is a secondary structure, the reaction region is formed by connecting two primary structures in series and in parallel); and controlling such different parameters as the type of precursor solution salt, flow velocity of liquid, the additional pressure, the length and the inner diameter of the capillary, the solution concentration, the reaction temperature and the like to acquire amorphous phosphate Fe-based anode material. The prepared material is directly synthesized in a liquid phase by solid-liquid discharging without a subsequent thermal treatment, has high discharge specific capacity and cycling stability under a low multiplying power and a high multiplying power.

Owner:BEIJING UNIV OF TECH

Method for quickly measuring transformer thermometer environment temperature influence quantity

ActiveCN104316222AEasy to carryAvoid routine testingThermometer testing/calibrationTemperature controlFuel tank

The invention relates to a method for quickly measuring the transformer thermometer environment temperature influence quantity. A test is conducted when the oil tank temperature of a transformer is stable, the environment temperature is T3, the length of a capillary tube is L1, and one end of the capillary is connected with a thermometer; a heating region with the length being L2 is taken from the capillary tube, a temperature control device is bound to the heating region, and the current temperature value T1 indicated by the thermometer pointer is read and the borne moment of force is M1; the temperature of a temperature control device is set and slowly raised to the target temperature T4; after the temperature is stable, the current temperature value T2 indicated by the thermometer pointer is read and the borne moment of force is M2; the temperature value difference of the thermometer before and after the temperature rises and the difference of the moment of force are calculated, the environment temperature influence quantity borne by the whole capillary tube is calculated according to the differences and the temperate difference delt T =(T2-T1)*L1 / L2 is generated by the thermometer; the thermometer moment force change delt M = (M2-M1)*L1 / L2; the environment temperature influence quantity = delt T (T4-T3)% / DEG C. Compared with the prior art, the method is easy to implement, capable of being implemented at field, and visual and accurate in result.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

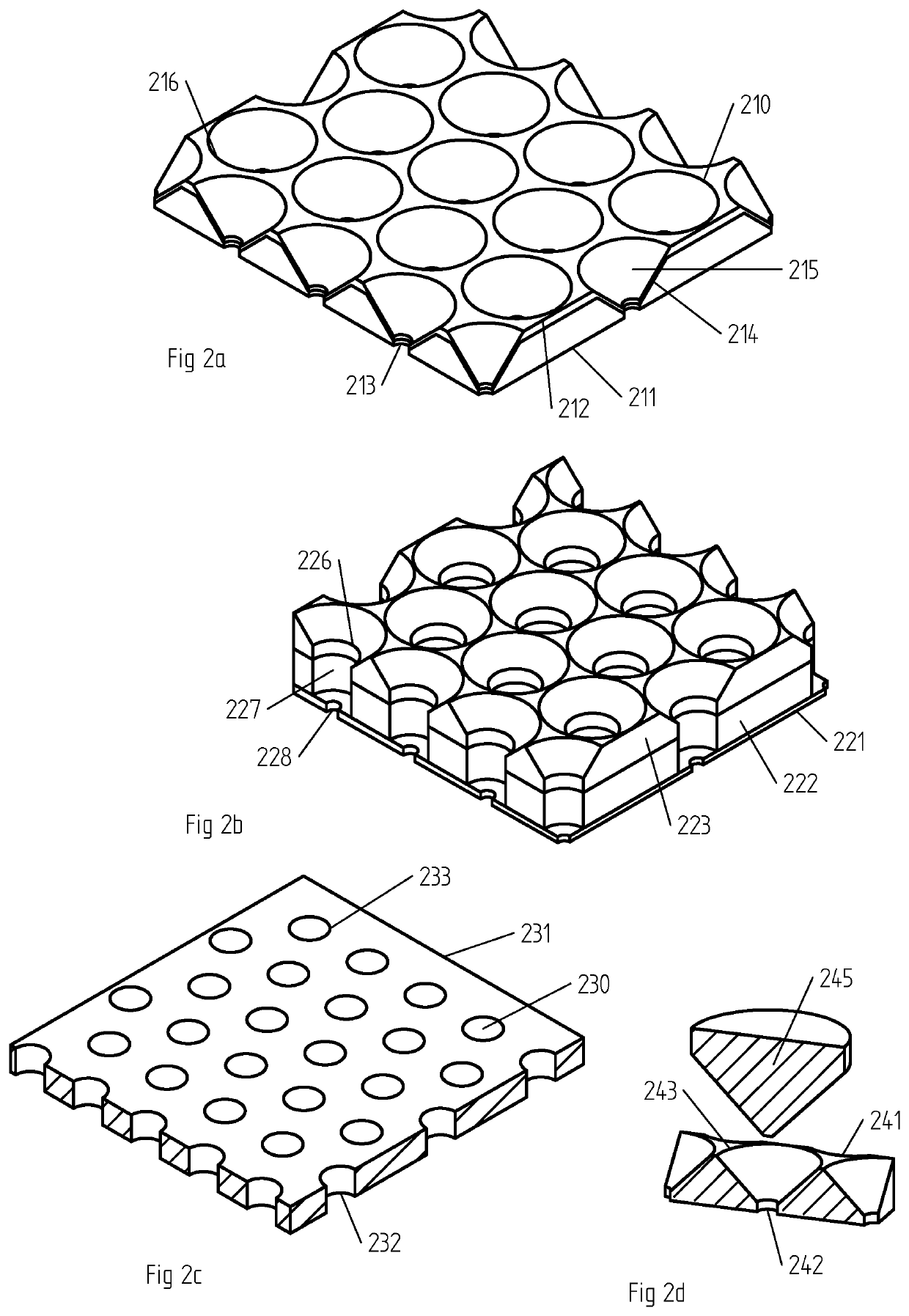

Viscous-drag-reducing cladding

PendingUS20200317295A1Reduce dirtHigh speedWatercraft hull designVessel designingWetted areaClassical mechanics

A viscous-drag-reducing cladding for a ship's hull whereby the wetted area of the hull is reduced by interspersing air between the hull surface and the water. A substantial portion of the submerged area of the ship's hull comprises densely packed air pockets. The dimension of the air pocket is less than twice the capillary length of water. Each air pocket is supplied with pressurised gas by means of a restrictor. The pressurised air is supplied to each air pocket by means of a network of corrugated channels.

Owner:OCEALLAIGH MICHEAL

Method for calculating simulated leakage rate

InactiveCN111914346AReduce testing costsReduce the difficulty of testingGeometric CADDesign optimisation/simulationCapillary TubingEngineering

The invention discloses a method for calculating a simulated leakage rate, which comprises the following steps of: inserting one end of a capillary tube into a simulated cavity, extending the other end of the capillary tube to the outside of the simulated cavity, and filling pressure gas into the simulated cavity through an inlet; and b, calculating the length of the capillary tube required duringleakage according to the mass flow of the capillary tube. Leakage resistance is controlled through the capillary tube, the capillary tube is inserted after the cavity wall of the simulation piece ispunched, flow resistance is adjusted by adjusting the length of the capillary tube, control over local flow loss is converted into control over on-way loss, the tiny leakage amount is simulated and calculated, and the tiny leakage amount can be simulated with high precision. Test cost and test difficulty of the ground performance test of the micro-leakage equipment are effectively reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Device forming a manometer intended for measuring biphasic fluid pressure, associated method of manufacture and fluidic network

InactiveUS9097599B2High measurement sensitivityValve arrangementsLine/current collector detailsFuel cellsDevice form

A device forming a manometer, configured to measure pressure of a biphasic fluid in a fluidic network, including: a first channel inside which a biphasic fluid is able to flow; a second channel emerging into the first channel, wherein the second channel is blind, with each of its dimensions less than capillary length of the fluid's liquid phase, and with at least one of its lengthways wall having a surface energy gradient that decreases from its inlet to the end. The surface energy gradient enables the wetting angle of the meniscus of the fluid's liquid phase to be increased in the blind channel from its inlet to the end. Such a device may find application to measurement of pressure of a biphasic fluid in a heat exchanger or in a fuel cell.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

