Throttling instrument for steam compression type refrigerating apparatus

A compression refrigeration and instrument technology, applied in the direction of instruments, refrigerators, refrigeration components, etc., can solve the problems of long experimental process and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

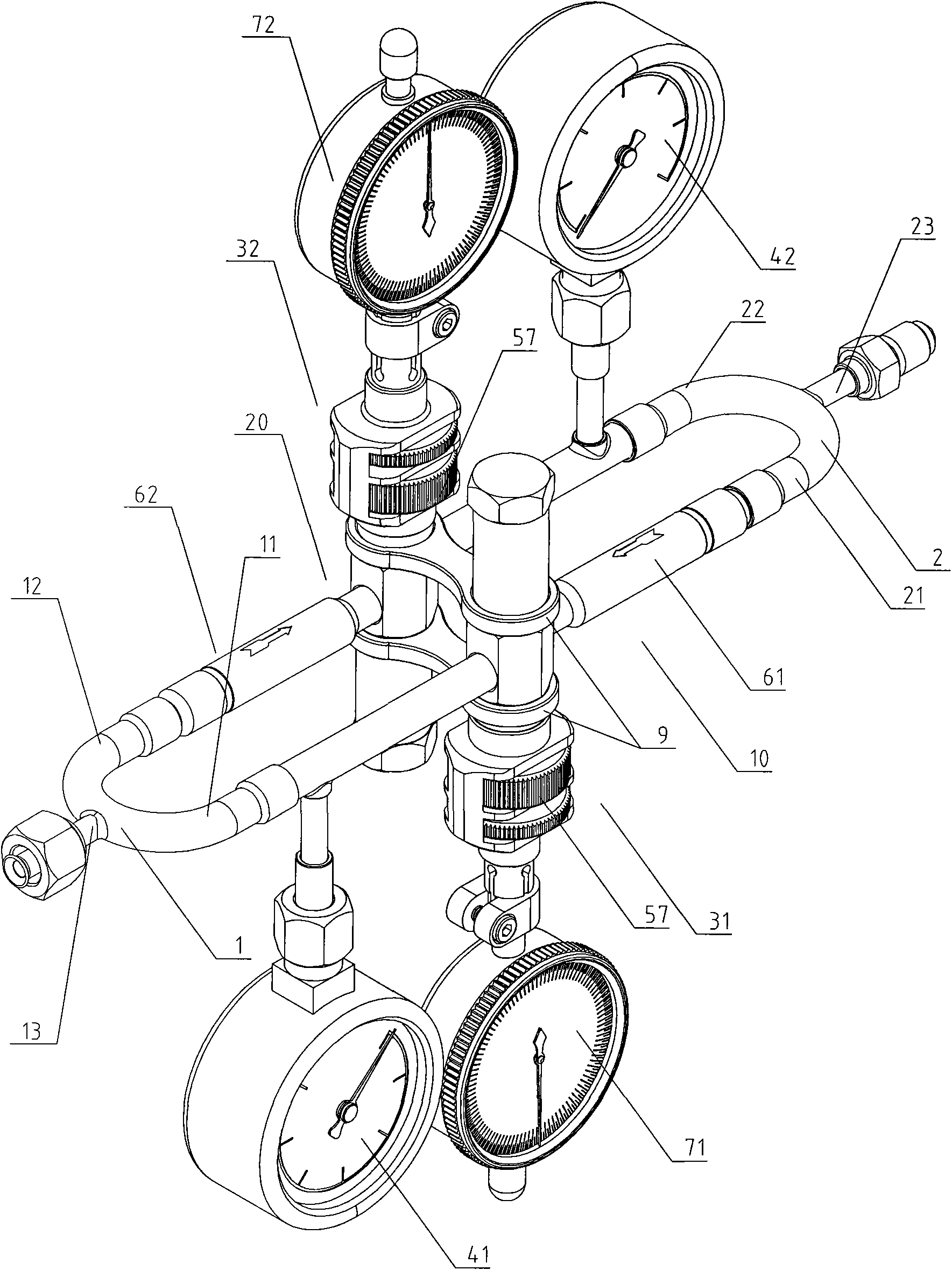

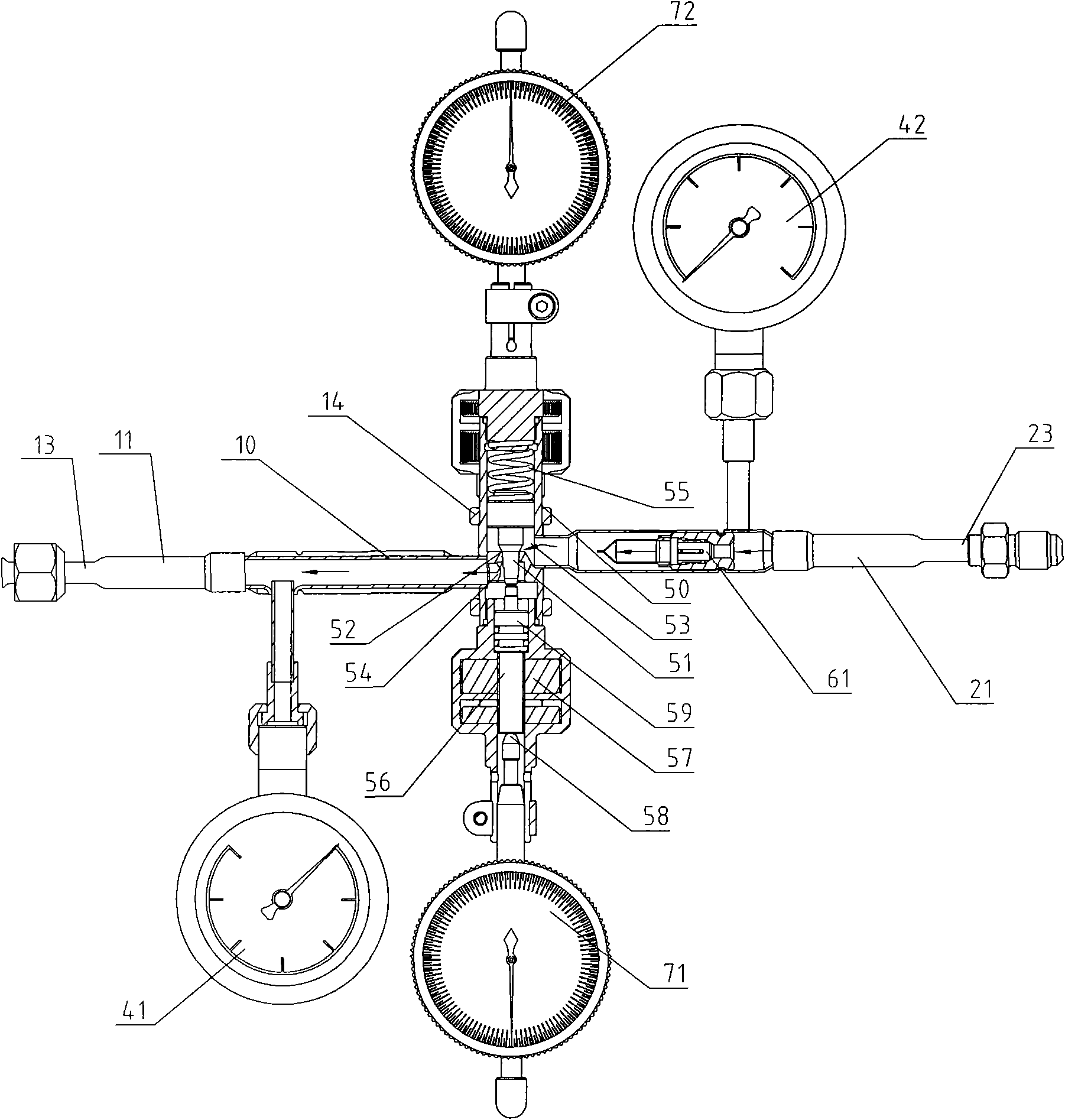

[0006] Refer to attached picture. The present invention is provided with the loop circuit of passing medium, is mainly formed by two tees 1,2, wherein one way 13 of tee 1 constitutes the first inlet and outlet of the loop, and one of them 23 of tee 2 constitutes the first inlet and outlet of the loop. The second inlet and outlet of the loop are respectively used for input and output of media. The other road 11 of the tee 1 and the other road 21 of the tee 2 constitute a part of the first pipeline 10 in the loop, and the other road 12 of the tee 1 and the other road 22 of the tee 2 constitute the first pipeline in the loop. part of the second line 20. The first pipeline is provided with a first valve 31, the second pipeline is provided with a second valve 32, and the pipeline between the first inlet and outlet and the first valve is provided with a first pressure measuring device, which is A pressure gauge 41, a second pressure measuring device is provided between the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com