Easily-adjusting and easily-measuring high-precision closed type constant-pressure static-pressure guide rail throttling device

The technology of static pressure guide rail and restrictor is applied in the field of hydraulic restrictor, which can solve the problems of troublesome assembly and disassembly, unadjustable throttling ratio, complex structure, etc., and achieves the effect of simple structure, simple processing and convenient assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

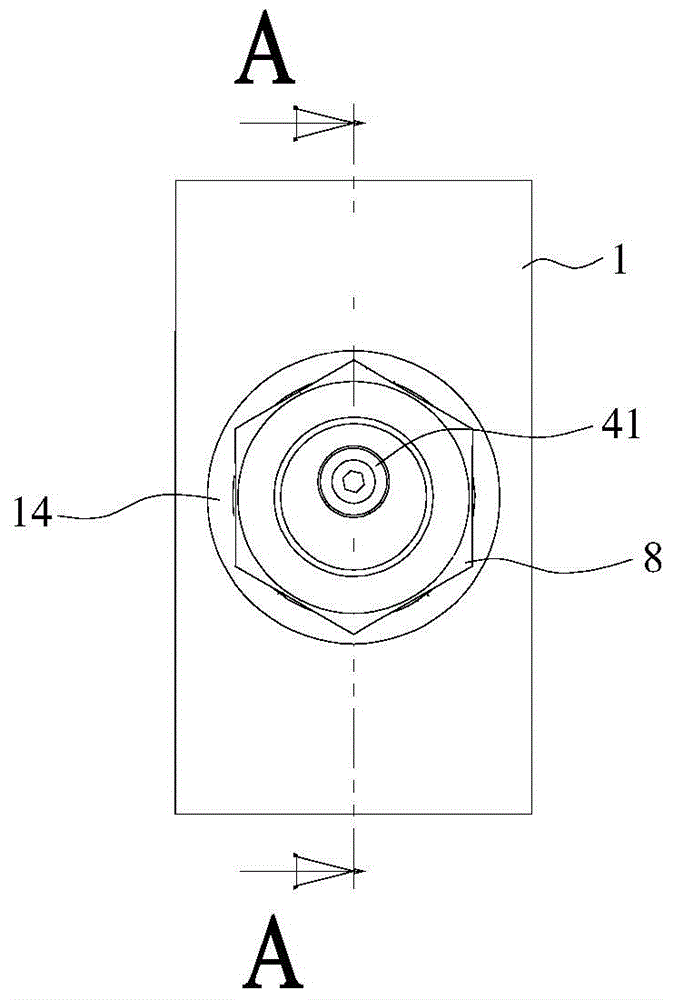

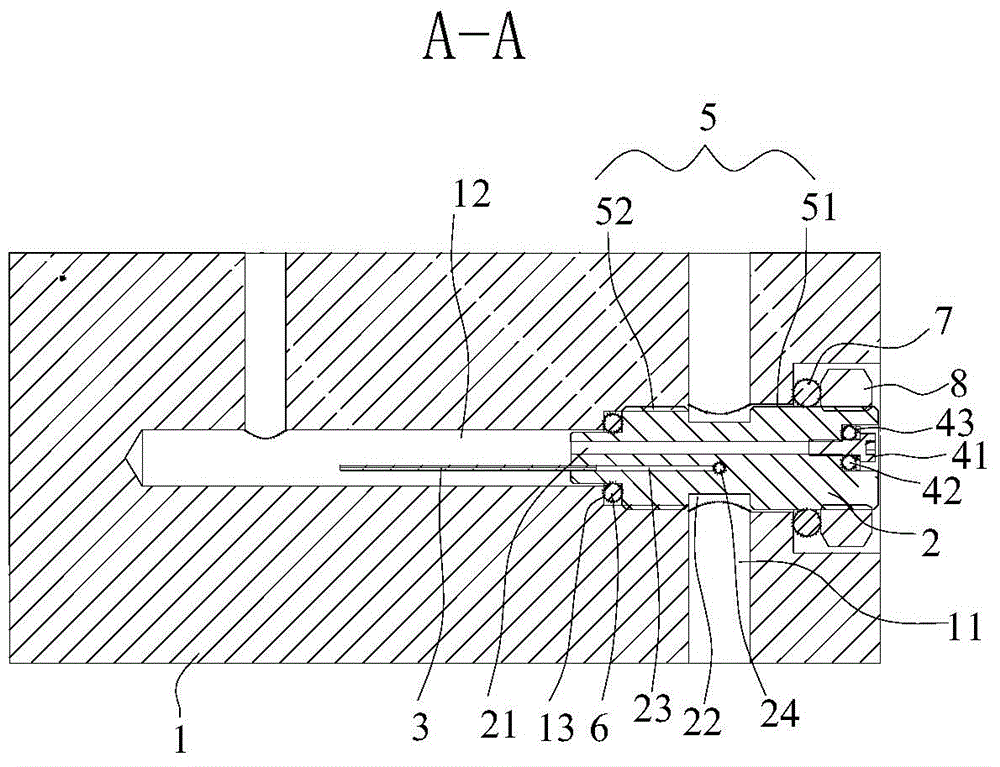

[0017] refer to figure 1 , figure 2 , the present invention provides an easy-to-adjust, easy-to-measure, high-precision closed-type constant pressure static pressure guide rail restrictor, including a casing 1 and a core 2, and the casing 1 is provided with an oil inlet cavity 11 and an oil outlet cavity 12 , the casing 1 is provided with a core body installation position that intersects with the oil inlet cavity 11 and the oil outlet cavity 12 respectively, the core body 2 is installed in the core body installation position, and the core body 2 is provided with The throttling oil circuit of the oil inlet chamber 11 and the oil outlet chamber 12 is connected, and the core 2 is connected with a capillary 3 extending into the oil outlet chamber 12 at the outlet of the throttling oil circuit, which can be determined by experiments. The optimal length of the capillary 3 can be cut off if it is too long, and a longer capillary 3 can be re-bonded if it is too short. The capillary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com