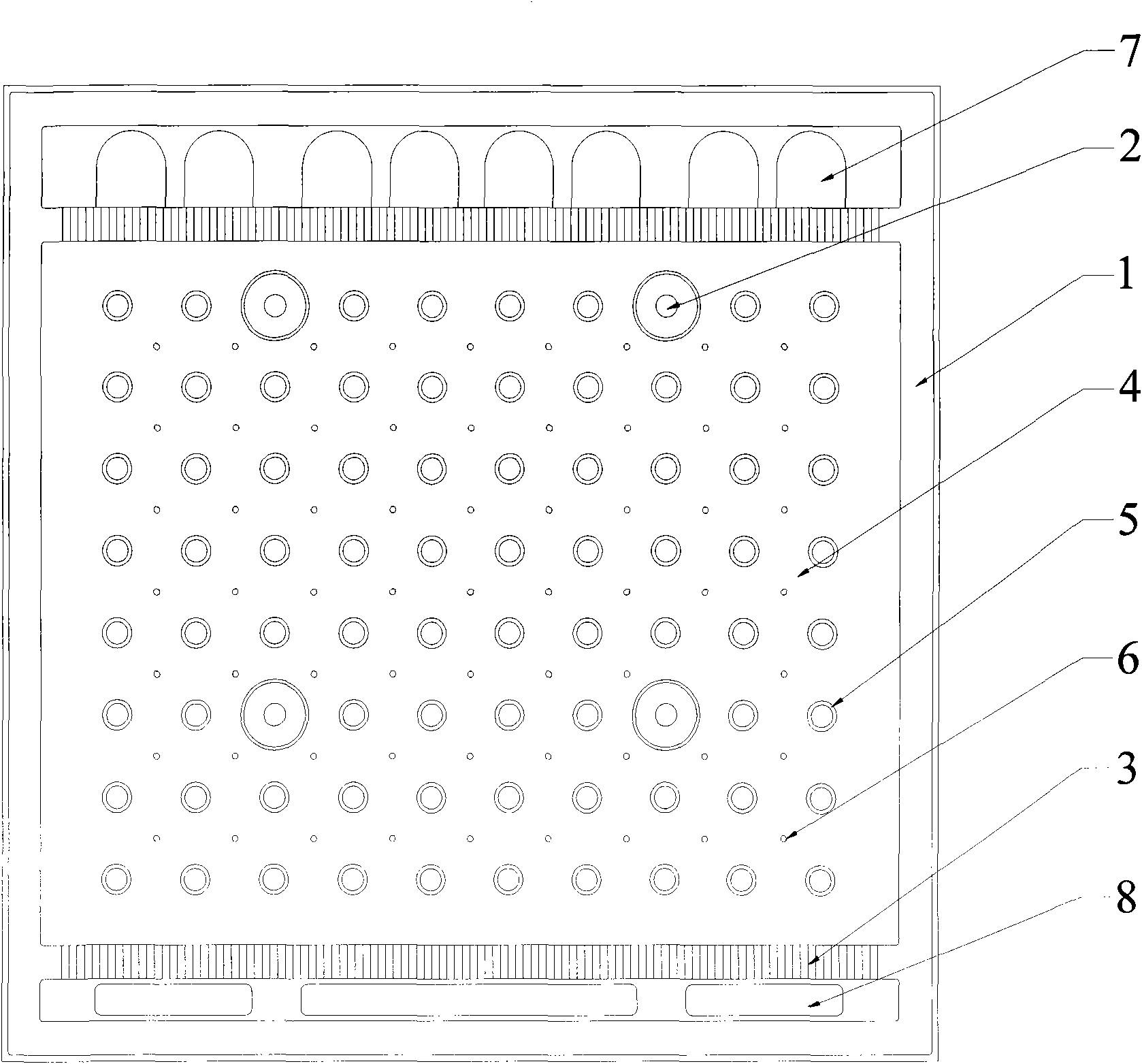

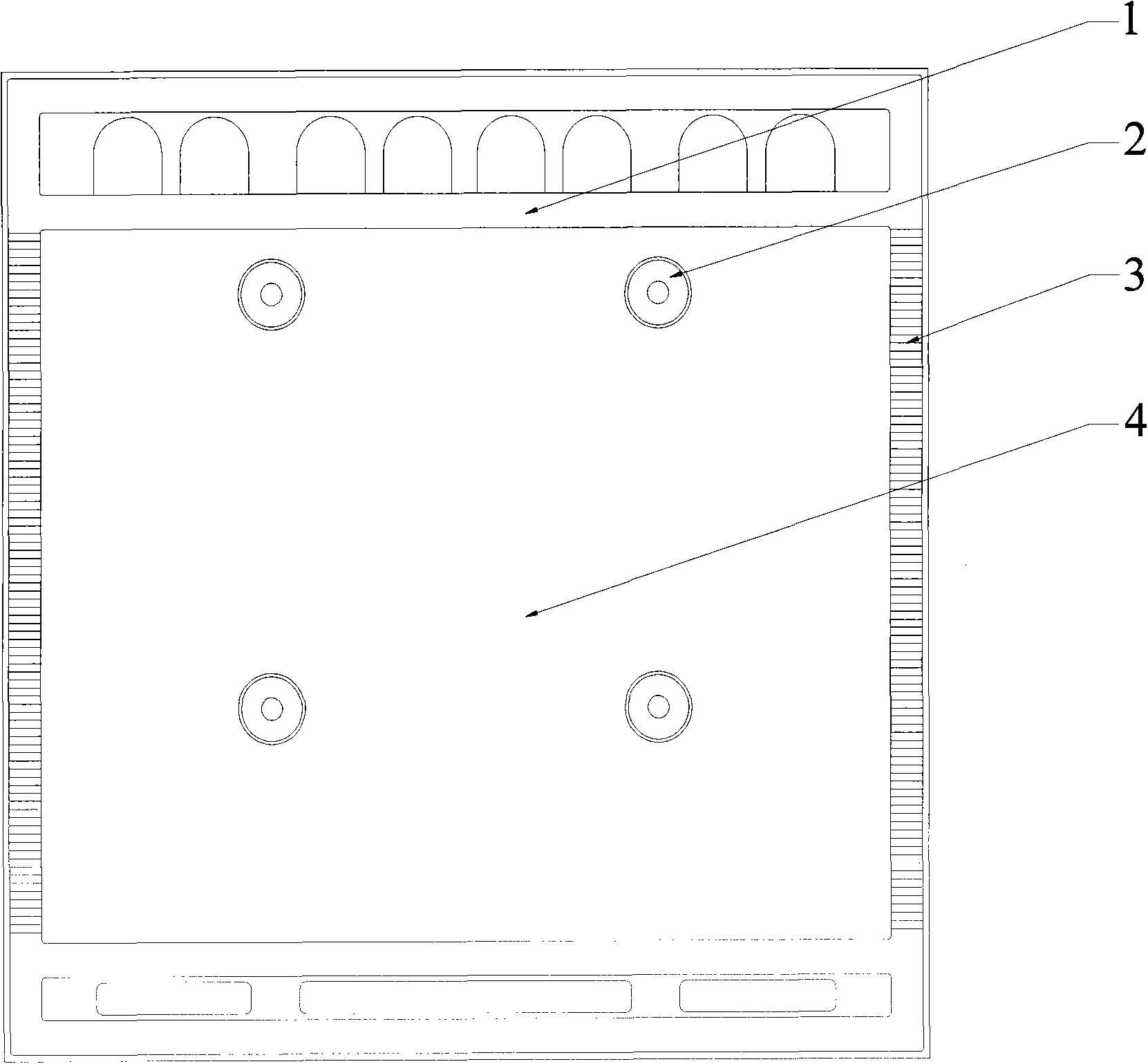

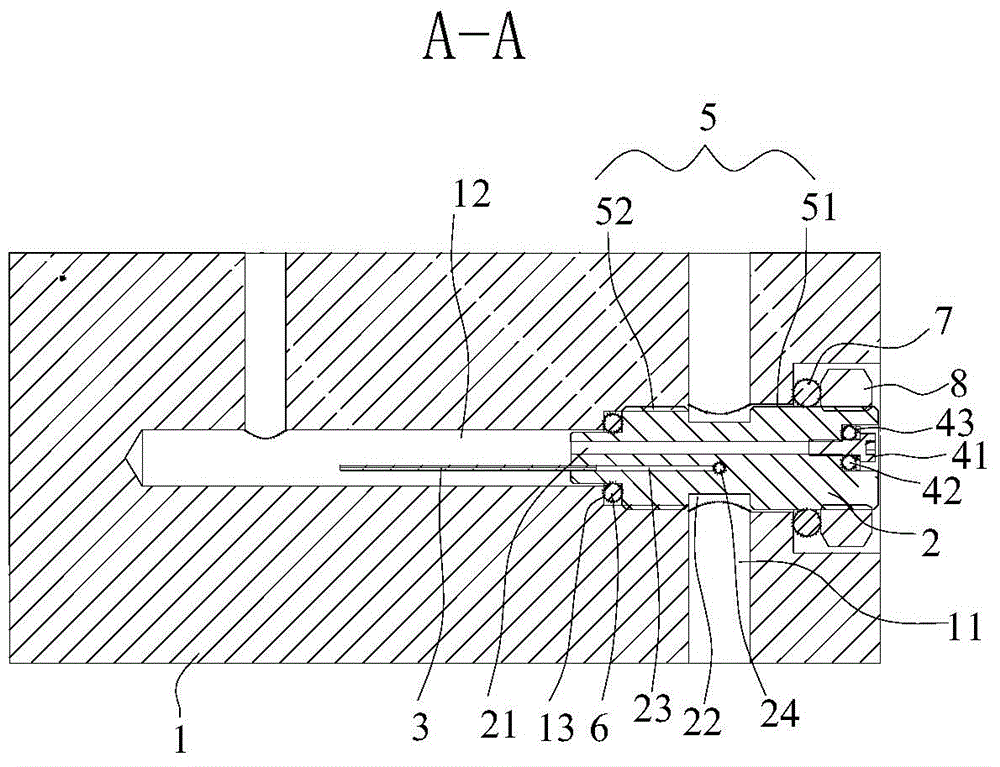

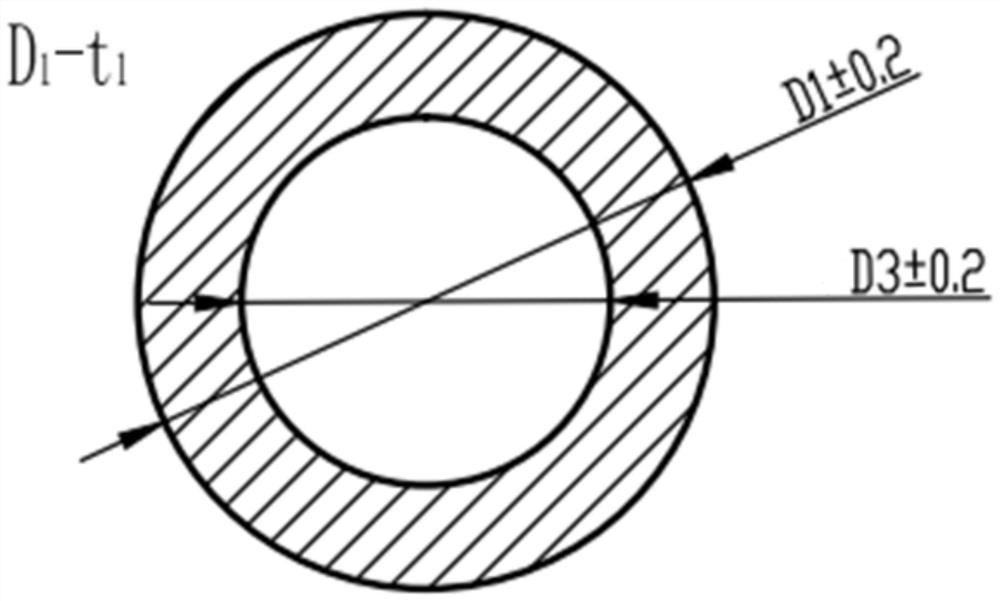

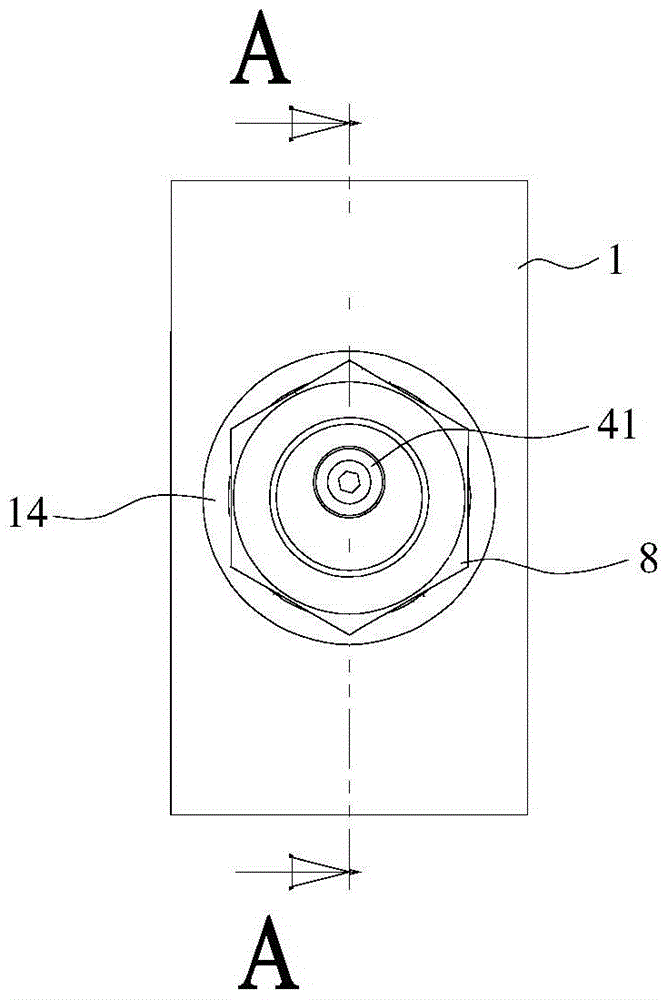

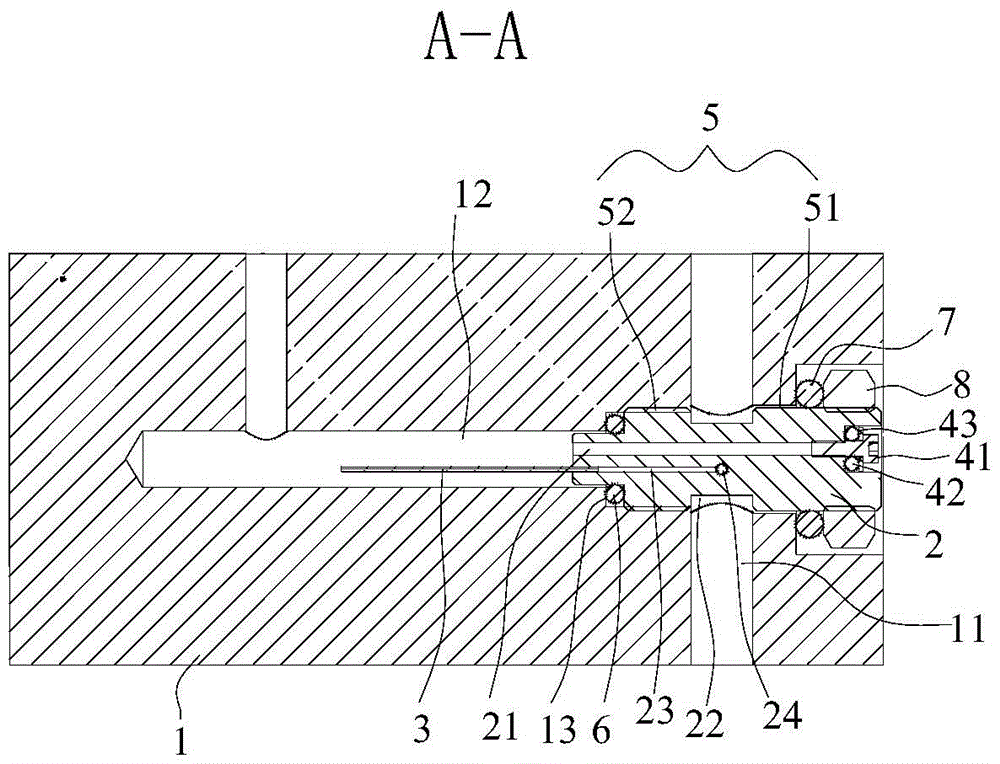

Easily-adjusting and easily-measuring high-precision closed type constant-pressure static-pressure guide rail throttling device

The invention discloses an easily-adjusting and easily-measuring high-precision closed type constant-pressure static-pressure guide rail throttling device. The easily-adjusting and easily-measuring high-precision closed type constant-pressure static-pressure guide rail throttling device comprises a shell body and a core body, wherein the shell body is internally provided with an oil inlet cavity and an oil outlet cavity; the shell body is provided with a core body mounting position joined with the oil inlet cavity and the oil outlet cavity; the core body is mounted in the core body mounting position; the core body is provided with a throttling oil path which is used for communicating the oil inlet cavity and the oil outlet cavity; and the outlet of the core body, in the throttling oil path, is connected with a capillary tube stretching into the oil outlet cavity. According to the throttling device, the oil inlet cavity and the oil outlet cavity which are connected with a guide rail oil cavity and an oil supplying system, and the core body mounting position are formed in the shell body respectively; when the throttling device is used, oil liquid enters the oil inlet cavity by the oil supplying system and enters the oil outlet cavity from the capillary tube through the throttling oil path on the core body, so that the throttling is realized. The throttling device has a simple structure and is convenient to detach; and the length of the capillary tube can be adjusted randomly according to requirements, the machining is simple and the cost is low. The core body is directly provided with a detection oil path for detecting the oil pressure of the oil outlet cavity, so that the oil pressure is convenient to detect and the on-line detection can be realized in real time.

Owner:GUANGDONG UNIV OF TECH

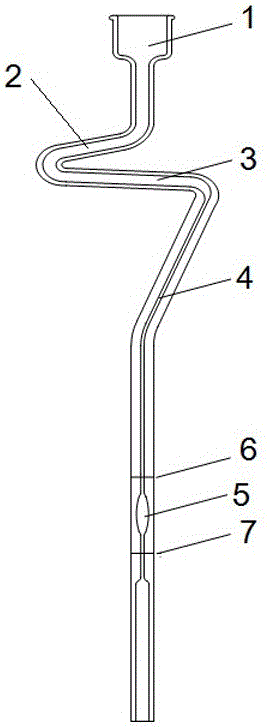

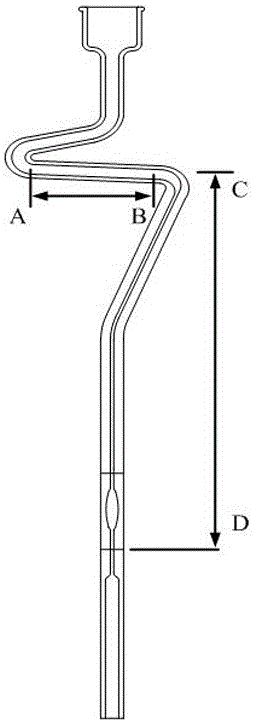

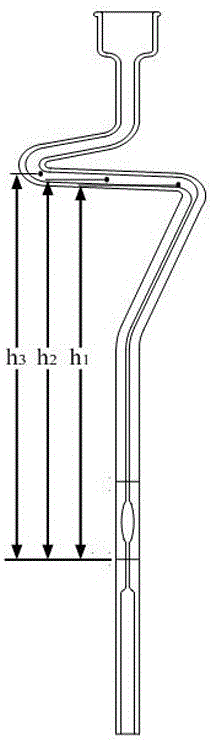

Capillary viscometer capable of realizing automatic quantification and testing method thereof

ActiveCN105928831ARealize automatic quantificationImprove accuracyDirect flow property measurementSufficient timeCapillary Tubing

The invention relates to a capillary viscometer capable of realizing automatic quantification and a testing method thereof. The capillary viscometer comprises a tube-bending type kinematic viscometer; the tube-bending type kinematic viscometer comprises a sample introduction cup, a honeycomb duct, a transverse arm, a capillary tube and a measuring bulb sphere which are successively communicated, and an upper scale mark and a lower scale mark respectively located above and below the measuring bulb sphere; the capillary viscometer further comprises a branch pipe; and one end of the branch pipe is communicated with the transverse arm, and the internal diameter of the branch pipe is smaller than the internal diameter of the transverse arm and greater than internal diameter of the capillary tube. According to the invention, since the branch pipe is arranged on the transverse arm of the viscometer, a sample located between the sample introduction cup and the branch pipe has enough time to thoroughly flow out from the branch pipe before a sample in the capillary tube reaches the upper scale mark, so it is guaranteed that the tail end of the sample is located at the edge of the joint of the branch pipe and the transverse arm, the viscometer is calibrated and the height of a liquid column in testing of a sample each time is identical to the length of the capillary tube; and thus, accuracy and repeatability of viscosity testing are improved.

Owner:湖南慑力电子科技有限公司

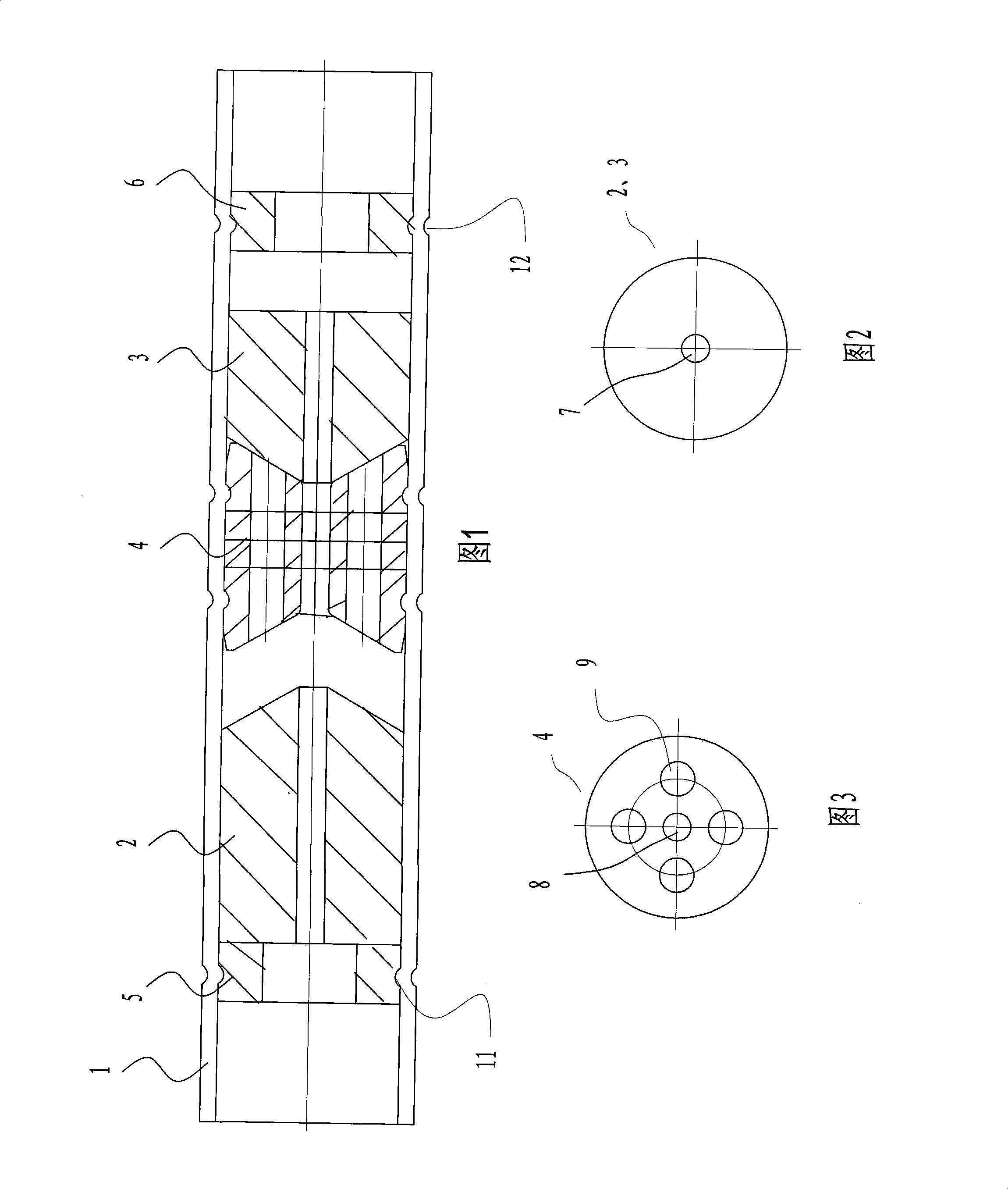

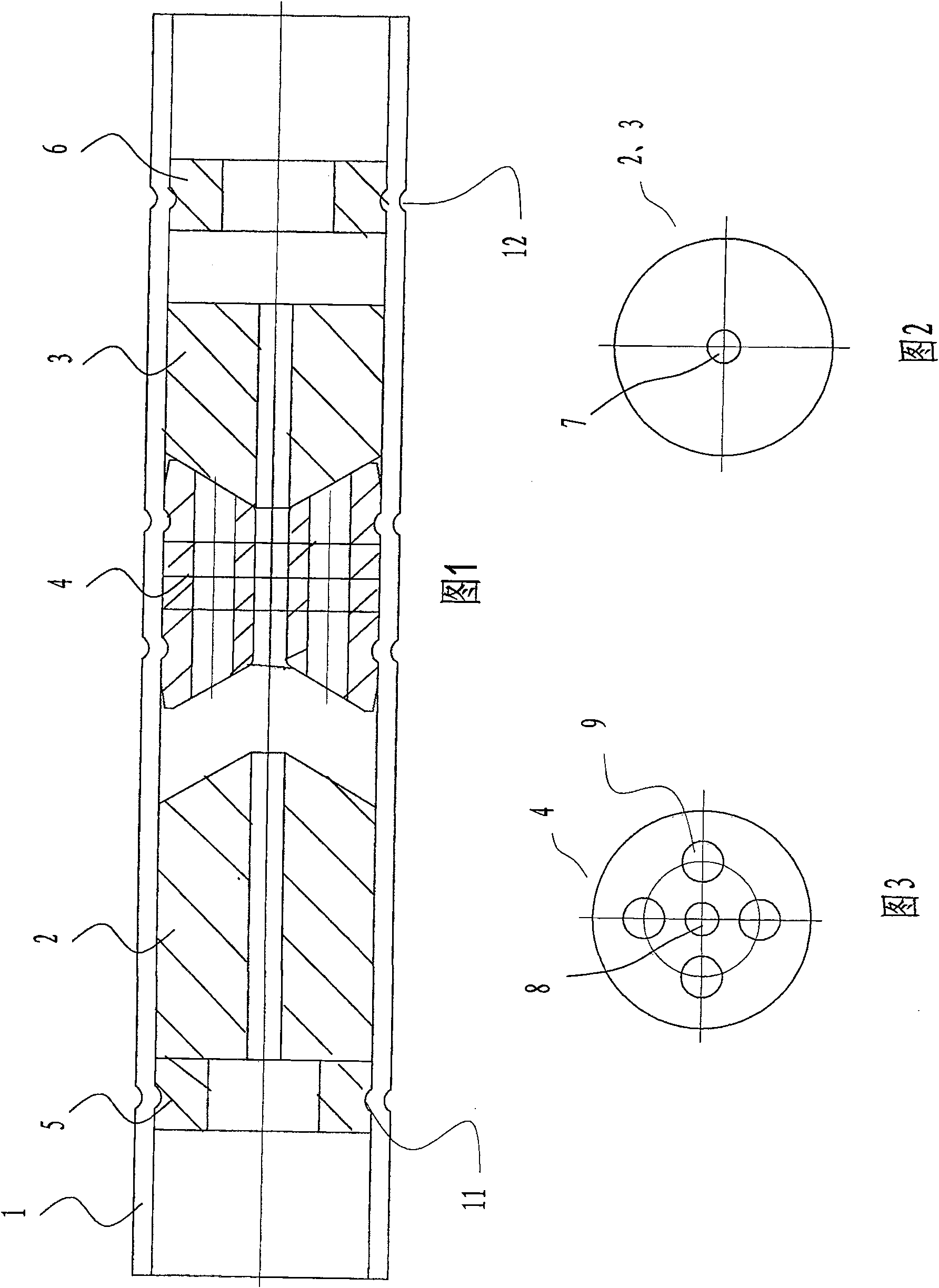

Household air conditioner throttle pipe

InactiveCN101319839AReduce consumptionImprove scalabilityMechanical apparatusFluid circulation arrangementWhole bodyMetal sheet

The invention discloses an air conditioning throttle pipe for domestic use, comprising a left movable block and a right movable block which are arranged in a metal pipe. A fixed block is arranged between the left movable block and the right movable block. A left stopping block is arranged outside the left movable block, and a right stopping block is arranged outside the right movable block. The left and the right stopping blocks are fixed on the internal wall of the metal pipe. The left and the right movable blocks are provided with movable block capillary small holes which penetrate through the axes thereof. The fixed block is provided with a fixed block capillary small hole which penetrates through the axes thereof and is corresponding to the positions of the movable block capillary small holes. The fixed block is also provided with a plurality of axial directional overflow holes. The left movable block can slide between the left stopping block and the fixed block. And the right movable block can slide freely between the right stopping block and the fixed block. The fixed block is made by multilayer metal sheets, forming into an integrative whole body. The left and right stopping blocks are made by copper or aluminum or steel or iron, and are ring-shaped or comprise a plurality of semi-rings. The air conditioning throttle pipe has the advantages that the air conditioning throttle pipe has more reasonable structure, is favorable to meet the length requirement of the capillary tube needed when refrigerating and heating, can debase the consumption of refrigerant and energy, and can improve the quality and functions of products.

Owner:金仁召

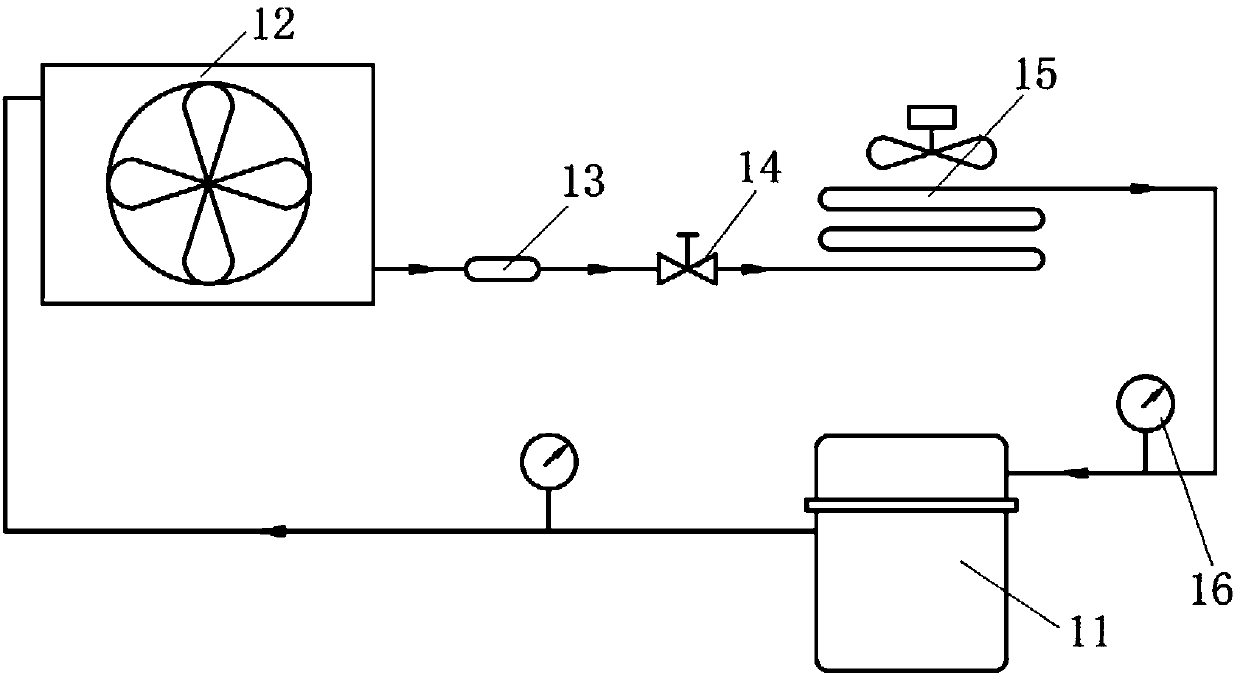

Refrigeration system throttling capillary tube length determining method

InactiveCN109751797AQuick fixEfficient determinationMechanical apparatusFluid circulation arrangementEngineeringRefrigerant

The invention discloses a refrigeration system throttling capillary tube length determining method. A refrigeration system is started, under the needed evaporation pressure value and evaporation temperature value, a manual expansion valve and the filling amount of a refrigerant in a refrigeration system are adjusted till the refrigeration effect of the refrigeration system is optimal; the apertureposition of the manual expansion valve is fixed; the manual expansion valve is taken out and arranged between a pressure reduction valve and a second low-pressure meter, gas injection is conducted, the output pressure of the pressure reduction valve is adjusted, the pressure value displayed by the second low-pressure meter is equal to the needed evaporation pressure value, and the flow value displayed through a flow meter at the time is recorded; a throttling capillary tube with the length larger than the estimated length is arranged between the pressure reduction valve and the second low-pressure meter, gas injection is conducted, the pressure reduction valve is adjusted, and the pressure value displayed by the second low-pressure meter is equal to the needed evaporation pressure value;and the length of the throttling capillary tube is constantly reduced through shearing, the flow value displayed by the flow meter is observed till the flow value displayed by the flow meter is the same with the above recorded flow value, and the length of the throttling capillary tube at the time is the optimal length.

Owner:上海力申科学仪器有限公司

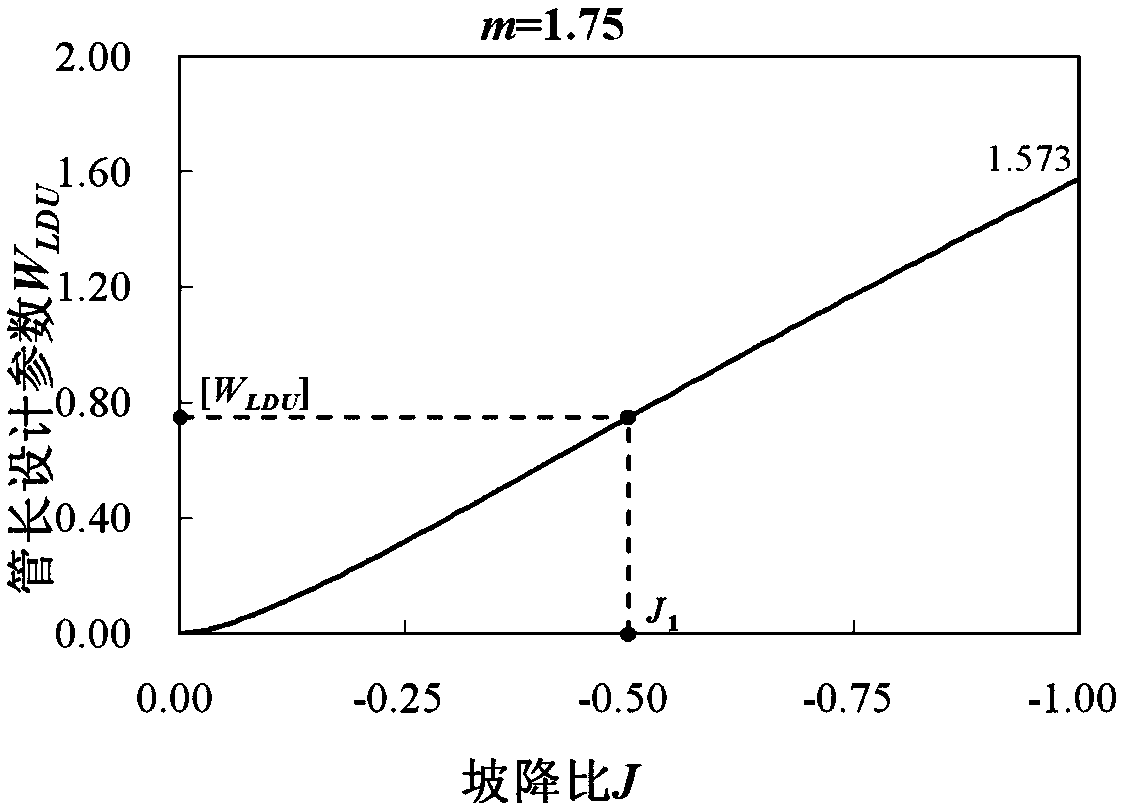

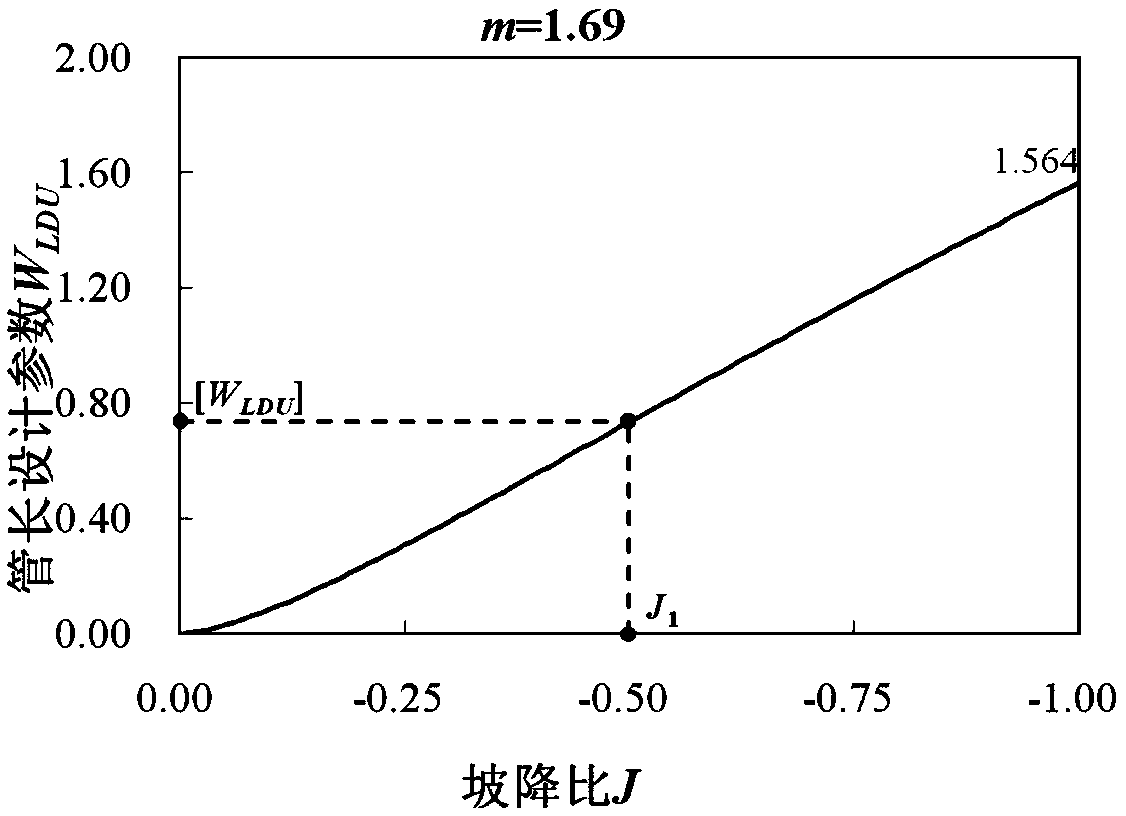

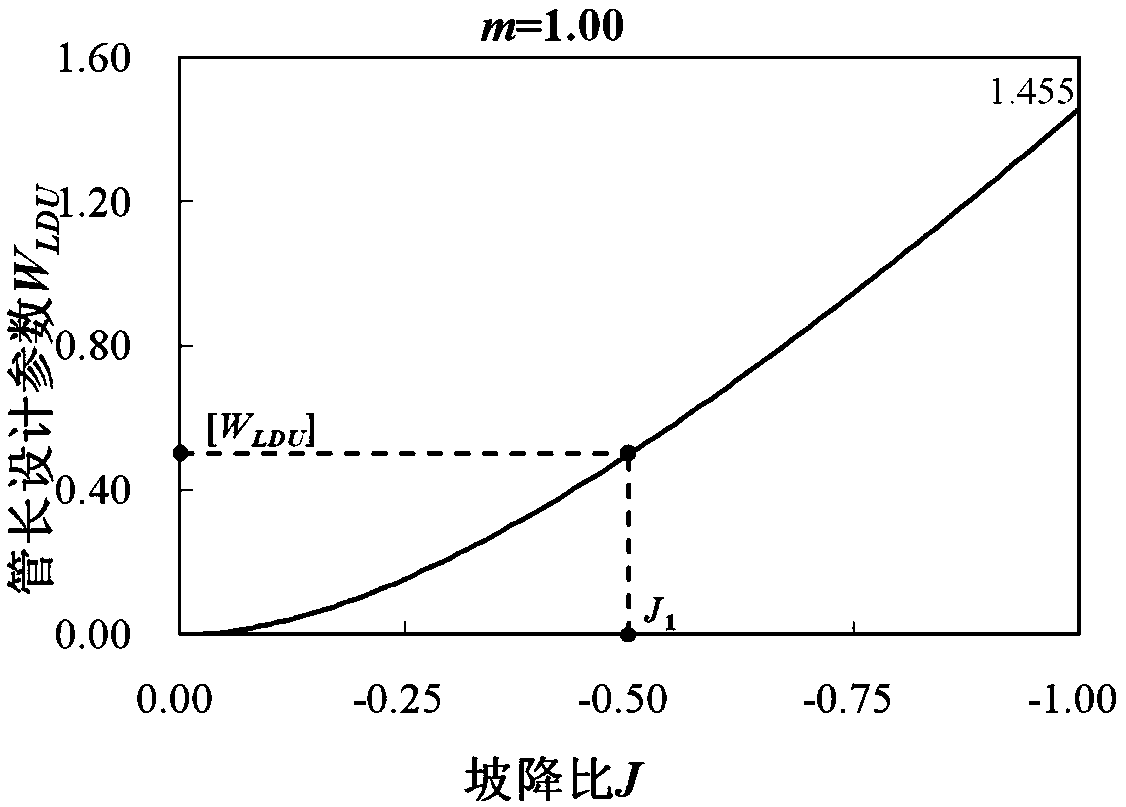

Micro-irrigation capillary tube length hydraulic design method based on a distribution uniformity coefficient

PendingCN109614716AImprove design efficiencyReduce cost inputGeometric CADSpecial data processing applicationsDesign standardSlope ratio

The invention discloses a micro-irrigation capillary tube length hydraulic design method based on a distribution uniformity coefficient. The method comprises the steps that capillary tube length design parameters based on the distribution uniformity coefficient are constructed according to a capillary tube slope ratio and a flow index; and determining a calculation formula of the micro-irrigationcapillary length according to the pipe network arrangement form, and calculating to obtain the capillary length based on the obtained capillary length design parameters based on the distribution uniformity coefficient. On the premise that a distribution uniformity coefficient design standard and other design indexes are given, the pipe length value meeting the distribution uniformity coefficient can be simply and conveniently calculated, the proper arrangement form of the hollow billet is determined, and the working water head of the hollow billet inlet is calculated. The design efficiency ofthe pipe length of the micro-irrigation capillary can be improved; By considering a proper capillary arrangement form, the design pipe length of the capillary is optimized, and the system investment is reduced.

Owner:CHINA THREE GORGES UNIV

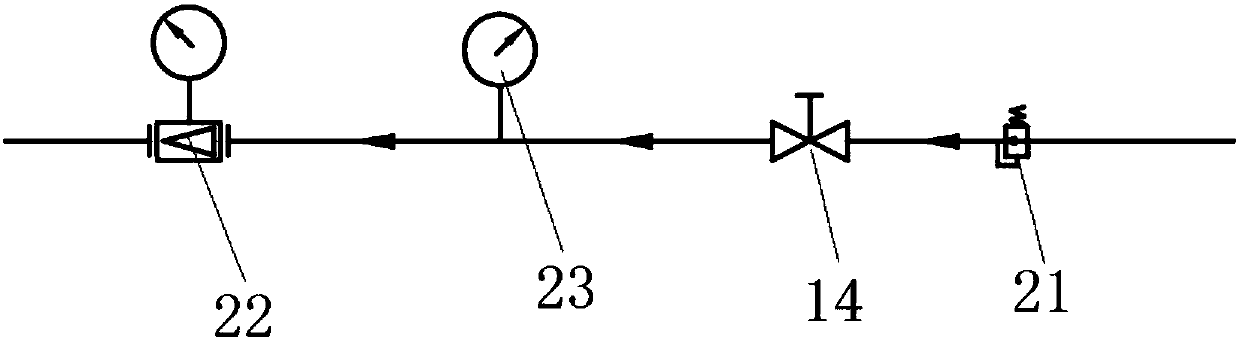

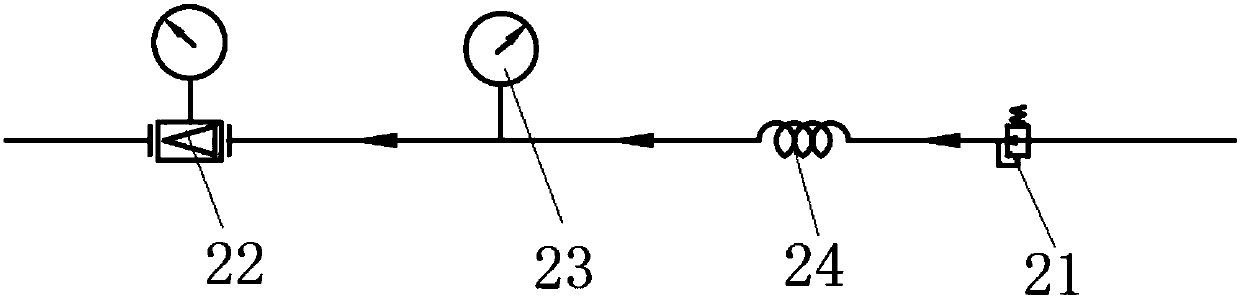

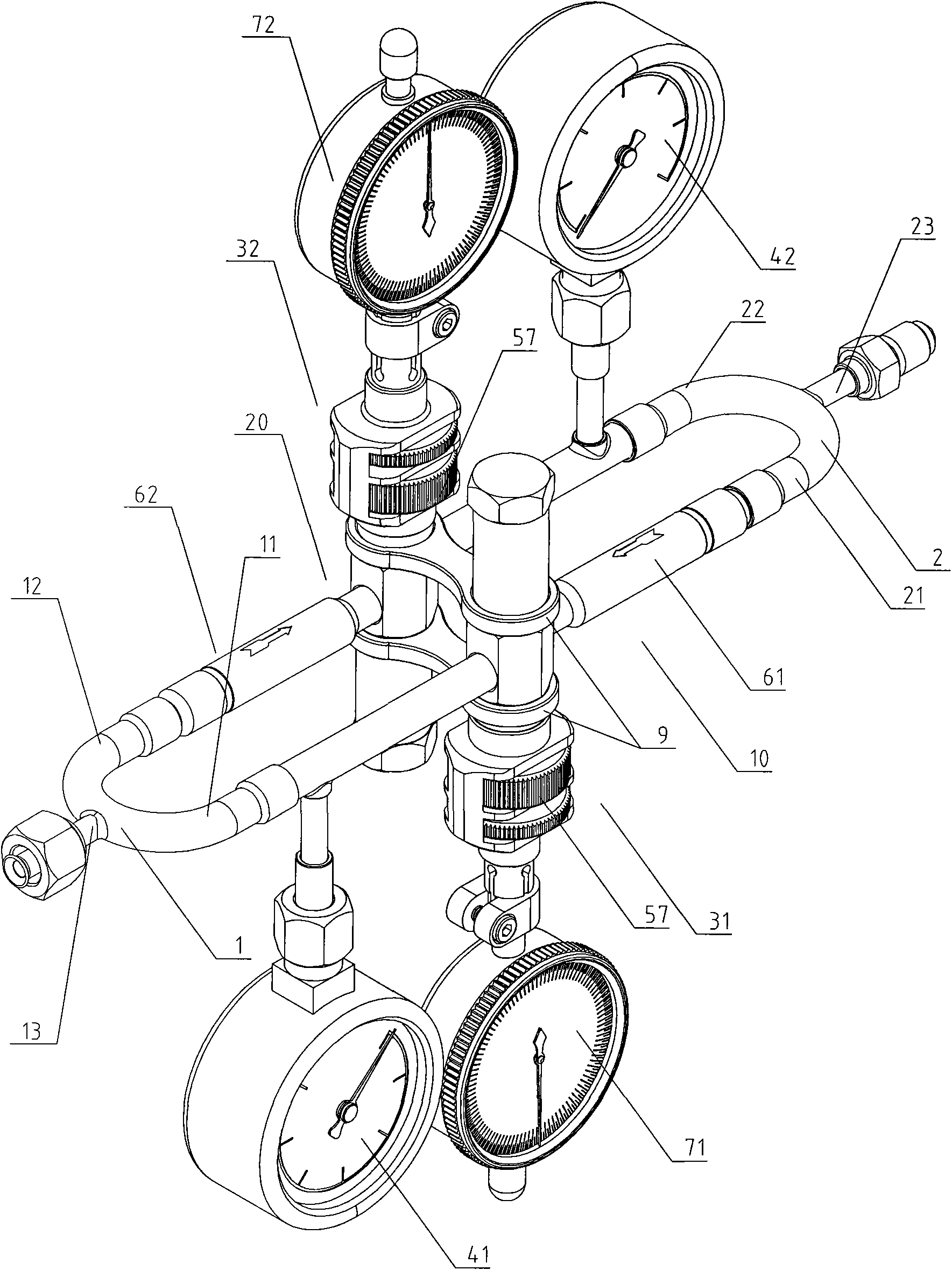

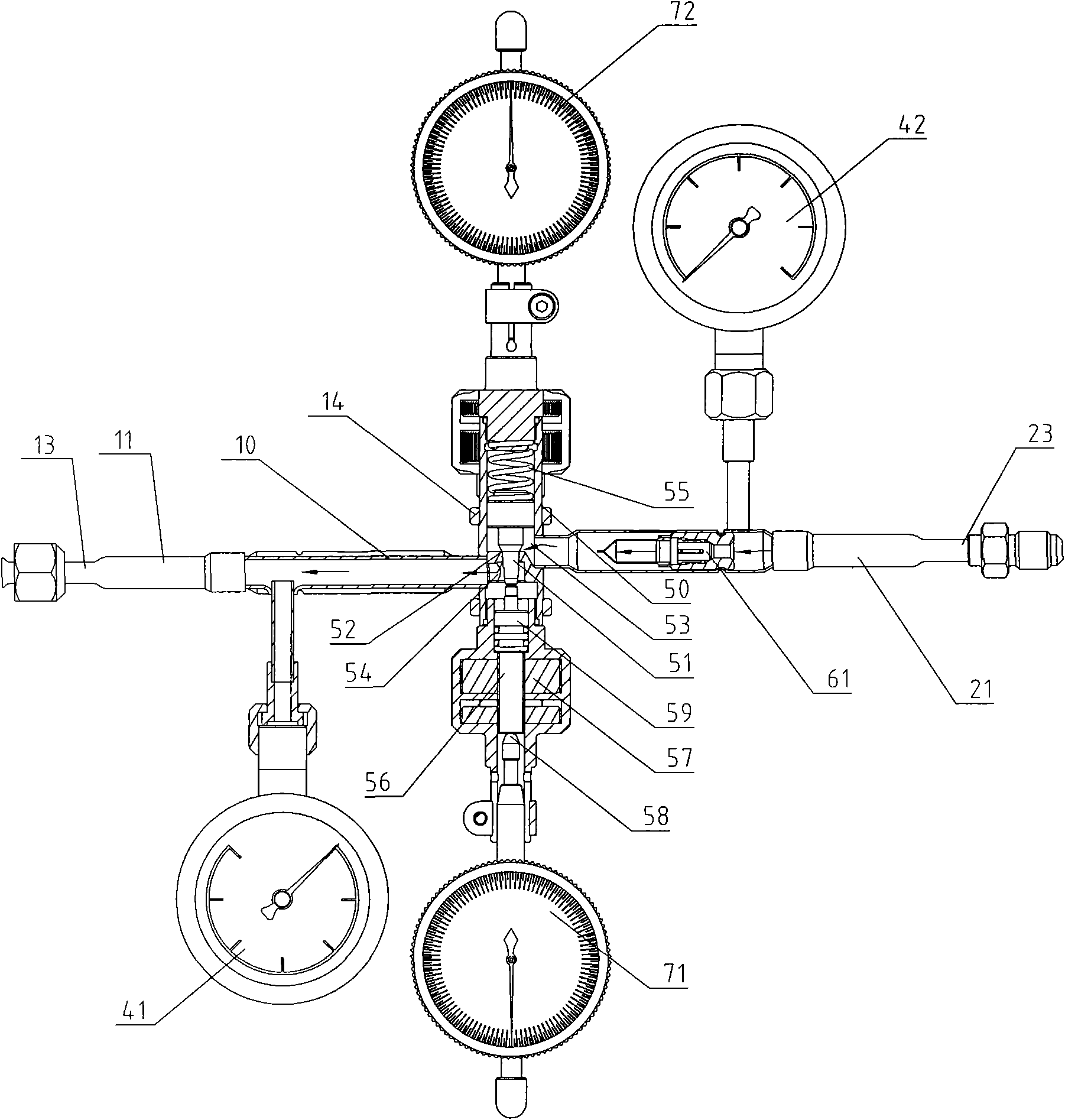

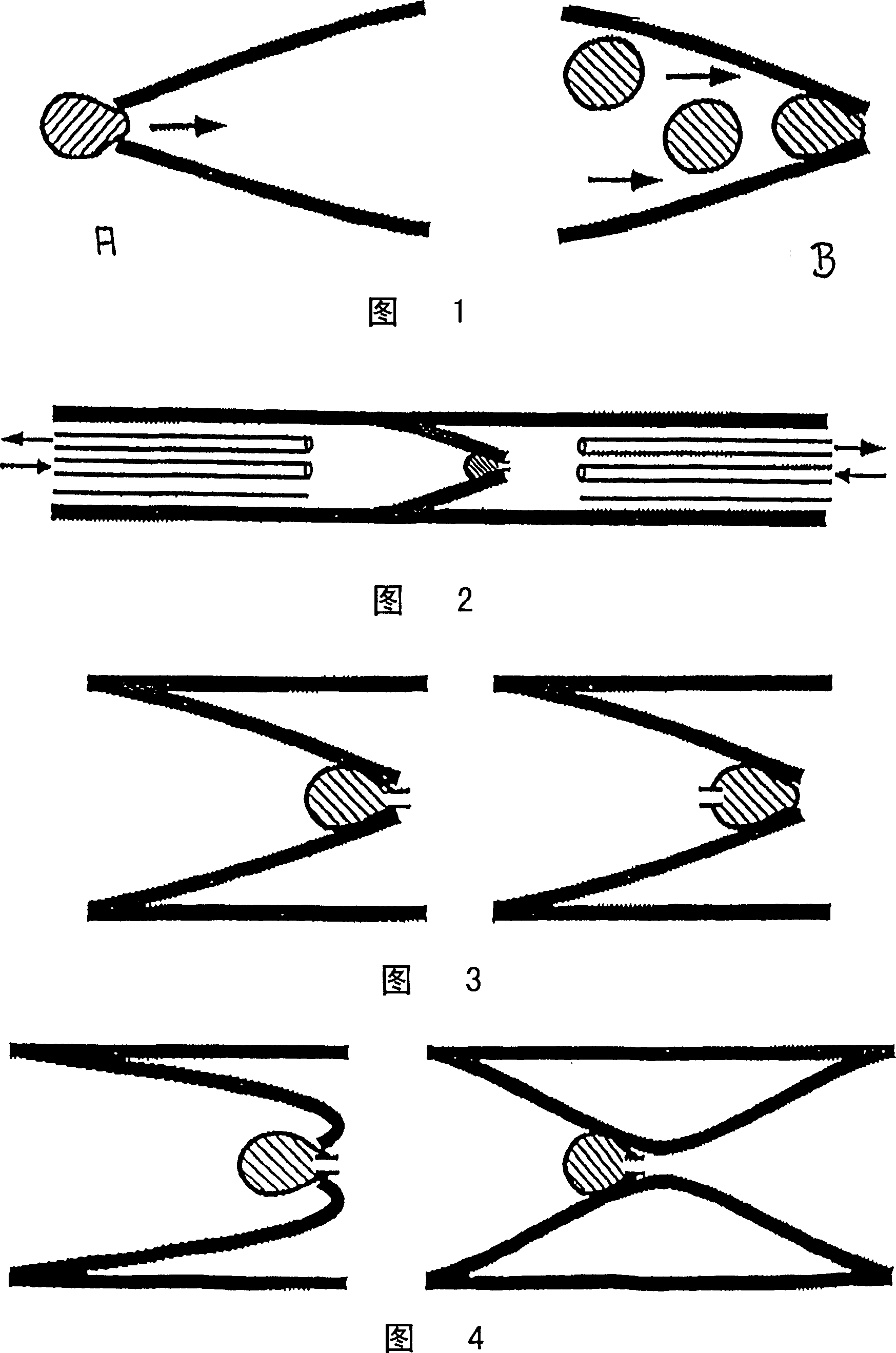

Throttling instrument for steam compression type refrigerating apparatus

InactiveCN101598527AImprove working conditionThe experiment process is fastMechanical area measurementsFluid circulation arrangementEngineeringPressure difference

The invention provides a throttling instrument for a steam compression type refrigerating apparatus. The throttling instrument is provided with a loop through which a medium can pass. The loop is provided with a first entering and exiting opening and a second entering and exiting opening. A first valve and a second valve are arranged between the first entering and exiting opening and the second entering and exiting opening. A pipeline between the first entering and exiting opening and the first valve is provided with a first pressure measuring device. A second pressure measuring device is arranged between the second entering and exiting opening and the second valve. The first valve and the second valve are respectively provided with throttling holes. The first pipeline and a second pipeline are provided with check valves with opposite directions. The throttling device is provided with a measuring device. The throttling device can obtain a throttling work point when an air conditioner is at an optimum work state, and can find a capillary aperture and a capillary length, or a throttling pipe nipple and a throttling hole aperture, which have corresponding specifications, according to the pressure difference before and after throttling and a throttling area which is calculated on the basis of the position of a valve plug. The throttling device has short experiment process and high work efficiency. The two sets of instruments in the loop are connected by the check valves in series and then can undergo respective adjustment and measurement in two opposite directions without mutual interference.

Owner:ACTION STAR TECH CO LTD

Improved air conditioner capillary pipe structure

InactiveCN101387465AEvenly distributedAvoid technical problems that can no longer be shortenedFluid circulation arrangementHeat transmissionEngineering

The invention provides an improved capillary pipe structure of an air-conditioner, which comprises a condenser, an outlet tube and a capillary pipe, wherein the outlet tube is connected with the condenser; the capillary pipe is connected with the outlet tube; and at least two pipelines consisting of the outlet tube and the capillary pipe are arranged. Flow paths of the pipelines are similar or approximately the same. The capillary pipe of each pipeline is a structure leading temperature of an outlet to have condensate depression close to 8 degrees; lengths or the inner diameters of the capillary pipes of the pipelines can be different to ensure that the temperature of the outlet of each pipeline has the condensate depression at about 8 degrees. The capillary pipe structure has the characteristics that branch paths of the condenser can respectively control flow, so that flow distribution can be more even; because of separated control, the length of the capillary pipe can be corresponding times longer than the prior path, thereby avoiding the problem that the capillary pipe can not be shortened any more; furthermore, because the two paths do not need to be combined into one path, heat waste and flowed friction caused by mutual heat transmission are reduced, and heat transferring capability can be greatly improved.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD

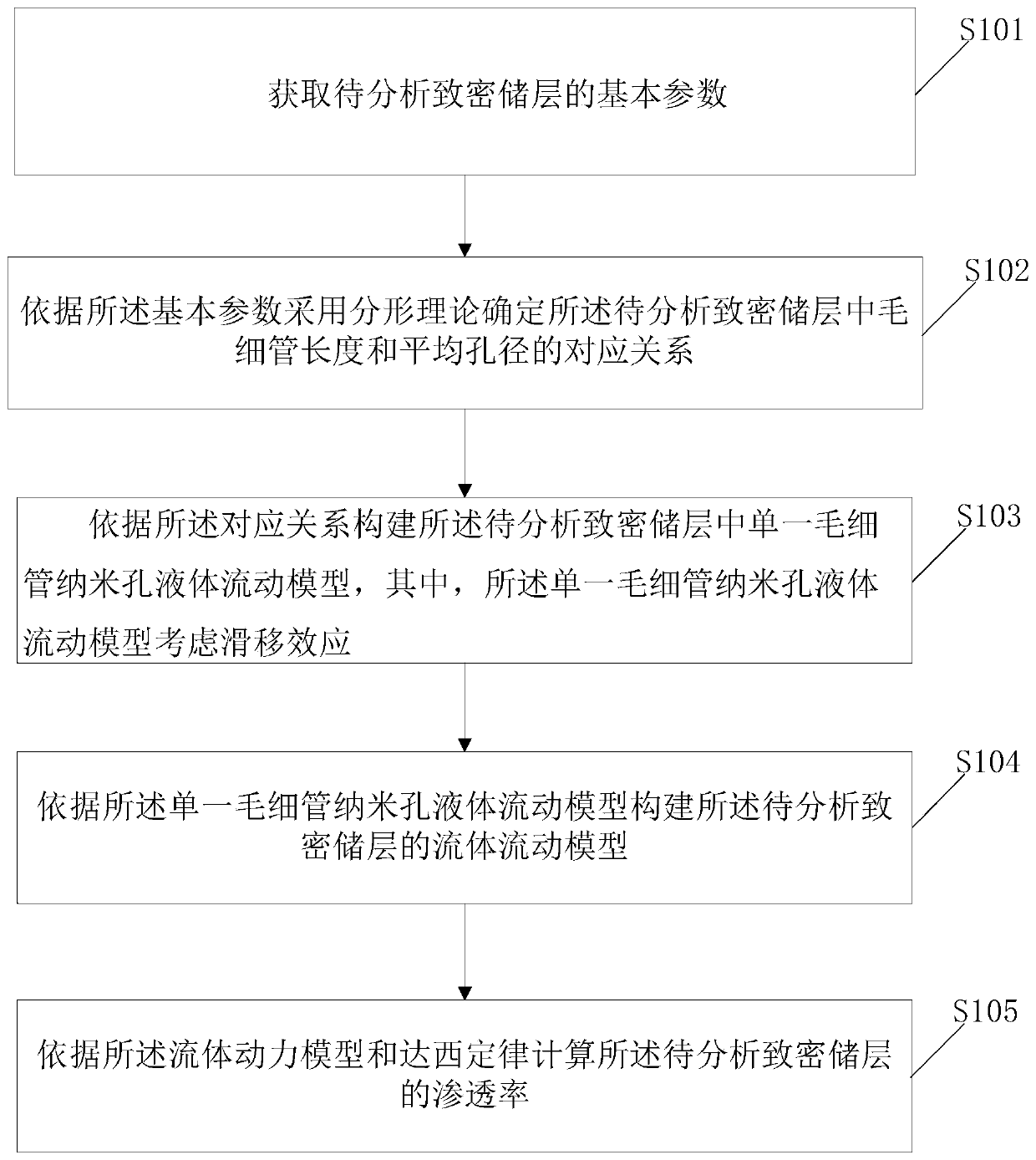

Tight reservoir liquid phase apparent permeability calculation method and device

ActiveCN111291521AReduce biasImprove accuracyFlow propertiesDesign optimisation/simulationChemical physicsFluid phase

The invention discloses a tight reservoir liquid phase apparent permeability calculation method and device. The method comprises the steps of acquiring basic parameters of a tight reservoir to be analyzed, determining the corresponding relationship between the capillary length and the average pore diameter in the tight reservoir to be analyzed by adopting a fractal theory according to the basic parameters, constructing a single capillary nanopore liquid flow model in the tight reservoir to be analyzed according to the corresponding relationship, wherein the single capillary nanopore liquid flow model considers a slip effect, constructing a fluid flow model of the tight reservoir to be analyzed according to the single capillary nano-pore liquid flow model, and calculating the permeability of the tight reservoir to be analyzed according to the hydrodynamic model and a Darcy law. According to the calculation method, the slip effect is considered, so that the deviation generated by predicting the apparent permeability of the tight reservoir by adopting continuous fluid mechanics and slip-free boundary conditions is reduced, and the calculation accuracy of the liquid-phase apparent permeability of the tight reservoir is improved.

Owner:SOUTHWEST PETROLEUM UNIV

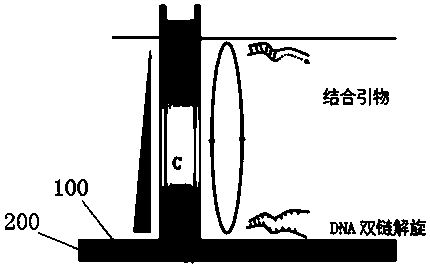

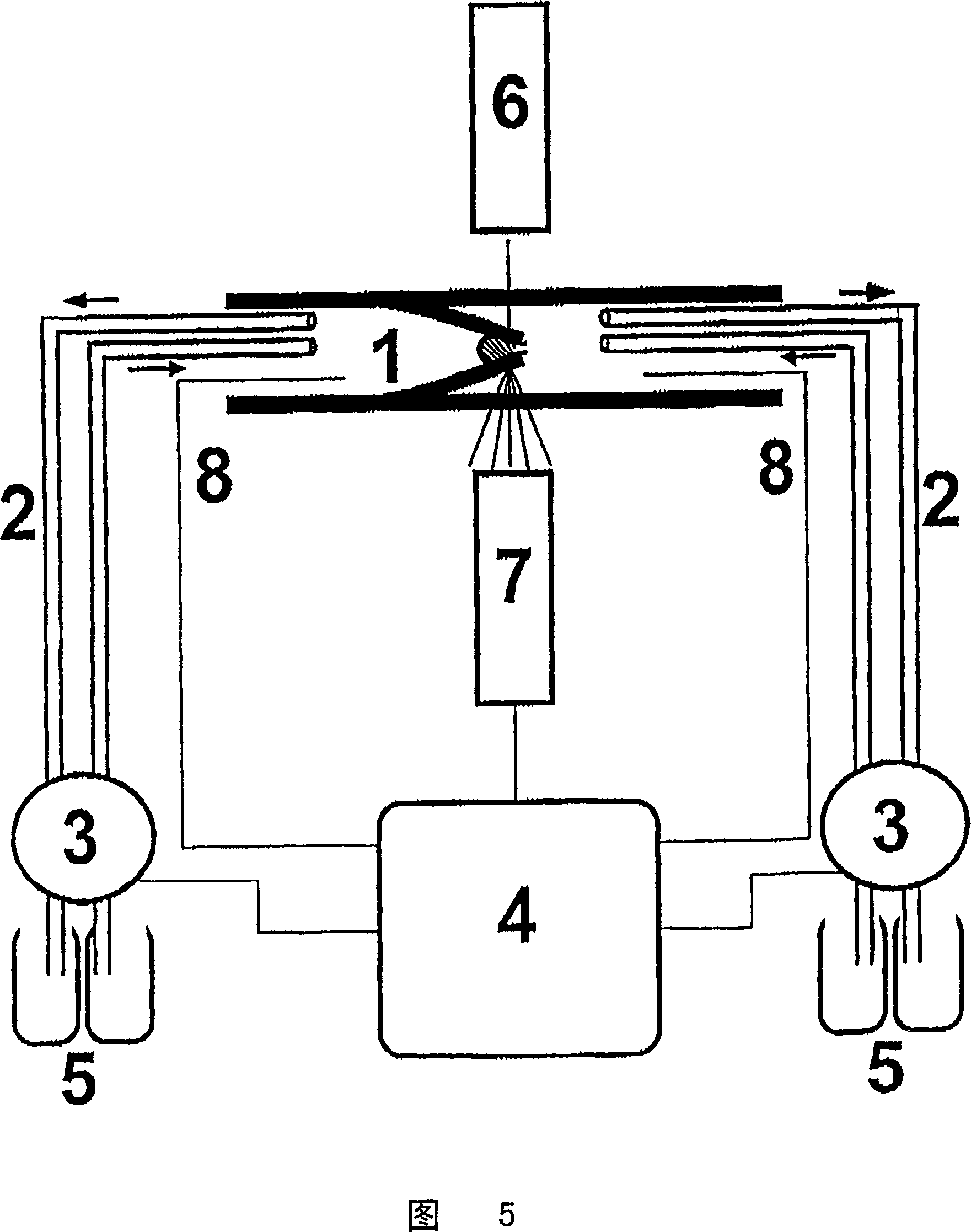

One-stage heat convection PCR instrument and control method

InactiveCN109294901ASmooth change in temperature distributionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringAlloy

The invention relates to a one-stage heat convection PCR instrument, which includes a temperature control system, a heating system, a control module and a power supply. According to a technical schemeadopted by the invention, the one-stage heat convection PCR instrument utilizes an aluminum alloy block heating plate at the bottom of the instrument for heating, the capillary bottom temperature iscontrolled at a denaturation temperature, and the capillary top temperature is controlled at an annealing temperature. Under the action of gravity difference and temperature difference, the reagent inthe capillary can reach different temperatures constantly through natural convection, thus realizing PCR. The temperature distribution of the system varies smoothly along the capillary length, and different PCR steps can be carried out simultaneously. In the simple system, DNA amplification can be accomplished without expensive and precise thermal cycler, and no additional complex hardware is needed.

Owner:福建省博凯科技有限公司

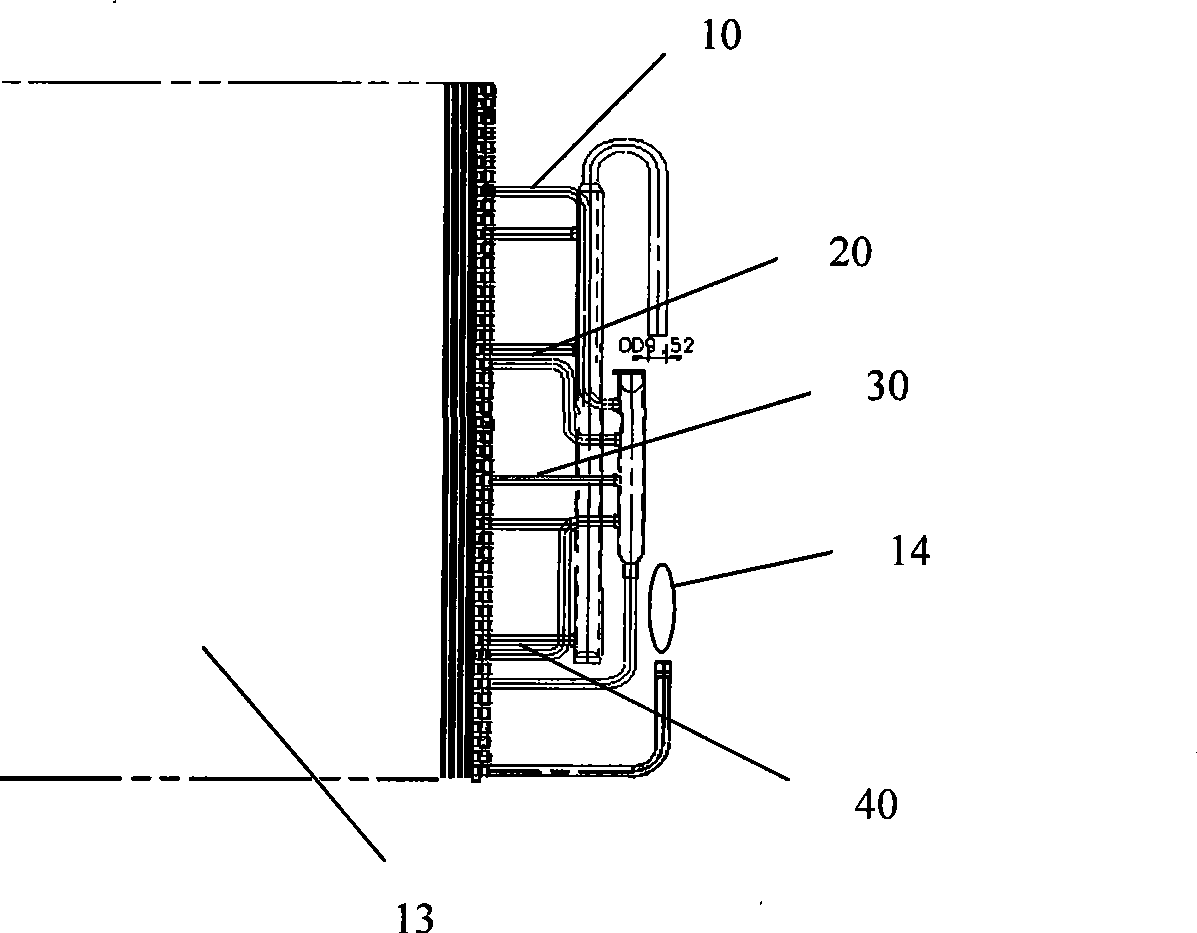

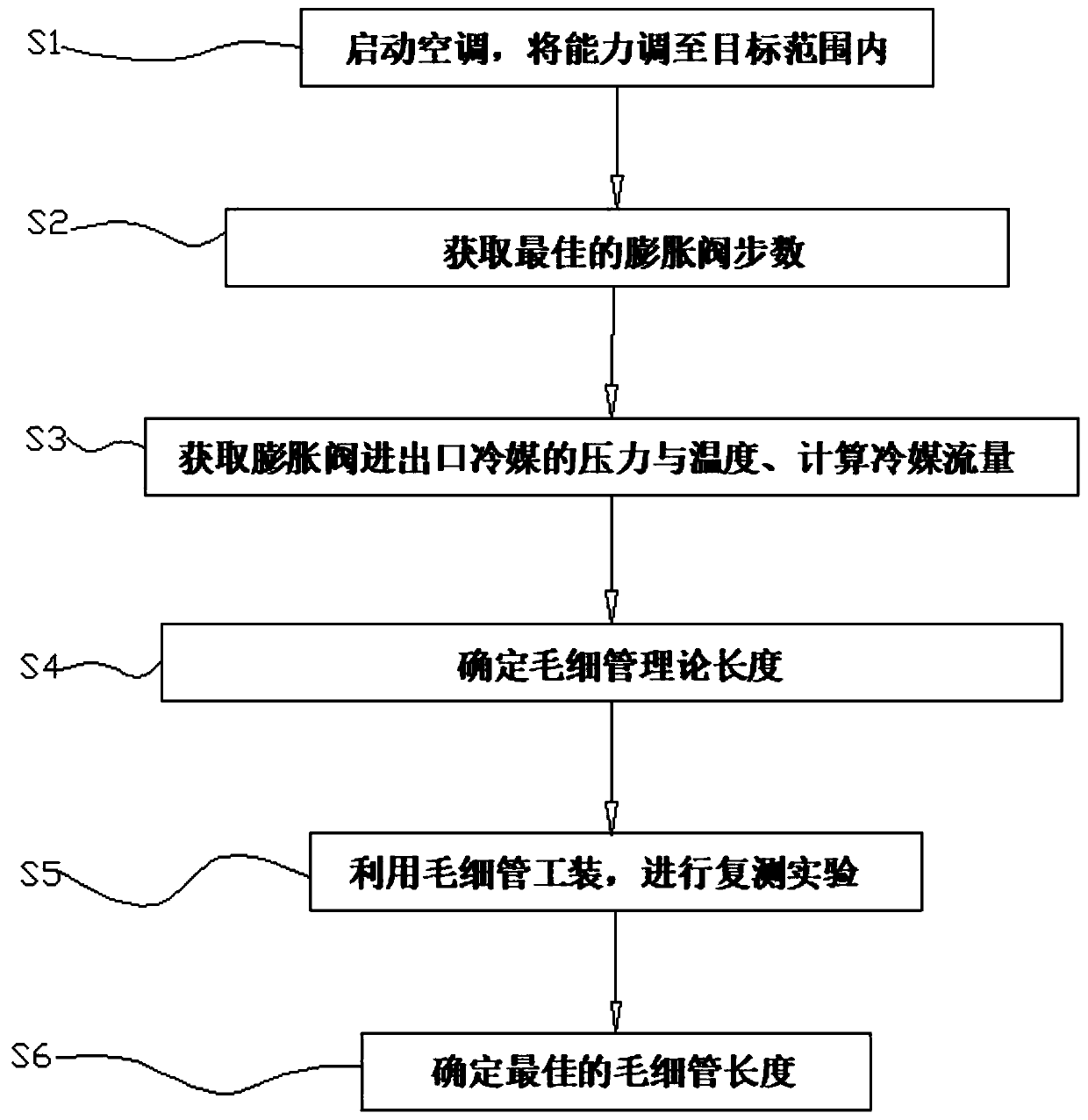

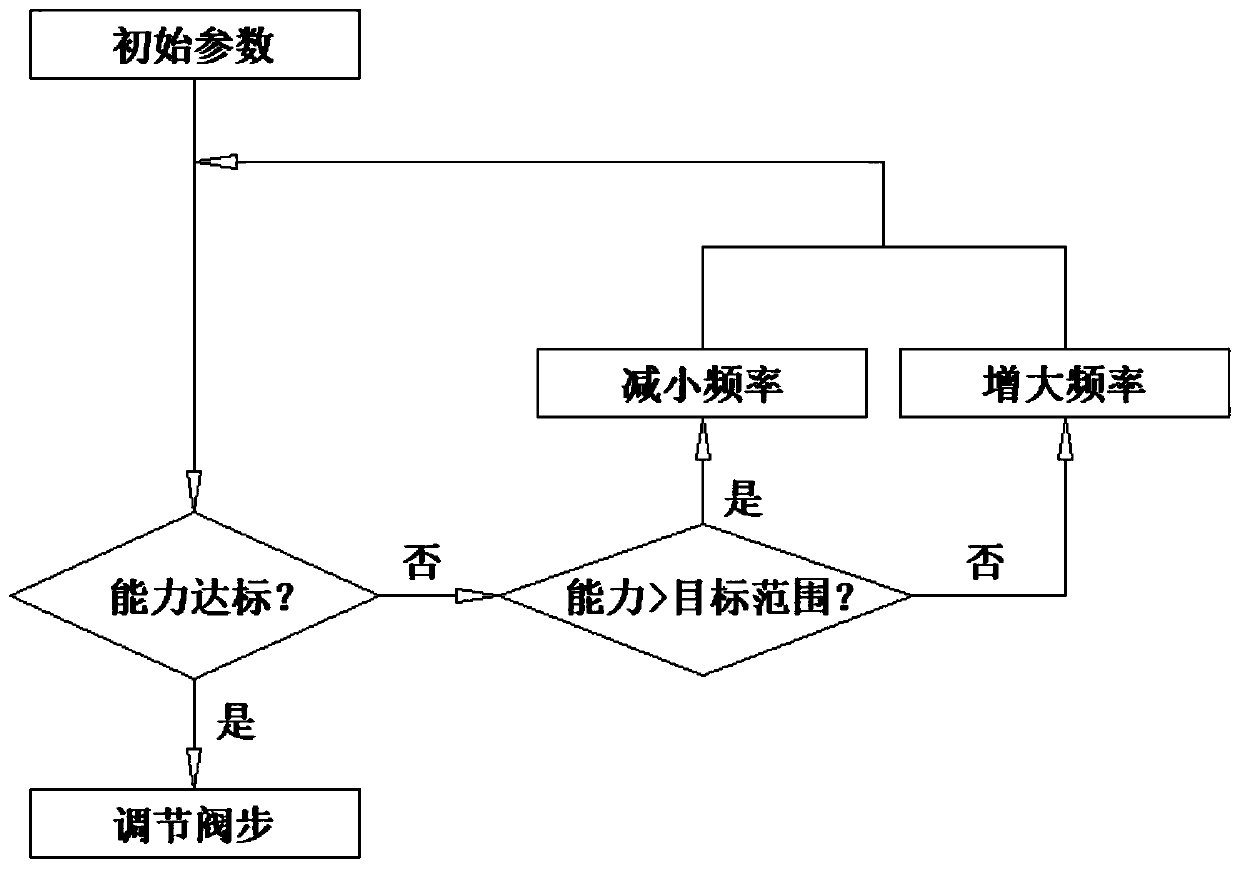

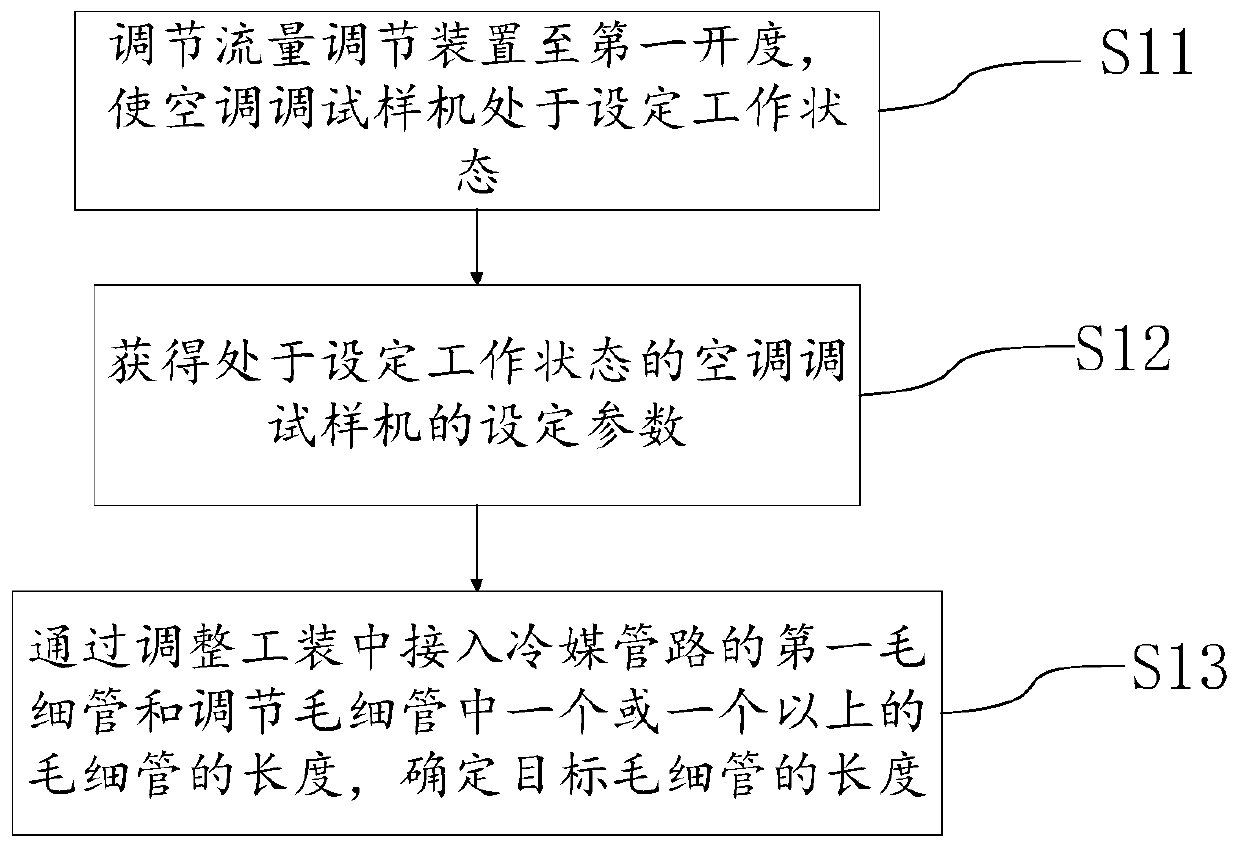

Air conditioner debugging system and method for confirming capillary tube length

InactiveCN111550907AMechanical apparatusSpace heating and ventilation safety systemsFour-way valveCapillary Tubing

The invention discloses an air conditioner debugging system and a method for confirming the capillary tube length. The air conditioner debugging system comprises a compressor, a four-way valve, a condenser and an evaporator which are connected in sequence, and an electronic expansion valve is arranged between the condenser and the evaporator. According to the air conditioner debugging system and the method for confirming the capillary tube length, the theoretical capillary tube length is calculated according to all parameters of the air conditioner debugging system in the best energy efficiency, the best capillary tube length can be obtained just needing to test two sets of capillary tubes after the theoretical capillary tube length is obtained, vacuumizing and gas injection operations donot need to be performed on a pipeline system repeatedly, manual and frequent replacement of the capillary tube length is also not needed, the optimal capillary tube length is rapidly, effectively andaccurately confirmed, the process is simple, time consuming is short, and manpower, material resources and time are saved.

Owner:NINGBO AUX ELECTRIC +1

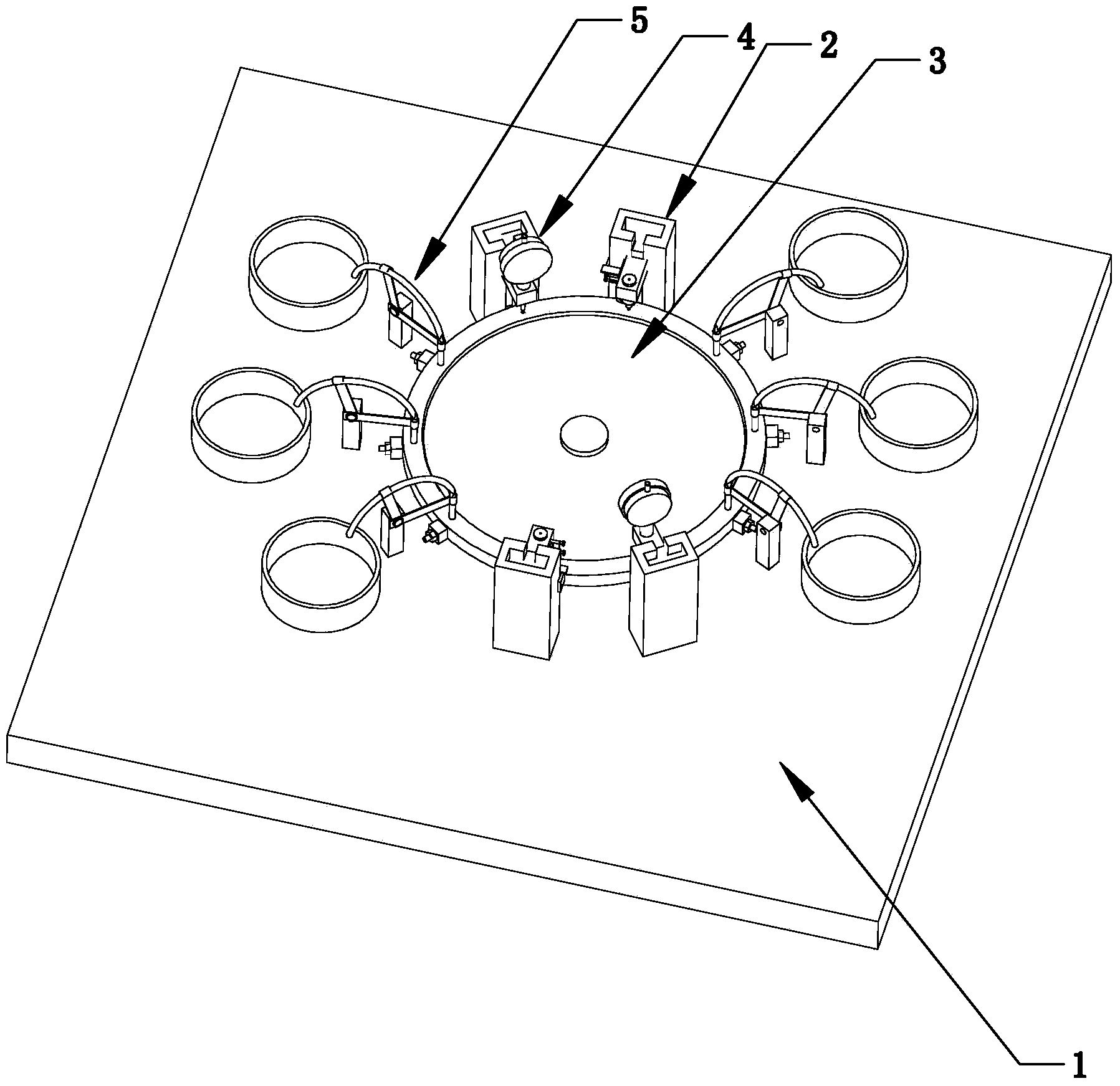

Full-automatic screening machine for refill capillary tube

The invention relates to a full-automatic screening machine for a refill capillary tube. According to the technical scheme, the full-automatic screening machine is characterized by comprising a stander, a rotating disc, refill capillary tube holding mechanisms, refill capillary tube length detection mechanisms, refill capillary tube screening mechanisms and a transmission mechanism, wherein refill capillary tube holding holes are uniformly formed around the circumference of the rotating disc, the diameter of each holding hole is slightly larger than the diameter of the refill capillary tube, and the refill capillary tube holding mechanisms, the refill capillary tube length detection mechanisms and the refill capillary tube screening mechanisms are sequentially arranged at the circumference of the rotating disc. By utilizing the technical scheme, the deficiency of the prior art is overcome.

Owner:温州尚伟笔业有限公司

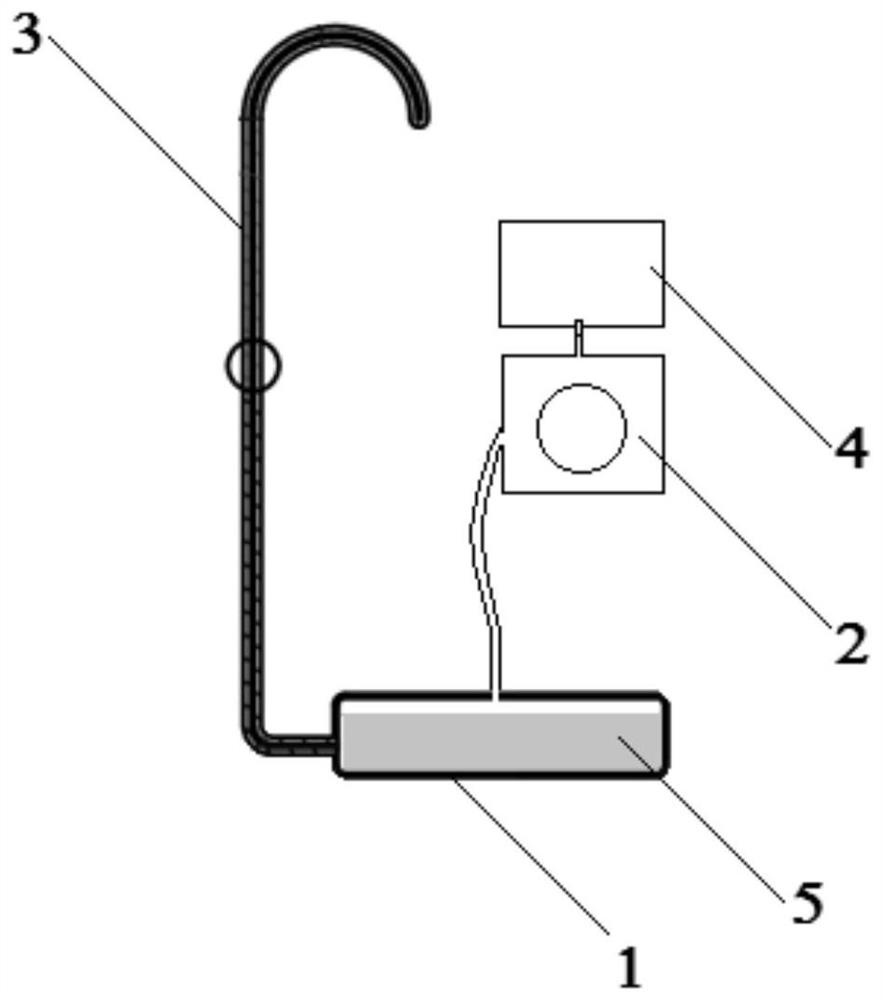

Tool for determining target capillary tube

InactiveCN110160288AShorten the lengthShorten the timeMechanical apparatusFluid circulation arrangementEngineeringRefrigeration

The invention discloses a tool for determining a target capillary tube, and belongs to the technical field of refrigeration. The tool for determining the target capillary tube comprises a first capillary tube and a throttling unit assembly, wherein the throttling unit assembly is connected with the first capillary tube in series; the throttling unit assembly comprises a main pipeline and an auxiliary pipeline, and an adjusting capillary tube and a first control device are arranged on the main pipeline; a connecting pipeline is arranged between the main pipeline and the auxiliary pipeline; andthe first capillary tube is connected with the main pipeline or the auxiliary pipeline in series. According to an embodiment of the invention, flow corresponding to the capillary tube with the lengthequivalent to the sum of the length of the first capillary tube and the length of the adjusting capillary tube can be measured through the tool, and capillary tubes in different specifications can betested on the premise of not replacing the first capillary tube, so that the length of the target capillary tube can be determined quickly, a process for determining the target capillary tube is simplified, and time for determining the target capillary tube is shortened.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

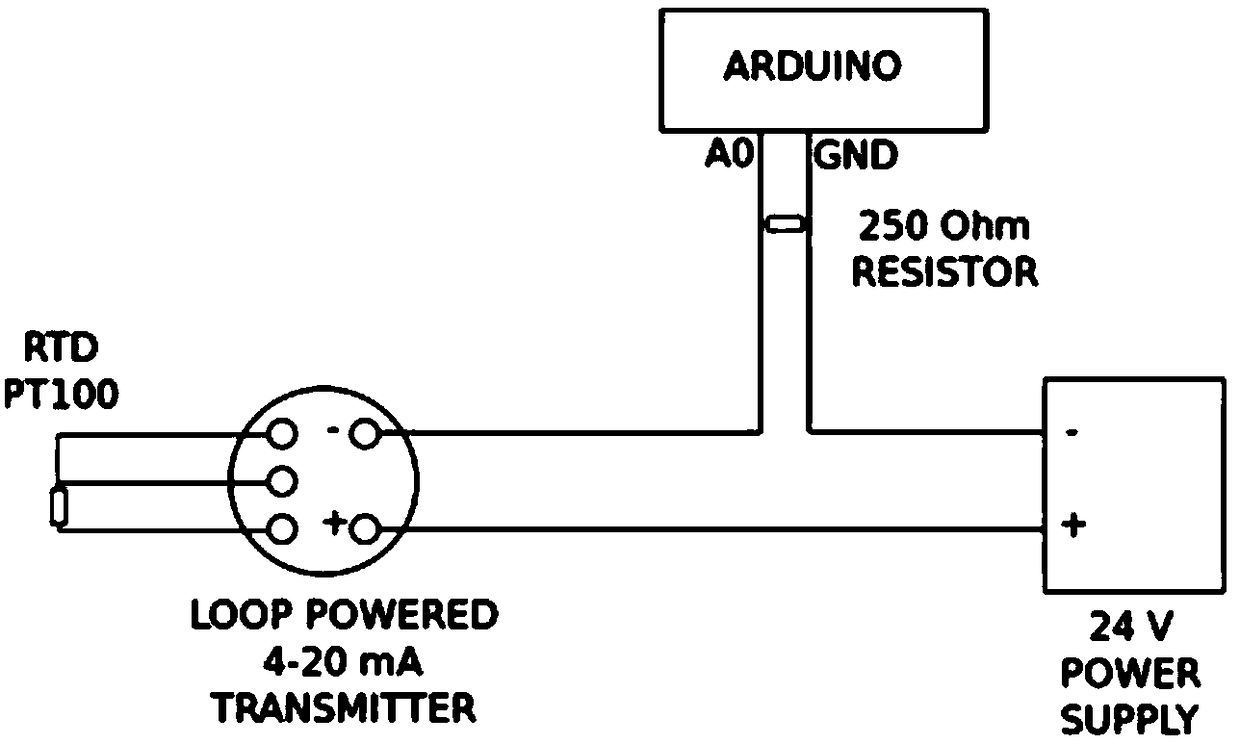

A sphygmomanometer and blood pressure calibration method based on gallium-based liquid alloy

ActiveCN113261927BPrevent oxidationHigh measurement accuracyEvaluation of blood vesselsAngiographyCapillary TubingMechanical engineering

The invention provides a gallium-based liquid alloy-based sphygmomanometer and a blood pressure calibration method, which relate to the technical field of medical equipment, and specifically use a gallium-based liquid alloy column as a pressure-sensitive liquid for blood pressure testing to measure the blood pressure of a human body; The capillary length cooperates with the pressure control chamber to control the pressure of the sphygmomanometer, realizes the precise control of the gallium-based liquid alloy column, improves the measurement accuracy and shortens the length of the glass capillary while preventing the gallium-based liquid alloy from being oxidized; the sphygmomanometer and the The proposal of the blood pressure calibration method can greatly reduce the society's dependence on harmful mercury metals, solve the problems of poor measurement accuracy of electronic thermometers, and is expected to be greatly popularized and applied.

Owner:SHANGHAI JIAOTONG UNIV

Household air conditioner throttle pipe

InactiveCN100570246CPrevent leakageImprove economyMechanical apparatusFluid circulation arrangementWhole bodyMetal sheet

The invention discloses an air conditioning throttle pipe for domestic use, comprising a left movable block and a right movable block which are arranged in a metal pipe. A fixed block is arranged between the left movable block and the right movable block. A left stopping block is arranged outside the left movable block, and a right stopping block is arranged outside the right movable block. The left and the right stopping blocks are fixed on the internal wall of the metal pipe. The left and the right movable blocks are provided with movable block capillary small holes which penetrate through the axes thereof. The fixed block is provided with a fixed block capillary small hole which penetrates through the axes thereof and is corresponding to the positions of the movable block capillary small holes. The fixed block is also provided with a plurality of axial directional overflow holes. The left movable block can slide between the left stopping block and the fixed block. And the right movable block can slide freely between the right stopping block and the fixed block. The fixed block is made by multilayer metal sheets, forming into an integrative whole body. The left and right stopping blocks are made by copper or aluminum or steel or iron, and are ring-shaped or comprise a plurality of semi-rings. The air conditioning throttle pipe has the advantages that the air conditioning throttle pipe has more reasonable structure, is favorable to meet the length requirement of the capillary tube needed when refrigerating and heating, can debase the consumption of refrigerant and energy, and can improve the quality and functions of products.

Owner:金仁召

Method and apparatus for patch-clamp measurements on cells

InactiveCN1327222CBioreactor/fermenter combinationsBiological substance pretreatmentsCentrifugationCell membrane

Owner:フリュイオン ゲゼルシャフト ミット ベシュレンクテル ハフツング

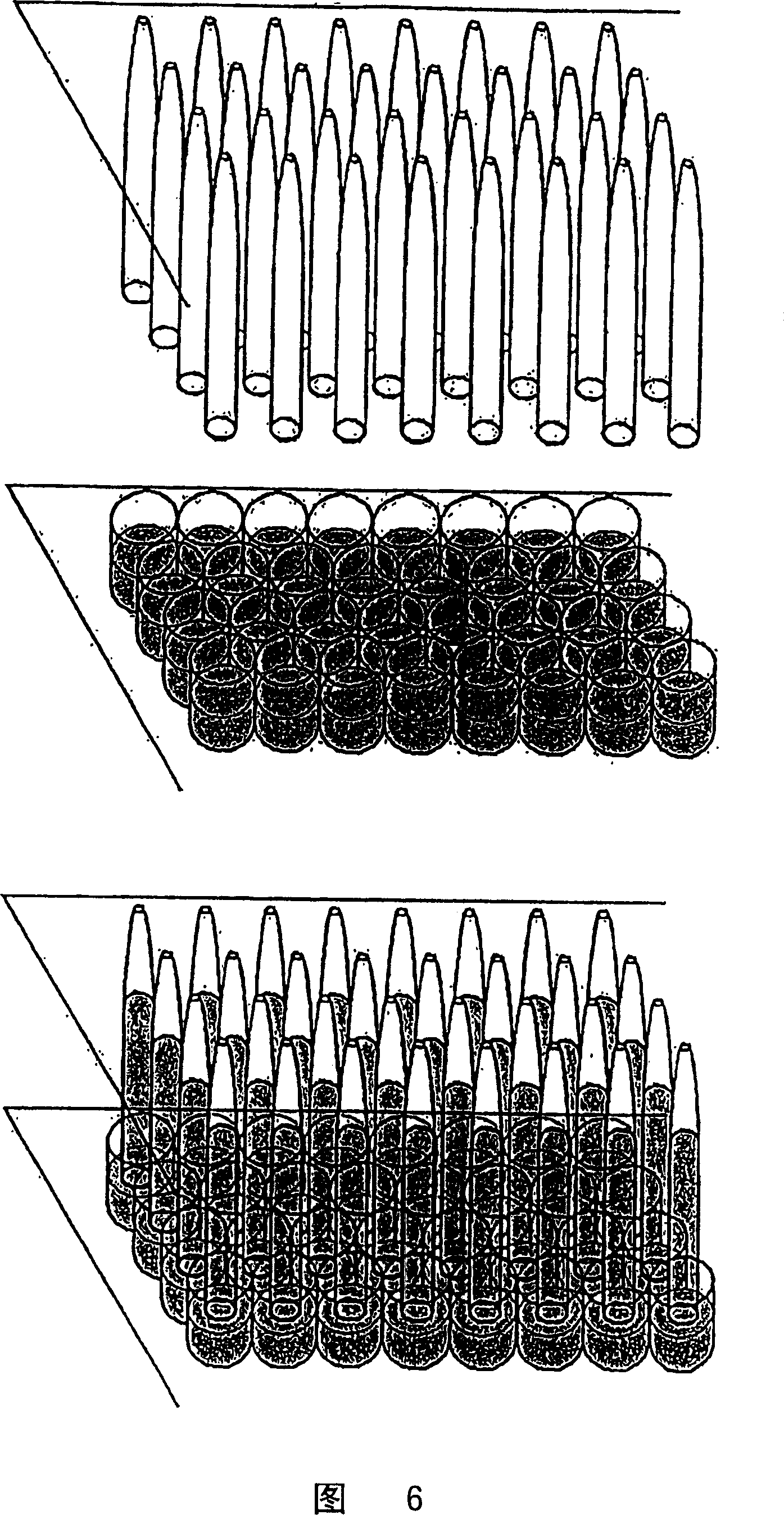

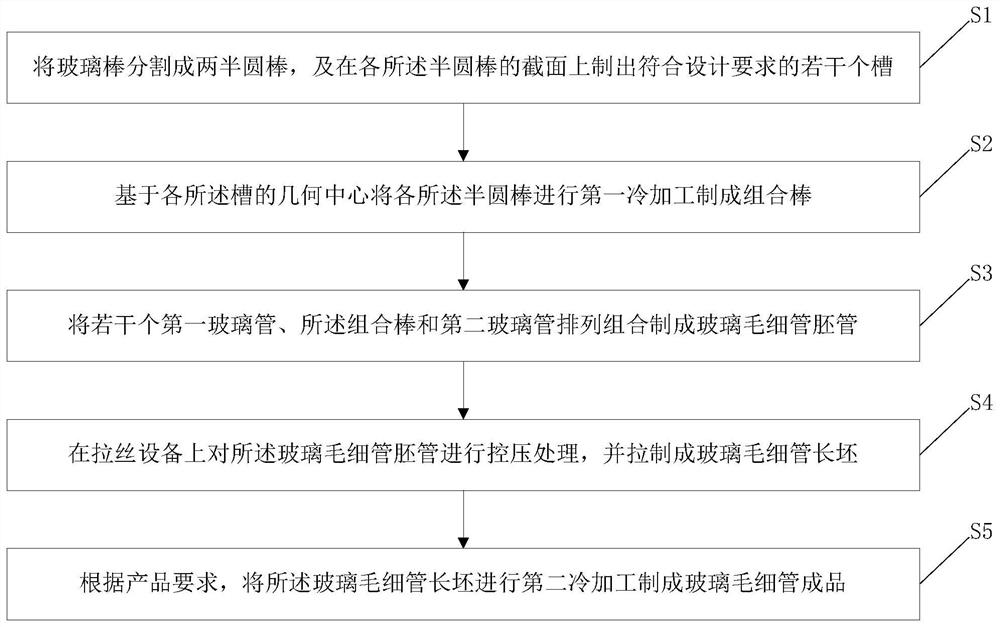

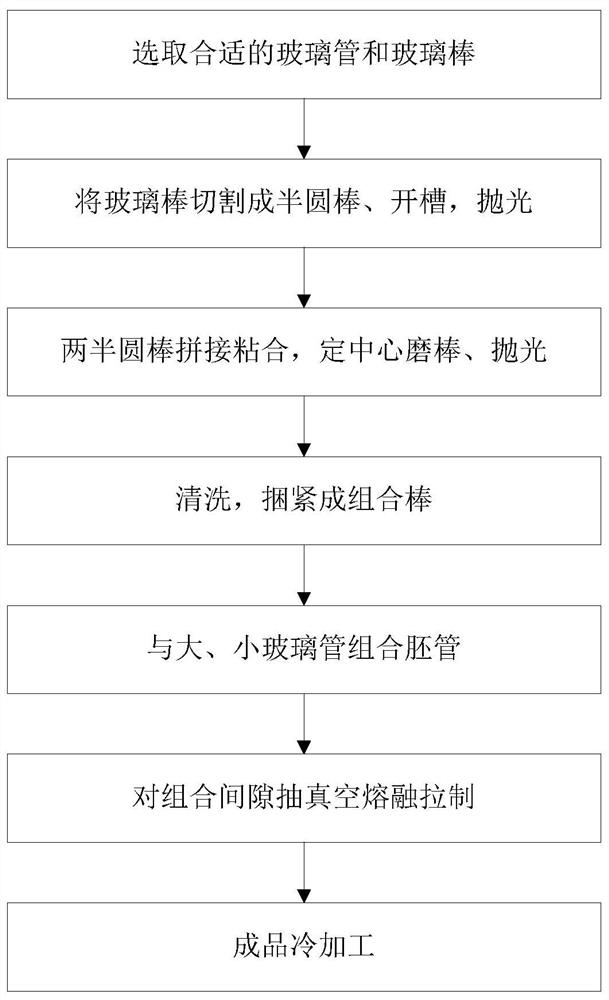

A kind of glass capillary and preparation method thereof

The present invention discloses a glass capillary and its preparation method. The method is: divide the glass rod into two half of the round stick, and the semi -circular sticks are produced on the semi -round sticks that meet the design requirements of the design requirements;The geometric center of the groove makes the first cold machining of each circular rod into a combination stick; arranges several first glass tubes, combined sticks, and second glass tubes to make glass capillary embryos;The capillary embryo is controlled and pulled into a glass capillary long blank; according to the product requirements, the glass capillary length of the glass is made of second cold processing into the finished product of the glass cap.The glass capacity preparation method provided by the present invention is simple. The combination rod composed of the first glass tube, the two -half round rods, and the second glass tube can achieve a good contraction and combination, and the slot spacing and slot size accuracy is high to avoid quality defects.Realize the preparation of low -cost, high -precision, high -efficiency glass hair tube.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS

Easy-to-adjust and easy-to-measure high-precision closed constant pressure static pressure guide rail restrictor

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com